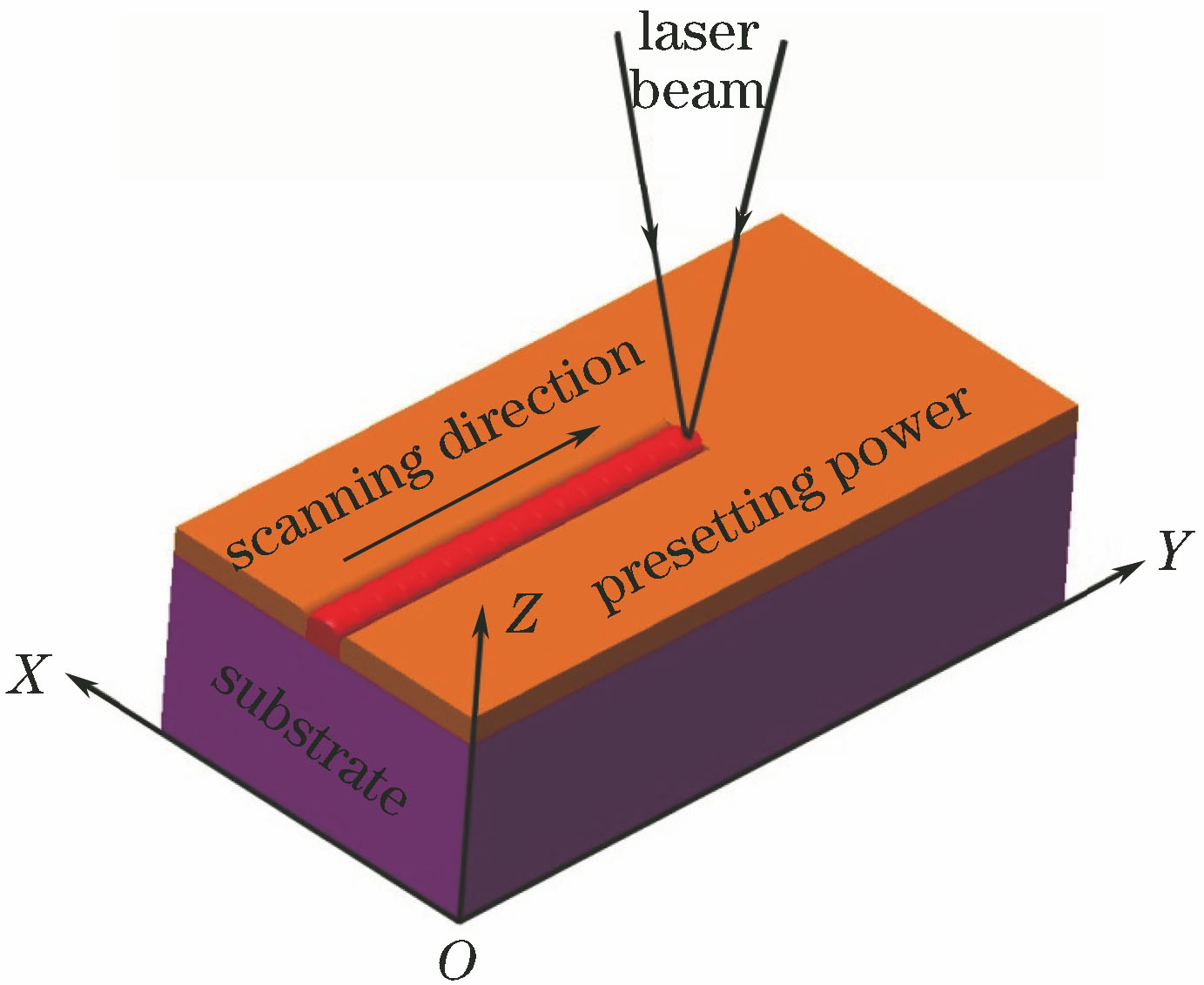

激光熔覆304不锈钢稀释效应的数值模拟与实验  下载: 1167次

下载: 1167次

郭卫, 李凯凯, 柴蓉霞, 张丽苹. 激光熔覆304不锈钢稀释效应的数值模拟与实验[J]. 激光与光电子学进展, 2019, 56(5): 051402.

Wei Guo, Kaikai Li, Rongxia Chai, Liping Zhang. Numerical Simulation and Experiment of Dilution Effect in Laser Cladding 304 Stainless Steel[J]. Laser & Optoelectronics Progress, 2019, 56(5): 051402.

[1] 卢秉恒, 李涤尘. 3D打印)技术发展[J]. 机械制造与自动化, 2013, 42(4): 1-4.

Lu B H, Li D C. Development of the additive manufacturing (3D printing) technology[J]. Machine Building & Automation, 2013, 42(4): 1-4.

[2] 方琴琴, 傅戈雁, 王聪, 等. 带连接筋双层薄壁件激光直接成形工艺[J]. 中国激光, 2017, 44(2): 0202005.

[3] 何博文, 冉先喆, 田象军, 等. 激光增材制造TC11钛合金的耐蚀性研究[J]. 中国激光, 2016, 43(4): 0403004.

[4] 王志会, 王华明, 刘栋. 激光增材制造AF1410超高强度钢组织与力学性能研究[J]. 中国激光, 2016, 43(4): 0403001.

[6] 韩会, 祁文军, 党元晓, 等. 路径设置对304不锈钢激光熔覆温度场及应力应变场的影响[J]. 热加工工艺, 2017( 12): 148- 152.

HanH, Qi WJ, Dang YX, et al. Effect of path set on laser cladding temperature field and stress and strain field of 304 stainless steel[J]. Hot Working Technology, 2017( 12): 148- 152.

[8] 郑丽娟, 李燕, 何大川, 等. 激光多道熔覆温度场及熔覆层组织分析[J]. 红外与激光工程, 2013, 42(S1): 52-57.

[9] 宫新勇, 高士友, 咸士玉, 等. 基于温度特征的单道激光熔覆翘曲变形[J]. 激光与光电子学进展, 2017, 54(10): 101410.

[10] 华亮, 田威, 廖文和, 等. 激光熔覆热影响区及残余应力分布特性研究[J]. 激光与光电子学进展, 2014, 51(9): 091401.

[11] 周野飞, 高士友, 王京京. 激光熔覆高碳铁基合金组织性能研究[J]. 中国激光, 2013, 40(12): 1203001.

[12] 鲍雨梅, 高海明, 张冬明, 等. 基于温度场模拟的激光熔覆生物陶瓷涂层工艺参数选择[J]. 激光与光电子学进展, 2014, 51(11): 111601.

[17] 李豪, 王彦芳, 石志强, 等. 基于椭圆热源模型的激光熔覆温度场与流场数值模拟[J]. 应用激光, 2017, 37(2): 218-222.

郭卫, 李凯凯, 柴蓉霞, 张丽苹. 激光熔覆304不锈钢稀释效应的数值模拟与实验[J]. 激光与光电子学进展, 2019, 56(5): 051402. Wei Guo, Kaikai Li, Rongxia Chai, Liping Zhang. Numerical Simulation and Experiment of Dilution Effect in Laser Cladding 304 Stainless Steel[J]. Laser & Optoelectronics Progress, 2019, 56(5): 051402.