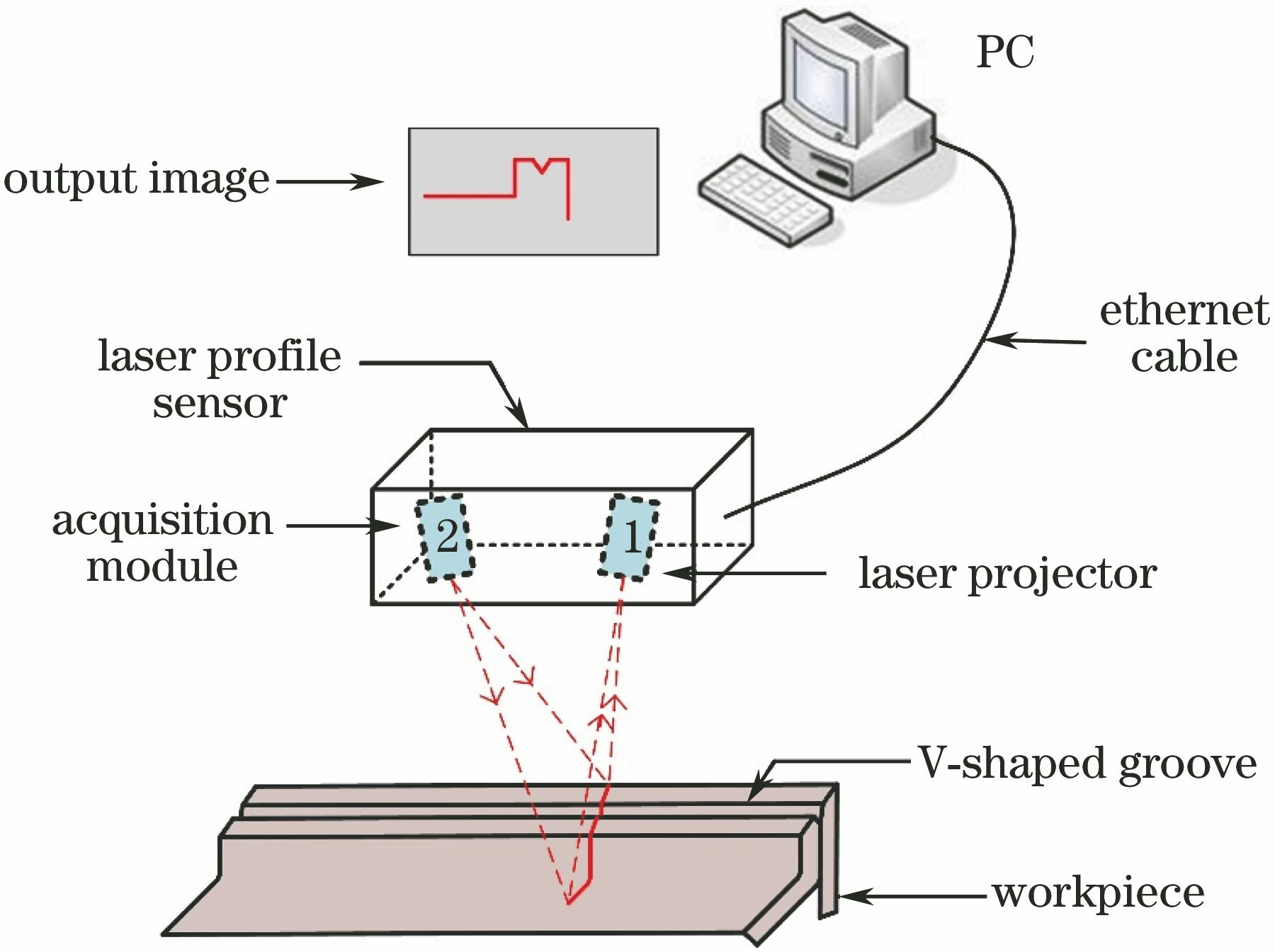

基于自动阈值的窄间隙端接焊缝识别技术  下载: 999次

下载: 999次

雷正龙, 沈健雄, 黎炳蔚, 周恒, 陈彦宾. 基于自动阈值的窄间隙端接焊缝识别技术[J]. 光学学报, 2018, 38(8): 0815011.

Zhenglong Lei, Jianxiong Shen, Bingwei Li, Heng Zhou, Yanbing Chen. Recognition of Narrow-Gap Edge Welding Seam Based on Autonomous Threshold Value[J]. Acta Optica Sinica, 2018, 38(8): 0815011.

[1] 陈彦宾. 现代激光焊接技术[M]. 北京: 科学出版社, 2005: 1- 4.

陈彦宾. 现代激光焊接技术[M]. 北京: 科学出版社, 2005: 1- 4.

Chen YB. Modern laser welding technology[M]. Beijing: Science Press, 2005: 1- 4.

Chen YB. Modern laser welding technology[M]. Beijing: Science Press, 2005: 1- 4.

[2] 游德勇, 高向东. 激光焊接技术的研究现状与展望[J]. 焊接技术, 2008, 37(4): 5-9.

游德勇, 高向东. 激光焊接技术的研究现状与展望[J]. 焊接技术, 2008, 37(4): 5-9.

You D Y, Gao X D. Studies and prospect of laser welding technology[J]. Welding Technology, 2008, 37(4): 5-9.

[3] 许二娟, 高向东, 萧振林, 等. 激光焊接过程焊缝跟踪传感方法[J]. 电焊机, 2016, 46(1): 28-35.

许二娟, 高向东, 萧振林, 等. 激光焊接过程焊缝跟踪传感方法[J]. 电焊机, 2016, 46(1): 28-35.

Xu E J, Gao X D, Xiao Z L, et al. Sensing methods of seam tracking in laser welding process[J]. Electric Welding Machine, 2016, 46(1): 28-35.

[4] 齐秀滨. 激光焊接过程视觉传感技术的发展现状[J]. 焊接学报, 2008(29): 108-112.

齐秀滨. 激光焊接过程视觉传感技术的发展现状[J]. 焊接学报, 2008(29): 108-112.

Qi X B. State-of-arts of visual sensing technology to monitor laser welding process[J]. Transactions of the China Welding Instruction, 2008(29): 108-112, 118.

[7] 陈彦宾, 李俐群, 陈凤东, 等. 图像处理在自动焊接中的应用和展望[J]. 材料科学与工艺, 2003, 11(1): 106-112.

陈彦宾, 李俐群, 陈凤东, 等. 图像处理在自动焊接中的应用和展望[J]. 材料科学与工艺, 2003, 11(1): 106-112.

Chen Y B, Li L Q, Chen F D, et al. Application and prospect of image processing in welding[J]. Materials Science & Technology, 2003, 11(1): 106-112.

[11] Qu Z G. Chong A Y B, Chacon J L F, et al. Study on the laser-based weld surface flaw identification system employing wavelet analysis methodology[J]. Research in Nondestructive Evaluation, 2016, 27(3): 137-154.

Qu Z G. Chong A Y B, Chacon J L F, et al. Study on the laser-based weld surface flaw identification system employing wavelet analysis methodology[J]. Research in Nondestructive Evaluation, 2016, 27(3): 137-154.

[13] 赵菁, 林三宝. 用于焊接自动化过程的激光视觉传感器[J]. 电焊机, 2010, 40(11): 1-5.

赵菁, 林三宝. 用于焊接自动化过程的激光视觉传感器[J]. 电焊机, 2010, 40(11): 1-5.

Zhao J, Lin S B. Introduction to laser sensors for automated welding[J]. Electric Welding Machine, 2010, 40(11): 1-5.

[14] 王欢, 王修晖. 基于阈值判断的自适应中值滤波算法[J]. 中国计量学院学报, 2011, 22(4): 382-385.

王欢, 王修晖. 基于阈值判断的自适应中值滤波算法[J]. 中国计量学院学报, 2011, 22(4): 382-385.

Wang H, Wang X H. An improved adaptive median filter based on noises detection[J]. Journal of China University of Metrology, 2011, 22(4): 382-385.

[15] PapoulisA, Pillai SU. Probability,random variables, and stochastic processes[M]. 3 rd ed. New York: McGraw-Hill, Inc. , 1991.

PapoulisA, Pillai SU. Probability,random variables, and stochastic processes[M]. 3 rd ed. New York: McGraw-Hill, Inc. , 1991.

雷正龙, 沈健雄, 黎炳蔚, 周恒, 陈彦宾. 基于自动阈值的窄间隙端接焊缝识别技术[J]. 光学学报, 2018, 38(8): 0815011. Zhenglong Lei, Jianxiong Shen, Bingwei Li, Heng Zhou, Yanbing Chen. Recognition of Narrow-Gap Edge Welding Seam Based on Autonomous Threshold Value[J]. Acta Optica Sinica, 2018, 38(8): 0815011.