5083铝合金真空激光焊缝成形的影响因素  下载: 1040次

下载: 1040次

王天鸽, 唐新华, 韩潇潇, 芦凤桂, 崔海超. 5083铝合金真空激光焊缝成形的影响因素[J]. 中国激光, 2018, 45(11): 1102001.

Wang Tiange, Tang Xinhua, Han Xiaoxiao, Lu Fenggui, Cui Haichao. Factors Influencing Weld Formation for Laser Welding of 5083 Aluminum Alloy in Vacuum[J]. Chinese Journal of Lasers, 2018, 45(11): 1102001.

[2] 许良红, 田志凌, 彭云, 等. 高强铝合金的激光焊接头组织及力学性能[J]. 中国激光, 2008, 35(3): 456-461.

[3] Iqbal S. Gualini M M S, Rehman A U. Dual beam method for laser welding of galvanized steel: Experimentation and prospects[J]. Optics & Laser Technology, 2010, 42(1): 93-98.

[5] 梅丽芳, 陈根余, 金湘中, 等. 车用铝合金光纤激光搭接焊的研究[J]. 中国激光, 2010, 37(8): 2091-2097.

[6] 王狮凌, 房丰洲. 大功率激光器及其发展[J]. 激光与光电子学进展, 2017, 54(9): 090005.

[7] Gapontsev V P, Fomin V, Ount A, et al. 100-kW ytterbium fiber laser[J]. Proceedings of SPIE, 1999, 3613: 49-54.

[8] 崔丽, 张彦超, 贺定勇, 等. 高功率光纤激光焊接的研究进展[J]. 激光技术, 2012, 36(2): 154-159.

[9] 黄坚, 李铸国, 唐新华. 中厚板的高功率激光焊接[J]. 航空制造技术, 2010( 2): 26- 29.

HuangJ, Li ZG, Tang XH. High-power laser welding of plate[J]. Aeronautical Manufacturing Technology, 2010( 2): 26- 29.

[10] 吴世凯, 肖荣诗, 陈铠. 大厚度不锈钢板的激光焊接[J]. 中国激光, 2009, 36(9): 2422-2425.

[11] 李小婷, 朱宝华. 铝合金激光焊接[J]. 电焊机, 2015, 45(2): 122-126.

Li X T, Zhu B H. Laser welding of aluminum alloy[J]. Electric Welding Machine, 2015, 45(2): 122-126.

[14] 王治宇. 激光—MIG电弧复合焊接基础研究及应用[D]. 武汉: 华中科技大学, 2006.

Wang ZY. Fundamental research on laser-MIG hybrid welding and its application[D]. Wuhan: Huazhong University of Science and Technology, 2006.

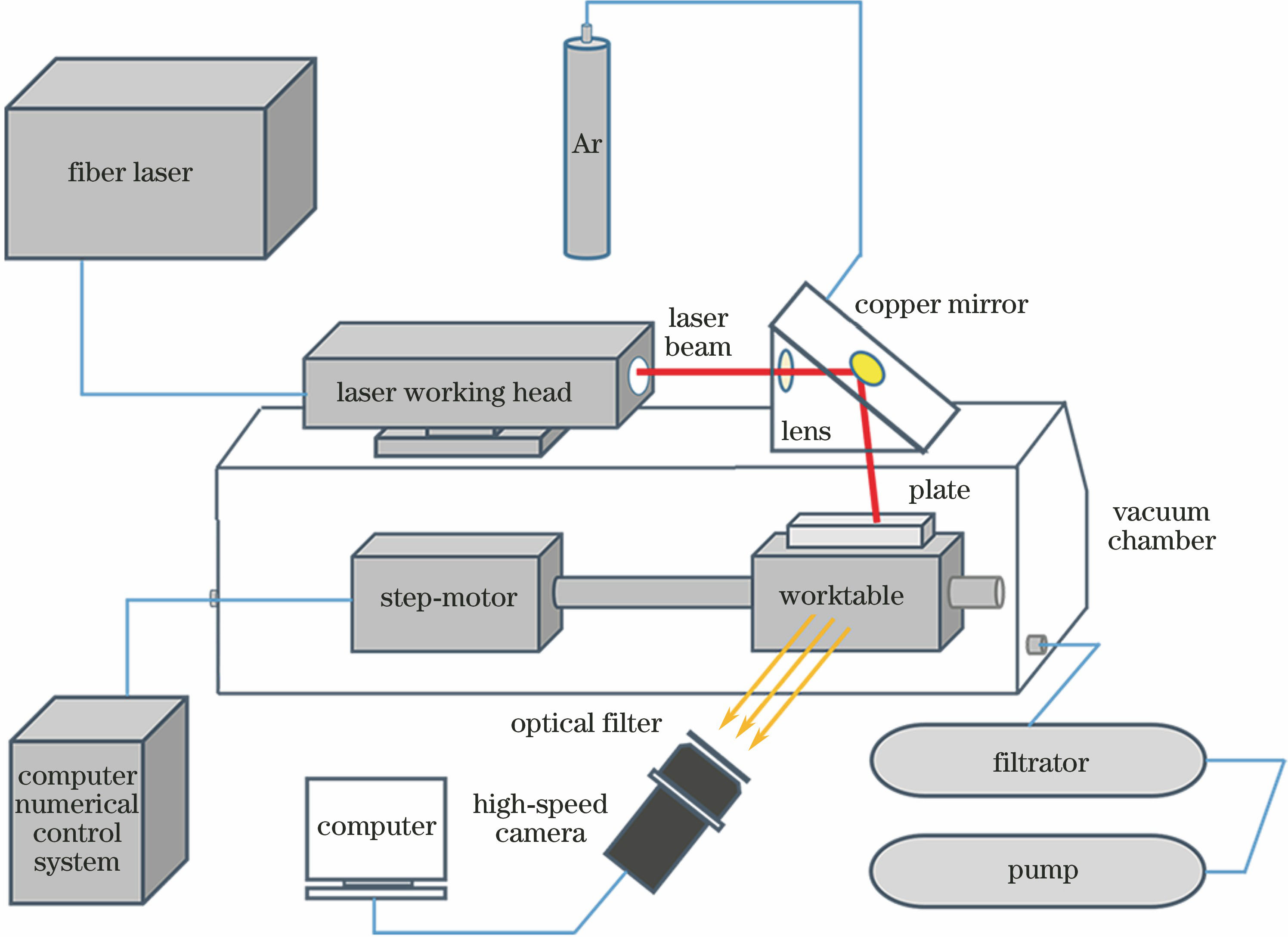

[18] 罗燕, 唐新华, 芦凤桂, 等. 局部负压激光焊缝成形特点及其影响因素[J]. 中国激光, 2014, 41(6): 0603008.

[20] 罗燕. 负压激光焊接过程蒸气羽烟及熔池行为研究[D]. 上海: 上海交通大学, 2015.

LuoY. Research on plasma plume and molten pool behavior in fiber laser welding under subatmospheric pressure[D]. Shanghai: Shanghai Jiao Tong University, 2015.

[21] 王军. 铝合金光纤激光及其复合焊接的等离子体行为与工艺研究[D]. 武汉: 华中科技大学, 2012.

WangJ. Study on the technology and plasma behaviour during the fiber laser and laser hybrid welding of aluminum alloy[D]. Wuhan: Huazhong University of Science and Technolog, 2012.

[22] 邱文聪, 杨立军, 刘桐, 等. 激光深熔焊等离子体波动特征光电信号分析[J]. 中国激光, 2018, 45(4): 0402001.

王天鸽, 唐新华, 韩潇潇, 芦凤桂, 崔海超. 5083铝合金真空激光焊缝成形的影响因素[J]. 中国激光, 2018, 45(11): 1102001. Wang Tiange, Tang Xinhua, Han Xiaoxiao, Lu Fenggui, Cui Haichao. Factors Influencing Weld Formation for Laser Welding of 5083 Aluminum Alloy in Vacuum[J]. Chinese Journal of Lasers, 2018, 45(11): 1102001.