[1] 周逸波, 秦渊, 杨森. 网状结构热障涂层的激光快速成型及抗热震性[J]. 激光与光电子学进展, 2018, 55(2): 021412.

Zhou Y B, Qin Y, Yang S. Thermal shock resistance and laser rapid prototyping of thermal barrier coatings with network structures[J]. Laser & Optoelectronics Progress, 2018, 55(2): 021412.

[2] 张天佑, 吴超, 熊征, 等. 热障涂层材料及其制备技术的研究进展[J]. 激光与光电子学进展, 2014, 51(3): 030004.

Zhang T Y, Wu C, Xiong Z, et al. Research progress in materials and preparation techniques of thermal barrier coatings[J]. Laser & Optoelectronics Progress, 2014, 51(3): 030004.

[3] Heuer A H, Lanteri V, Farmer S C, et al. On the orthorhombic phase in ZrO2-based alloys[J]. Journal of Materials Science, 1989, 24(1): 124-132.

[4] Clarke D R, Levi C G. Materials design for the next generation thermal barrier coatings[J]. Annual Review of Materials Research, 2003, 33: 383-417.

[5] Kelly J, Denry I. Stabilized zirconia as a structural ceramic: an overview[J]. Dental Materials, 2008, 24(3): 289-298.

[6] Curtis C E. Development of zirconia resistant to thermal shock[J]. Journal of the American Ceramic Society, 1947, 30(6): 180-196.

[7] Feuerstein A, Knapp J, Taylor T, et al. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: a review[J]. Journal of Thermal Spray Technology, 2008, 17(2): 199-213.

[8] Li L Q, Liu D J, Chen Y B, et al. Electron microscopy study of reaction layers between single-crystal WC particle and Ti-6Al-4V after laser melt injection[J]. Acta Materialia, 2009, 57(12): 3606-3614.

[9] Liu D J, Chen Y B, Li L Q, et al. In situ investigation of fracture behavior in monocrystalline WCp-reinforced Ti-6Al-4V metal matrix composites produced by laser melt injection[J]. Scripta Materialia, 2008, 59(1): 91-94.

[10] Vreeling J A. Ocelík V, de Hosson J T M. Ti-6Al-4V strengthened by laser melt injection of WCp particles[J]. Acta Materialia, 2002, 50(19): 4913-4924.

[11] Pei Y T. Ocelik V, de Hosson J T M. SiCp/Ti6Al4V functionally graded materials produced by laser melt injection[J]. Acta Materialia, 2002, 50(8): 2035-2051.

[12] 王梁, 胡勇, 林英华, 等. 电磁复合场对激光熔注增强颗粒分布梯度的调控[J]. 中国激光, 2018, 45(10): 1002001.

Wang L, Hu Y, Lin Y H, et al. Distribution gradient control of laser melt injection reinforcement particles by electromagnetic compound field[J]. Chinese Journal of Lasers, 2018, 45(10): 1002001.

[13] 宋诗英, 王梁, 胡勇, 等. 稳态磁场辅助激光熔注制备梯度涂层[J]. 中国激光, 2016, 43(5): 0503005.

Song S Y, Wang L, Hu Y, et al. Graded coating produced by laser melt injection under steady magnetic field[J]. Chinese Journal of Lasers, 2016, 43(5): 0503005.

[14] 刘德健, 唐峰, 郭溪溪, 等. ZrO2p/Ti-6Al-4V梯度热障复合材料层制备及组织性能[J]. 华中科技大学学报(自然科学版), 2017, 45(12): 112-117.

Liu D J, Tang F, Guo X X, et al. Preparation method, microstructure and properties of ZrO2p/Ti-6Al-4V functionally graded thermal barrier composites layers[J]. Journal of Huazhong University of Science and Technology(Nature Science Edition), 2017, 45(12): 112-117.

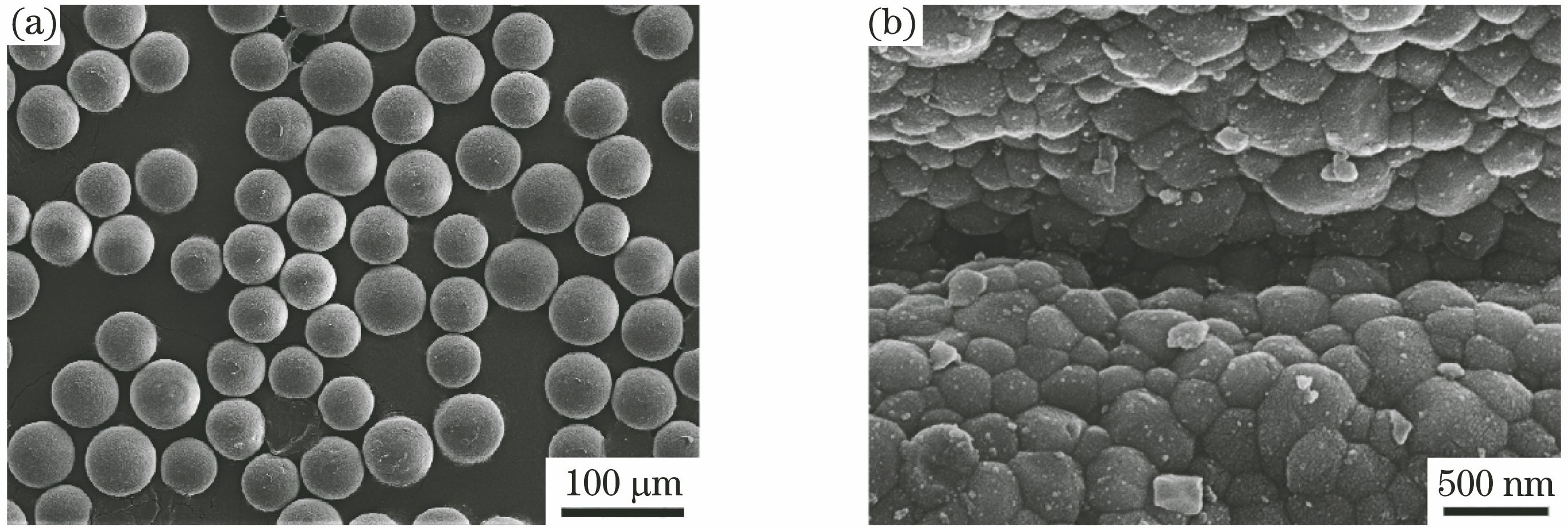

[15] 郭溪溪, 路媛媛, 林守钢, 等. ZrO2陶瓷颗粒在激光作用下组织形貌演变规律[J]. 材料科学与工艺, 2019, 27(2): 22-28.

Guo X X, Lu Y Y, Lin S G, et al. The evolution mechanism of morphology and microstructure for ZrO2 ceramic powders irradiated with a laser beam[J]. Materials Science And Technology, 2019, 27(2): 22-28.

[16] Song X W, Xie M, Mu R D, et al. Influence of the partial substitution of Y2O3 with Ln2O3 (Ln=Nd, Sm, Gd) on the phase structure and thermophysical properties of ZrO2-Nb2O5-Y2O3 ceramics[J]. Acta Materialia, 2011, 59(10): 3895-3902.

[17] van Sluytman J S, Krämer S, Tolpygo V K, et al. . Microstructure evolution of ZrO2-YbTaO4 thermal barrier coatings[J]. Acta Materialia, 2015, 96: 133-142.

[18] Miller R A, Smialek J, Garlick R G. Phase stability in plasma-sprayed partially stabilized zirconia-yttria[J]. Advances in Ceramics, 1981, 3: 241-253.

[19] Cao X Q, Vassen R, Stoever D. Ceramic materials for thermal barrier coatings[J]. Journal of the European Ceramic Society, 2004, 24(1): 1-10.

[20] Viazzi C, Bonino J P, Ansart F, et al. Structural study of metastable tetragonal YSZ powders produced via a sol-gel route[J]. Journal of Alloys and Compounds, 2008, 452(2): 377-383.

[21] Loghman-Estark MR,

Razavi RS,

Edris H.Synthesis and

thermal stability of nontransformable tetragonal (

ZrO2)

0.96(

REO1.5)

0.04 (

RE=Sc

3+

,

Y

3+

)

nanocrystals[J].Defect and

DiffusionForum,

2013,

334/335:

60-

64.

[22] 陈彦宾, 刘德健, 李俐群, 等. 激光熔注WCp/Ti-6Al-4V梯度复合材料层形成机制[J]. 中国激光, 2008, 35(11): 1718-1722.

Chen YB,

Liu DJ,

Li LQ, et al.

Formation mechanism of WCp/Ti-6Al-4V graded metal matrix composites layer produced by laser melt injection.

Chinese Journal of Lasers,

2008,

35(

11):

1718-

1722.

[23] Fabris S, Paxton A T, Finnis M W. A stabilization mechanism of zirconia based on oxygen vacancies only[J]. Acta Materialia, 2002, 50(20): 5171-5178.

[24] Málek J, Beneš L, Mitsuhashi T. Powder diffraction data and Rietveld refinement of metastable t-ZrO2 at low temperature[J]. Powder Diffraction, 1997, 12(2): 96-98.

[25] Tomaszewski H, Godwod K. Influence of oxygen partial pressure on the metastability of undoped zirconia dispersed in alumina matrix[J]. Journal of the European Ceramic Society, 1995, 15(1): 17-23.

[26] Suyama R, Ashida T. 68(12): C-314-C-315[J]. Kume S. Synthesis of theorthorhombic phase of ZrO2. Journal of the American Ceramic Society, 1985.

下载: 909次

下载: 909次