Ti811表面激光熔覆复合涂层的微观组织及摩擦磨损性能  下载: 956次

下载: 956次

刘亚楠, 孙荣禄, 牛伟, 张天刚, 谭金花. Ti811表面激光熔覆复合涂层的微观组织及摩擦磨损性能[J]. 中国激光, 2019, 46(1): 0102010.

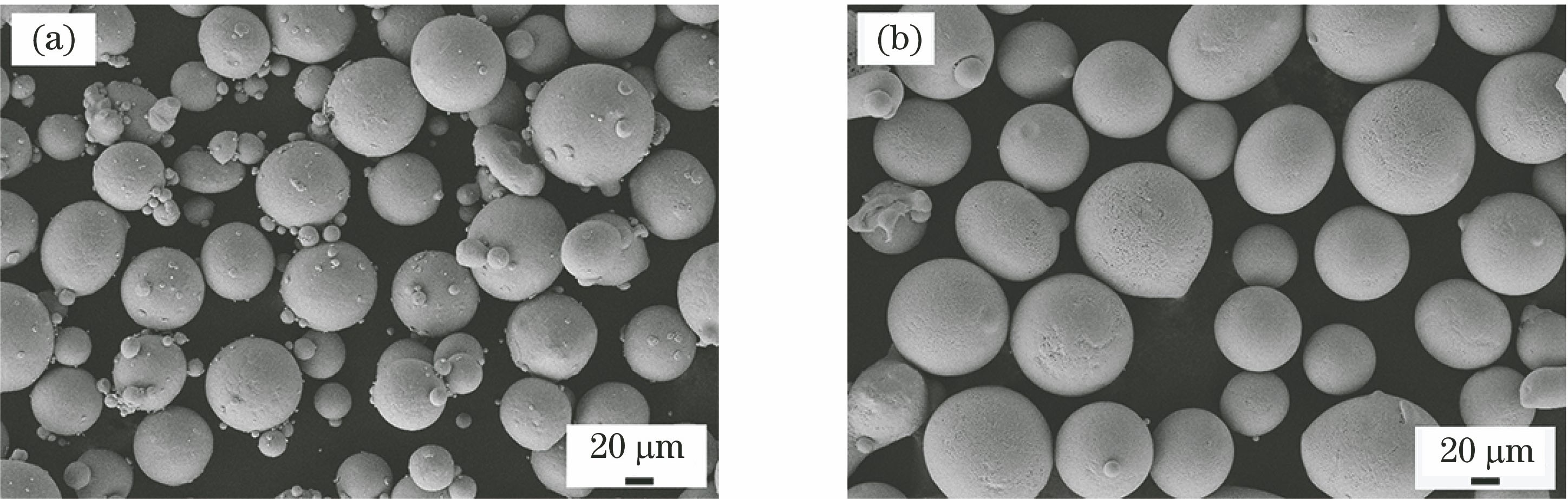

Liu Yanan, Sun Ronglu, Niu Wei, Zhang Tiangang, Tan Jinhua. Microstructure and Friction and Wear Resistance of Laser Cladding Composite Coating on Ti811 Surface[J]. Chinese Journal of Lasers, 2019, 46(1): 0102010.

[1] 赵永庆, 朱康英, 李佐臣, 等. Ti811合金的热稳定性能[J]. 稀有金属材料与工程, 1997, 26(3): 35-39.

[2] 赵永庆. Ti-8Al-1Mo-1V合金[J]. 钛工业进展, 1994( 6): 11- 12.

Zhao YQ. Ti-8Al-1Mo-1V alloy[J]. Titanium Industry Progress, 1994( 6): 11- 12.

[6] 孙荣禄, 杨德庄, 郭立新, 等. 激光工艺参数对钛合金表面NiCrBSi合金熔覆层组织及硬度的影响[J]. 光学技术, 2001, 27(1): 34-36, 38.

[8] 孙荣禄, 牛伟, 雷贻文, 等. 钛合金表面激光熔覆TiB2-TiC/Ni复合涂层的真空摩擦磨损性能[J]. 材料热处理学报, 2012, 33(5): 131-135.

[9] 张天刚, 孙荣禄. Ti811表面原位生成纳米Ti3Al激光熔覆层的组织和性能[J]. 中国激光, 2018, 45(1): 0102002.

[11] 张光耀, 王成磊, 高原, 等. 稀土La2O3对6063Al激光熔覆Ni基熔覆层微观结构的影响[J]. 中国激光, 2014, 41(11): 1103001.

[12] Zhou S F, Zeng X Y. Growth characteristics and mechanism of carbides precipitated in WC-Fe composite coatings by laser induction hybrid rapid cladding[J]. Journal of Alloys and Compounds, 2010, 505(2): 685-691.

[18] 翁飞. 钛合金表面陶瓷强化金属基复合激光熔覆层的微观组织与耐磨性能研究[D]. 济南: 山东大学, 2017.

WengF. Microstructure and wear property of ceramics reinforced metal matrix composite laser cladding coatings on titanium alloy[D]. Jinan: Shandong University, 2017.

[21] 杨庆祥, 赵斌, 员霄, 等. 纳米Y2O3对过共晶Fe-Cr-C堆焊合金表面微观组织与耐磨性的影响[J]. 表面技术, 2015, 44(4): 42-47, 53.

[24] 朱春城, 曲伟, 张幸红, 等. TiC-TiB2复合材料的研究进展[J]. 材料导报, 2003, 17(1): 48-50, 54.

[25] 王盈, 邹兵林, 曹学强. Al-Ti-B4C体系熔体内燃烧合成TiC-TiB2颗粒局部增强钢基复合材料[J]. 金属学报, 2014, 50(3): 367-372.

[27] 孙荣禄, 杨贤金. 激光熔覆原位合成TiC-TiB2/Ni基金属陶瓷涂层的组织和摩擦磨损性能[J]. 硅酸盐学报, 2003, 31(12): 1221-1224.

[28] 王舒, 程序, 田象军, 等. TiC添加量对激光增材制造MC碳化物增强Inconel625复合材料组织及性能的影响[J]. 中国激光, 2018, 45(6): 0602002.

刘亚楠, 孙荣禄, 牛伟, 张天刚, 谭金花. Ti811表面激光熔覆复合涂层的微观组织及摩擦磨损性能[J]. 中国激光, 2019, 46(1): 0102010. Liu Yanan, Sun Ronglu, Niu Wei, Zhang Tiangang, Tan Jinhua. Microstructure and Friction and Wear Resistance of Laser Cladding Composite Coating on Ti811 Surface[J]. Chinese Journal of Lasers, 2019, 46(1): 0102010.