[1] LeyensC, PetersM. Titanium and titanium alloys:Fundamentals and applications[M]. New York: John Wiley & Sons, 2003: 3.

[2] 付艳艳, 宋月清, 惠松骁, 等. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006, 30(6): 850-856.

Fu Y Y, Song Y Q, Hui S X, et al. Progress in research and application of titanium alloys used in aeronautical field[J]. Chinese Journal of Rare Metals, 2006, 30(6): 850-856.

[3] 李俐群, 王建东, 吴潮潮, 等. Ti6Al4V激光熔化沉积熔池温度场与微观组织特性[J]. 中国激光, 2017, 44(3): 0302009.

Li L Q, Wang J D, Wu C C, et al. Temperature field of molten pool and microstructure property in laser melting depositions of Ti6Al4V[J]. Chinese Journal of Lasers, 2017, 44(3): 0302009.

[4] 王祥, 周建忠, 黄舒, 等. 激光喷丸对 TC4 钛合金抗氢脆性能的影响[J]. 光学学报, 2017, 37(9): 0914006.

Wang X, Zhou J Z, Huang S, et al. Effect of laser peening on hydrogen embrittlement resistance of TC4 titanium alloys[J]. Acta Optica Sinica, 2017, 37(9): 0914006.

[5] 赵永庆, 陈永楠, 张学敏, 等. 钛合金相变及热处理[M]. 长沙: 中南大学出版社, 2012.

Zhao YQ, Chen YN, Zhang XM, et al.Phase transformation and heat treatment of titanium alloys[M]. Changsha: Zhongnan University Press, 2012.

[6] 朱知寿. 我国航空用钛合金技术研究现状及发展[J]. 航空材料学报, 2014, 34(4): 44-50.

Zhu Z S. Recent research and development of titanium alloys for aviation application in China[J]. Journal of Aeronautical Materials, 2014, 34(4): 44-50.

[7] 李富长, 宋祖铭, 杨典军. 钛合金加工工艺技术研究[J]. 新技术新工艺, 2010, 5: 66-69.

Li F C, Song Z M, Yang D J. Research on titanium alloy machining technology[J]. New Technology & New Process, 2010, 5: 66-69.

[8] 巩水利, 锁红波, 李怀学. 金属增材制造技术在航空领域的发展与应用[J]. 航空制造技术, 2013, 433(13): 66-71.

Gong S L, Suo H B, Li H X. Development and application of metal additive manufacturing technology[J]. Aeronautical Manufacturing Technology, 2013, 433(13): 66-71.

[9] 王华明. 高性能金属构件增材制造技术开启国防制造新篇章[J]. 国防制造技术, 2013, 3: 5-7.

Wang H M. High-performance metal component manufacturing technology opens a new chapter in national defense[J]. Defense Manufacturing Technology, 2013, 3: 5-7.

[10] 邓贤辉, 杨治军. 钛合金增材制造技术研究现状及展望[J]. 材料开发与应用, 2014, 29(5): 113-120.

Deng X H, Yang Z J. Current situation and prospect of titanium alloy additive manufacturing technology[J]. Development and Application of Materials, 2014, 29(5): 113-120.

[11] 李静, 林鑫, 钱远宏, 等. 激光立体成形TC4钛合金组织和力学性能研究[J]. 中国激光, 2014, 41(11): 1103010.

Li J, Lin X, Qian Y H, et al. Study on microstructure and property of laser solid forming TC4 titanium alloy[J]. Chinese Journal of Lasers, 2014, 41(11): 1103010.

[12] 李怀学, 巩水利, 孙帆, 等. 金属零件激光增材制造技术的发展及应用[J]. 航空制造技术, 2012, 416(20): 26-31.

Li H X, Gong S L, Sun F, et al. Development and application of laser additive manufacturing for metal component[J]. Aeronautical Manufacturing Technology, 2012, 416(20): 26-31.

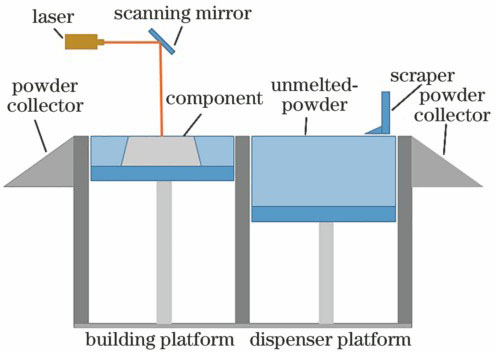

[13] 潘爱琼, 张辉, 王泽敏. 选区激光熔化镍基单晶高温合金的熔池显微组织[J]. 激光与光电子学进展, 2017, 54(7): 041702.

Pan A Q, Zhang H, Wang Z M. Molten pool microstructure of Ni-based single crystal superalloys fabricated by selective laser melting[J]. Laser & Optoelectronics Progress, 2017, 54(7): 041702.

[14] 侯慧鹏, 梁永朝, 何艳丽, 等. 选区激光熔化Hastelloy-X合金组织演变及拉伸性能[J]. 中国激光, 2017, 44(2): 0202007.

Hou H P, Liang Y C, He Y L, et al. Microstructure evolution and tensile property of Hastelloy-X alloys produced by selective laser melting[J]. Chinese Journal of Lasers, 2017, 44(2): 0202007.

[15] 杨全占, 魏彦鹏, 高鹏, 等. 金属增材制造技术及其专用材料研究进展[J]. 材料导报, 2016( s1): 107- 111.

Yang QZ, Wei YP, GaoP, et al. Research progress of metal additive manufacturing technologies and related materials[J]. Materials Review, 2016( s1): 107- 111.

[16] Edwards P. O'Conner A, Ramulu M. Electron beam additive manufacturing of titanium components:Properties and performance[J]. Journal of Manufacturing Science and Engineering, 2013, 135(6): 061016.

[17] Baufeld B, van der Biest O, Gault R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition:Microstructure and mechanical properties[J]. Materials & Design, 2010, 31(1): S106-S111.

[18] 王霄, 王东生, 高雪松, 等. 轻合金构件激光增材制造研究现状及其发展[J]. 应用激光, 2016, 36(4): 478-483.

Wang X, Wang D S, Gao X S, et al. Research status and development in laser additive manufacturing of light alloy components[J]. Applied Laser, 2016, 36(4): 478-483.

[19] 王华明, 张述泉, 汤海波, 等. 大型钛合金结构激光快速成形技术研究进展[J]. 航空精密制造技术, 2008, 44(6): 28-30.

Wang H M, Zhang S Q, Tang H B, et al. Development of laser rapid prototyping technology for large titanium alloy structures[J]. Aviation Precision Manufacturing Technology, 2008, 44(6): 28-30.

[20] 冯颖芳. 西工大用3D打印制造3米长C919飞机钛合金部件[J]. 工艺技术研究, 2013, 1: 24.

Feng Y F. Northwestern polytechnical university made 3 meters titanium alloy parts of C919 aircraft with 3D printing[J]. Technology Research, 2013, 1: 24.

[21] 董鹏, 李忠华, 严振宇, 等. 铝合金激光选区熔化成形技术研究现状[J]. 应用激光, 2015, 5: 607-611.

Dong P, Li Z H, Yan Z Y, et al. Research status of selective laser melting of aluminum alloys[J]. Applied Laser, 2015, 5: 607-611.

[22] 董鹏, 陈济轮. 国外选区激光熔化成形技术在航空航天领域应用现状[J]. 航天制造技术, 2014, 1: 1-5.

Dong P, Chen J L. Current status of selective laser melting for aerospace applications abroad[J]. Aeronautical Manufacturing Technology, 2014, 1: 1-5.

[23] 杨永强, 吴伟辉, 来克娴, 等. 金属零件选区激光熔化直接快速成形工艺及最新进展[J]. 航空制造技术, 2006, 2: 73-76.

Yang Y Q, Wu W H, Lai K X, et al. Newest process of direct rapid prototyping of metal part by selective laser melting[J]. Aeronautical Manufacturing Technology, 2006, 2: 73-76.

[24] 尹华, 白培康, 刘斌, 等. 金属粉末选区激光熔化技术的研究现状及其发展趋势[J]. 热加工工艺, 2010, 39(1): 140-144.

Yin H, Bai P K, Liu B, et al. Present situation and development trend of selective laser melting technology for metal powder[J]. Hot Working Technology, 2010, 39(1): 140-144.

[25] 顾冬冬, 沈以赴. 基于选区激光融化的金属材料零件快速成形现状与技术展望[J]. 航空制造技术, 2012, 8: 32-37.

Gu D D, Shen Y F. Research status and technical prospect of rapid manufacturing of metallic part by selective laser melting[J]. Aeronautical Manufacturing Technology, 2012, 8: 32-37.

[26] 党新安, 张晓博, 杨立军, 等. 钛粉激光选区熔化成型特性的研究[J]. 陕西科技大学学报, 2014, 1: 68-73.

Dang X A, Zhang X B, Yang L J, et al. Researching forming property of titanium powder in selective laser melting[J]. Journal of Shaanxi University Science & Technology, 2014, 1: 68-73.

[27] Abe F, Santos E C, Kitamura Y, et al. Influence of forming conditions on the titanium model in rapid prototyping with the selective laser melting process[J]. Journal of Mechanical Engineering Science, 2003, 217(1): 119-126.

[28] Gu D, Hagedorn Y C, Meiners W, et al. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium[J]. Acta Materialia, 2012, 60(9): 3849-3860.

[29] Attar H, Calin M, Zhang L C, et al. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium[J]. Materials Science and Engineering, 2014, 593(2): 170-177.

[30] Li X P, Humbeeck J V, Kruth J P. Selective laser melting of weak-textured commercially pure titanium with high strength and ductility: A study from laser power perspective[J]. Mater& Design, 2017, 116: 352-358.

[31] Kang N, Yuan H, Coddet P, et al. On the texture, phase and tensile properties of commercially pure Ti produced via selective laser melting assisted by static magnetic field[J]. Mater Science and Engineering, 2017, 70: 405-407.

[32] Barbas A, Bonnet A S, Lipinski P, et al. Development and mechanical characterization of porous titanium bone substitutes[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2012, 9(3): 34.

[33] 梁永仁, 吴引江. 3D打印用钛及钛合金球形粉末制备技术[J]. 世界有色金属, 2016, 12: 150-151.

Liang Y R, Wu Y J. Production technology of titanium and its alloy spherical powders used in 3D printing[J]. World Nonferrous Metals, 2016, 12: 150-151.

[34] Seyda V, Herzog D, Emmelmann C. Relationship between powder characteristics and part properties in laser beam melting of Ti-6Al-4V, and implications on quality[J]. Journal of Laser Applications, 2017, 29(2): 022311.

[35] 姚妮娜, 彭雄厚. 3D打印金属粉末的制备方法[J]. 四川有色金属, 2013, 4: 48-51.

Yao N N, Peng X H. The preparation method of metal powder for 3D printing[J]. Sichuan Nonferrous Metals, 2013, 4: 48-51.

[36] 赵霄昊, 左振博, 韩志宇, 等. 粉末钛合金3D打印技术研究进展[J]. 材料导报, 2016, 30(23): 120-126.

Zhao X H, Zuo Z B, Han Z Y, et al. A review on powder titanium alloy 3D printing technology[J]. Materials Review, 2016, 30(23): 120-126.

[37] 姚文静. Iluka追加投资研发低成本钛金属粉末[J]. 中国钛业, 2016, 2: 50.

Yao W J. Iluka additional investment in the low-cost development of titanium metal powders[J]. China Titanium Industry, 2016, 2: 50.

[38] GongH, GuH, ZengK, et al. Melt pool characterization for selective laser melting of Ti-6Al-4V pre-alloyed powder[C]. Solid Freeform Fabrication Symposium, 2014: 256- 267.

[39] Gong HJ, RafiK, Gu HF, et al. Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes[J]. Additive Manufacturing, 2014, 1/2/3/4: 87- 98.

[40] 孙健峰, 杨永强, 杨洲. 基于粉末特性的选区激光熔化Ti6Al4V表面粗糙度研究[J]. 中国激光, 2016, 43(7): 0702004.

Sun J F, Yang Y Q, Yang Z. Study on surface roughness of selective laser melting Ti6Al4V based on powder characteristics[J]. Chinese Journal of Lasers, 2016, 43(7): 0702004.

[41] Sato Y, Tsukamoto M, Yamashita Y. Surface morphology of Ti-6Al-4V plate fabricated by vacuum selective laser melting[J]. Applied Physics B, 2015, 119(3): 545-549.

[42] Simonelli M, Tuck C, Aboulkhair N T, et al. A study on the laser spatter and the oxidation reactions during selective laser melting of 316L stainless steel, Al-Si10-Mg, and Ti-6Al-4V[J]. Metallurgical & Materials Transactions A, 2015, 46(9): 3842-3851.

[43] SatoY, TsukamotoM, YamashitaY, et al. Effect on beam profile of Ti alloy plate fabrication from powder by sputter-less selective laser melting[C]. SPIE, 2017, 10095: 100950Z.

[44] Kasperovich G, Haubrich J, Gussone J, et al. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting[J]. Materials & Design, 2016, 105: 160-170.

[45] Song B, Dong S J, Liao H L, et al. Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering[J]. The International Journal of Advanced Manufacturing Technology, 2012, 61(9/10/11/12): 967-974.

[46] Sun J F, Yang Y Q, Wang D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method[J]. Optics & Laser Technology, 2013, 49(7): 118-124.

[47] 叶梓恒. Ti6Al4V胫骨植入体个性化设计及其激光选区熔化制造工艺研究[D]. 广州: 华南理工大学, 2014.

Ye ZH. The personalized design and process research of selective laser melting manufacturing of Ti6Al4V tibial implant[D]. Guangzhou: South China University of Technology, 2014.

[48] 王小龙. 钛合金激光选区熔化工艺优化与性能研究[D]. 广州: 华南理工大学, 2016.

Wang XL. Study on process optimization and property of titanium alloy manufactured by selective laser melting[D]. Guangzhou: South China University of Technology, 2016.

[49] 王建宏, 白培康. Ti6Al4V粉末选区激光熔化单层扫描工艺研究[J]. 热加工工艺, 2013, 42(15): 13-15.

Wang J H, Bai P K. Study on process parameters on surface quality of Ti6Al4V by selective laser melting[J]. Hot Working Technology, 2013, 42(15): 13-15.

[50] 张升. 医用合金粉末激光选区熔化成形工艺与性能研究[D]. 武汉: 华中科技大学, 2014.

ZhangS. Research on the forming processes and properties in selective laser melting of medical alloy powders[D]. Wuhan: Huang Zhong University of Science and Technology, 2014.

[51] Shi X, Ma S, Liu C, et al. Performance of high layer thickness in selective laser melting of Ti6Al4V[J]. Materials, 2016, 9(12): 975.

[52] Simonelli M, Tse Y Y, Tuck C. Microstructure of Ti-6Al-4V produced by selective laser melting[J]. Journal of Physics, 2012, 371(1): 012084.

[53] Thijs L, Verhaeghe F, Craeghs T, et al. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V[J]. Acta Mater, 2010, 58(9): 3303-3312.

[54] Do D K, Li P F. The effect of laser energy input on the microstructure, physical and mechanical properties of Ti-6Al-4V alloys by selective laser melting[J]. Virtual and Physical Prototyping, 2016, 11(1): 41-47.

[55] Yang J J, Yu H C, Yin J, et al. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting[J]. Materials & Design, 2016, 108: 308-318.

[56] SimonelliM, Tse YY, TuckC. Further understanding of Ti-6Al-4V selective laser melting using texture analysis[C]// Proceedings of 23rd Annual International Solid Freeform Fabrication Symposium, 2012: 480- 491.

[57] Han J, Yang J J, Yu H C, et al. Microstructure and mechanical property of selective laser melted Ti6Al4V dependence on laser energy density[J]. Rapid Prototyping Journal, 2017, 23(2): 217-226.

[58] Dutta B. Froes F H S. The additive manufacturing (AM) of titanium alloys[J]. Metal Powder Report, 2017, 72(2): 96-106.

[59] Simonelli M, Tse Y Y, Tuck C. On the texture formation of selective laser melted Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 2014, 45(6): 2863-2872.

[60] Barriobero V P, Gussone J, Haubrich J, et al. Inducing stable α+β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments[J]. Materials, 2017, 10(3): 268.

[61] Facchini L, Magalini E, Robotti P, et al. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders[J]. Rapid Prototyping Journal, 2010, 16(6): 450-459.

[62] Ali H, Ma L, Ghadbeigi H, et al. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of selective laser melted Ti6Al4V[J]. Materials Science & Engineering, 2017, 695: 211-220.

[63] Xu W, Lui E W, Pateras A, et al. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance[J]. Acta Mater, 2017, 125: 390-400.

[64] Xu W, Sun S, Elambasseril J, et al. Ti-6Al-4V additively manufactured by selective laser melting with superior mechanical properties[J]. JOM, 2015, 67(3): 668-673.

[65] Vrancken B, Thijs L, Kruth J P, et al. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties[J]. Journal of Alloys and Compounds, 2012, 541: 177-185.

[66] Khorasani A, Gibson I, Goldberg M, et al. On the role of different annealing heat treatments on mechanical properties and microstructure of selective laser melted and conventional wrought Ti-6Al-4V[J]. Rapid Prototyping Journal, 2017, 23(2): 295-304.

[67] Kasperovich G, Hausmann J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting[J]. Journal of Materials Processing Technology, 2015, 220: 202-214.

[68] 梁晓康, 董鹏, 陈济轮, 等. 激光选区熔化成形Ti-6Al-4V钛合金的显微组织及性能[J]. 应用激光, 2014, 34(2): 101-104.

Liang X K, Dong P, Chen J L, et al. Microstructure and mechanical properties of selective laser melting Ti6Al4V alloy[J]. Applied Laser, 2014, 34(2): 101-104.

[69] Cain V, Thijs L, Humbeeck J V, et al. Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting[J]. Additive Manufacturing, 2015, 5: 68-76.

[70] Benedetti M, Torresani E, Leoni M, et al. The effect of post-sintering treatments on the fatigue and biological behavior of Ti-6Al-4V ELI parts made by selective laser melting[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 71: 295.

[71] Simonelli M, Tse Y Y, Tuck C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V[J]. Materials Science & Engineering, 2014, 616: 1-11.

[72] 张凯, 刘婷婷, 张长东, 等. 基于熔池数据分析的激光选区熔化成形件翘曲变形行为研究[J]. 中国激光, 2015, 42(9): 0903007.

Zhang K, Liu T T, Zhang C D, et al. Study on deformation behavior in selective laser melting based on the analysis of the melt pool data[J]. Chinese Journal of Lasers, 2015, 42(9): 0903007.

[73] Casavola C, Campanelli S L, Pappalettere C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process[J]. The Journal of Strain Analysis for Engineering Design, 2009, 44(1): 93-104.

[74] Liu Y, Yang Y, Wang D. A study on the residual stress during selective laser melting (SLM) of metallic powder[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87(1/2/3/4): 647-656.

[75] Megahed M, Mindt H W. N’Dri N, et al. Metal additive-manufacturing process and residual stress modeling[J]. Integrating Materials & Manufacturing Innovation, 2016, 5(1): 4.

[76] Mercelis P, Kruth J P. Residual stresses in selective laser sintering and selective laser melting[J]. Rapid Prototyping Journal, 2013, 12(5): 254-265.

[77] Vrancken B, Cain V, Knutsen R. et al. Residual stress via the contour method in compact tension specimens produced via selective laser melting[J]. Scripta Materialia, 2014, 87: 29-32.

[78] Yadroitsev I, Yadroitsava I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting[J]. Virtual & Physical Prototyping, 2015, 10(2): 1-10.

[79] Parry L, Ashcroft I A, Wildman R D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation[J]. Additive Manufacturing, 2016, 12: 1-15.

[80] MohantyS, Hattel JH. Reducing residual stresses and deformations in selective laser melting through multilevel multiscale optimization of cellular scanning strategy[C]. SPIE, 2016, 9738: 97380Z.

[81] 邓诗诗, 杨永强, 李阳, 等. 分区扫描路径规划及其对SLM成型件残余应力分布的影响[J]. 中国激光, 2016, 43(12): 1202003.

Deng S S, Yang Y Q, Li Y, et al. Planning of area-partition scanning path and its effect on residual stress of SLM molding parts[J]. Chinese Journal of Lasers, 2016, 43(12): 1202003.

[82] 张升, 桂睿智, 魏青松, 等. 选择性激光熔化成形TC4钛合金开裂行为及其机理研究[J]. 机械工程学报, 2013, 49(23): 21-27.

Zhang S, Gui R Z, Wei Q S, et al. Cracking behavior and formation mechanism of TC4 alloy fabricated by selective laser melting[J]. Journal of Mechanical Engineering, 2013, 49(23): 21-27.

[83] Mishurova T, Cabeza S, Artzt K, et al. An assessment of subsurface residual stress analysis in SLM Ti-6Al-4V[J]. Materials, 2017, 10(4): 348.

[84] Vastola G, Zhang G, Pei Q X, et al. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling[J]. Additive Manufacturing, 2016, 12: 231-239.

[85] Rotaru H, Armencea G, Spirchez D, et al. In vivo behavior of surface modified Ti6Al7Nb alloys used in selective laser melting for custom-made implants. A preliminary study[J]. Romanian Journal of Morphology Embryology, 2013, 54(3): 791-796.

[86] Łyczkowska E, Szymczyk P, Dybała B, et al. Chemical polishing of scaffolds made of Ti-6Al-7Nb alloy by additive manufacturing[J]. Archives of Civil and Mechanical Engineering, 2014, 14(4): 586-594.

[87] Marcu T, Todea M, Gligor I, et al. Effect of surface conditioning on the flowability of Ti6Al7Nb powder for selective laser melting applications[J]. Applied Surface Science, 2012, 258(7): 3276-3282.

[88] Marcu T, Menapace C, Girardini L. et al. Selective laser melting of Ti6Al7Nb with hydroxyapatite addition[J]. Rapid Prototyping Journal, 2014, 20(4): 301-310.

[89] Chlebus E. Ku

nicka B, Kurzynowski T, et al. Microstructure and mechanical behavior of Ti-6Al-7Nb alloy produced by selective laser melting[J]. Materials Characterization, 2011, 62(5): 488-495.

[90] Sercombe T, Jones N, Day R, et al. Heat treatment of Ti-6Al-7Nb components produced by selective laser melting[J]. Rapid Prototyping Journal, 2008, 14(5): 300-304.

[91] BolzoniL, Ruiz-Navas E M, Gordo E. Influence of HIP parameters on the microstructure and mechanical properties of elemental titanium and Ti-6Al-7Nb alloy[C]. European Powder Metallurgy, 2012.

[92] Zhang L C, Klemm D, Eckert J, et al. Manufacture by selective laser melting and mechanical behavior of a biomedical Ti-24Nb-4Zr-8Sn alloy[J]. Scripta Materialia, 2011, 65(1): 21-24.

[93] Zhang L C, Sercombe T B. Selective laser melting of low-modulus biomedical Ti-24Nb-4Zr-8Sn alloy: Effect of laser point distance[J]. Key Engineering Materials, 2012, 520: 226-233.

[94] Liu Y J, Li X P, Zhang L C, et al. Processing and properties of topologically optimized biomedical Ti-24Nb-4Zr-8Sn scaffolds manufactured by selective laser melting[J]. Materials Science and Engineering, 2015, 642: 268-278.

[95] 党兴. 我国钛铝合金领域专利技术发展综述[J]. 新材料产业, 2017, 3: 30-34.

Dang X. Overview of development of patent technology in titanium alloy field in China[J]. Advanced Materials Industry, 2017, 3: 30-34.

[96] Shi X, Ma S, Liu C, et al. Parameter optimization for Ti-47Al-2Cr-2Nb in selective laser melting based on geometric characteristics of single scan tracks[J]. Optics & Laser Technology, 2017, 90: 71-79.

[97] Li W, Liu J, Zhou Y, et al. Effect of substrate preheating on the texture, phase and nanohardness of a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting[J]. Scripta Materials, 2016, 118: 13-18.

[98] Li W, Liu J, Wen S, et al. Crystal orientation, crystallographic texture and phase evolution in the Ti-45Al-2Cr-5Nb alloy processed by selective laser melting[J]. Materials Characterization, 2016, 113: 125-133.

[99] Li W, Liu J, Zhou Y, et al. Effect of laser scanning speed on a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting: Microstructure, phase and mechanical properties[J]. Journal of Alloys and Compounds, 2016, 688: 626-636.

[100] Li W, Liu J, Zhou Y, et al. Texture evolution, phase transformation mechanism and nanohardness of selective laser melted Ti-45Al-2Cr-5Nb alloy during multi-step heat treatment process[J]. Intermetallics, 2017, 85: 130-138.

[101] Li W, Yang Y, Liu J, et al. Enhanced nanohardness and new insights into texture evolution and phase transformation of TiAl/TiB2in-situ metal matrix composites prepared via selective laser melting[J]. Acta Materialia, 2017, 136: 90-104.

[102] Krakhmalev P, Yadroitsev I. Microstructure and properties of intermetallic composite coatings fabricated by selective laser melting of Ti-SiC powder mixtures[J]. Intermetallics, 2014, 46: 147-155.

[103] Attar H, Ehtemam-Haghighi S, Kent D, et al. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting[J]. Materials Science and Engineering, 2017, 688: 20-26.

[104] Attar H, Löber L, Funk A, et al. Mechanical behavior of porous commercially pure Ti and Ti-TiB composite materials manufactured by selective laser melting[J]. Materials Science and Engineering, 2015, 625: 350-356.

[105] Attar H, Prashanth K G, Zhang L C, et al. Effect of powder particle shape on the properties of in situ Ti-TiB composite materials produced by selective laser melting[J]. Journal of Materials Science & Technology, 2015, 31(10): 1001-1005.

[106] Fischer M, Joguet D, Robin G, et al. In situ elaboration of a binary Ti-26Nb alloy by selective laser melting of elemental titanium and niobium mixed powders[J]. Materials Science and Engineering, 2016, 62(2): 852-859.

[107] Speirs M, Humbeeck J V, Schrooten J, et al. The effect of pore geometry on the mechanical properties of selective laser melted Ti-13Nb-13Zr scaffolds[J]. Procedia CIRP, 2013, 5: 79-82.

[108] Grigoriev A, Polozov I, Sufiiarov V, et al. In-situ synthesis of Ti2AlNb-based intermetallic alloy by selective laser melting[J]. Journal of Alloys and Compounds, 2017, 704: 434-442.

[109] Sharkeev Y P, Eroshenko A Y, Kovalevskaya Z G, et al. Structural and phase state of Ti-Nb alloy at selective laser melting of the composite powder[J]. Russian Physics Journal, 2016, 59(3): 1-5.

[110] Wang Q, Han C J, Choma T, et al. Effect of Nb content on microstructure, property and in vitro apatite-forming capability of Ti-Nb alloys fabricated via selective laser melting[J]. Materials & Design, 2017, 126: 268-277.

[111] Sing S L, Wang S, Agarwala S, et al. Fabrication of titanium based biphasic scaffold using selective laser melting and collagen immersion[J]. International Journal of Bioprinting, 2017, 3(1): 1-7.

[112] Wang D, Wang Y, Wu S, et al. Customized a Ti6Al4V bone plate for complex pelvic fracture by selective laser melting[J]. Materials, 2017, 10(1): 10010035.

[113] Pan C T, Lin C H, Huang Y S, et al. Design of interbody fusion cages of Ti6Al4V with gradient porosity using a selective laser melting process for spinal fusion arthroplasty[J]. Journal of Laser Micro/Nanoengineering, 2017, 12(1): 34-44.

[114] Cheng L W, Cheng C W, Chung K C, et al. Sound absorption of metallic sound absorbers fabricated via the selective laser melting process[J]. Applied Physics A, 2017, 123(1): 37-37.

[115] Campanelli S L, Contuzzi N, Ludovico A D, et al. Manufacturing and characterization of Ti6Al4V lattice components manufactured by selective laser melting[J]. Materials, 2014, 7(6): 4803-4822.

[116] 赵志国, 柏林, 李黎, 等. 激光选区熔化成形技术的发展现状及研究进展[J]. 航空制造技术, 2014, 463(19): 46-49.

Zhao Z G, Bo L, Li L, et al. Status and progress of selective laser melting forming technology[J]. Aeronautical Manufacturing Technology, 2014, 463(19): 46-49.

[117] 丁红瑜, 孙中刚, 初铭强, 等. 选区激光熔化技术发展现状及在民用飞机上的应用[J]. 航空制造技术, 2015, 473(4): 102-104.

Ding H Y, Sun Z G, Chu M Q, et al. Development and application of selective laser melting technology in civil aircraft[J]. Aeronautical Manufacturing Technology, 2015, 473(4): 102-104.

下载: 2440次

下载: 2440次