工业领域的激光清洗技术  下载: 3764次

下载: 3764次

Laser Cleaning Technology in Industrial Fields

哈尔滨工业大学先进焊接与连接国家重点实验室, 黑龙江 哈尔滨 150001

图 & 表

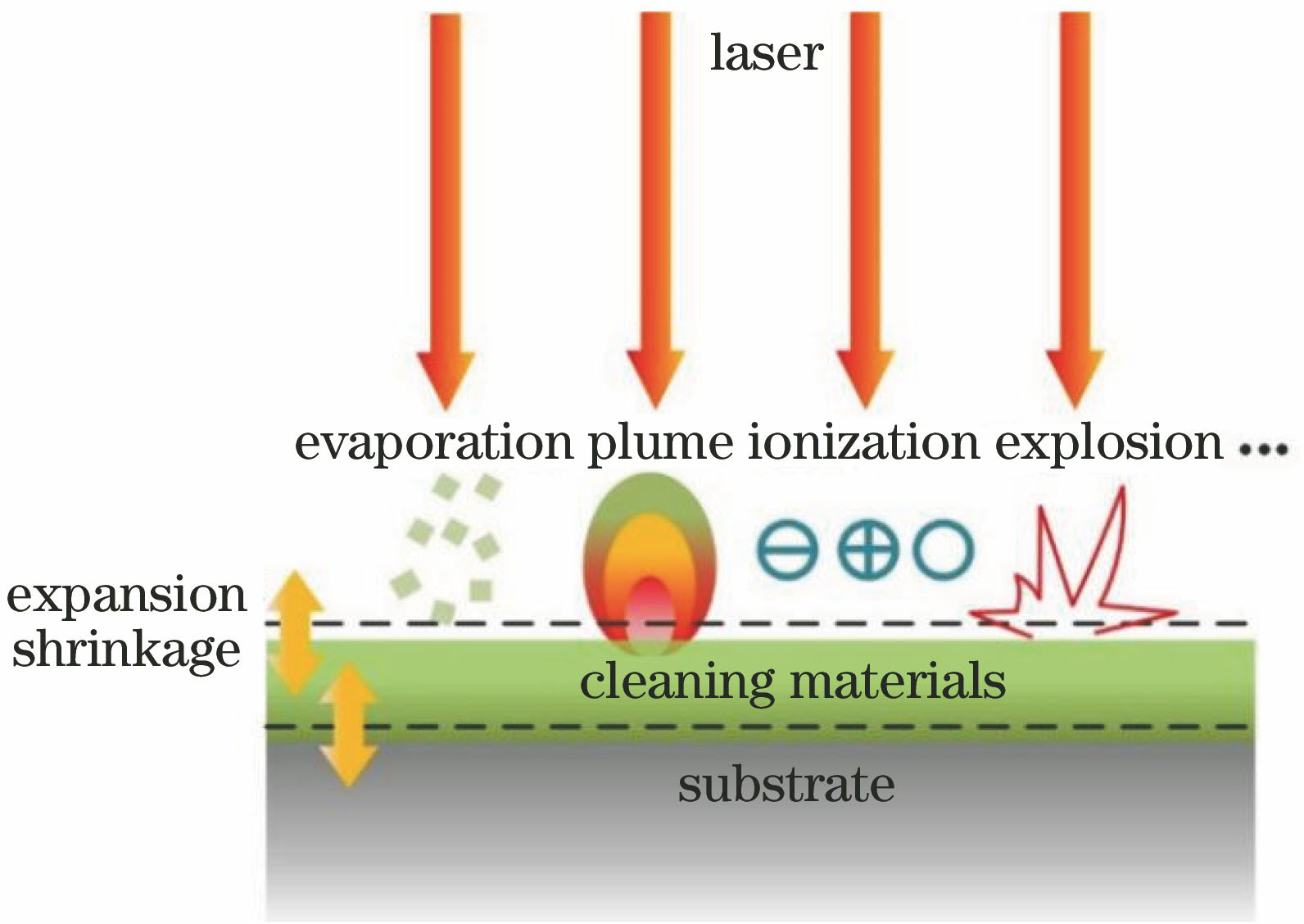

图 1. 激光烧蚀清洗方法的工艺示意图

Fig. 1. Process diagram of laser ablation cleaning

下载图片 查看原文

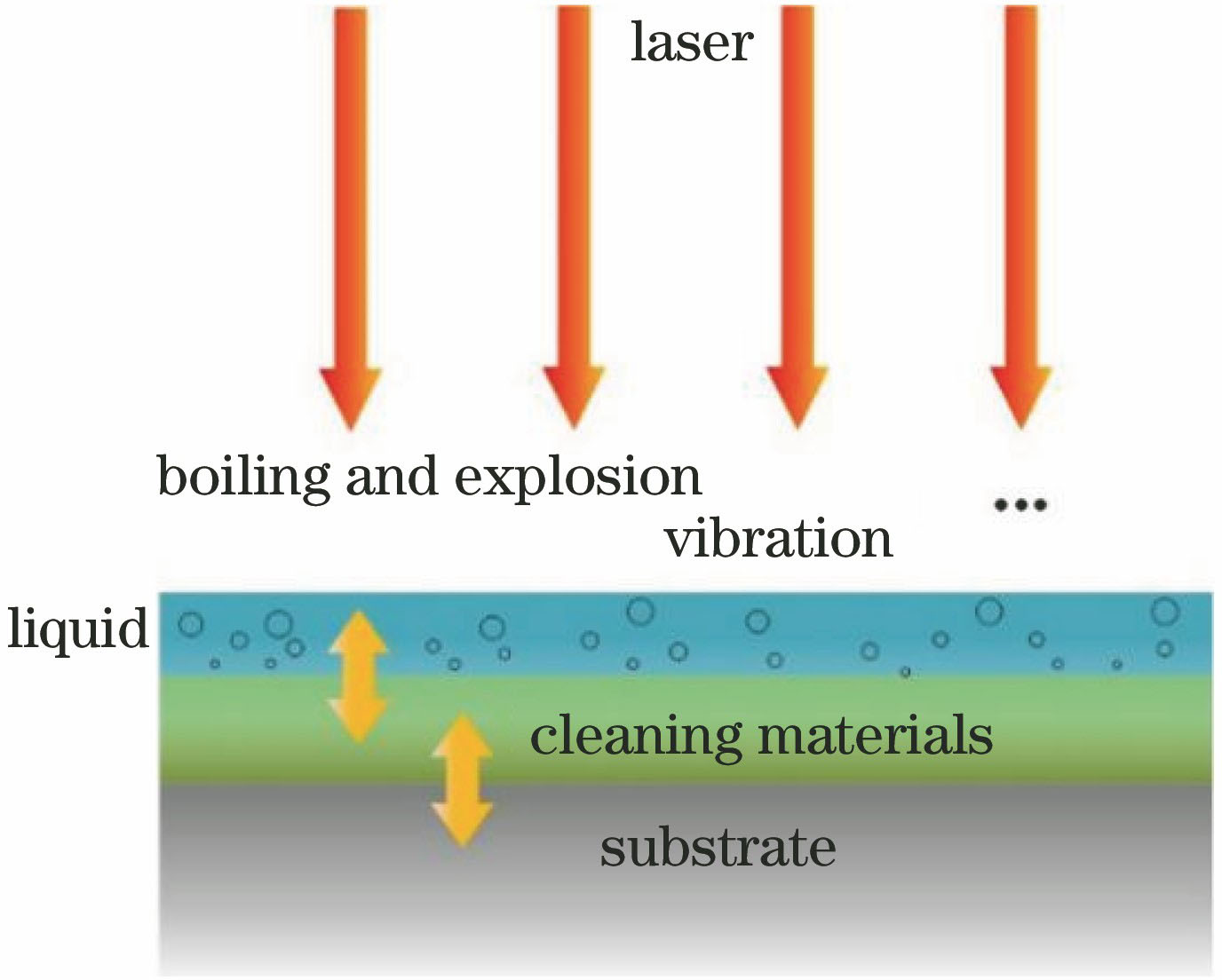

图 2. 液膜辅助式激光清洗的工艺示意图

Fig. 2. Process diagram of liquid film assisted laser cleaning

下载图片 查看原文

图 3. 激光冲击波式清洗的工艺示意图[14]

Fig. 3. Process diagram of laser shockwave cleaning[14]

下载图片 查看原文

图 4. Al-Si涂层单点激光清洗工艺示意图。(a)能量耦合;(b)热传导;(c)等离子体屏蔽;(d)材料驱逐[15]

Fig. 4. Process diagrams of single pot laser ablation cleaning of Al-Si coating. (a) Energy coupling; (b) heat conduction; (c) plasma shielding; (d) material expulsion[15]

下载图片 查看原文

图 5. 光谱总强度随加工深度的变化[29]

Fig. 5. Total emission intensity as a function of depth of processing[29]

下载图片 查看原文

图 6. 材料的表面的X射线断层扫描图。(a)激光清洗前;(b)激光清洗后[32]

Fig. 6. X-ray tomography of material surface. (a) Before laser cleaning; (b) after laser cleaning[32]

下载图片 查看原文

图 7. (a)当激光能量密度为6.1 J/cm2时,900次激光脉冲辐照后的材料横截面形貌;(b)激光辐照后样品截面结构示意图[36]

Fig. 7. (a) Cross-sectional morphology of material after 900 pulses of laser irradiation with a laser energy density of 6.1 J·cm-2; (b) structural diagram of cross section of sample after laser irradiation[36]

下载图片 查看原文

图 8. 焊缝的X射线照片。(a)焊前未经激光清洗的接头;(b)焊前激光清洗的接头[37]

Fig. 8. X-ray photos of weld. (a) Joint without any cleaning before welding; (b) joint with laser cleaning before welding[37]

下载图片 查看原文

图 9. 0.35 mJ激光处理后的材料横截面形貌。(a)激光轨迹中心区的碳纤维;(b)激光轨迹边缘区的碳纤维[42]

Fig. 9. Cross-sectional morphologies of material after 0.35 mJ laser treatment. (a) Carbon fiber at center of laser trajectory; (b) carbon fiber at border of laser trajectory[42]

下载图片 查看原文

图 10. 经能量密度为800 mJ/cm2的准分子激光清洗后的CFRP表面形貌。(a)无脉冲;(b) 2次脉冲;(c) 6次脉冲[43]

Fig. 10. CFRP surface morphologies after excimer laser cleaning with energy density of 800 mJ·cm-2. (a) No pulse; (b) two pulses; (c) six pulses[43]

下载图片 查看原文

图 11. 钨丝氧化区和激光清洗区的AFM图[53]

Fig. 11. AFM image of tungsten wire across oxidized and laser cleaning areas[53]

下载图片 查看原文

表 1近十年国内外激光清洗研究小结

Table1. Research summary of domestic and overseas laser cleaning in recent decade

| Substrate | Cleaning material | Laser | Year |

|---|

| HPF steel | Coating | Pulsed fiber laser (1064 nm) | 2017[15] | | Nd∶YAG laser (1064 nm) | 2016[16-17] | | Stainless steel | Rust | Pulsed green laser (532 nm) | 2016[18] | | Coating | Pulsed fiber laser (1064 nm) | 2015[19] | | Oil, lubricant | Nd∶YAG laser (1064 nm) | 2012[20] | | Carbon steel | Paint | Pulsed fiber laser (1064 nm) | 2015[21] | | Rust | Pulsed fiber laser (1064 nm) | 2014[22-25] | | Nd∶YAG laser (1064 nm) | 2013[26] | | Hot rolled steel | Rust | Pulsed fiber laser (1064 nm) | 2016[27-28] | | Paint | Pulsed fiber laser (1064 nm) | 2017[29]2015[30] | | Aluminum alloy | Particle, oxide film | Nd∶YAG laser (532 nm) | 2016[31] | | Coating, lubricant | Nd∶YAG laser (1064 nm) | 2014[32] | | Surface of substrate | Nd∶YAG laser (1064 nm) | 2016[33] | | Pulsed fiber laser (1064 nm) | 2015[34] | | Titanium alloy | Coating | Femtosecond laser (800 nm) | 2013[35] | | Excimer laser (248 nm) | 2012[12,36] | | Oxide film | Pulsed fiber laser (1064 nm) | 2010[37] | | Glass | Film | Nd∶YAG laser (1064 nm, 532 nm) | 2013[38] | | Particle, oil | Nd∶YAG laser (1064 nm, 532 nm) | 2014[39]2011[40]2012[41] | | CO2 laser (10.6 μm) | 2012[41] | | CFRP | Contaminants, epoxy resin | Femtosecond laser (1024 nm) | 2017[42] | | | Excimer laser (308 nm) | | 2016[43] | | Pulsed CO2 laser (10.6 μm) | | 2016[44] | | UV laser (308 nm), NIR laser (1064 nm) | | 2013[45] | | Paint | TEA-CO2 laser (10.6 μm) | 2007[46] | | HIPS | Particle | Nd∶YAG laser (1064 nm) | 2014[47] | | Si wafer | Particle | XeCl excimer laser (308 nm) | 2009[48] | | Nd∶YAG laser (1064 nm) | 2009[14,49]2007[50]2005[51] | | Nickel-based superalloy AM1 | Surface of substrate | Diode-pumped solid-state laser (532 nm) | 2016[52] | | Tungsten ribbon | Oxide film | Nd∶YAG laser (1064, 532, 355 nm) | 2014[53] | | Brass rings | Coating | Pulsed fiber laser (1064 nm) | 2014[54] |

|

查看原文

雷正龙, 田泽, 陈彦宾. 工业领域的激光清洗技术[J]. 激光与光电子学进展, 2018, 55(3): 030005. Zhenglong Lei, Ze Tian, Yanbin Chen. Laser Cleaning Technology in Industrial Fields[J]. Laser & Optoelectronics Progress, 2018, 55(3): 030005.

下载: 3764次

下载: 3764次