小模数齿轮齿面双道激光熔覆工艺  下载: 826次

下载: 826次

Double-Pass Laser Cladding Process for Small-Modulus Gear-Tooth Surface

湖北工业大学机械工程学院, 湖北 武汉 430068

图 & 表

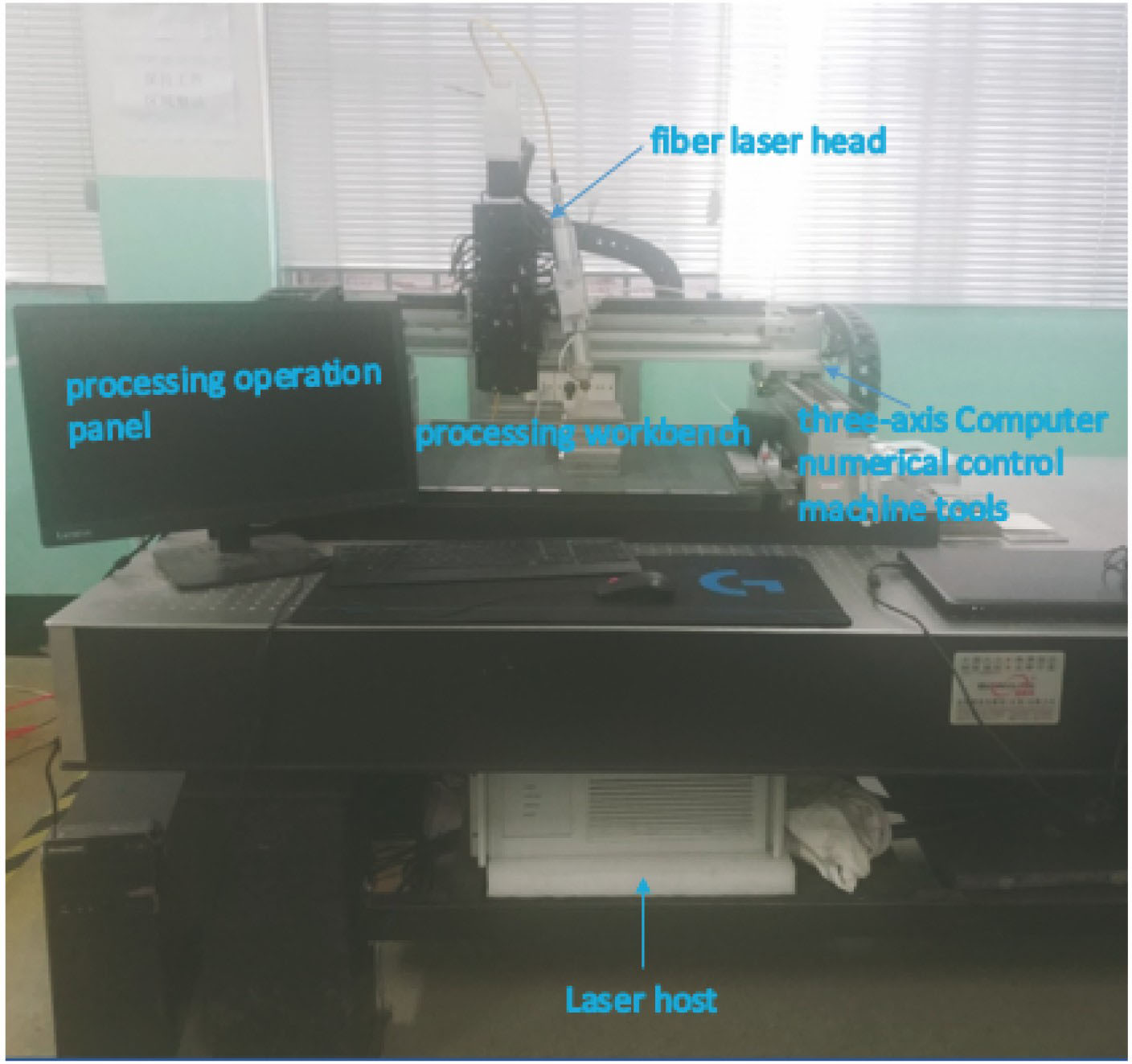

图 1. 三轴联动数控激光加工操作系统

Fig. 1. Three-axis linkage numerical control laser processing system

下载图片 查看原文

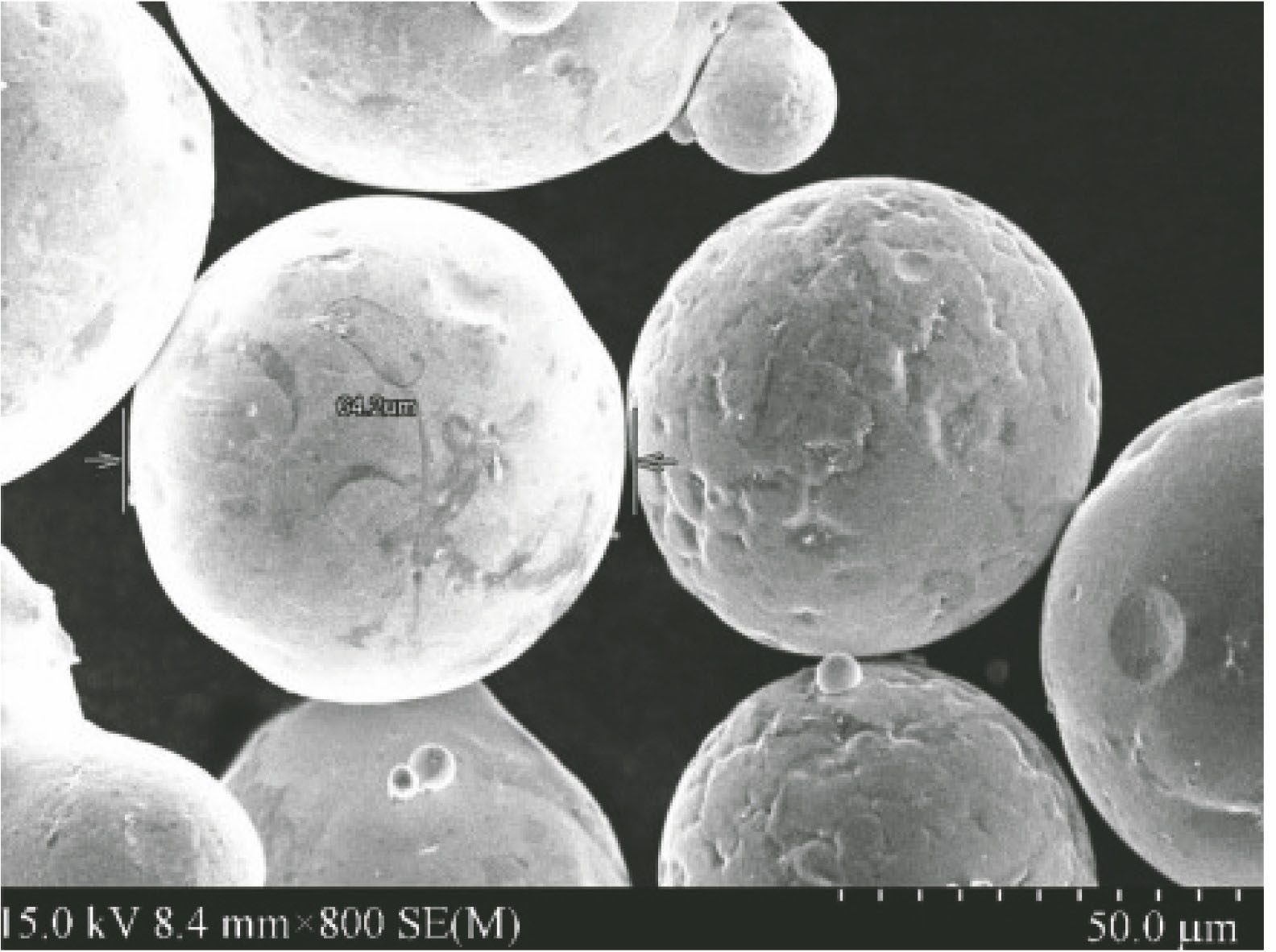

图 2. Ni60自熔性合金粉末的扫描电子显微镜图

Fig. 2. Scanning electron microscope graph of Ni60 self-fluxing alloy powder

下载图片 查看原文

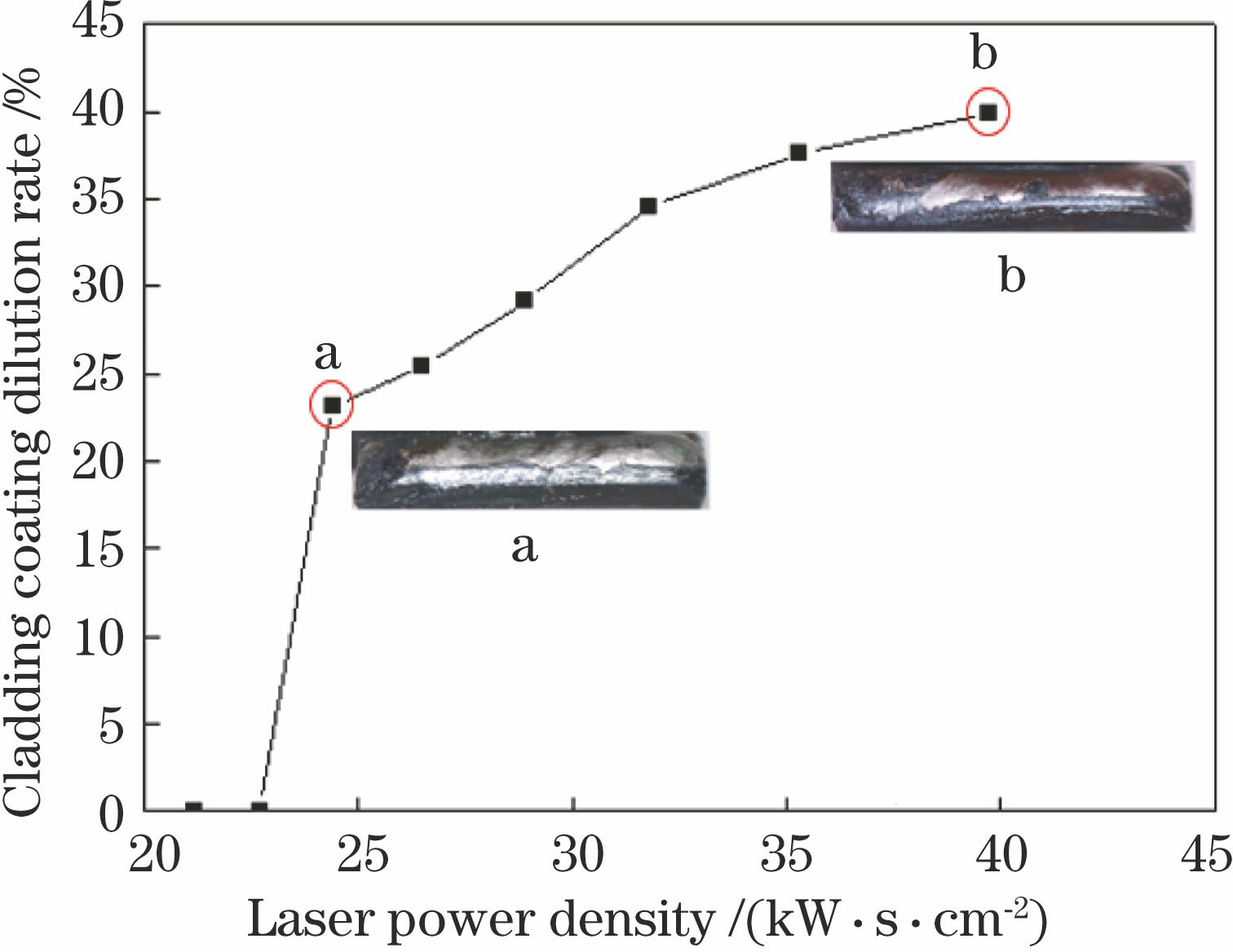

图 3. 不同激光功率密度下齿面单道激光熔覆涂层的稀释率

Fig. 3. Dilution rates of single-pass laser cladding coatings on gear-tooth surface at different laser power densities

下载图片 查看原文

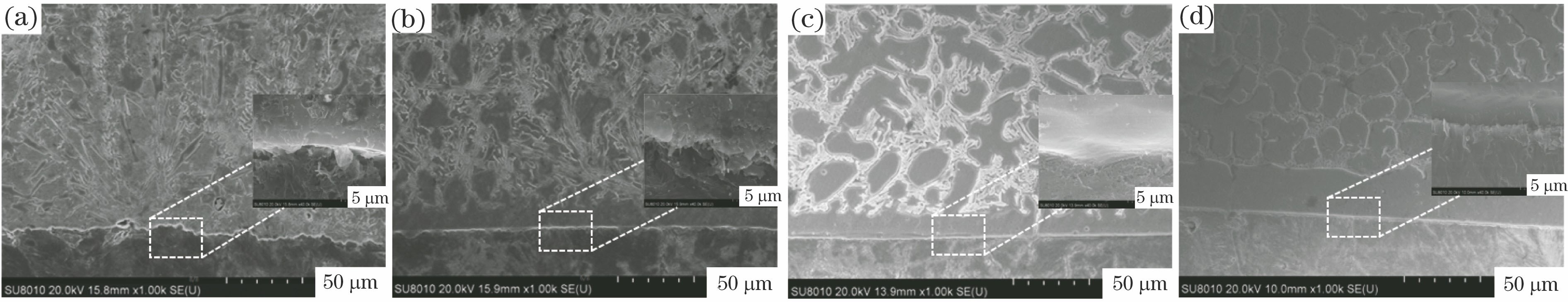

图 4. 不同功率密度下制备的熔覆层底部的显微形貌。(a) 24.4 kW·s·cm-2;(b) 26.5 kW·s·cm-2;(c) 31.8 kW·s·cm-2;(d) 35.8 kW·s·cm-2

Fig. 4. Microstructures of bottom of cladding layers at different power densities. (a) 24.4 kW·s·cm-2;(b) 26.5 kW·s·cm-2; (c) 31.8 kW·s·cm-2; (d) 35.8 kW·s·cm-2

下载图片 查看原文

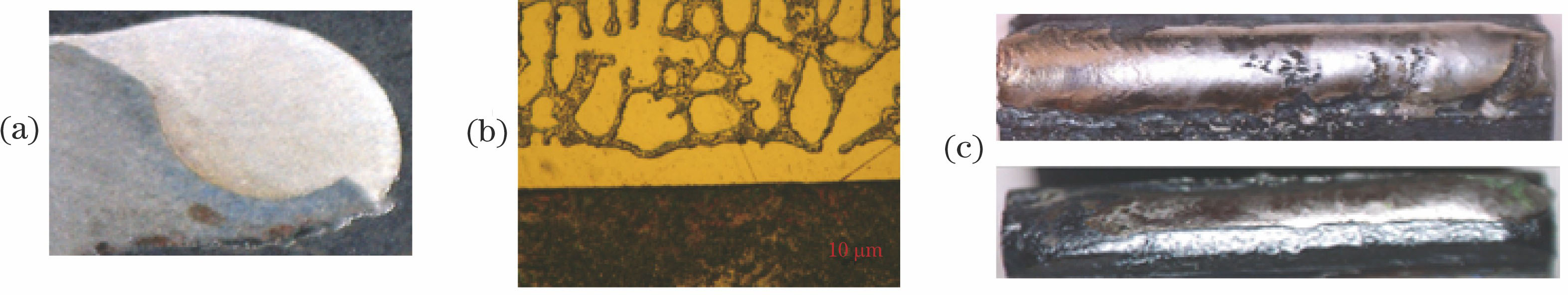

图 5. 激光功率密度为31.8 kW·s·cm-2时制备的单道激光熔覆涂层。(a)熔覆层的橫截面形貌;(b)熔覆层的显微组织;(c)熔覆层的宏观形貌

Fig. 5. Single-pass laser cladding coatings obtained with laser power density of 31.8 kW·s·cm-2.(a) Cross-sectional morphology of coating; (b) microstructure of coating; (c) macroscopic morphologies of coatings

下载图片 查看原文

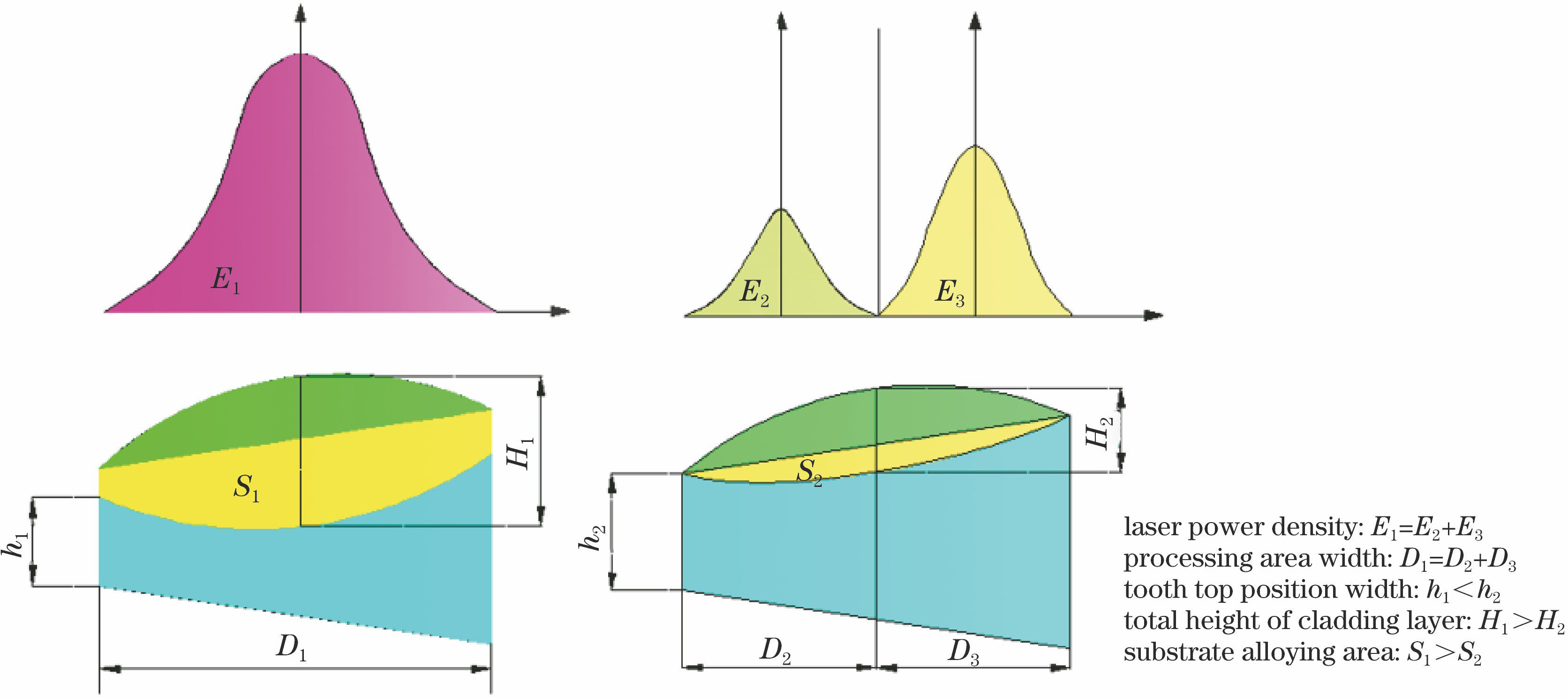

图 6. 双道光束加工示意图及其预期目标改善效果

Fig. 6. Schematic of double-pass laser processing and its expected effect of target improvement

下载图片 查看原文

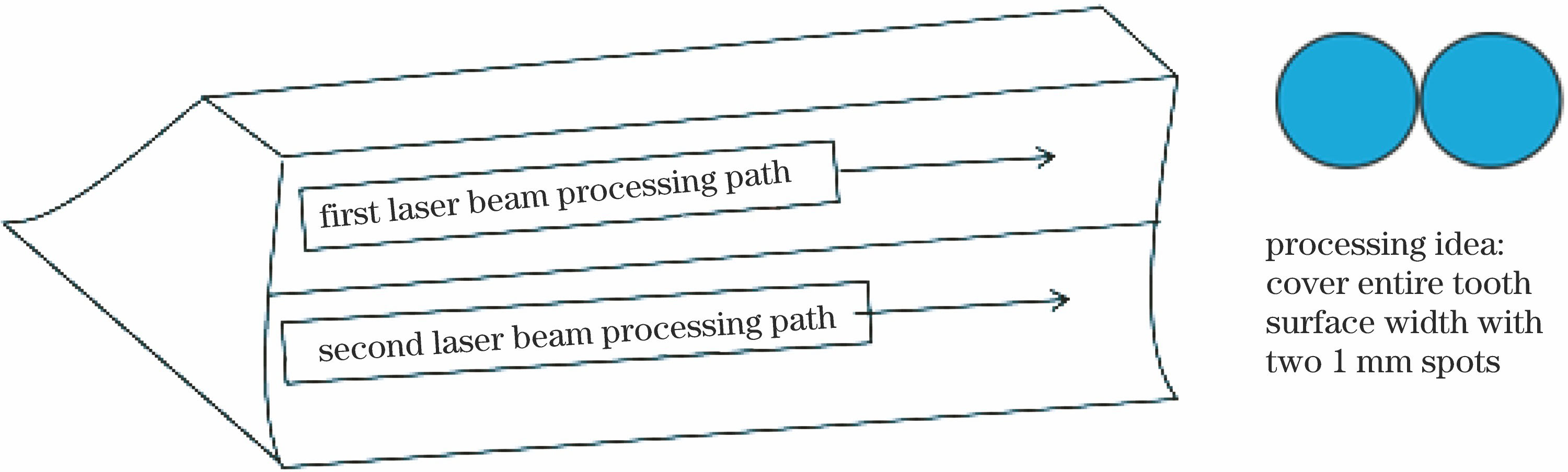

图 7. 双道1 mm激光光斑加工示意图

Fig. 7. Schematic of laser processing by using two 1-mm spots

下载图片 查看原文

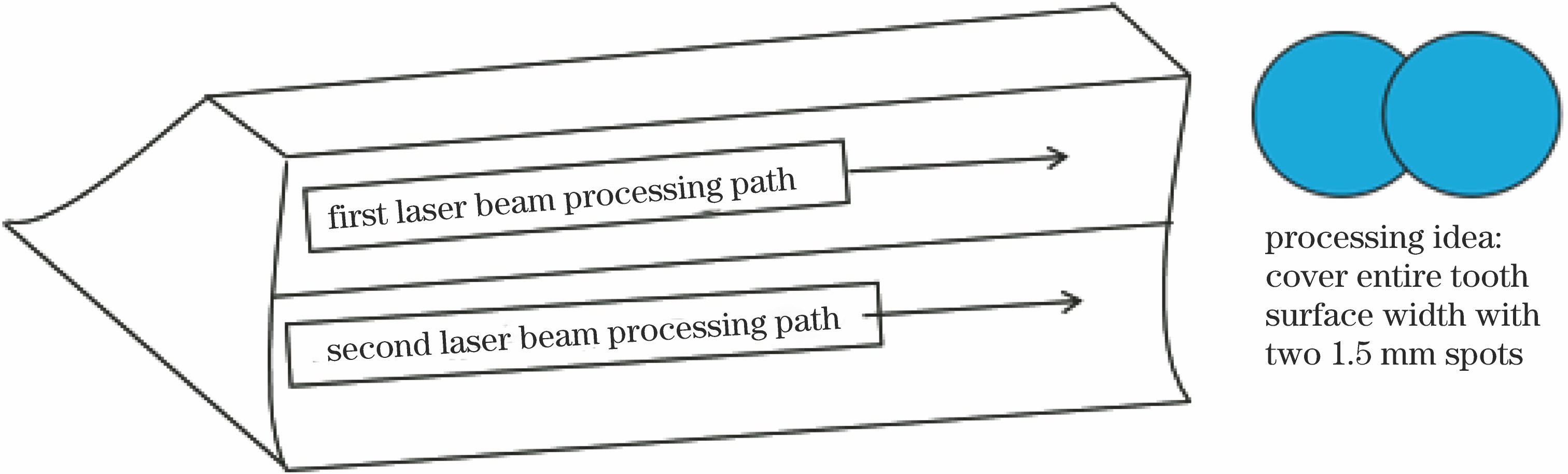

图 8. 双道1.5mm激光光斑加工示意图

Fig. 8. Schematic of laser processing by using two 1.5-mm spots

下载图片 查看原文

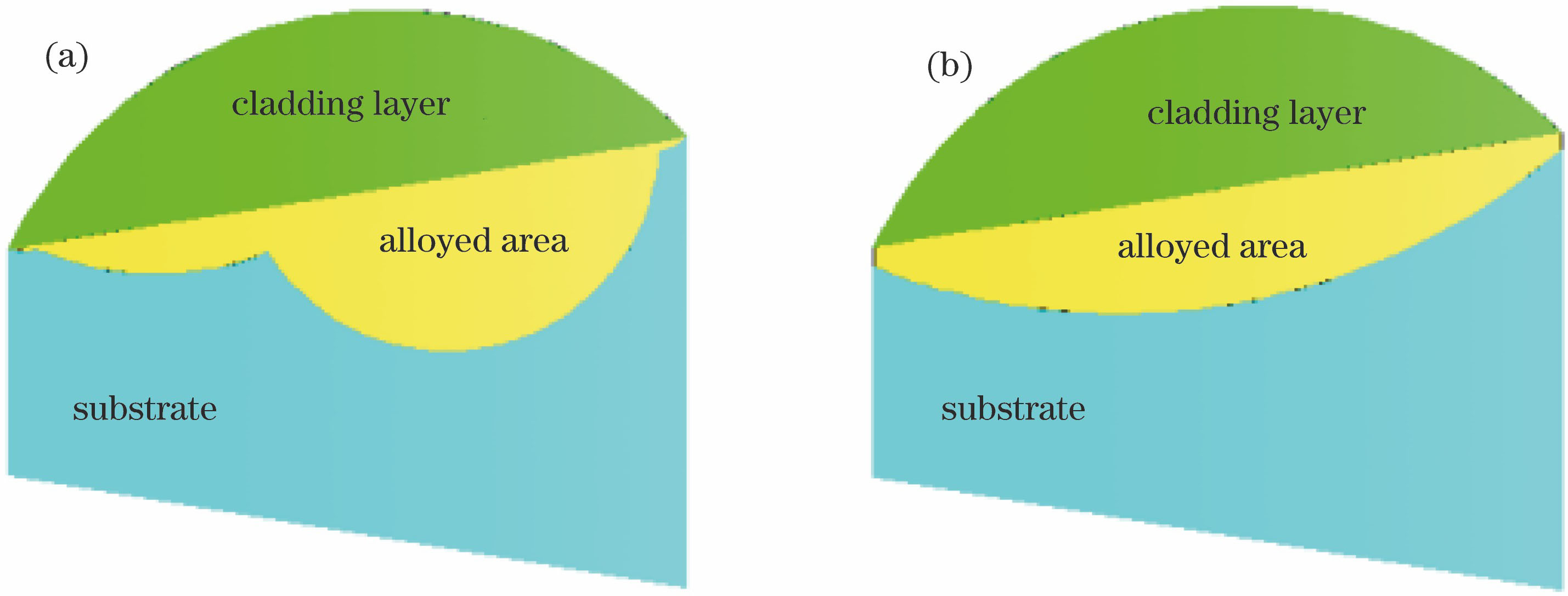

图 9. 不同加工工艺下的熔覆层截面形貌。(a)双道光斑功率密度相差较大;(b)双道光斑功率密度相差较小

Fig. 9. Cross-sectional morphologies of cladding layers under different processing techniques. (a) Large difference between power densities of double-pass laser spots; (b) small difference between power densities of double-pass laser spots

下载图片 查看原文

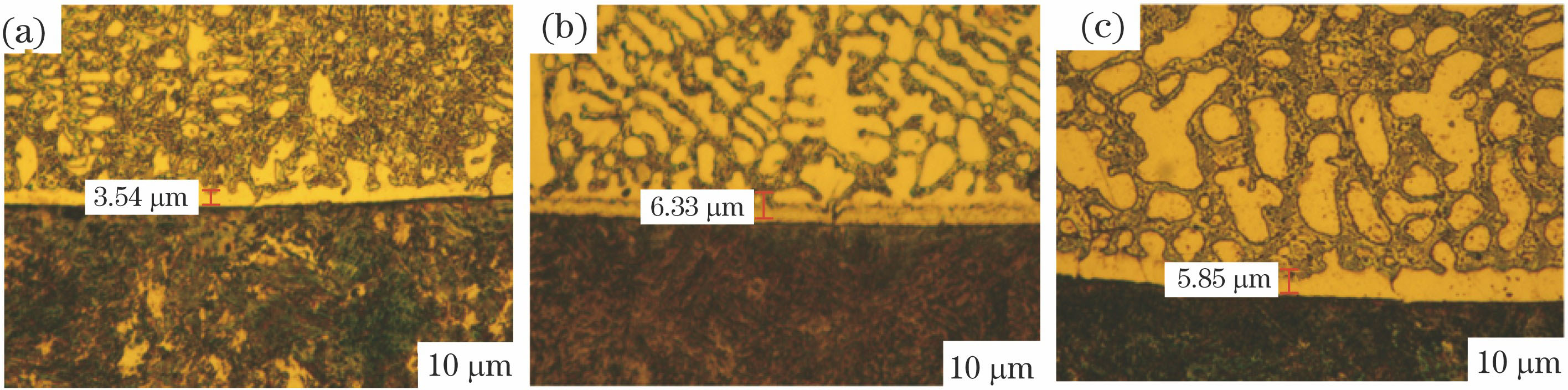

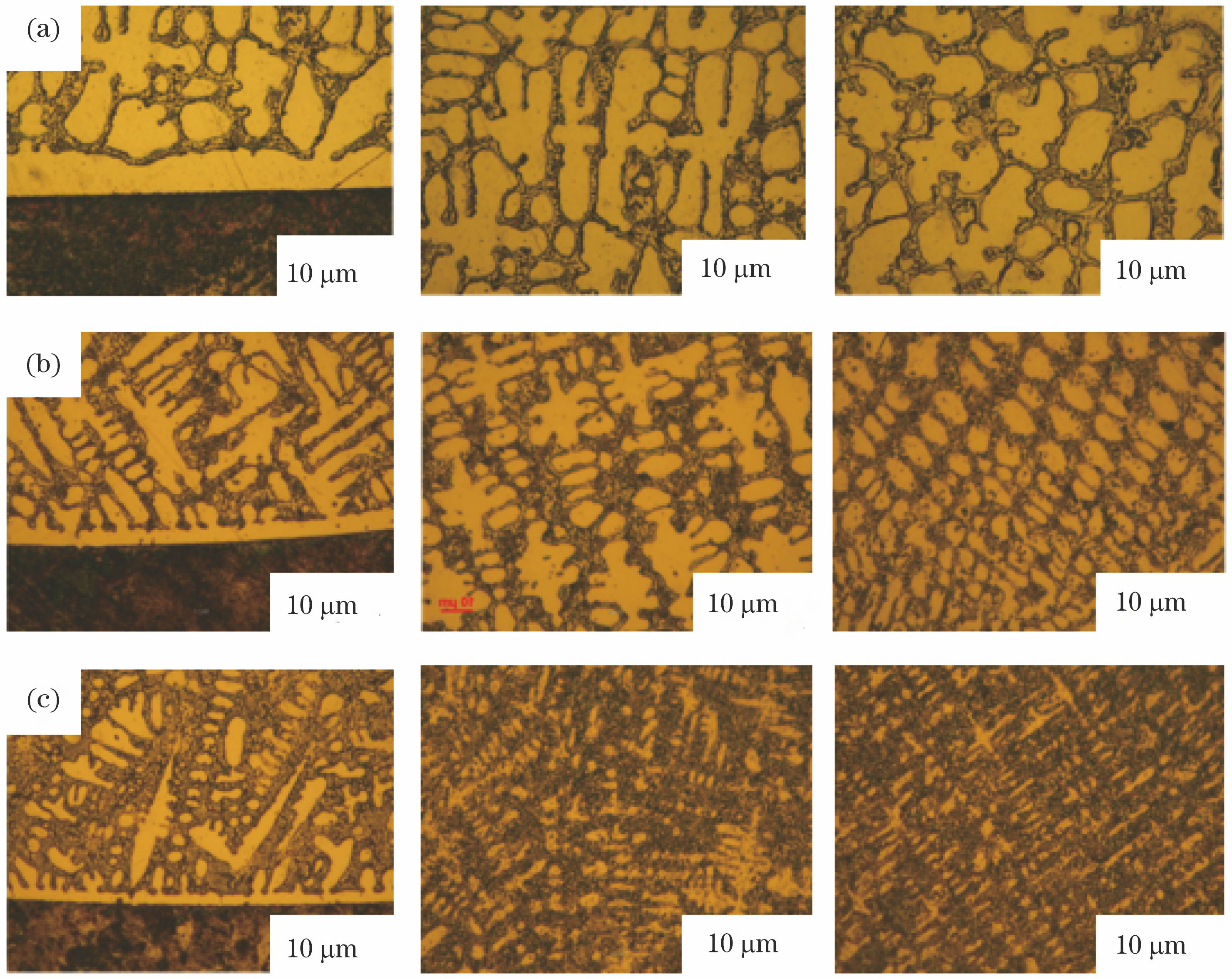

图 10. 不同工艺参数下得到的合金涂层的截面组织。(a)齿顶输入的激光功率密度大于12.72 kW·s·cm-2;(b)齿底输入的激光功率密度大于19.08 kW·s·cm-2;(c)齿顶和齿底输入的激光功率密度为15.9 kW·s·cm-2

Fig. 10. Cross-sectional microstructures of alloy coatings under different process parameters. (a) Input laser power density at tooth top of gear is greater than 12.72 kW·s·cm-2; (b) input laser power density at tooth bottom of gear is greater than 19.08 kW·s·cm-2; (c) input laser power densities at tooth top and bottom of gear are both 15.9 kW·s·cm-2

下载图片 查看原文

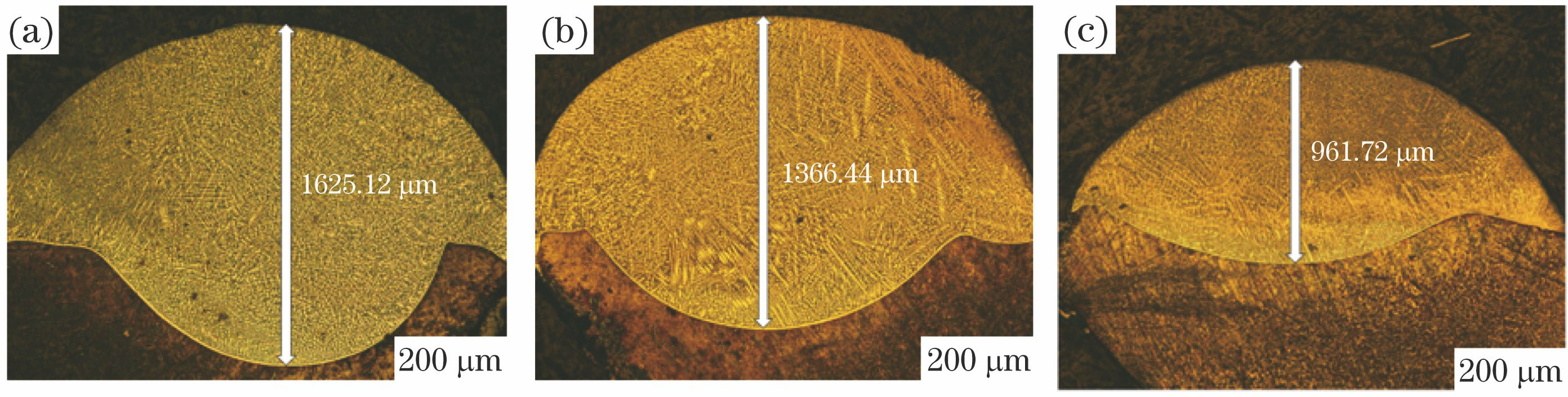

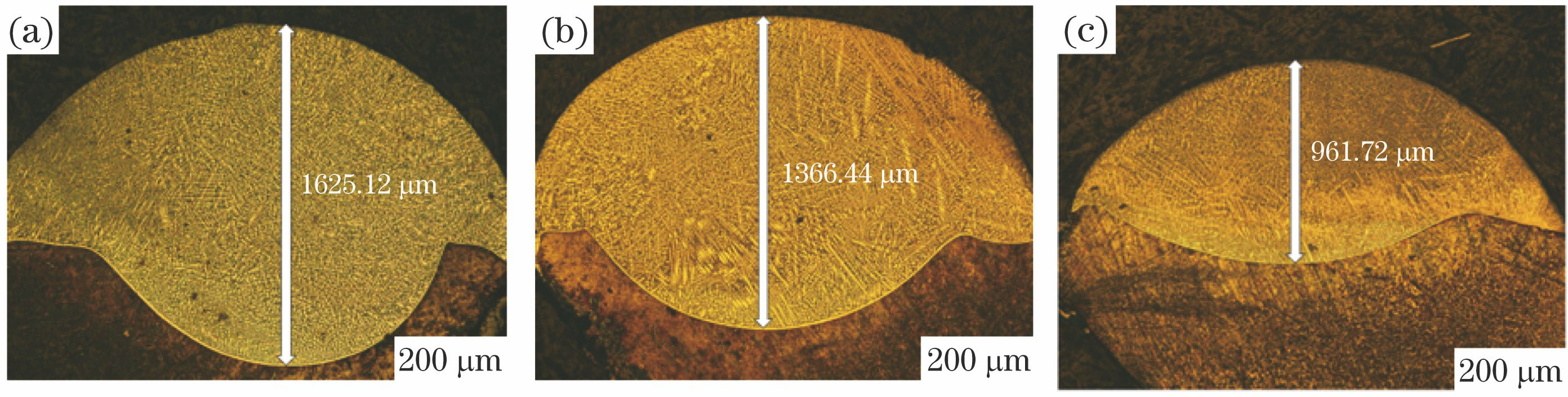

图 11. 不同加工工艺下熔覆层截面的熔深的对比。(a)单道激光工艺参数:P=250 W,u=0.5 mm/s,D =2 mm;(b)双道1.5 mm激光工艺参数:P=250 W,u1=1.67 mm/s,u2=1.12 mm/s,D=1.5 mm,η=40%;(c)双道1 mm激光工艺参数:P=250 W,u1=2.5 mm/s,u2=1.67 mm/s,D=1 mm

Fig. 11. Comparison of penetration depths of cladding layers under different processing techniques. (a) Single-pass laser process parameters: P=250 W, u=0.5 mm/s, D=2 mm; (b) double-pass 1.5-mm laser process parameters: P=250 W, u1=1.67 mm/s, u2=1.12 mm/s, D=1.5 mm, η=40%; (c) double-pass 1 mm-laser process parameters: P=250 W, 下载图片 查看原文

图 12. 不同加工工艺下制备的镍基合金熔覆涂层的截面形貌。(a)单道激光加工;(b)双道激光搭接加工;(c)双道激光独立加工

Fig. 12. Cross-sectional morphologies of nickel-based alloy cladding coatings under different processing techniques.(a) Single-pass laser processing; (b) double-pass laser lap processing; (c) double-pass laser independent processing

下载图片 查看原文

图 13. Hoadley热输入模型[5]

Fig. 13. Hoadley heat input model[5]

下载图片 查看原文

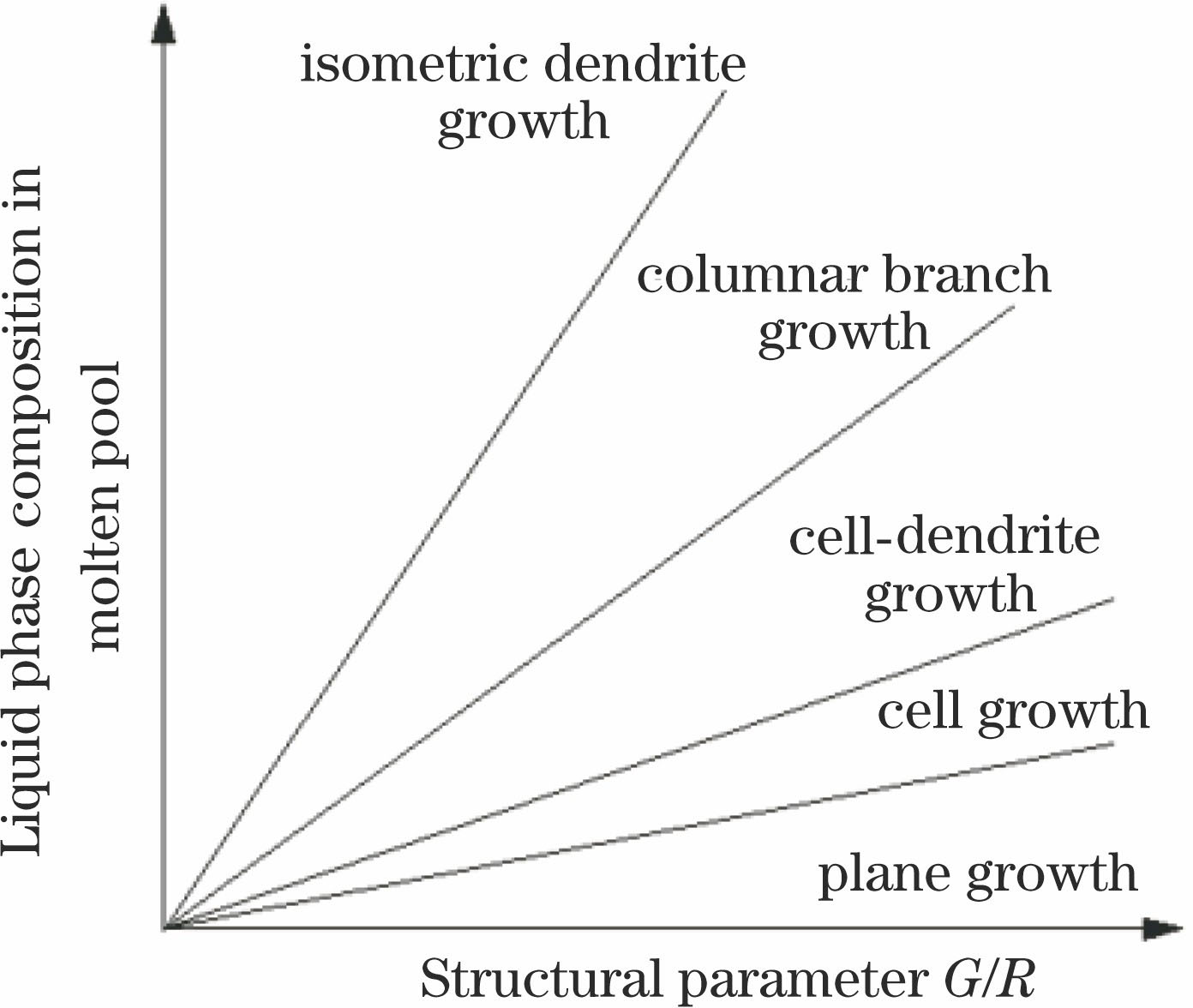

图 14. 熔池内液相成分变化曲线

Fig. 14. Variation curves of liquid phase compositions in molten pool

下载图片 查看原文

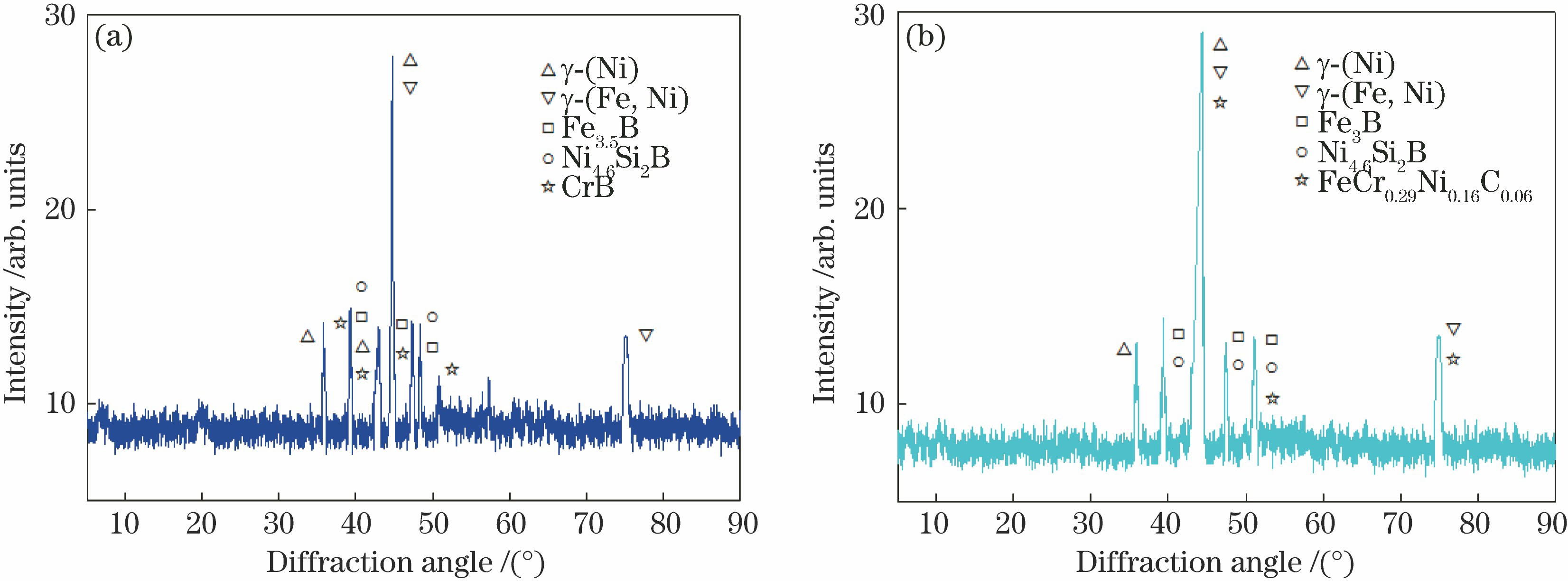

图 15. 不同加工工艺下制备的镍基合金熔覆涂层的XRD图谱。(a)双道1 mm光斑;(b)双道1.5 mm光斑

Fig. 15. XRD spectra of nickel-based alloy cladding coatings under different processing techniques. (a) Double-pass 1-mm laser spots; (b) double-pass 1.5-mm laser spots

下载图片 查看原文

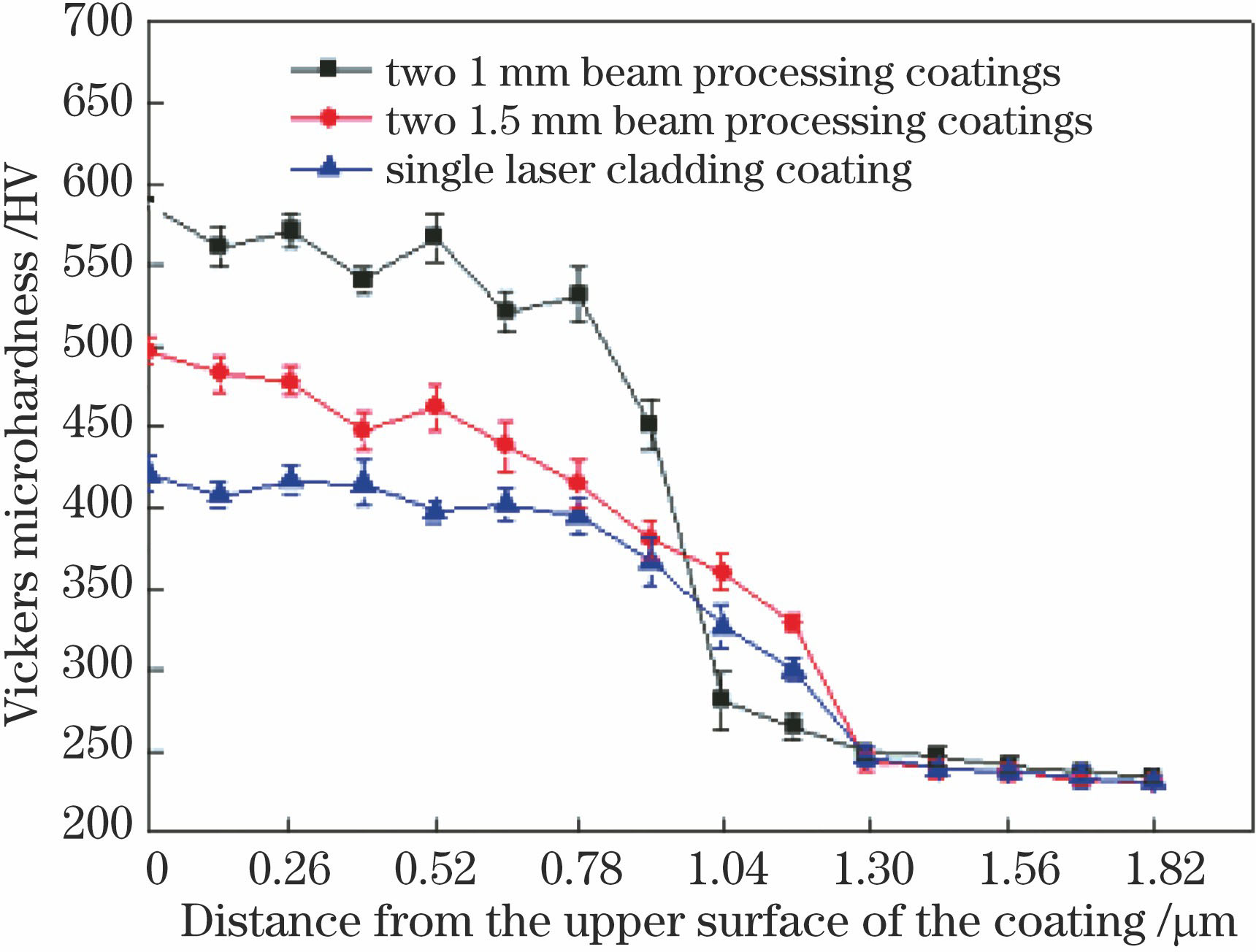

图 16. 不同加工工艺下制备的熔覆层截面的显微硬度变化曲线

Fig. 16. Variation curves of cladding coatings' cross-sectional microhardness under different processing techniques

下载图片 查看原文

表 1单道激光熔覆齿轮齿面的加工参数

Table1. Processing parameters of single-pass laser cladding coatings on gear-tooth surface

| Number | Scanning speed /(mm·s-1) | Power density /(kW·s·cm-2) |

|---|

| 1 | 0.75 | 21.2 | | 2 | 0.70 | 22.7 | | 3 | 0.65 | 24.4 | | 4 | 0.60 | 26.5 | | 5 | 0.55 | 28.9 | | 6 | 0.50 | 31.8 | | 7 | 0.45 | 35.3 | | 8 | 0.40 | 39.7 |

|

查看原文

表 2不同功率密度下齿面镍基合金涂层的截面 尺寸及稀释率

Table2. Cross-sectional dimensions and dilution rates of nickel-based alloy coatings on tooth surface at different power densities

| Number | Powerdensity /(kW·s·cm-2) | Claddingmaximumheight /μm | Substratepenetrationdepth /μm | Coatingdilutionrate /% |

|---|

| 1 | 21.2 | 947.12 | 0 | 0 | | 2 | 22.7 | 989.20 | 0 | 0 | | 3 | 24.4 | 1109.84 | 257.03 | 23.16 | | 4 | 26.5 | 1324.35 | 337.53 | 25.48 | | 5 | 28.9 | 1537.51 | 447.65 | 29.12 | | 6 | 31.8 | 1627.21 | 562.04 | 34.54 | | 7 | 35.3 | 1725.61 | 648.37 | 37.57 | | 8 | 39.7 | 1749.89 | 698.21 | 39.90 |

|

查看原文

表 31 mm光斑下双道激光熔覆的功率密度配比以及每道激光的扫描速度

Table3. Power-density ratio of double-pass laser cladding with two 1-mm spots and scanning speed of each laser

| Number | Double beamenergy ratio | Power densityper beam /(kW·s·cm-2) | Spot diameter /mm | Scanning speed perbeam /(mm·s-1) |

|---|

| 1 | 2∶8 | P1=6.36,P2=25.44 | 1 | u1=5,u2=1.25 | | 2 | 3∶7 | P1=9.54,P2=22.26 | 1 | u1=3.33,u2=1.43 | | 3 | 4∶6 | P1=12.72,P2=19.08 | 1 | u1=2.5,u2=1.67 | | 4 | 5∶5 | P1=15.9,P2=15.9 | 1 | u1=2,u2=2 |

|

查看原文

表 41 mm光斑下双道激光熔覆实验参数表

Table4. Experimental parameters of double-pass laser cladding with two 1-mm spots

| Number | Laser power /W | Scanning speed perbeam /(mm·s-1) | Powder thickness /mm | Double beamenergy ratio |

|---|

| 1 | 250 | u1=5,u2=1.25 | 1 | 2∶8 | | 2 | 250 | u1=3.33,u2=1.43 | 1 | 3∶7 | | 3 | 250 | u1=2.5,u2=1.67 | 1 | 4∶6 | | 4 | 250 | u1=2,u2=2 | 1 | 5∶5 |

|

查看原文

表 5双道1 mm光斑加工下熔覆层的截面形貌参数

Table5. Cross-sectional morphology parameters of cladding layers under laser processing by using two 1-mm spots

| Number | Double beamenergy ratio | Gear tipheight /μm | Cladding maximumheight /μm | Dilution rateof coating /% | Bottom edge width ofalloyed area /μm |

|---|

| 1 | 2∶8 | 517.37 | 1208.02 | 29.89 | 1564.62 | | 2 | 3∶7 | 485.64 | 1068.11 | 28.93 | 1779.50 | | 3 | 4∶6 | 460.61 | 961.72 | 27.28 | 1825.39 | | 4 | 5∶5 | 426.44 | 1127.61 | 29.32 | 1912.43 |

|

查看原文

表 61.5 mm光斑下双道激光熔覆实验参数表

Table6. Experimental parameters of double-pass laser cladding with 1.5-mm spots

| Number | Laser power /W | Scanning speedper beam /(mm·s-1) | Powderthickness /mm | Double beamenergy ratio | Spot overlaprate /% |

|---|

| 1 | 250 | u1=3.34,u2=0.83 | 1 | 2∶8 | 30 | | 2 | 250 | u1=2.22,u2=0.95 | 1 | 3∶7 | 30 | | 3 | 250 | u1=1.67,u2=1.12 | 1 | 3∶7 | 30 | | 4 | 250 | u1=1.33,u2=1.33 | 1 | 5∶5 | 30 | | 5 | 250 | u1=3.34,u2=0.83 | 1 | 2∶8 | 40 | | 6 | 250 | u1=2.22,u2=0.95 | 1 | 3∶7 | 40 | | 7 | 250 | u1=1.67,u2=1.12 | 1 | 3∶7 | 40 | | 8 | 250 | u1=1.33,u2=1.33 | 1 | 5∶5 | 40 | | 9 | 250 | u1=3.34,u2=0.83 | 1 | 2∶8 | 50 | | 10 | 250 | u1=2.22,u2=0.95 | 1 | 3∶7 | 50 | | 11 | 250 | u1=1.67,u2=1.12 | 1 | 3∶7 | 50 | | 12 | 250 | u1=1.33,u2=1.33 | 1 | 5∶5 | 50 |

|

查看原文

表 7双道1.5 mm光斑加工下的熔覆层截面形貌参数

Table7. Cross-sectional morphology parameters of cladding layers under laser processing by using two 1.5-mm spots

| Number | Double beam power densityratio and spot overlap ratio | Gear tipheight /μm | Cladding maximumheight /μm | Dilution rateof coating /% | Bottom edge widthof alloyed area /μm |

|---|

| 1 | Energy ratio of 5∶5, overlap of 30% | 403.29 | 1408.31 | 32.77 | 1917.12 | | 2 | Energy ratio of 4∶6, overlap of 40% | 427.53 | 1366.44 | 31.48 | 1878.77 | | 3 | Energy ratio of 5∶5, overlap of 40% | 414.37 | 1402.73 | 32.45 | 1815.64 | | 4 | Energy ratio of 3∶7, overlap of 50% | 436.57 | 1446.28 | 32.51 | 1633.46 | | 5 | Energy ratio of 4∶6, overlap of 50% | 428.25 | 1493.69 | 32.87 | 1677.82 | | 6 | Energy ratio of 5∶5, overlap of 50% | 408.46 | 1520.81 | 33.59 | 1714.03 |

|

查看原文

刘干成, 黄博. 小模数齿轮齿面双道激光熔覆工艺[J]. 中国激光, 2019, 46(10): 1002009. Gancheng Liu, Bo Huang. Double-Pass Laser Cladding Process for Small-Modulus Gear-Tooth Surface[J]. Chinese Journal of Lasers, 2019, 46(10): 1002009.

下载: 826次

下载: 826次