基于遗传算法的激光切割镍基合金质量优化  下载: 916次

下载: 916次

张艺赢, 曹妍, 陈宇翔, 牟向伟. 基于遗传算法的激光切割镍基合金质量优化[J]. 激光与光电子学进展, 2018, 55(11): 111404.

Yiying Zhang, Yan Cao, Yuxiang Chen, Xiangwei Mu. Quality Optimization of Laser-Cutted Ni-Based Alloys Based on Genetic Algorithm[J]. Laser & Optoelectronics Progress, 2018, 55(11): 111404.

[1] 冯威琦, 张云丰, 陶汪, 等. 高温合金/不锈钢异种材料T型接头激光穿透焊工艺研究[J]. 中国激光, 2012, 39(10): 1003003.

[2] 罗登, 路媛媛, 郭溪溪, 等. 单晶高温合金V槽的激光修复工艺研究[J]. 中国激光, 2016, 43(5): 0503001.

[3] 明宪良, 陈静, 谭华, 等. 激光修复GH4169高温合金的持久断裂机制研究[J]. 中国激光, 2015, 42(4): 0403005.

[4] 陈宇翔, 高亮. 正交法分析激光切割高温合金钢工艺参数[J]. 激光与光电子学进展, 2016, 53(11): 111403.

[5] 于天驰, 陈宇翔, 岳鑫, 等. 交互作用优化激光切割镍基合金工艺参数[J]. 激光与光电子学进展, 2018, 55(2): 021413.

[6] 赵晋平, 彭玉海, 南永博, 等. 2Al2铝合金切割工艺参数分析与预测[J]. 陕西理工学院学报(自然科学版), 2017, 33(2): 28-33.

[7] 陈继民, 左铁钏. CO2激光三维方位切割的人工神经网络分析[J]. 中国激光, 2004, 31(2): 245-248.

[8] 郭华锋, 李菊丽, 孙涛. 基于BP神经网络的光纤激光切割切口粗糙度预测[J]. 激光技术, 2014, 38(6): 798-803.

[9] 李建敏, 李国柱, 王春明, 等. 基于MATLAB神经网络激光切割质量预测系统设计[J]. 应用激光, 2014, 34(2): 122-125.

[10] 丁华, 李炎蔚, 袁冬青. 反向传播人造神经网络预测激光微孔表面粗糙度[J]. 激光与光电子学进展, 2017, 54(1): 011407.

[11] 童桂, 徐宏, 郁汉琪. 基于模拟退火的BP神经网络激光切割质量控制模型[J]. 机械设计与制造, 2016( 6): 85- 87.

TongG, XuH, Yu HQ. Control model of laser cutting quality based on simulated annealing and BP neural network[J]. Machinery Design & Manufacture, 2012( 6): 85- 87.

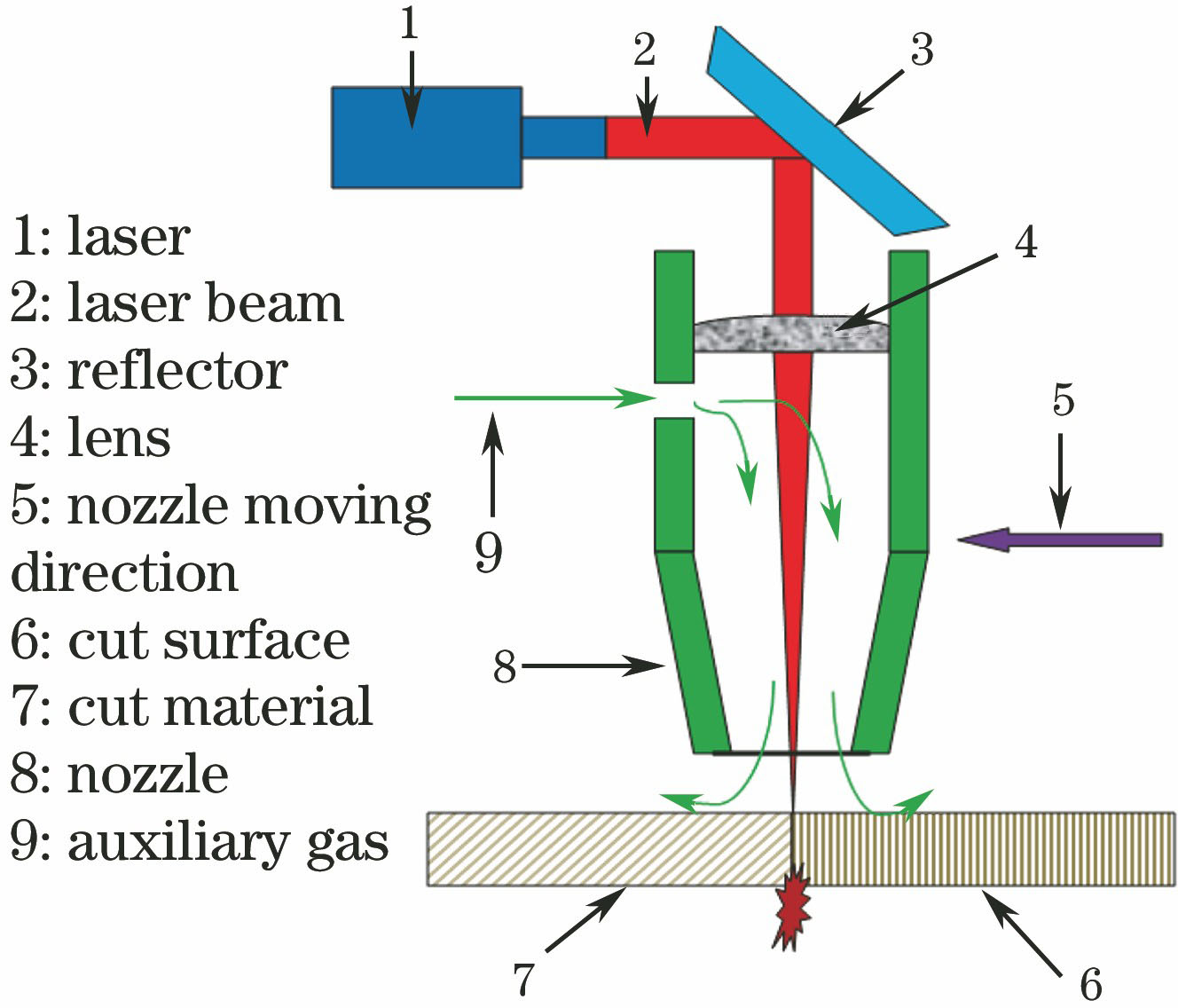

[14] 曹凤国. 激光加工[M]. 北京: 化学工业出版社, 2015: 67.

Cao FG. Laser beam machining[M]. Beijing: Chemical Industry Press, 2015: 67.

[15] 韩力群, 施彦. 人工神经网络理论及应用[M]. 北京: 机械工业出版社, 2016: 51- 52.

Han LQ, ShiY. Artificial neural network theory and application[M]. Beijing: China Machine Press, 2016: 51- 52.

[16] 王小川, 史峰, 郁磊, 等. Matlab神经网络43个案例分析[M]. 北京: 北京航空航天大学出版社, 2013: 36- 38.

Wang XC, ShiF, YuL, et al.Matlab neural networks 43 cases analysis[M]. Beijing: Beihang University Press, 2013: 36- 38.

[17] 郁胜过, 张玲, 谢玮霖, 等. 基于遗传算法与Zoom FFT的光频域反射仪快速高精度频谱分析[J]. 光学学报, 2017, 37(4): 0406003.

[18] 周祥燕, 张超, 匡尚奇, 等. 基于量子衍生遗传算法的光学薄膜结构分析[J]. 中国激光, 2017, 44(12): 1203002.

[19] 高航, 薛凌云. 基于改进遗传算法的反向传播神经网络拟合LED光谱模型[J]. 激光与光电子学进展, 2017, 54(7): 072302.

张艺赢, 曹妍, 陈宇翔, 牟向伟. 基于遗传算法的激光切割镍基合金质量优化[J]. 激光与光电子学进展, 2018, 55(11): 111404. Yiying Zhang, Yan Cao, Yuxiang Chen, Xiangwei Mu. Quality Optimization of Laser-Cutted Ni-Based Alloys Based on Genetic Algorithm[J]. Laser & Optoelectronics Progress, 2018, 55(11): 111404.