基于光压原理的高功率激光测量装置  下载: 1121次

下载: 1121次

Objective High-power lasers have important applications in industrial processing, military defense, scientific research, and other fields. With the development of laser technology in recent years, the output power level of lasers has been continuously improved. The accurate measurement of power is the basis of researches and applications of high-power lasers. Traditional high-power laser measurement mainly uses calorimetric methods. The device is large and heavy, and the surface of the absorption material is easily damaged by laser.

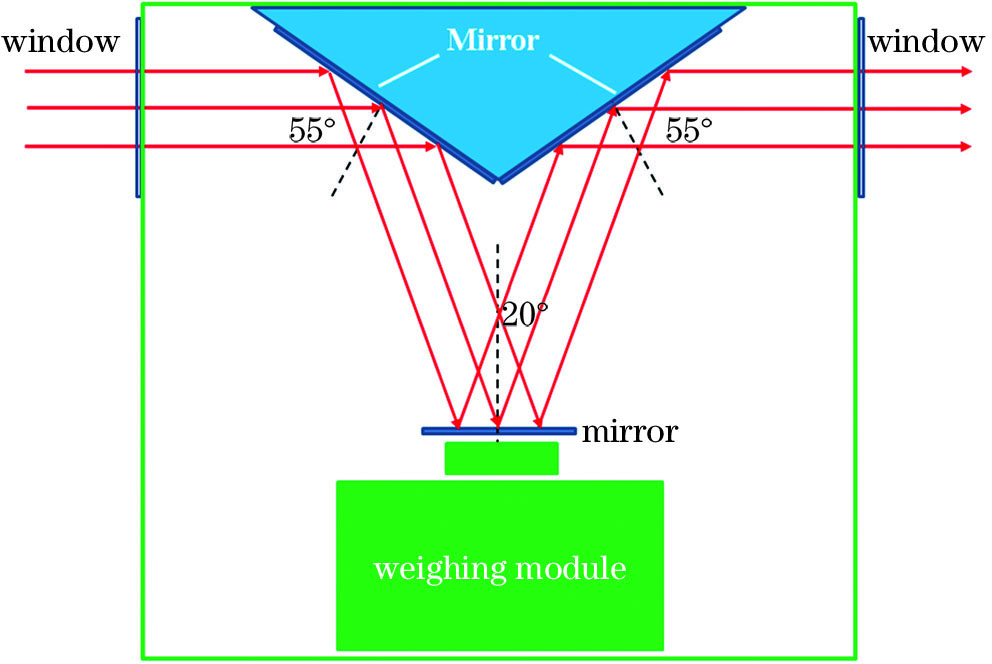

Methods Although the photon has no static mass, it has momentum. When the laser is irradiated on the surface of the object, pressure will be generated. Using the light pressure effect, the laser power can be traced directly to the micro-nano force or micro-mass. Figure 1 is the principle diagram of the measuring device, which adopts the structural design of three mirrors, and the transmission direction of the laser remains unchanged after three reflections. One of the mirrors is installed on the weighing module, and the weighing module is placed horizontally in the same manner as the mass calibration.

Results and Discusions Figure 2 shows the time response curve of the optical pressure measurement device. The laser emission time is set to 20 s, and the response time of the measurement device is only 3 s. A calorimetric laser power meter that has been accurately calibrated is placed behind the optical pressure measurement device for simultaneous measurement. The measurement results of the two methods are compared. The maximum relative deviation is less than 1%. Limited by the output power of the test light source, the upper limit of power measurement is only verified to 15 kW. In fact, the upper limit of power measurement of the device is only limited by the damage threshold of the laser mirror, so the upper limit of power measurement can reach 100 kW or even higher.

Conclusions Based on the principle of light pressure, a set of high-power laser measurement devices is established, and the power measurement uncertainty is better than 2% (confidence factor k is 2). The light pressure method is compared with the calorimetric method in the power range of 0.6--15 kW, and the maximum relative deviation is less than 1%. At the same time, the measurement device has the advantages of fast response speed, high measurement accuracy, and online measurement.

高功率激光在工业加工、****和科学研究等领域具有重要的应用[1-2]。近年来,随着激光技术的发展,激光器输出功率水平不断提升,我国激光产业也经历了“黄金十年”的飞速发展。目前,工业用激光加工主流设备的输出功率为1~10 kW,高端设备的输出功率达30 kW以上。功率的准确测量是高功率激光研究和应用的基础,传统高功率激光测量主要采用量热方法,装置体积和质量都较大,且测量的功率越高装置的体积越大,测量装置的吸收材料表面极易被激光损伤[3-4]。取样方法虽然具有装置体积较小的优点,但对激光取样比的准确性和稳定性要求极高,相比量热方法的测量误差大、稳定性差。因此国际上还在探索新的高功率激光测量方法[5-7]。

光子虽然没有静止质量但是有动量,激光照射到物体表面时会产生压力,利用光压效应,可以实现将激光功率溯源至质量,这为高功率激光测量提供一种全新的思路。2017年美国标准技术研究院(NIST)基于光压原理研制了新一代高功率激光计量装置,实现了1~50 kW激光功率的快速准确测量[8-9];相比于传统量热型装置,该装置具有体积小、质量轻、响应速度快、无需水冷等优点,且测量的激光功率越高,测量结果的信噪比越高,因此在测量高功率激光时该方法具有明显的优势。

中国计量科学研究院光学与激光计量科学研究所从2018年开始跟踪国际相关研究进展,经过近两年的探索与实验,于2020年9月成功研制了一套基于光压原理的高功率激光测量装置。

图 1. 基于光压原理的高功率激光测量装置原理图

Fig. 1. Schematic diagram of high power laser measurement device based on principle of light pressure

当功率为P的激光照射到反射镜上时,称重模块测得的质量为

式中:c为真空光速;g为重力加速度;θ为激光入射角度;R和A分别为反射镜的反射率和吸收率。称重模块的分辨率为10 μg,等效的激光功率分辨率为15.64 W。装置的测量不确定度主要来源于称重模块的质量测量不确定度与分辨率、激光入射角度以及镜片反射率。经初步评估,当激光功率高于2 kW时,测量不确定度优于2%(置信因子k=2)。

该装置的建立从原理上初步解决了我国高功率激光尤其是超高功率激光的高准确度测量难题,下一步工作将进一步提升装置测量分辨率和不确定度水平,并建立溯源至质量的高功率激光国家计量标准,从源头上解决我国高功率激光的溯源问题,满足我国高功率激光的测量与校准需求。

致谢 感谢阿帕奇(北京)光纤激光技术有限公司提供测试激光器。

[1] 赵乐, 曹政, 邹江林, 等. 高功率光纤激光深熔焊接小孔的形貌特征[J]. 中国激光, 2020, 47(11): 1102005.

[2] 林炜恒, 朱健强, 任磊. 高功率激光装置中的靶定位及束靶耦合技术研究进展[J]. 中国激光, 2020, 47(4): 0400001.

[3] Williams P, Hadler J, Cromer C, et al. Flowing-water optical power meter for primary-standard, multi-kilowatt laser power measurements[J]. Metrologia, 2018, 55: 427-436.

[4] 魏继锋, 蒋志雄, 卢飞, 等. 石墨锥型高能激光全吸收能量计设计[J]. 中国激光, 2015, 42(2): 0208006.

[5] Agatsuma K, Friedrich D, Ballmer S, et al. Precise measurement of laser power using an optomechanical system[J]. Optics Express, 2014, 22(2): 2013-2030.

[6] Ryger I. Artusio-Glimpse A B, Williams P, et al. Micromachined force scale for optical power measurement by radiation pressure sensing[J]. IEEE Sensors Journal, 2018, 18(19): 7941-7948.

[8] Williams P, Hadler J, Maring F, et al. Portable, high-accuracy, non-absorbing laser power measurement at kilowatt levels by means of radiation pressure[J]. Optics Express, 2017, 25(4): 4382-4392.

[9] Williams P A. Artusio-Glimpse A B, Hadler J A, et al. Radiation-pressure-enabled traceable laser sources at CW powers up to 50 kW[J]. IEEE Transactions on Instrumentation and Measurement, 2019, 68(6): 1833-1839.

孙青, 马冲, 林延东, 张云鹏, 徐涛. 基于光压原理的高功率激光测量装置[J]. 中国激光, 2021, 48(3): 0315002. Qing Sun, Chong Ma, Yandong Lin, Yunpeng Zhang, Tao Xu. High-Power Laser Measurement Device Based on Light Pressure Principle[J]. Chinese Journal of Lasers, 2021, 48(3): 0315002.