工艺参数对选区激光熔化中成形形变的影响  下载: 936次

下载: 936次

吴懋亮, 孙翰霆, 孙玄锴, 刘中俊, 李汝润. 工艺参数对选区激光熔化中成形形变的影响[J]. 激光与光电子学进展, 2020, 57(5): 051403.

Maoliang Wu, Hanting Sun, Xuankai Sun, Zhongjun Liu, Rurun Li. Effect of Process Parameters on the Deformation of Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2020, 57(5): 051403.

[1] 杨泽, 李建永, 高兴华, 等. 浅析增材制造技术在制造业中的特点与应用[J]. 机床与液压, 2017, 45(3): 189-192.

Yang Z, Li J Y, Gao X H, et al. Simple descriptions of the characteristics and applications of additive manufacturing technology in manufacture[J]. Machine Tool & Hydraulics, 2017, 45(3): 189-192.

[2] 文世峰, 季宪泰, 周燕, 等. 激光选区熔化成形模具钢的发展现状及前景[J]. 激光与光电子学进展, 2018, 55(1): 011404.

Wen S F, Ji X T, Zhou Y, et al. Development status and prospect of selective laser melting of mould steels[J]. Laser & Optoelectronics Progress, 2018, 55(1): 011404.

[3] 史玉升, 鲁中良, 章文献, 等. 选区激光熔化快速成形技术与装备[J]. 中国表面工程, 2006, 19(z1): 150-153.

Shi Y S, Lu Z L, Zhang W X, et al. The technology and equipment of selective laser melting[J]. China Surface Engineering, 2006, 19(z1): 150-153.

[4] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[5] Jeya R P K, Bouzid A H. Effect of thermal ratcheting on the mechanical properties of Teflon and fiber based gasket materials[J]. Journal of Applied Polymer Science, 2019, 136(13): 47265.

[6] 何贝贝. 选区激光熔化TiNi形状记忆合金热—力耦合数值模拟及实验研究[D]. 南京: 南京航空航天大学, 2016.

He BB. Numerical simulation and experimental investigation on thermal-mechanical behavior during selective laser melting of TiNi shape memory alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016.

[7] Dixit US, Joshi SN, Davim JP. Application of lasers in manufacturing[M]. Singapore: Springer, 2019.

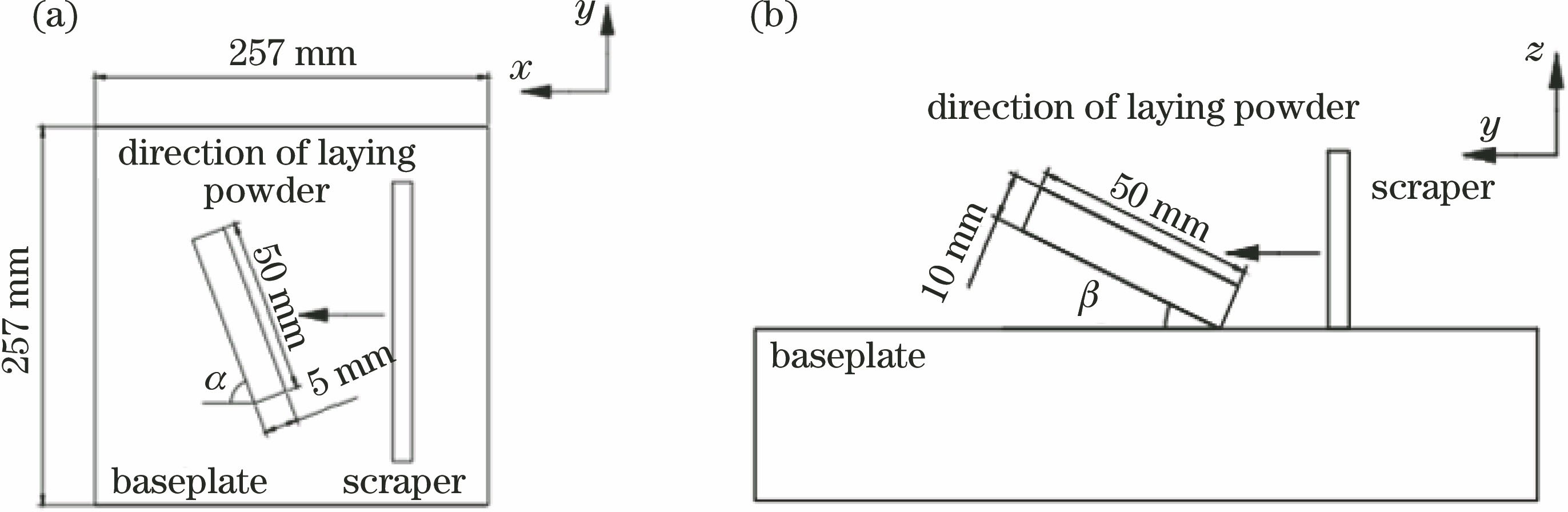

[8] 吴根丽, 刘婷婷, 张长东, 等. Ti6Al4V激光选区熔化成形悬垂结构的质量研究[J]. 中国机械工程, 2016, 27(13): 1810-1815.

Wu G L, Liu T T, Zhang C D, et al. Research on forming quality of overhanging structure by selective laser melting[J]. China Mechanical Engineering, 2016, 27(13): 1810-1815.

[9] 姜献峰, 熊志越, 王同鹤, 等. 选区激光熔化成形中零件成形角度对其机械性能的影响[J]. 浙江工业大学学报, 2017, 45(5): 510-515.

Jiang X F, Xiong Z Y, Wang T H, et al. Investigation on the mechanical properties of 316L metal powders by SLM[J]. Journal of Zhejiang University of Technology, 2017, 45(5): 510-515.

[10] Mugwagwa L, Dimitrov D, Matope S, et al. Influence of process parameters on residual stress related distortions in selective laser melting[J]. Procedia Manufacturing, 2018, 21: 92-99.

[11] Mazur M, Brincat P, Leary M, et al. Numerical and experimental evaluation of a conformally cooled H13 steel injection mould manufactured with selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2017, 93: 881-900.

[12] 马涛, 刘婷婷, 廖文和, 等. 激光选区熔化成形Ti-6Al-4V疲劳性能研究[J]. 中国激光, 2018, 45(11): 1102012.

[13] Chen H Y, Gu D D, Dai D H, et al. Microstructure and composition homogeneity, tensile property, and underlying thermal physical mechanism of selective laser melting tool steel parts[J]. Materials Science and Engineering: A, 2017, 682: 279-289.

[14] 肖振楠, 刘婷婷, 廖文和, 等. 激光选区熔化成形TC4钛合金热处理后微观组织和力学性能[J]. 中国激光, 2017, 44(9): 0902001.

吴懋亮, 孙翰霆, 孙玄锴, 刘中俊, 李汝润. 工艺参数对选区激光熔化中成形形变的影响[J]. 激光与光电子学进展, 2020, 57(5): 051403. Maoliang Wu, Hanting Sun, Xuankai Sun, Zhongjun Liu, Rurun Li. Effect of Process Parameters on the Deformation of Selective Laser Melting[J]. Laser & Optoelectronics Progress, 2020, 57(5): 051403.