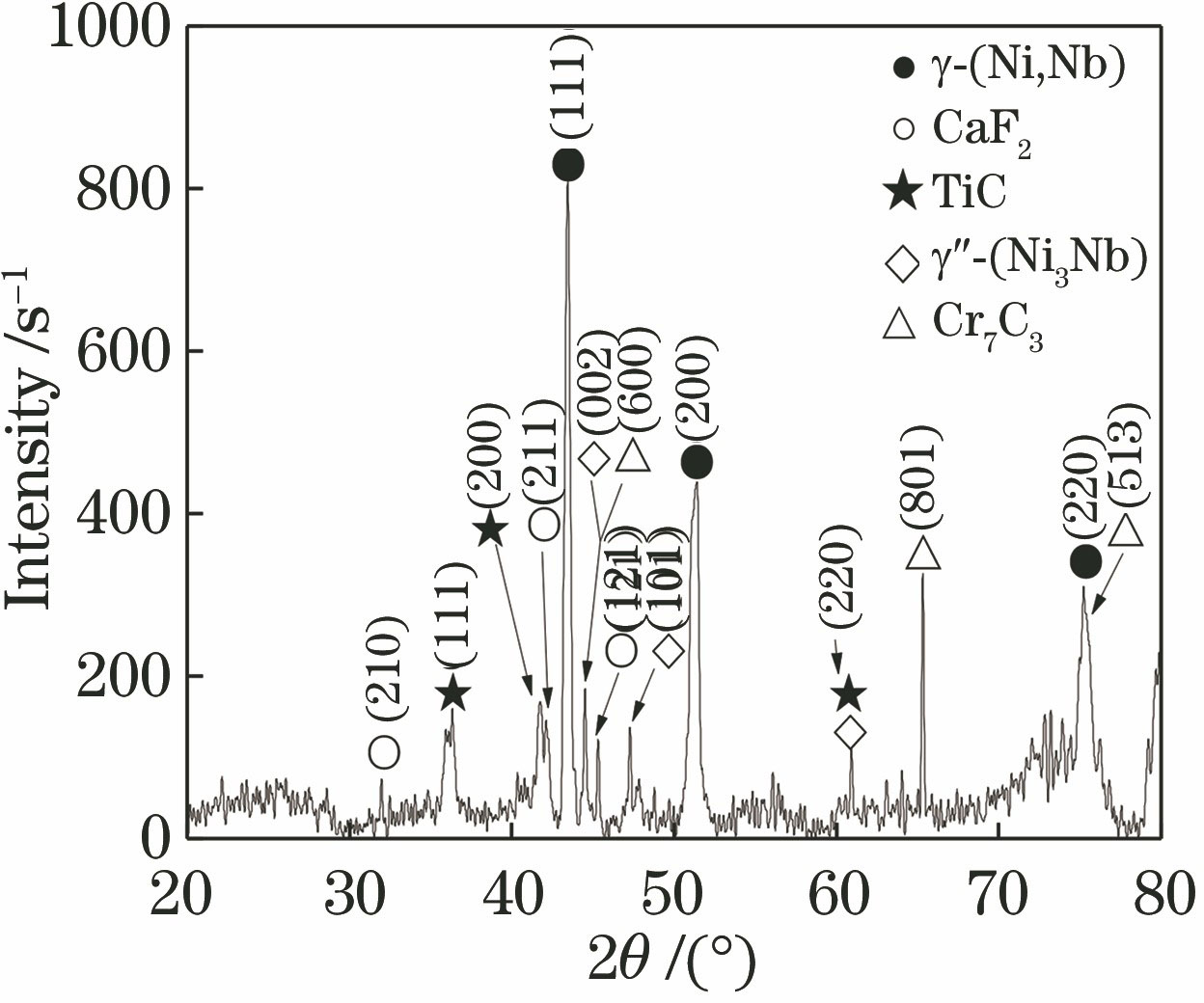

激光熔化沉积TiC/CaF2/Inconel 718复合材料的组织及高温摩擦磨损性能  下载: 1261次

下载: 1261次

刘志宏, 刘元富, 张乐乐, 陈德强, 石晨晓, 陆富刚, 冯志成, 金杰. 激光熔化沉积TiC/CaF2/Inconel 718复合材料的组织及高温摩擦磨损性能[J]. 中国激光, 2020, 47(1): 0102008.

Zhihong Liu, Yuanfu Liu, Lele Zhang, Deqiang Chen, Chenxiao Shi, Fugang Lu, Zhicheng Feng, Jie Jin. Microstructure and High-Temperature Friction and Wear Properties of TiC/CaF2/Inconel 718 Composite Fabricated Using Laser Melting Deposition Technique[J]. Chinese Journal of Lasers, 2020, 47(1): 0102008.

[1] 刘永长, 郭倩颖, 李冲, 等. Inconel 718高温合金中析出相演变研究进展[J]. 金属学报, 2016, 52(10): 1259-1266.

Liu Y C, Guo Q Y, Li C, et al. Recent progress on evolution of precipitates in Inconel 718 superalloy[J]. Acta Metallurgica Sinica, 2016, 52(10): 1259-1266.

[2] 孙昊昉, 田素贵, 金莹. Nb掺杂对Ni基合金中γ'→γ″相转变影响的第一原理研究[J]. 稀有金属材料与工程, 2017, 46(2): 449-455.

Sun H F, Tian S G, Jin Y. First-principle investigation on Nb doping promoting γ'→γ″ phase transformation in Ni-based superalloy[J]. Rare Metal Materials and Engineering, 2017, 46(2): 449-455.

[3] Xiao W H, Lu S Q, Wang Y C, et al. Mechanical and tribological behaviors of graphene/Inconel 718 composites[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 1958-1969.

[4] 刘永长, 张宏军, 郭倩颖, 等. Inconel 718变形高温合金热加工组织演变与发展趋势[J]. 金属学报, 2018, 54(11): 1653-1664.

Liu Y C, Zhang H J, Guo Q Y, et al. Microstructure evolution of Inconel 718 superalloy during hot working and its recent development tendency[J]. Acta Metallurgica Sinica, 2018, 54(11): 1653-1664.

[5] Ma W H, Xie Y C, Chen C Y, et al. Microstructural and mechanical properties of high-performance Inconel 718 alloy by cold spraying[J]. Journal of Alloys and Compounds, 2019, 792: 456-467.

[6] Lee J, Lee D, Song M H, et al. In-situ synthesis of TiC/Fe alloy composites with high strength and hardness by reactive sintering[J]. Journal of Materials Science & Technology, 2018, 34(8): 1397-1404.

[7] Zhou Y, Duan L C, Wen S F, et al. Enhanced micro-hardness and wear resistance of Al-15Si/TiC fabricated by selective laser melting[J]. Composites Communications, 2018, 10: 64-67.

[8] 王舒, 程序, 田象军, 等. TiC添加量对激光增材制造MC碳化物增强Inconel 625复合材料组织及性能的影响[J]. 中国激光, 2018, 45(6): 0602002.

[9] 靳鸣, 贺定勇, 王曾洁, 等. 激光熔覆2205双相不锈钢/TiC复合涂层的显微组织与性能[J]. 激光与光电子学进展, 2018, 55(11): 111403.

[10] Liu L X, Wang B, Li X H, et al. Liquid phase assisted high pressure sintering of dense TiC nanoceramics[J]. Ceramics International, 2018, 44(15): 17972-17977.

[11] Gorji M R, Edtmaier C, Sanjabi S. Synthesis of Ni/TiC composite coating by infiltration sintering of electrophoretic deposited layers[J]. Materials & Design, 2017, 125: 167-179.

[12] Muvvala G, Karmakar D P, Nath A K. In-process detection of microstructural changes in laser cladding of in situ Inconel 718/TiC metal matrix composite coating[J]. Journal of Alloys and Compounds, 2018, 740: 545-558.

[13] Hong C, Gu D D, Dai D H, et al. Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures[J]. Optics & Laser Technology, 2013, 54: 98-109.

[14] Yang X F, Wang Z R, Song P L, et al. Laminated structure optimization and drawing performance of Al2O3-TiC/Al2O3-TiC-CaF2 self-lubricating laminated ceramic conical die[J]. Ceramics International, 2015, 41(9): 12480-12489.

[15] Wang H M, Yu Y L, Li S Q. Microstructure and tribological properties of laser clad CaF2/Al2O3 self-lubrication wear-resistant ceramic matrix composite coatings[J]. Scripta Materialia, 2002, 47(1): 57-61.

[16] Yan H, Zhang J, Zhang P L, et al. Laser cladding of Co-based alloy/TiC/CaF2 self-lubricating composite coatings on copper for continuous casting mold[J]. Surface and Coatings Technology, 2013, 232: 362-369.

[17] Wu G Y, Xu C H, Xiao G C, et al. Structure design of Al2O3/TiC/CaF2 multicomponent gradient self-lubricating ceramic composite and its tribological behaviors[J]. Ceramics International, 2018, 44(5): 5550-5563.

[18] 时海芳, 任鑫. 材料力学性能[M]. 2版. 北京: 北京大学出版社, 2015: 249.

Shi HF, RenX. Mechanical properties of materials[M]. 2nd ed. Beijing: Peking University Press, 2015: 249.

[19] 伊赫桑·巴伦. 纯物质热化学数据手册[M]. 程乃良, 牛四通, 徐桂英, 等, 译. 3版. 北京: 科学出版社, 2003: 427- 1674.

BarinI. Thermochemical data of pure substance[M]. Cheng N L, Niu S T, Xu G Y, et al., Transl. 3rd ed. Beijing: Science Press, 2003: 427- 1674.

[20] 谭树杰, 李多生, 叶寅, 等. 激光熔化沉积Inconel 718合金温度场及形貌的数值模拟[J]. 中国有色金属学报, 2018, 28(11): 2296-2304.

Tan S J, Li D S, Ye Y, et al. Temperature field and morphology simulation of laser melting deposited Inconel 718 alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(11): 2296-2304.

[21] 宋衎, 喻凯, 林鑫, 等. 热处理态激光立体成形Inconel 718高温合金的组织及力学性能[J]. 金属学报, 2015, 51(8): 935-942.

Song K, Yu K, Lin X, et al. Microstructure and mechanical properties of heat treatment laser solid forming superalloy Inconel 718[J]. Acta Metallurgica Sinica, 2015, 51(8): 935-942.

[22] 付立铭, 单爱党, 王巍. 低碳Nb微合金钢中Nb溶质拖曳和析出相NbC钉扎对再结晶晶粒长大的影响[J]. 金属学报, 2010, 46(7): 832-837.

Fu L M, Shan A D, Wang W. Effect of Nb solute drag and NbC precipitate pinning on the recrystallization grain growth in low carbon Nb-microalloyed steel[J]. Acta Metallurgica Sinica, 2010, 46(7): 832-837.

[23] 王焕荣, 叶以富, 闵光辉, 等. TiC价电子结构及其性质分析[J]. 科学通报, 2001, 46(3): 215-218.

Wang H R, Ye Y F, Min G H, et al. Analysis of TiC valence electron structure and its properties[J]. Chinese Science Bulletin, 2001, 46(3): 215-218.

刘志宏, 刘元富, 张乐乐, 陈德强, 石晨晓, 陆富刚, 冯志成, 金杰. 激光熔化沉积TiC/CaF2/Inconel 718复合材料的组织及高温摩擦磨损性能[J]. 中国激光, 2020, 47(1): 0102008. Zhihong Liu, Yuanfu Liu, Lele Zhang, Deqiang Chen, Chenxiao Shi, Fugang Lu, Zhicheng Feng, Jie Jin. Microstructure and High-Temperature Friction and Wear Properties of TiC/CaF2/Inconel 718 Composite Fabricated Using Laser Melting Deposition Technique[J]. Chinese Journal of Lasers, 2020, 47(1): 0102008.