Author Affiliations

Abstract

State Key Laboratory of Precision Measurements Technology and Instruments, Department of Precision Instrument, Tsinghua University, Beijing 100084, China

Freeform surfaces are difficult to manufacture due to their lack of rotational symmetry. To reduce the requirements for manufacturing precision, a design method is proposed for freeform reflective-imaging systems with low surface-figure-error sensitivity. The method considers both the surface-figure-error sensitivity and optical specifications, which can design initial systems insensitive to surface figure errors. Design starts with an initial planar system; the surface-figure-error sensitivity of the system is reduced during construction. The proposed method and another that is irrelevant to figure-error sensitivity are used to design a freeform off-axis three-mirror imaging system. Comparison of the sensitivities of the two systems indicates the superiority of our proposed method.

220.4830 Systems design 080.4228 Nonspherical mirror surfaces 220.4610 Optical fabrication 080.4035 Mirror system design Chinese Optics Letters

2019, 17(9): 092201

Author Affiliations

Abstract

State Key Laboratory of Precision Measurement Technology and Instruments, Department of Precision Instrument, Tsinghua University, Beijing 100084, China

In this Letter, a novel and compact freeform off-axis three-mirror imaging system and its detailed design method are proposed. The primary mirror and tertiary mirror of the system have the same surface analytical expression and they are integrated on one single freeform surface. In this way, the alignment process is made much easier due to the much fewer degrees of freedom. In addition, the difficulty and cost for the data handling, fabrication, and testing of the freeform surfaces and system can also be significantly reduced in some cases, especially compared with the configuration having multiple surfaces of different expressions integrated on one monolithic substrate. The final system has a 100 mm effective focal length and a 4°×3° field of view. The modulation transfer function of the system is close to the diffraction-limit.

220.2740 Geometric optical design 080.4225 Nonspherical lens design 080.4228 Nonspherical mirror surfaces Chinese Optics Letters

2016, 14(6): 060801

Author Affiliations

Abstract

State Key Laboratory of Precision Measurement Technology and Instruments, Department of Precision Instrument, Tsinghua University, Beijing 100084, China

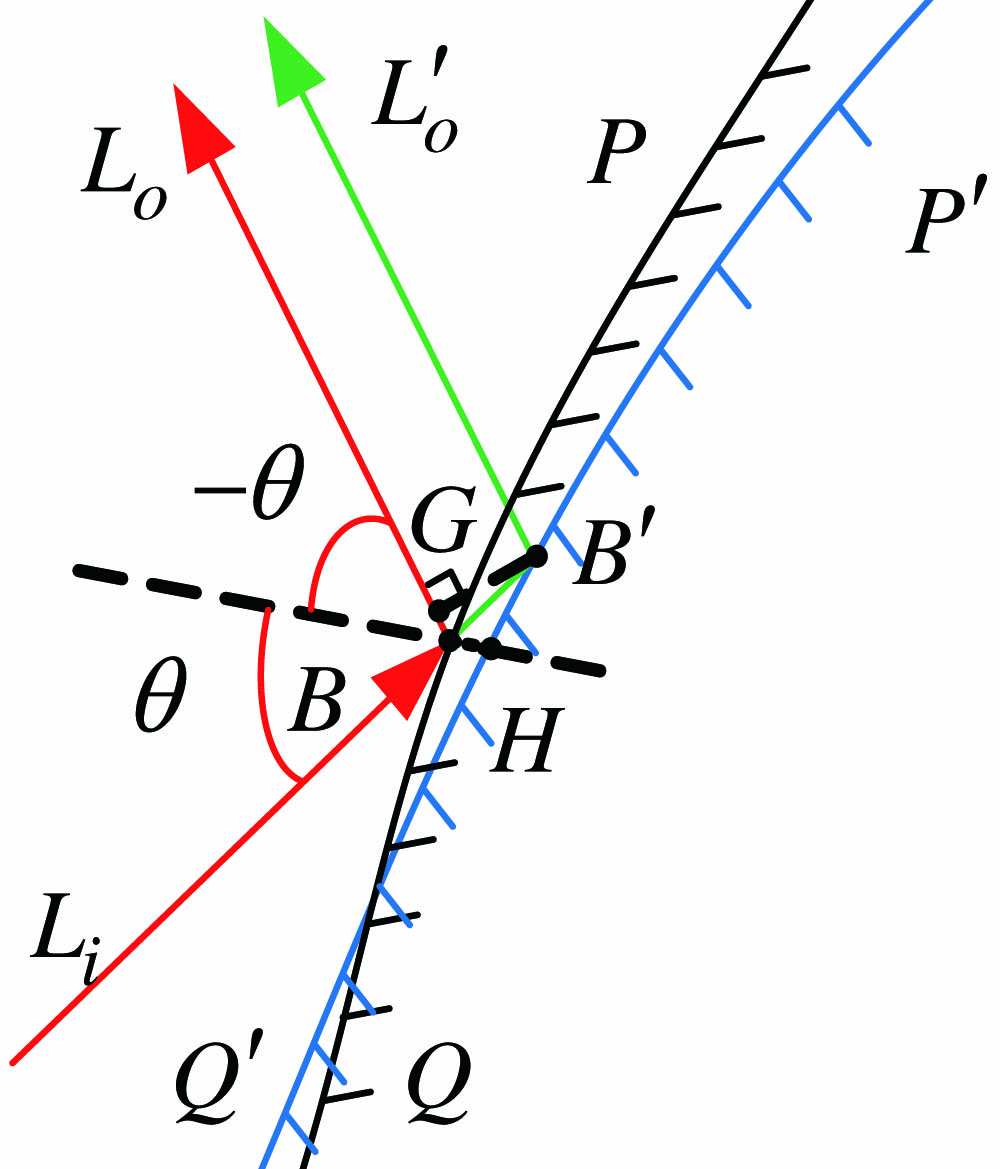

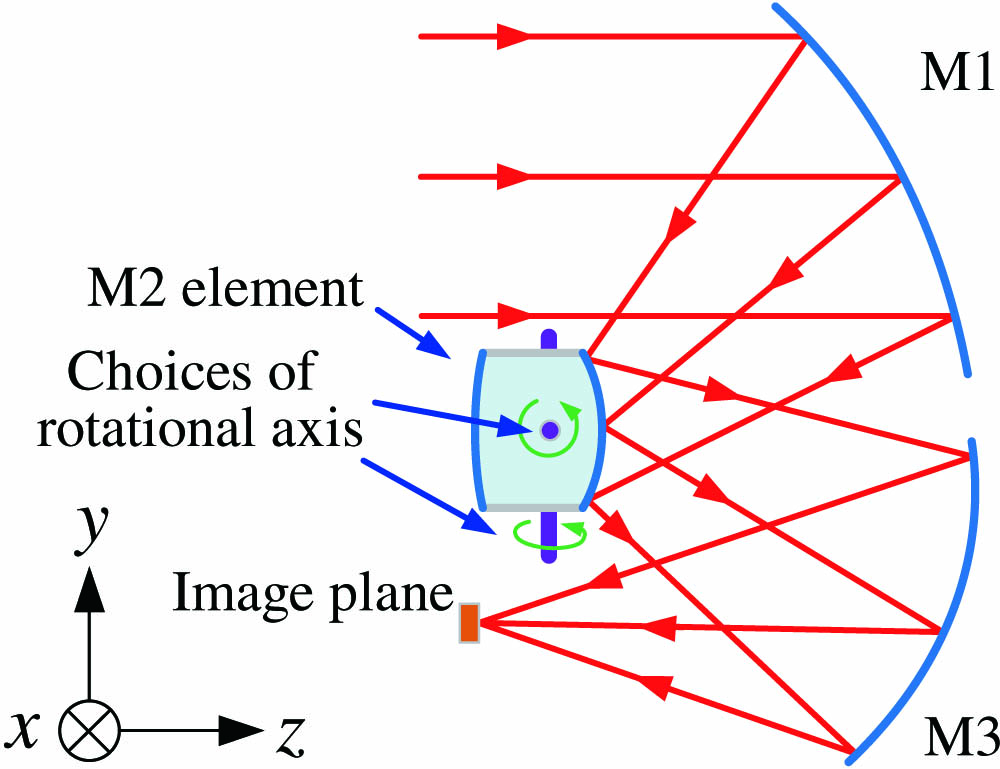

In this Letter, we propose a novel configuration and design method of freeform, dual fields-of-view (FOVs), dual focal lengths, off-axis three-mirror zoom imaging systems. The switch of the two zooms is achieved by rotating a single mirror element. The design of a freeform, dual focal lengths zoom system is realized by a point-by-point design approach for the first time to our knowledge. This method enables the direct design of freeform surfaces from initial planes using given system specifications and configuration, and the designed system can be taken as a good starting point for further optimization. A freeform, dual FOVs, dual focal lengths, off-axis three-mirror zoom system is demonstrated. The F-numbers of the two zooms are 2 and 2.4. The dual FOVs are 3°×3° and 2.5°×2.5°. After final optimization, both of the zooms achieve high performances.

080.4228 Nonspherical mirror surfaces 080.4035 Mirror system design 220.2740 Geometric optical design Chinese Optics Letters

2016, 14(10): 100801

1 中国科学院光电技术研究所, 四川 成都 610209

2 四川大学电子信息学院光电系, 四川 成都 610065

将相位测量偏折术应用于非球面反射镜面形检测,并对实验检测结果的中高频误差进行了分析研究。计算机产生正弦性条纹图,并且显示在薄膜场效应晶体管显示屏上。摄像机通过被测反射镜观察并拍摄显示屏上的条纹图。利用相移技术和相位展开技术计算得到相位分布。以相位信息为载体对光线进行追迹,并根据反射定律得到面形梯度分布,由数值积分重建面形分布。最后使用泽尼克多项式拟合分析了其中高频误差。

测量 面形测量 非球面镜 条纹分析