基体取向对激光熔覆修复区域杂晶形成的影响  下载: 895次

下载: 895次

荣鹏, 郭嘉琛. 基体取向对激光熔覆修复区域杂晶形成的影响[J]. 中国激光, 2021, 48(6): 0602110.

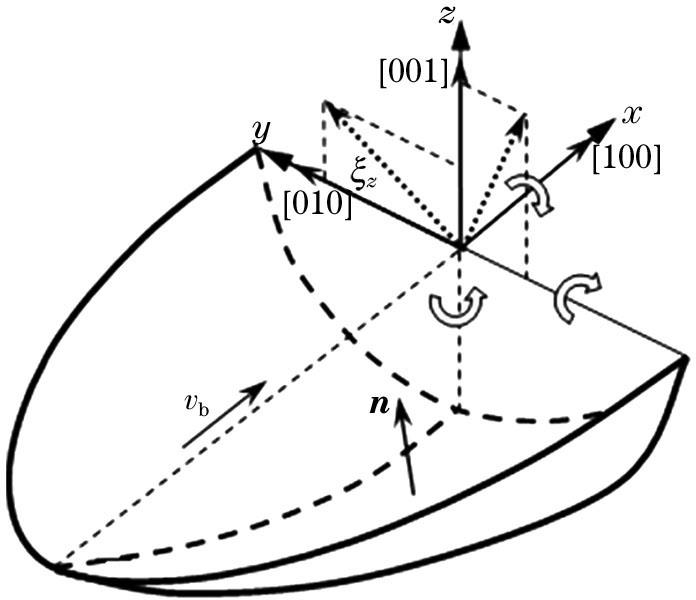

Peng Rong, Jiachen Guo. Effect of Substrate Orientation on Formation of Heterocrystals in Laser Cladding Zone[J]. Chinese Journal of Lasers, 2021, 48(6): 0602110.

[1] BöllinghausT, HeroldH. Hot cracking phenomena in welds[M]. Berlin/Heidelberg: Springer-Verlag, 2005.

[2] Reed RC. The Superalloys: fundamentals and applications[M]. Cambridge: Cambridge university press, 2008.

[3] 陈炳贻. 航空发动机材料的发展[J]. 航空科学技术, 1998, 9(2): 13-15.

[4] Sims CT, Stoloff NS, Hagel WC. Superalloys II[M]. New York: John Wiley & Sons, 1987.

[6] Vitek J M, David S A, Boatner L A. Microstructural development in single crystal nickel base superalloy welds[J]. Science and Technology of Welding and Joining, 1997, 2(3): 109-118.

[10] Anderson T D. DuPont J N, DebRoy T. Stray grain formation in welds of single-crystal Ni-base superalloy CMSX-4[J]. Metallurgical and Materials Transactions A, 2009, 41(1): 181-193.

[11] Anderson T D. DuPont J N, DebRoy T. Origin of stray grain formation in single-crystal superalloy weld pools from heat transfer and fluid flow modeling[J]. Acta Materialia, 2010, 58(4): 1441-1454.

[15] 郭文渊, 王东生, 王茂才. 镍基超合金的Nd-YAG激光熔敷涂层行为研究[J]. 应用激光, 2002, 22(2): 101-104, 154.

[16] 唐林峰, 王楠, 管强, 等. 单晶合金激光熔凝过程中晶向对单晶完整性的影响[J]. 物理学报, 2010, 59(11): 7941-7948.

[17] Rong P, Wang N, Wang L, et al. The influence of grain boundary angle on the hot cracking of single crystal superalloy DD6[J]. Journal of Alloys and Compounds, 2016, 676: 181-186.

[20] Li JR, Zhong ZG, Liu SZ, et al. A low-cost second generation single crystal superalloy DD6[C] //Superalloys 2000 (Ninth International Symposium), September 17-21, 2000. Warrendale, PA: TMS, 2000: 777- 783.

[22] Gäumann M, Trivedi R, Kurz W. Nucleation ahead of the advancing interface in directional solidification[J]. Materials Science and Engineering:A, 1997, 226/227/228: 763-769.

[24] Rappaz M, David S A, Vitek J M, et al. Development of microstructures in Fe-15Ni-15Cr single crystal electron beam welds[J]. Metallurgical Transactions A, 1989, 20(6): 1125-1138.

[27] Mokadem S. Bezen{c}on C, Hauert A, et al. Laser repair of superalloy single crystals with varying substrate orientations[J]. Metallurgical and Materials Transactions A, 2007, 38(7): 1500-1510.

[28] Wei Y H, Liu R P, Dong Z J, et al. Stress/strain distributions for weld metal solidification crack in stainless steels[J]. China Welding, 2000, 9(1): 36-41.

[29] Wei Y H, Liu R P, Dong Z J. Development of the model for simulating weld metal solidification cracking in stainless steel[J]. China Welding, 1999, 8(2): 3-5.

[30] Dong H B, Lee P D. Simulation of the columnar-to-equiaxed transition in directionally solidified Al-Cu alloys[J]. Acta Materialia, 2005, 53(3): 659-668.

[31] 李祚, 隋尚, 袁子豪, 等. 高沉积率激光熔覆沉积GH4169合金的微观组织与拉伸性能[J]. 中国激光, 2019, 46(1): 0102004.

[32] 周显新, 辛博, 巩亚东, 等. 扫描方向对变厚度熔覆成形件组织与力学性能的影响[J]. 中国激光, 2019, 46(8): 0802003.

[33] 张金智, 张安峰, 王宏, 等. 微锻造激光熔覆沉积高性能TC4组织与各向异性[J]. 中国激光, 2019, 46(4): 0402009.

荣鹏, 郭嘉琛. 基体取向对激光熔覆修复区域杂晶形成的影响[J]. 中国激光, 2021, 48(6): 0602110. Peng Rong, Jiachen Guo. Effect of Substrate Orientation on Formation of Heterocrystals in Laser Cladding Zone[J]. Chinese Journal of Lasers, 2021, 48(6): 0602110.