Metamorphic growth of 1.55 μm InGaAs/InGaAsP multiple quantum wells laser structures on GaAs substrates

Long-wavelength (1.55 or 1.31 μm) semiconductor lasers are the essential devices in the fiber communication systems. InP-based optoelectronic devices are essential for optical communication and have shown great potential for long-distance fiber communication, such as lasers and detectors[1,2]. Most of commercial 1.55 μm semiconductor lasers are InP-based InGaAsP lasers. Unsatisfactorily, some insufficient of InP substrates, such as high cost and frailness, limit some applications in several areas (large area integrated devices)[3,4]. GaAs substrates have many good performances, such as relatively low cost and good mechanical properties, which can make up for the inadequacy of InP substrates. Moreover, GaAs-based integrated circuit (IC) technology is relatively mature in comparison with that of InP-based IC[5,6]. If GaAs electronic devices and InP-related optoelectronic devices are combined with GaAs substrates, optoelectronic ICs could be realized easily, and the optical fiber communication systems can be made an important progress[6]. Therefore, the technology of growth high-quality InP-based epilayers on GaAs substrates have been attracted considerable attention recently[7,8].

However, a large number of threading dislocations will appear when InP layers are directly grown more than 5 nm thick on GaAs substrates under normal growth conditions, because there is 3.8% lattice mismatch of InP/GaAs heterostructure[8,9]. In order to obtain high-quality InP epilayers on GaAs substrates for devices, the two-step growth method, thermal cyclic annealing (TCA) and strained-layer superlattice (SLS) are widely used[3,7,8,10]. In 1991, Kimura

At present, four approaches are used for 1.55 μm range GaAs-based lasers. The first one is InP/GaAs wafer bonding technology. The device is based on fusion of the InGaAsP active layer grown on InP substrates and the AlGaAs Bragg reflectors grown on GaAs substrates[15,16]. But, this technology is too complex and difficult to be used to produce diode lasers with low-cost[17]. The second one is growth of GaInNAsSb QW laser materials on GaAs substrate[18,19], while the peak wavelength was not easy to control. The third one is to use In(Ga)As/GaAs quantum dots (QDs) as the active region[20,21]. The fourth one is to use InGaAs/GaAs QW as the active region which is grown on metamorphic InGaAs layers deposited on GaAs substrates[22]. Both QDs and QW lasers have common insufficient that the peak wavelength of spectrum is not strictly 1.55 μm. To avoid these problems, we propose a method that direct growth of 1.55 μm InP-based laser structures on GaAs substrates to compensate for the lack of complex technology and uncontrolled wavelength.

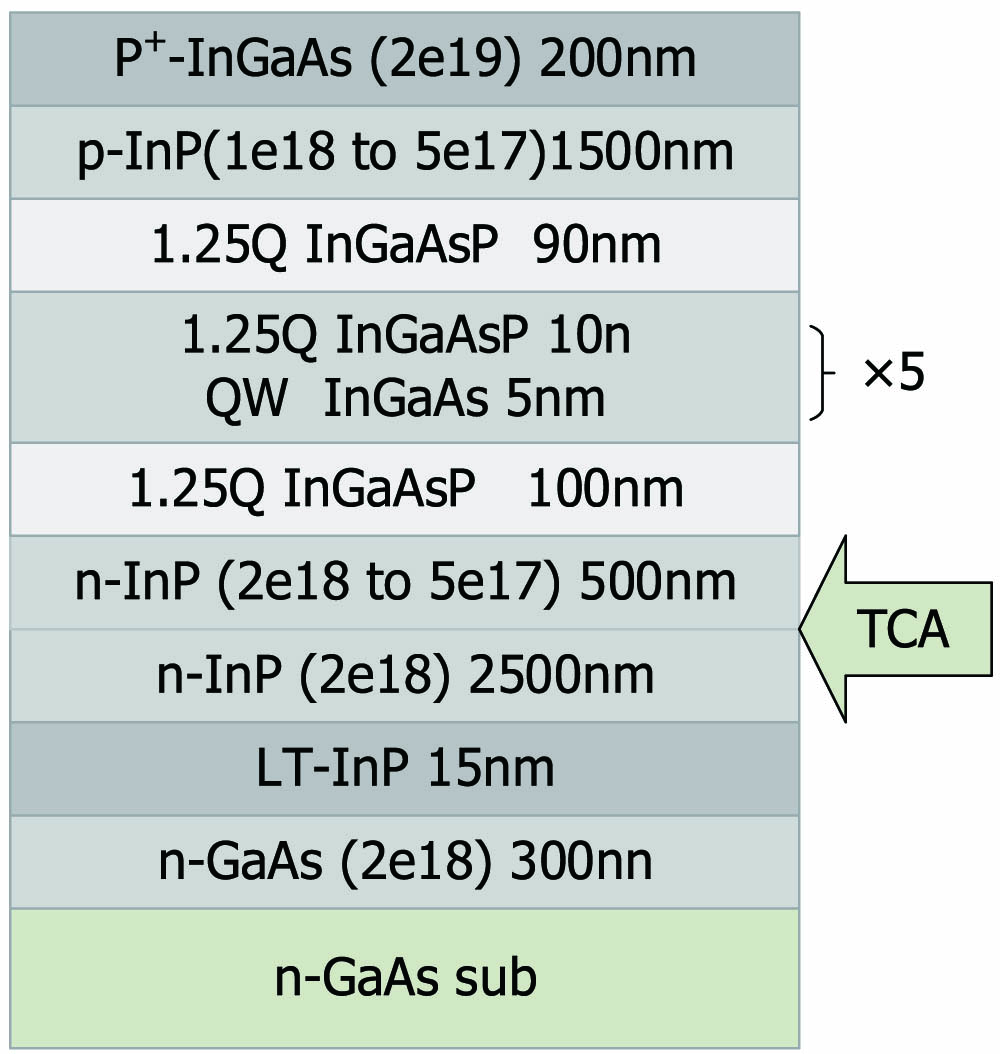

In this Letter, we report metamorphic growth of 1.55 μm InGaAs/InGaAsP multiple QWs (MQWs) laser structures on GaAs substrates by low-pressure (LP) metal organic chemical vapor deposition (MOCVD) technology. The laser structures were grown on GaAs substrates by two-step growth method in which we had optimized the growth temperature, growth rate and V/III ratio[12]. The GaAs-based laser structures were characterized by double crystal XRD (DC-XRD), room-temperature (RT) photoluminescence (PL), atomic force microscopy (AFM), transmission electron microscopy (TEM) and electrochemical current-voltage (ECV). The test results show that the quality of epilayers is satisfactory and the epitaxial materials can be used to fabricate devices. A broad area laser emitter with 50 μm strip was fabricated and the pulse wave threshold current of the device is 476 mA at RT. Multi-longitudinal mode with a peak wavelength of 1549.5 nm is presented and FWHM of the envelope is 4.9 nm when the injection current is 700 mA. Under auto-current-control (ACC) mode, the diode laser had been operated for more than 2000 h at 600 mA and RT.

The epitaxial layers were grown by LP-MOCVD system on a n-type GaAs substrate. The pressure of the reactor chamber was 100 Torr. The 2 inch (100) oriented GaAs wafers were used as the substrates. The source materials were trimethyl-indium, trimethyl-gallium, arsine and phosphine. Silane and diethylzinc were used as the precursors of p-dopants and n-dopants, respectively. Palladium-diffused

Figure

The DC-XRD spectra (solid line) of the epitaxial structure are shown in Fig.

Fig. 2. Rocking curve (

The carrier concentration of the InP/GaAs laser materials was measured by ECV. Figure

Fig. 3. Measured carrier concentration profiles of MQWs InP/GaAs laser material by ECV. Inset shows the hole concentration of p-type contact layer and part of cladding layer.

Fig. 4. (a) Cross-sectional TEM images of epilayers on GaAs substrate; (b) TEM images of active regions and (c) TEM images of active regions with dislocations.

Surface morphology of the wafers was investigated by AFM. The root mean square (RMS) surface roughnesses of 5 μm think laser structure, as measured by AFM over

A 50 μm strip carved by conventional photolithography was used as P-contact metallization (Ti-Pt-Au). After substrate thinning and polishing, N-metallization (Au-Ge-Ni) was deposited onto the bottom side of the wafer. The wafer was cleaved (

Fig. 5. (a) Schematic structures of the device with 50 μm strip. (b) A single emitter laser. Inset shows the individual chip of the laser diode.

The device characteristics were measured under quasi-continuous wave condition with a pulse width of 5 μs and a repetition rate of 1 kHz. Figure

Fig. 6. Typical curves of output power and voltage versus injection current for the emitter laser at RT. The threshold current is 476 mA. Inset (a) shows optical spectrum taken at 400 mA. Inset (b) shows optical spectrum taken at 1.5-times threshold (700 mA). The ordinate values of the Inset (a) and Inset (b) are normalized intensity.

The aging test has been made in the ACC mode with a driving current of 600 mA at RT as shown in Fig.

Fig. 8. Light-output power at RT and 600 mA as a function of time during the ACC aging tests with a driving current of 600 mA. Inset shows the aging test in the first 200 h.

In conclusion, the 1.55 μm InGaAs/InGaAsP MQWs laser structures are grown on n-type GaAs substrates by using two-step grown method and TCA. The XRD, TEM, AFM and ECV profiles show that the epitaxial materials could be used to fabricate devices. A broad area emitter laser with 50 μm strip is fabricated. The RT threshold current density of device is

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[19]

[21]

[22]

[23]

小波 李, 永清 黄, 俊 王, 晓峰 段, 瑞康 张, 弘 李业, 正 刘, 琦 王, 霞 张, 晓敏 任. Metamorphic growth of 1.55 μm InGaAs/InGaAsP multiple quantum wells laser structures on GaAs substrates[J]. Chinese Optics Letters, 2015, 13(3): 031401.