光学 精密工程, 2024, 32 (1): 84, 网络出版: 2024-01-23

超精密磨削YAG晶体的脆塑转变临界深度预测

Prediction of brittle-to-ductile transition depth in ultra-precision grinding YAG crystals

超精密磨削 YAG晶体 纳米压痕 纳米划痕 脆塑转变 YAG crystal nano-indentation nano-scratch brittle-to-ductile transition ultra-precision grinding

摘要

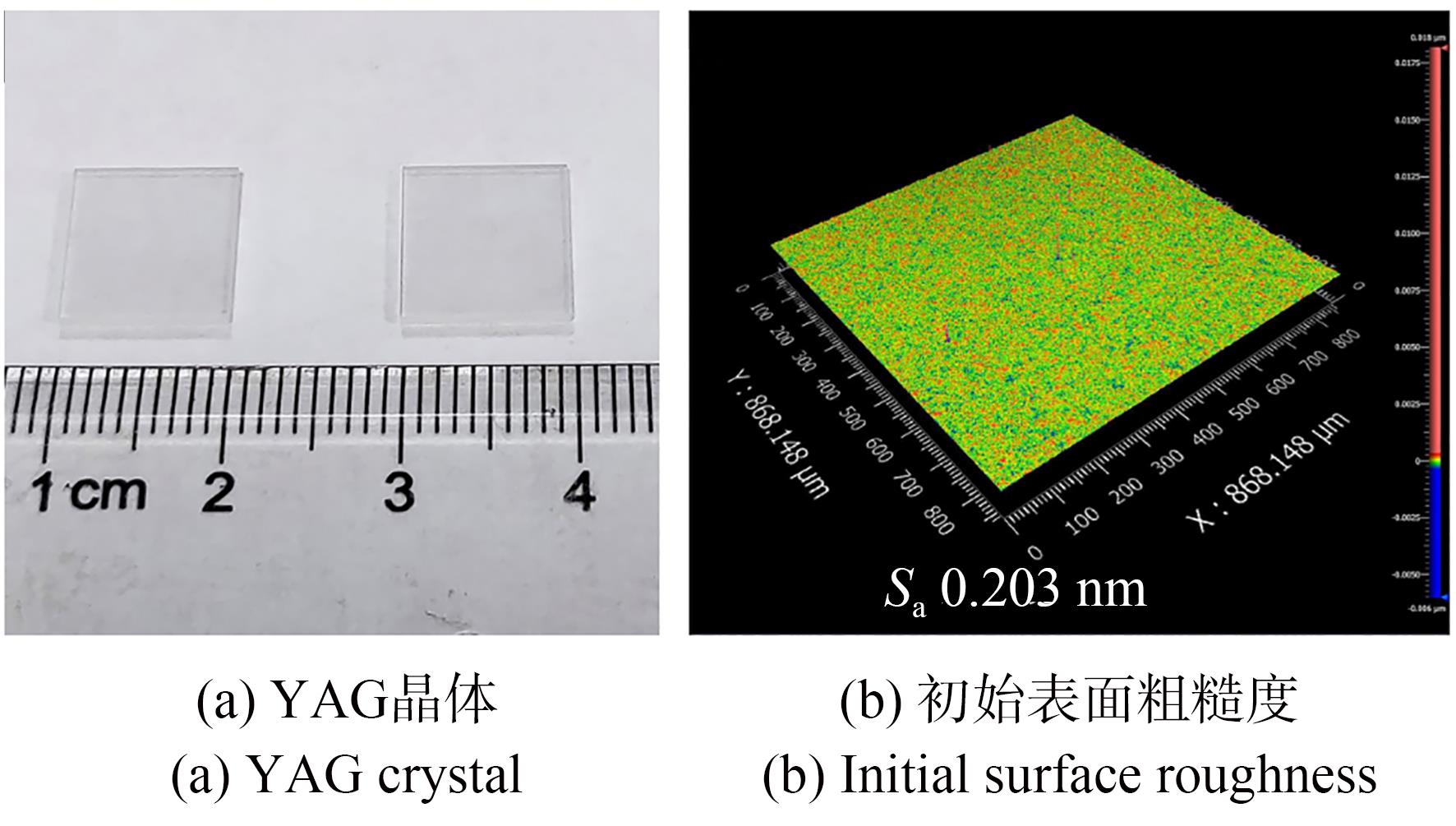

钇铝石榴石(YAG)晶体是制造固体激光器的重要材料,超精密磨削是加工YAG晶体等硬脆材料零件的重要方法,研究硬脆材料加工表面的微观变形、脆塑转变机理对超精密磨削加工具有重要的指导作用。为了实现YAG晶体低损伤磨削加工,获得高质量表面,基于弹塑性接触理论和压痕断裂力学,通过分析单磨粒划擦作用下材料表面的变形过程,考虑材料的弹性回复、微观下力学性能的尺寸效应,建立了脆塑转变临界深度的预测模型,并计算得到YAG晶体的脆塑转变临界深度为66.7 nm。在此基础上,通过不同粒度砂轮超精密磨削YAG晶体试验对建立的脆塑转变临界深度预测模型进行验证,并计算不同粒度砂轮在相应工艺条件下的磨粒切深。结果表明,磨粒切深高于脆塑转变临界深度时,YAG晶体磨削表面材料以脆性方式被去除,磨削表面损伤严重;磨粒切深低于脆塑转变临界深度时,磨削表面材料以塑性方式被去除,能够获得高质量磨削表面,加工表面粗糙度达到1 nm。建立的脆塑转变临界深度预测模型能够为YAG晶体的低损伤超精密磨削加工提供理论指导。

Abstract

Yttrium aluminum garnet (YAG) crystals are widely used for manufacturing solid-state lasers, and ultraprecision grinding is critical for machining hard and brittle material parts, such as YAG crystals. The investigation of microdeformation and brittle-to-ductile transition mechanisms of hard and brittle material-machined surfaces is necessary for ultraprecision grinding. Based on the elastic-plastic contact theory and indentation fracture mechanics, a model for predicting the critical depth of brittle-to-ductile transitions was established to achieve low-damage grinding of YAG crystals and obtain high-quality surfaces. The deformation process of the material surface under the action of a single abrasive scratch was analyzed, considering the elastic recovery of the material and the size effect of micromechanical properties. The critical depth of the brittle-to-ductile transition of the YAG crystal is 66.7 nm. The proposed prediction model of the critical depth of the brittle-to-ductile transition was verified by ultraprecision grinding of YAG crystals with grinding wheels of different grain sizes. In addition, the grit-cutting depths of different grain-size grinding wheels under the corresponding process conditions were calculated. The results show that when the grit-cutting depth is more extended than the critical depth of the brittle-to-ductile transition, the surface material of the YAG crystal is removed in a brittle manner, and the grinding surface is severely damaged. However, when the grit-cutting depth is less than the critical depth of the brittle-to-ductile transition, the grinding surface material is removed in a ductile manner, high-quality grinding surface can be obtained, and the machined surface roughness can reach 1 nm. The proposed model for predicting the critical depth of the brittle-to-ductile transition provides theoretical guidance for low-damage ultraprecision grinding of YAG crystals.

敖萌灿, 黄金星, 曾毓贤, 吴跃勤, 康仁科, 高尚. 超精密磨削YAG晶体的脆塑转变临界深度预测[J]. 光学 精密工程, 2024, 32(1): 84. Mengcan AO, Jinxing HUANG, Yuxian ZENG, Yueqin WU, Renke KANG, Shang GAO. Prediction of brittle-to-ductile transition depth in ultra-precision grinding YAG crystals[J]. Optics and Precision Engineering, 2024, 32(1): 84.