激光与光电子学进展, 2019, 56 (10): 101601, 网络出版: 2019-07-04

激光熔覆NiCrBSi涂层的高温摩擦行为  下载: 1237次

下载: 1237次

High Temperature Wear Behaviors of Laser Cladded NiCrBSi Coatings

材料 激光加工 激光熔覆 NiCrBSi合金 镍基合金 高温摩擦 工作温度 materials laser processing laser cladding NiCrBSi alloy Ni-based alloy high temperature wear working temperature

摘要

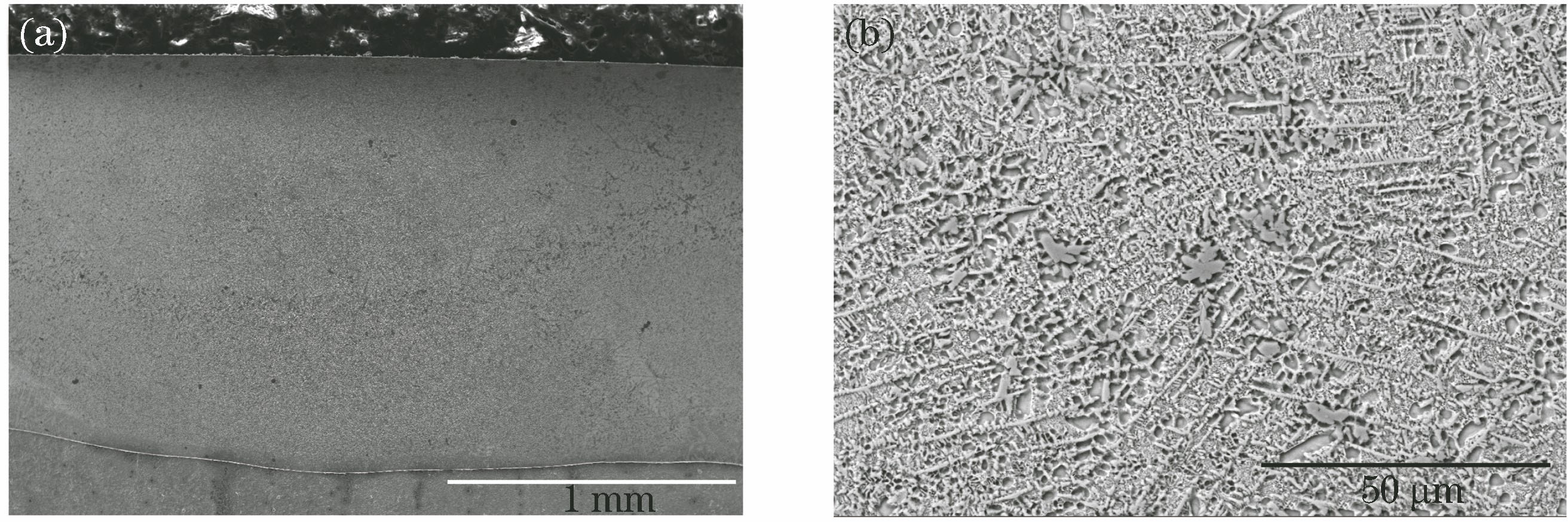

通过激光熔覆技术制备得到NiCrBSi涂层,分析了涂层的显微组织和物相,研究了不同温度下涂层的耐磨性能,讨论了700 ℃和750 ℃高温摩擦环境下显微组织演变和摩擦磨损机制,确定了涂层适用的工作温度区间。结果表明,涂层主要包括γ-Ni、Cr3C7、CrB和Ni-B-Si共晶组织;700 ℃时增强相Cr3C7和CrB保持稳定,共晶组织轻微分解,涂层的耐磨性较常温略有减弱,磨损机制为磨粒磨损和黏着磨损;750 ℃时CrB未分解,但Cr3C7和共晶组织明显分解,这导致涂层磨损和软化严重,在边缘形成飞边,涂层因严重塑性变形而失效。

Abstract

The NiCrBSi coatings are produced by the laser cladding technique. The microstructures and phases of these coatings are analyzed. The wear tests are carried out at different temperatures. The evolution of microstructures and the wear mechanism at high temperatures of 700 ℃ and 750 ℃ are discussed. The applicable working temperature range of coatings is determined. The results show that the coatings are mainly composed of γ-Ni, Cr3C7, CrB, and Ni-B-Si eutectics. At the temperature of 700 ℃, the reinforced phases of Cr3C7 and CrB are kept stable, and the eutectics are slightly decomposed. The wear resistance is a little lower than that at room temperature, and the wear mechanism is adhesion wear and abrasion wear. In contrast, at the temperature of 750 ℃, Cr3C7 and the eutectics are obviously decomposed, but CrB is kept stable. As a result, the coating is severely worn and softened. Moreover, the fins are formed at its periphery. The coating is subjected to failure due to severe plastic deformation.

余廷, 陈杰, 饶锡新, 张子翔. 激光熔覆NiCrBSi涂层的高温摩擦行为[J]. 激光与光电子学进展, 2019, 56(10): 101601. Ting Yu, Jie Chen, Xixin Rao, Zixiang Zhang. High Temperature Wear Behaviors of Laser Cladded NiCrBSi Coatings[J]. Laser & Optoelectronics Progress, 2019, 56(10): 101601.