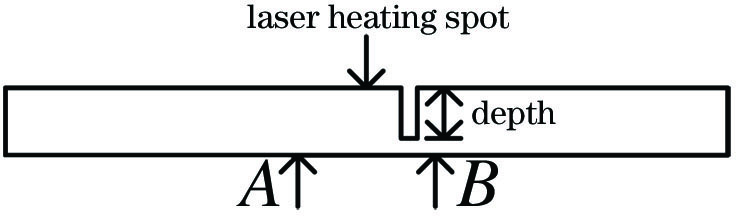

基于激光热成像的金属表面缺陷深度检测  下载: 681次

下载: 681次

刘佳琪, 张志杰, 林振钰, 尹武良. 基于激光热成像的金属表面缺陷深度检测[J]. 激光与光电子学进展, 2021, 58(4): 0411002.

Jiaqi Liu, Zhijie Zhang, Zhenyu Lin, Wuliang Yin. Depth Detection of Material Surface Defects Based on Laser Thermography[J]. Laser & Optoelectronics Progress, 2021, 58(4): 0411002.

[1] 刘晓丰, 田雅馨, 邹静, 等. 直升机关键金属TB6钛合金的划伤、冲击缺陷容限性能[J]. 科学技术与工程, 2019, 19(29): 349-355.

[2] 沈晓海, 栗泽昊, 李敏, 等. 基于多任务深度学习的铝材表面缺陷检测[J]. 激光与光电子学进展, 2020, 57(10): 101501.

[5] 董宁琛, 张志杰, 尹武良, 等. 基于脉冲激光点光源热成像方法检测钢材表面裂纹[J]. 激光与红外, 2019, 49(10): 1195-1200.

[7] 江海军, 陈力. 闪光灯热激励红外热波成像无损检测设备及应用[J]. 无损检测, 2017, 39(9): 57-60, 64.

Jiang H J, Chen L. Application of flash thermal excitation infrared thermographic nondestructive testing equipment[J]. Nondestructive Testing, 2017, 39(9): 57-60, 64.

[8] 李玉杰, 李科, 钟安彪, 等. 卤素灯加热红外成像检测技术仿真研究[J]. 激光与红外, 2016, 46(12): 1477-1480.

Li Y J, Li K, Zhong A B, et al. Simulation research of infrared image detection technology for halogen lamp heating[J]. Laser & Infrared, 2016, 46(12): 1477-1480.

[10] 许颖, 王青原, 罗聪聪, 等. 基于线激光锁相热成像的芯片裂纹成像检测[J]. 激光与光电子学进展, 2020, 57(6): 061018.

[11] 杨连杰, 李阳, 孙俊杰, 等. 激光超声表面波在表面缺陷上的反射与透射[J]. 激光与光电子学进展, 2019, 56(4): 041203.

[12] Vavilov V P. Modeling thermal NDT problems[J]. International Journal of Heat and Mass Transfer, 2014, 72: 75-86.

[14] He Z Y, Wang H J, He Y Z, et al. Joint scanning laser thermography defect detection method for carbon fiber reinforced polymer[J]. IEEE Sensors Journal, 2020, 20(1): 328-336.

[15] 董宁琛, 张志杰, 尹武良, 等. 基于激光热成像方法的奥氏体钢表面缺陷表征[J]. 激光与红外, 2020, 50(2): 179-183.

[18] 王卓, 张云伟, 喻勇, 等. 主动热激励式红外热成像管道缺陷深度检测[J]. 光学学报, 2018, 38(9): 0912003.

[19] Yu P, Zeng Y. Characterization of laser-induced local heating in a substrate[J]. International Journal of Heat & Mass Transfer, 2017, 106: 989-996.

[21] 张杰. 红外热成像测温技术及其应用研究[D]. 成都: 电子科技大学, 2011.

ZhangJ. Research on infrared thermal imaging temperature measurement technology and its application[D]. Chengdu: University of Electronic Science and Technology of China, 2011.

刘佳琪, 张志杰, 林振钰, 尹武良. 基于激光热成像的金属表面缺陷深度检测[J]. 激光与光电子学进展, 2021, 58(4): 0411002. Jiaqi Liu, Zhijie Zhang, Zhenyu Lin, Wuliang Yin. Depth Detection of Material Surface Defects Based on Laser Thermography[J]. Laser & Optoelectronics Progress, 2021, 58(4): 0411002.