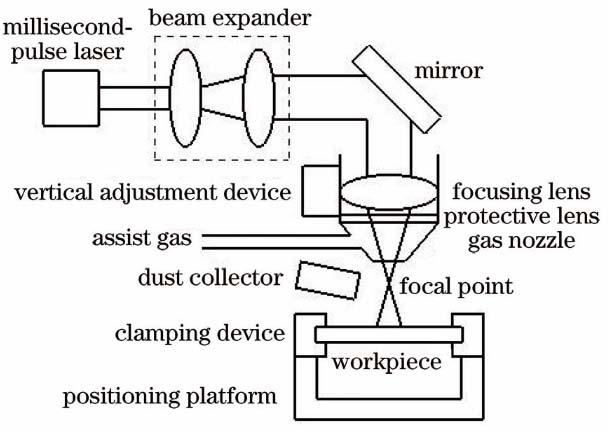

基于改进型控制变量法的脉冲激光打孔研究  下载: 783次

下载: 783次

李涛, 夏凯波, 任乃飞, 高福强, 张文, 田佳男, 范永胜. 基于改进型控制变量法的脉冲激光打孔研究[J]. 激光与光电子学进展, 2020, 57(19): 191403.

Tao Li, Kaibo Xia, Naifei Ren, Fuqiang Gao, Wen Zhang, Jianan Tian, Yongsheng Fan. Study on Pulse Laser Drilling Based on Improved Parameter Control Method[J]. Laser & Optoelectronics Progress, 2020, 57(19): 191403.

[1] 赵四辈. GH4037合金I级涡轮叶片断裂失效分析[J]. 失效分析与预防, 2007, 2(4): 31-34.

Zhao S B. Rupture failure analysis of GH4037 stage I turbo blade[J]. Failure Analysis and Prevention, 2007, 2(4): 31-34.

[2] 郭文渊, 王茂才, 张晓兵. 镍基超合金激光打孔再铸层及其控制研究进展[J]. 激光杂志, 2003( 4): 1- 3.

Guo WY, Wang MC, Zhang XB. Recast layer formed by laser drilling of Ni-based superalloys and progress on its control[J]. Laser Journal, 2003( 4): 1- 3.

[3] 罗垚, 庞盛永, 周建新, 等. 镍基高温合金纳秒激光脉冲制孔再铸层形成过程数值模拟[J]. 中国激光, 2014, 41(4): 0403007.

[4] Okasha M M, Mativenga P T, Driver N, et al. Sequential laser and mechanical micro-drilling of Ni superalloy for aerospace application[J]. CIRP Annals, 2010, 59(1): 199-202.

[6] Fan Z J, Dong X, Wang K D, et al. Effect of drilling allowance on TBC delamination, spatter and re-melted cracks characteristics in laser drilling of TBC coated superalloys[J]. International Journal of Machine Tools and Manufacture, 2016, 106: 1-10.

[7] 朱海南, 齐歆霞. 涡轮叶片气膜孔加工技术及其发展[J]. 航空制造技术, 2011( 13): 71- 74.

Zhu HN, Qi XX. Development of machining technology gas holes on turbine blades[J]. Aeronautical Manufacturing Gechnology, 2011( 13): 71- 74.

[8] 荣烈润. 激光微细孔加工技术及其在航空航天领域中的应用[J]. 航空精密制造技术, 2009, 45(6): 30-33.

Rong L R. The laser microhol processing technolgy and its applications in space navigation field[J]. Aviation Precision Manufacturing Technology, 2009, 45(6): 30-33.

[9] 晏绪光, 高文斌, 杨水其, 等. 激光脉冲和工件参数对激光微孔加工质量的影响[J]. 应用激光, 1994, 14(3): 127-130.

Yan X G, Gao W B, Yang S Q, et al. Effect of laser pulse and workpiece parameters on microhole quality in laser drilling[J]. Applied Laser, 1994, 14(3): 127-130.

[10] 褚庆臣, 虞钢, 卢国权, 等. 激光打孔工艺参数对孔型影响的二维数值模拟研究[J]. 中国激光, 2011, 38(6): 0603001.

[11] 刘秀清. 传统机械加工与激光加工通孔质量的比较研究[J]. 煤矿机械, 2010, 31(10): 125-127.

Liu X Q. Comparative study of quality for conventional machining and laser processing holes[J]. Coal Mine Machinery, 2010, 31(10): 125-127.

[12] 臧彦楠, 倪晓武, 陈彦北. 基于ANSYS生死单元法的长脉冲激光金属打孔仿真[J]. 中国激光, 2013, 40(6): 0603005.

[13] 张廷忠, 张冲, 李晋, 等. Ti6Al4V合金毫秒激光打孔重铸层的形成机制[J]. 光学学报, 2017, 37(2): 0214001.

[14] 段文强, 王恪典, 董霞, 等. 激光旋切法加工高质量微小孔工艺与理论研究[J]. 西安交通大学学报, 2015, 49(3): 95-103,112.

Duan W Q, Wang K D, Dong X, et al. Study on machining of high-quality micro-holes by laser trepan drilling[J]. Journal of Xi'an Jiaotong University, 2015, 49(3): 95-103,112.

[15] Fornaroli C, Holtkamp J, Gillner A. Laser-beam helical drilling of high quality micro holes[J]. Physics Procedia, 2013, 41: 661-669.

[16] Wlodarczyk K L, Brunton A, Rumsby P, et al. Picosecond laser cutting and drilling of thin flex glass[J]. Optics and Lasers in Engineering, 2016, 78: 64-74.

[17] 黄建伟, 宋爱平, 张礼峰. 微深孔激光加工方法及其应用[J]. 机械工程与自动化, 2011( 4): 102- 104.

Huang JW, Song AP, Zhang LF. Micro-deep holes laser processing method and its application[J]. Mechanical Engineering & Automation, 2011( 4): 102- 104.

[18] 王广安, 章玉珠, 倪晓武, 等. 离焦量对空气中纳秒激光打孔效率的影响[J]. 中国激光, 2007, 34(12): 6121-1624.

[19] Silvennoinen M. Kaakkunen J J J, Paivasaari K, et al. Water spray assisted ultrashort laser pulse ablation[J]. Applied Surface Science, 2013, 265: 865-869.

李涛, 夏凯波, 任乃飞, 高福强, 张文, 田佳男, 范永胜. 基于改进型控制变量法的脉冲激光打孔研究[J]. 激光与光电子学进展, 2020, 57(19): 191403. Tao Li, Kaibo Xia, Naifei Ren, Fuqiang Gao, Wen Zhang, Jianan Tian, Yongsheng Fan. Study on Pulse Laser Drilling Based on Improved Parameter Control Method[J]. Laser & Optoelectronics Progress, 2020, 57(19): 191403.