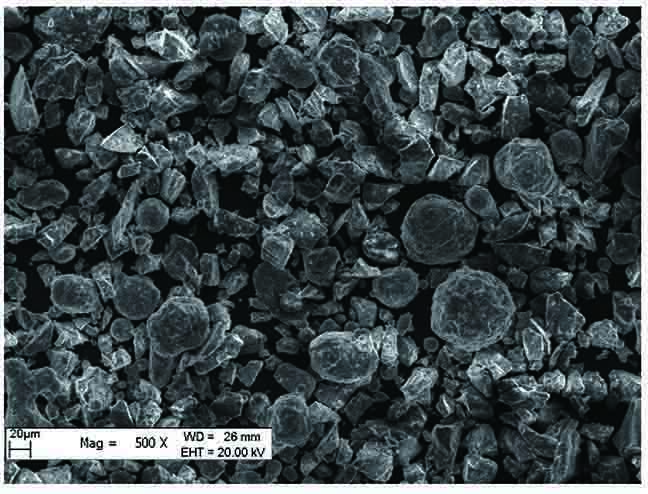

激光熔覆Ni-Al/Al2O3-13%TiO2金属陶瓷涂层的组织性能研究  下载: 711次

下载: 711次

赵海洋, 李新梅, 卢彩彬. 激光熔覆Ni-Al/Al2O3-13%TiO2金属陶瓷涂层的组织性能研究[J]. 激光与光电子学进展, 2020, 57(21): 211406.

Zhao Haiyang, Li Xinmei, Lu Caibin. Microstructure and Properties of Laser Cladding Ni-Al/Al2O3-13%TiO2 Cermet Coating[J]. Laser & Optoelectronics Progress, 2020, 57(21): 211406.

[1] 王一博, 应丽霞, 董国君, 等. 激光熔覆技术研究进展及其工业应用[J]. 中国材料进展, 2009, 28(3): 17-21.

Wang Y B, Ying L X, Dong G J, et al. Development and industrial application of laser cladding technology[J]. Materials China, 2009, 28(3): 17-21.

[2] Liu H X, Wang C Q, Zhang X W, et al. Improving the corrosion resistance and mechanical property of 45 steel surface by laser cladding with Ni60CuMoW alloy powder[J]. Surface and Coatings Technology, 2013, 228: S296-S300.

[3] Wang Y F, Lu Q L, Xiao L J, et al. Laser cladding Fe-Cr-Si-P amorphous coatings on 304L stainless[J]. Rare Metal Materials and Engineering, 2014, 43(2): 274-277.

[4] 张静, 刘继常, 张福全, 等. 球墨铸铁表面激光熔覆Fe-Cr-Si-B涂层[J]. 材料热处理学报, 2010, 31(5): 133-137.

Zhang J, Liu J C, Zhang F Q, et al. Fe-Cr-Si-B coating by laser cladding on nodular cast iron[J]. Transactions of Materials and Heat Treatment, 2010, 31(5): 133-137.

[5] Hemmati I. Ocelík V, de Hosson J T M. Dilution effects in laser cladding of Ni-Cr-B-Si-C hardfacing alloys[J]. Materials Letters, 2012, 84: 69-72.

[6] Lu Y Z, Huang G K, Wang Y Z, et al. Crack-free Fe-based amorphous coating synthesized by laser cladding[J]. Materials Letters, 2018, 210: 46-50.

[7] 封慧, 李剑峰, 孙杰. 曲轴轴颈损伤表面的激光熔覆再制造修复[J]. 中国激光, 2014, 41(8): 0803003.

[8] 韩玉勇, 鲁俊杰, 李剑峰, 等. 基于激光熔覆的车床主轴再制造[J]. 中国表面工程, 2015, 28(6): 147-153.

Han Y Y, Lu J J, Li J F, et al. Lathe spindle remanufacturing based on laser cladding technology[J]. China Surface Engineering, 2015, 28(6): 147-153.

[9] 吴国龙, 任方成, 姚建华, 等. 半导体激光熔覆新型Co基合金耐擦伤性机制[J]. 中国激光, 2017, 44(6): 0602006.

[10] 陈菊芳, 李小平, 薛亚平. 45钢表面激光熔覆Fe901合金的摩擦磨损性能[J]. 中国激光, 2019, 46(5): 0502001.

[11] 刘伟, 谭僖, 曹腊梅. Si(B)CN陶瓷及其复合材料评价与应用研究现状[J]. 装备环境工程, 2016, 13(3): 98-104.

Liu W, Tan X, Cao L M. Research progress in the evaluation and application of Si(B)CN ceramics and ceramic matrix composites[J]. Equipment Environmental Engineering, 2016, 13(3): 98-104.

[12] 程广萍, 何宜柱. 镍包铝激光熔覆层的显微组织[J]. 热处理, 2009, 24(3): 51-54.

Cheng G P, He Y Z. Microstructure of coating prepared by laser-cladding nickel-coated aluminum composite powder[J]. Heat Treatment, 2009, 24(3): 51-54.

[13] Cai Y C, Luo Z, Feng M N, et al. The effect of TiC/Al2O3 composite ceramic reinforcement on tribological behavior of laser cladding Ni60 alloys coatings[J]. Surface and Coatings Technology, 2016, 291: 222-229.

[14] 吴王平, 刘剑文, 王辉, 等. 激光熔覆NiAl-SiC复合涂层的组织与摩擦性能[J]. 激光与光电子学进展, 2018, 55(9): 091406.

[15] 任仲贺, 武美萍, 李广阳, 等. TiO2/CeO2对Ni基激光熔覆层组织和性能的影响[J]. 激光与光电子学进展, 2019, 56(7): 071402.

[16] 周建忠, 何文渊, 徐家乐, 等. 激光熔覆Al2O3/Fe901复合涂层的强化机制及耐磨性[J]. 光学学报, 2019, 39(5): 0514001.

[17] 周笑薇, 晁明举, 杨坤. Al2O3对Ni60激光熔覆层组织和耐磨性的影响[J]. 激光杂志, 2006, 27(5): 81-83.

[18] 高雪松, 田宗军, 沈理达, 等. 激光熔覆Al2O3-13% TiO2陶瓷层制备及其抗热震性能[J]. 中国激光, 2012, 39(2): 0203006.

[19] 张垚磊. 激光近净成形Al2O3-ZrO2(Y2O3)共晶陶瓷工艺基础研究[D]. 大连: 大连理工大学, 2014: 62- 63.

Zhang YL. Technology foundation of laseer engineered net shaping of Al2O3-ZrO2(Y2O3) eutectic ceramic[D]. Dalian: Dalian University of Technology, 2014: 62- 63.

[20] 程锐. 38CrMoAl表面激光熔覆Ni/Al2O3-La2O3工艺与熔覆层性能研究[D]. 南昌: 华东交通大学, 2009: 22- 23.

ChengR. Research of technology and properties of laser cladding on Ni/Al2O3-La2O3 surface of 38CrMoAl steel[D]. Nanchang: East China Jiaotong University, 2009: 22- 23.

[21] 李明喜, 何宜柱, 孙国雄. 纳米Al2O3/Ni基合金复合材料激光熔覆层组织[J]. 中国激光, 2004, 31(9): 1149-1152.

[22] Wang H Y, Zuo D W, Sun Y L, et al. Microstructure of nanometer Al2O3 dispersion strengthened Ni-based high-temperature protective coatings by laser cladding[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 586-591.

赵海洋, 李新梅, 卢彩彬. 激光熔覆Ni-Al/Al2O3-13%TiO2金属陶瓷涂层的组织性能研究[J]. 激光与光电子学进展, 2020, 57(21): 211406. Zhao Haiyang, Li Xinmei, Lu Caibin. Microstructure and Properties of Laser Cladding Ni-Al/Al2O3-13%TiO2 Cermet Coating[J]. Laser & Optoelectronics Progress, 2020, 57(21): 211406.