熔融石英光学元件亚表面缺陷三维重构技术  下载: 2154次

下载: 2154次

张健浦, 孙焕宇, 王狮凌, 黄进, 周晓燕, 王凤蕊, 刘红婕, 刘东. 熔融石英光学元件亚表面缺陷三维重构技术[J]. 光学学报, 2020, 40(2): 0216001.

Jianpu Zhang, Huanyu Sun, Shiling Wang, Jin Huang, Xiaoyan Zhou, Fengrui Wang, Hongjie Liu, Dong Liu. Three-Dimensional Reconstruction Technology of Subsurface Defects in Fused Silica Optical Components[J]. Acta Optica Sinica, 2020, 40(2): 0216001.

[1] 钟勉. 辐照对蓝宝石、熔石英光学和激光损伤特性的影响[D]. 成都: 电子科技大学, 2016: 6- 8.

ZhongM. Radiation effects on optical properties and laser damage performance of sapphire and fused silica[D]. Chengdu: University of Electronic Science and Technology of China, 2016: 6- 8.

[2] 李富全, 韩伟, 王芳, 等. 高功率激光驱动器终端光学组件研究现状[J]. 激光与光电子学进展, 2013, 50(6): 060002.

[3] 曲兴华, 何滢, 韩峰, 等. 强反射复杂表面随机缺陷检测照明系统分析[J]. 光学学报, 2003, 23(5): 547-551.

[4] Wang S H, Luo G. Naturalness preserved image enhancement using a priori multi-layer lightness statistics[J]. IEEE Transactions on Image Processing, 2018, 27(2): 938-948.

[5] 杨甬英, 陆春华, 梁蛟, 等. 光学元件表面缺陷的显微散射暗场成像及数字化评价系统[J]. 光学学报, 2007, 27(6): 1031-1038.

[6] 姒绍辉, 胡伏原, 顾亚军, 等. 一种基于不规则区域的高斯滤波去噪算法[J]. 计算机科学, 2014, 41(11): 313-316.

Si S H, Hu F Y, Gu Y J, et al. Improved denoising algorithm based on non-regular area Gaussian filtering[J]. Computer Science, 2014, 41(11): 313-316.

[7] 徐超, 平雪良. 基于改进随机Hough变换的直线检测算法[J]. 激光与光电子学进展, 2019, 56(5): 051001.

[8] Duncan M D, Bashkansky M, Reintjes J. Subsurface defect detection in materials using optical coherence tomography[J]. Optics Express, 1998, 2(13): 540-545.

[9] 陈军, 尤政, 周兆英, 等. 硅材料微/纳米级体缺陷激光无损检测的新途径[J]. 应用激光, 1997, 17(2): 54-56, 68.

Chen J, You Z, Zhou Z Y, et al. A new laser non-destructive method of detecting micro/nano bulk defects in silicon materials[J]. Applied Laser, 1997, 17(2): 54-56, 68.

[10] Williams WB. A novel fluorescence based method of assessing subsurface damage in optical materials[D]. Charlotte: The University of North Carolina, 2009: 45- 47.

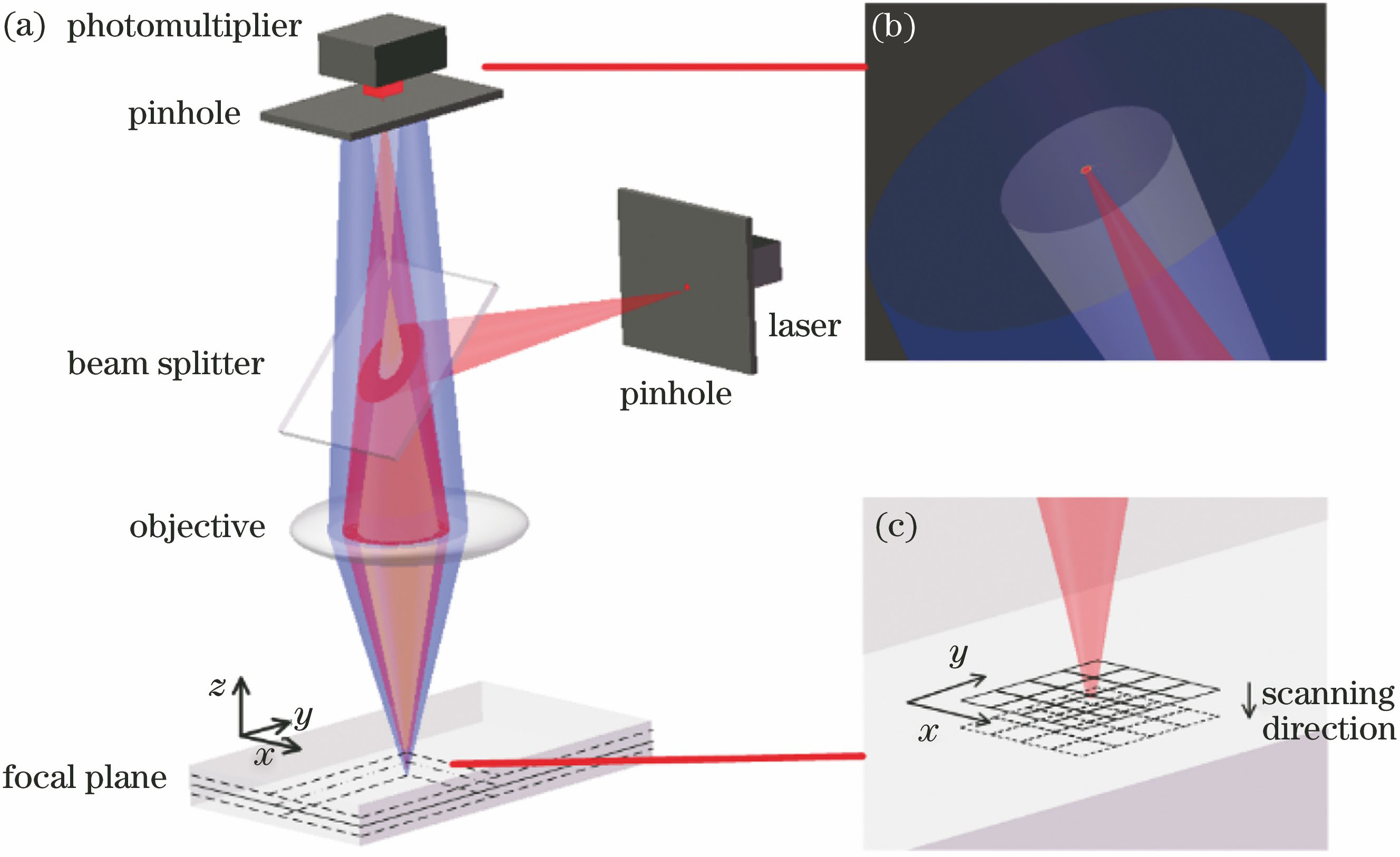

[11] 王景贺, 张磊, 王洪祥, 等. 基于荧光共聚焦技术熔石英亚表层损伤检测方法[J]. 中国激光, 2015, 42(4): 0406004.

[12] 王辉, 田爱玲, 王春慧. 基于共焦成像法的亚表层损伤散射仿真[J]. 光学仪器, 2013, 35(3): 1-6.

[13] Neauport J, Cormont P, Legros P, et al. Imaging subsurface damage of grinded fused silica optics by confocal fluorescence microscopy[J]. Optics Express, 2009, 17(5): 3543-3554.

[14] Herman G T, Liu H K. Three-dimensional display of human organs from computed tomograms[J]. Computer Graphics and Image Processing, 1979, 9(1): 1-21.

[15] Schroeder WJ, LorensenB, MartinK. The visualization toolkit: an object-oriented approach to 3D graphics[M]. 3rd ed. New York: Kitware, 2004: 178- 180.

[16] Lorensen W E, Cline H E. Marching cubes: a high resolution 3D surface construction algorithm[J]. ACM SIGGRAPH Computer Graphics, 1987, 21(4): 163-169.

[17] 田爱玲, 王会婷, 党娟娟, 等. 抛光表面的亚表层损伤检测方法研究[J]. 光子学报, 2013, 42(2): 214-218.

[18] 杜秀蓉, 张晓强, 王慧, 等. 抛光石英玻璃亚表面缺陷研究[J]. 硅酸盐通报, 2017, 36(S1): 47-49, 77.

Du X R, Zhang X Q, Wang H, et al. Study of subsurface damage in polished silica glass[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(S1): 47-49, 77.

[19] 王洪祥, 朱本温, 王景贺, 等. 熔石英元件抛光加工亚表面缺陷的检测[J]. 材料科学与工艺, 2015, 23(2): 8-12.

Wang H X, Zhu B W, Wang J H, et al. Subsurface defects detection for the polishing surface of fused silica optics[J]. Materials Science and Technology, 2015, 23(2): 8-12.

[20] 王洪祥, 沈璐, 李成福, 等. 光学元件激光诱导损伤分析及实验研究[J]. 中国激光, 2017, 44(3): 0302006.

张健浦, 孙焕宇, 王狮凌, 黄进, 周晓燕, 王凤蕊, 刘红婕, 刘东. 熔融石英光学元件亚表面缺陷三维重构技术[J]. 光学学报, 2020, 40(2): 0216001. Jianpu Zhang, Huanyu Sun, Shiling Wang, Jin Huang, Xiaoyan Zhou, Fengrui Wang, Hongjie Liu, Dong Liu. Three-Dimensional Reconstruction Technology of Subsurface Defects in Fused Silica Optical Components[J]. Acta Optica Sinica, 2020, 40(2): 0216001.