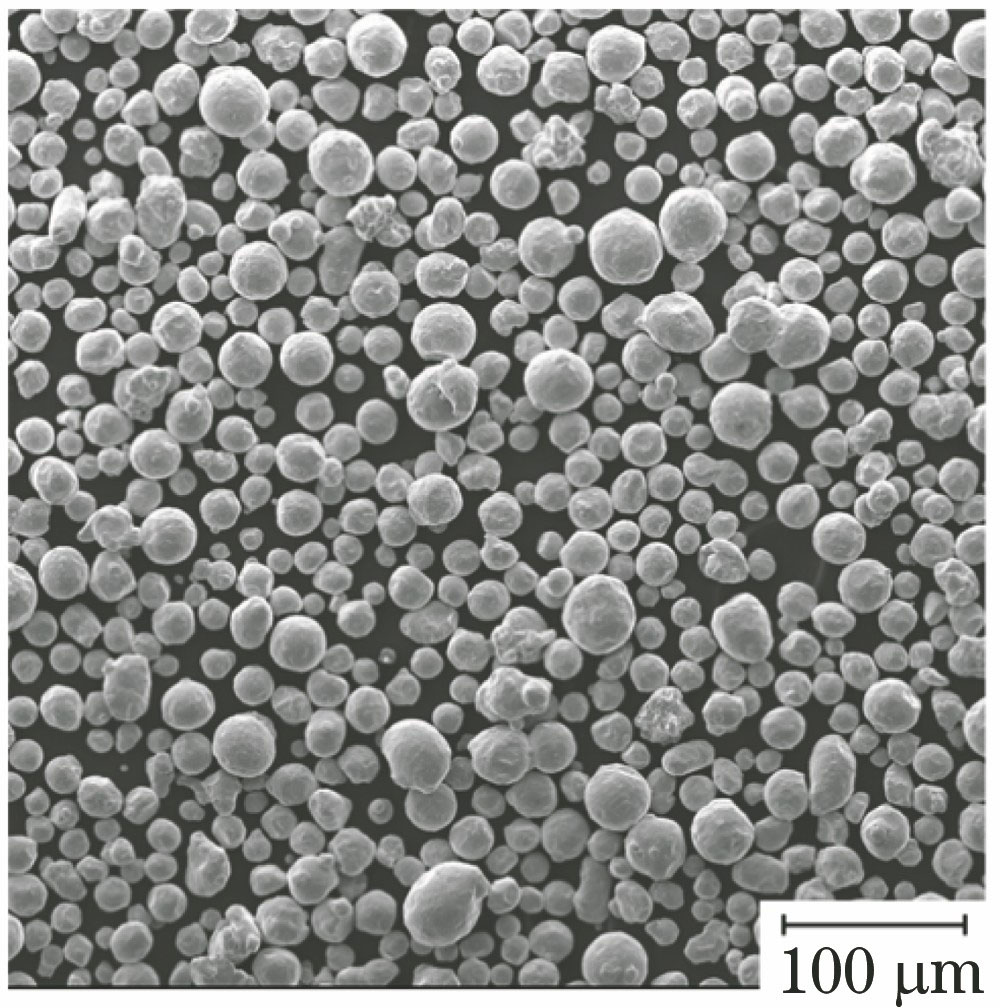

大层厚316L选区激光熔化工艺优化及性能研究  下载: 1414次

下载: 1414次

杨锦, 刘玉德, 石文天, 张飞飞, 祁斌, 韩冬. 大层厚316L选区激光熔化工艺优化及性能研究[J]. 激光与光电子学进展, 2019, 56(1): 011401.

Jin Yang, Yude Liu, Wentian Shi, Feifei Zhang, Bin Qi, Dong Han. Process Optimization and Performance Investigation in Selective Laser Melting of Large Layer-Thickness 316L Powder[J]. Laser & Optoelectronics Progress, 2019, 56(1): 011401.

[2] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[3] 杨永强, 王迪, 吴伟辉. 金属零件选区激光熔化直接成型技术研究进展[J]. 中国激光, 2011, 38(6): 0601007.

[4] 王迪, 杨永强, 吴伟辉. 光纤激光选区熔化316L不锈钢工艺优化[J]. 中国激光, 2009, 36(12): 3233-3239.

[14] Herzog D, Seyda V, Wycisk E, et al. Additive manufacturing of metals[J]. Acta Materialia, 2016, 117: 371-392.

[18] 赵曙明, 沈显峰, 杨家林, 等. 水雾化316L不锈钢选区激光熔化致密度与组织性能研究[J]. 应用激光, 2017, 37(3): 319-326.

[19] 吴伟辉, 杨永强, 王迪. 选区激光熔化成型过程的球化现象[J]. 华南理工大学学报(自然科学版), 2010, 38(5): 110-115.

杨锦, 刘玉德, 石文天, 张飞飞, 祁斌, 韩冬. 大层厚316L选区激光熔化工艺优化及性能研究[J]. 激光与光电子学进展, 2019, 56(1): 011401. Jin Yang, Yude Liu, Wentian Shi, Feifei Zhang, Bin Qi, Dong Han. Process Optimization and Performance Investigation in Selective Laser Melting of Large Layer-Thickness 316L Powder[J]. Laser & Optoelectronics Progress, 2019, 56(1): 011401.