激光与光电子学进展, 2019, 56 (19): 190003, 网络出版: 2019-10-12

飞秒激光加工超硬材料的研究进展  下载: 2823次

下载: 2823次

Femtosecond Laser Processing of Ultrahard Materials

图 & 表

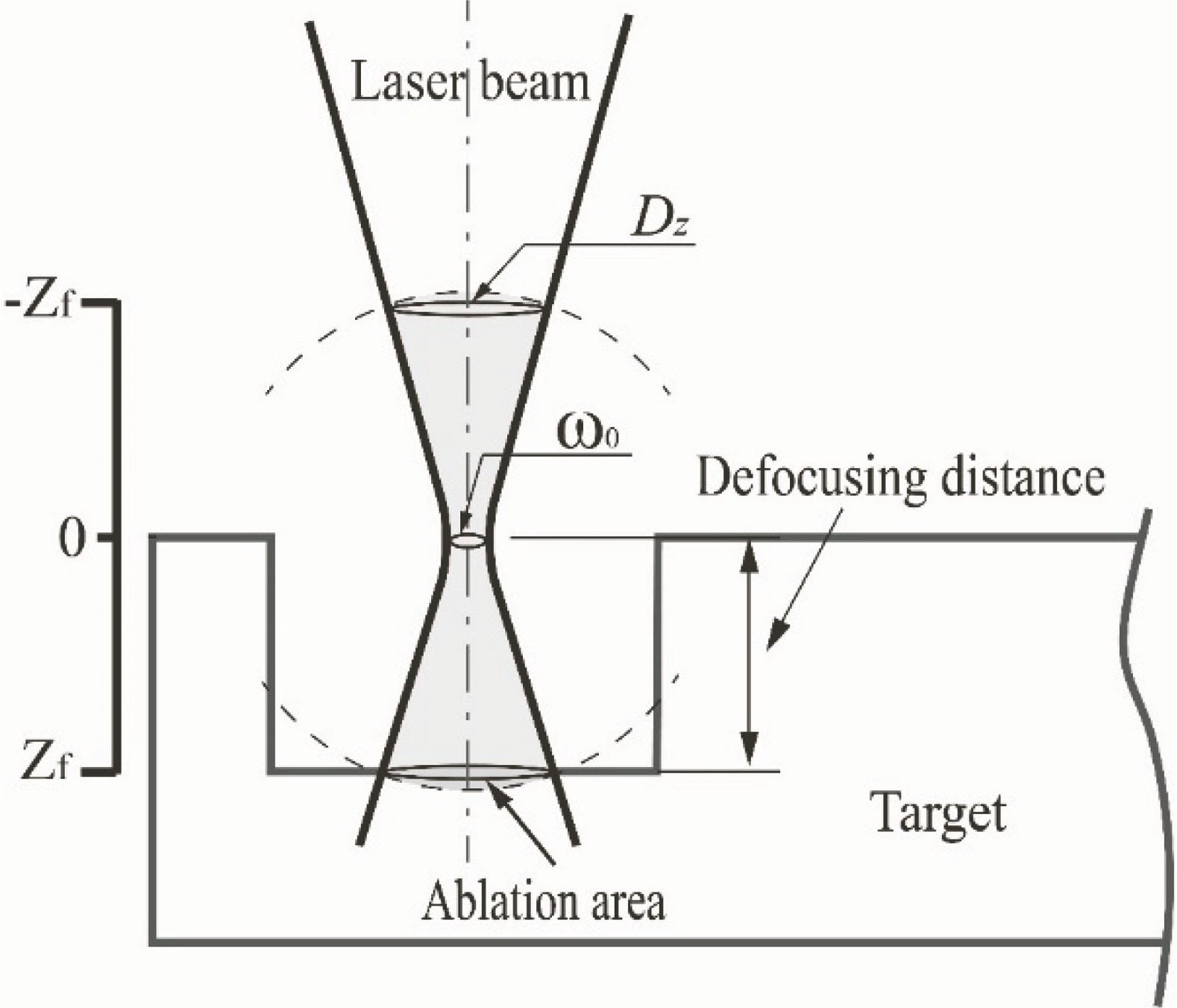

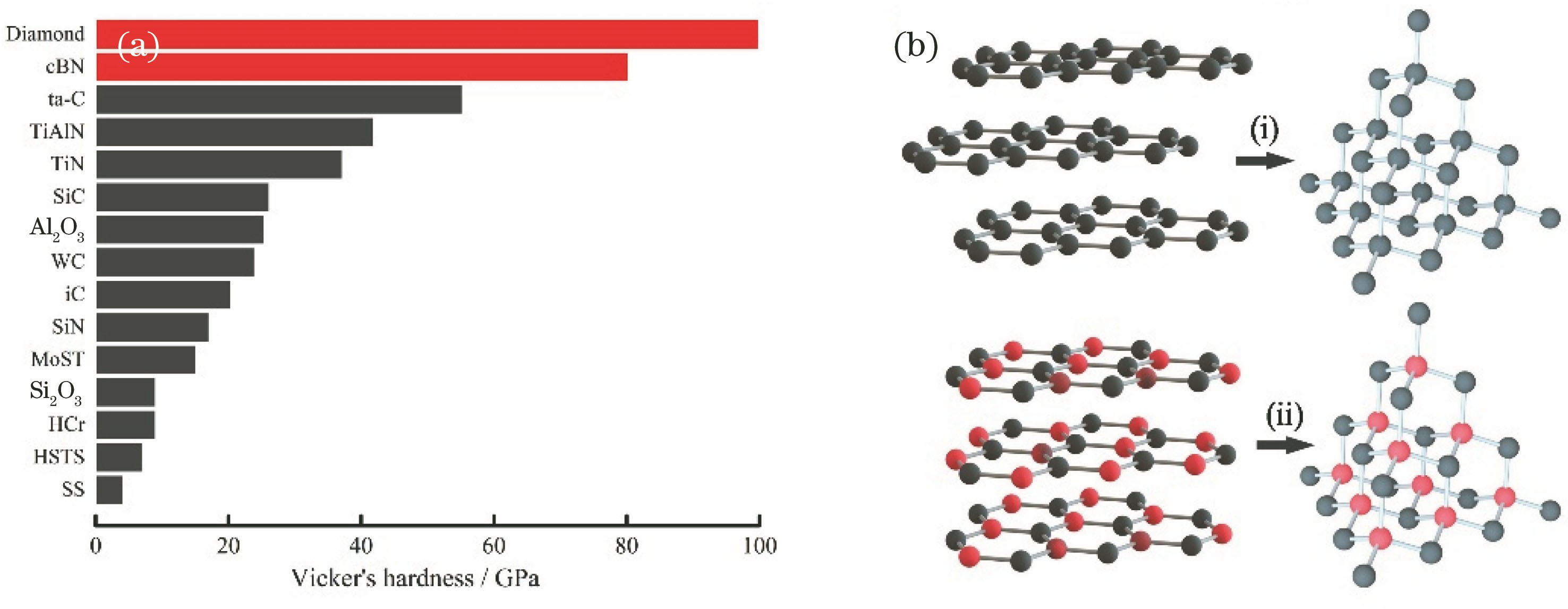

图 1. 两种典型超硬材料的硬度及其原子结构。(a)不同材料的硬度表;(b)金刚石及立方氮化硼的立方晶体结构

Fig. 1. Hardness and atomic structures of two typical ultrahard materials. (a) Hardness of different materials; (b) cubic crystal structures of diamond and CBN

图 2. 激光-靶材交互作用过程中一系列物理现象的发生时域[21]

Fig. 2. Timescale of physical phenomena involved in laser-material interaction[21]

图 3. 长脉冲激光加工和短脉冲激光加工区别示意图[23]

Fig. 3. Schematic of difference between long-pulse laser processing and short-pulse laser processing[23]

图 4. 飞秒脉冲激光作用下靶材表面最大温度演化及激光能量累积效应示意图[26-27]。(a)靶材表面最大温度演化;(b)激光能量累积效应

Fig. 4. Schematics of evolution of maximum temperature of target and pulse energy incubation effect in femtosecond laser processing[26-27]. (a) Evolution of maximum temperature of target; (b) pulse energy incubation effect

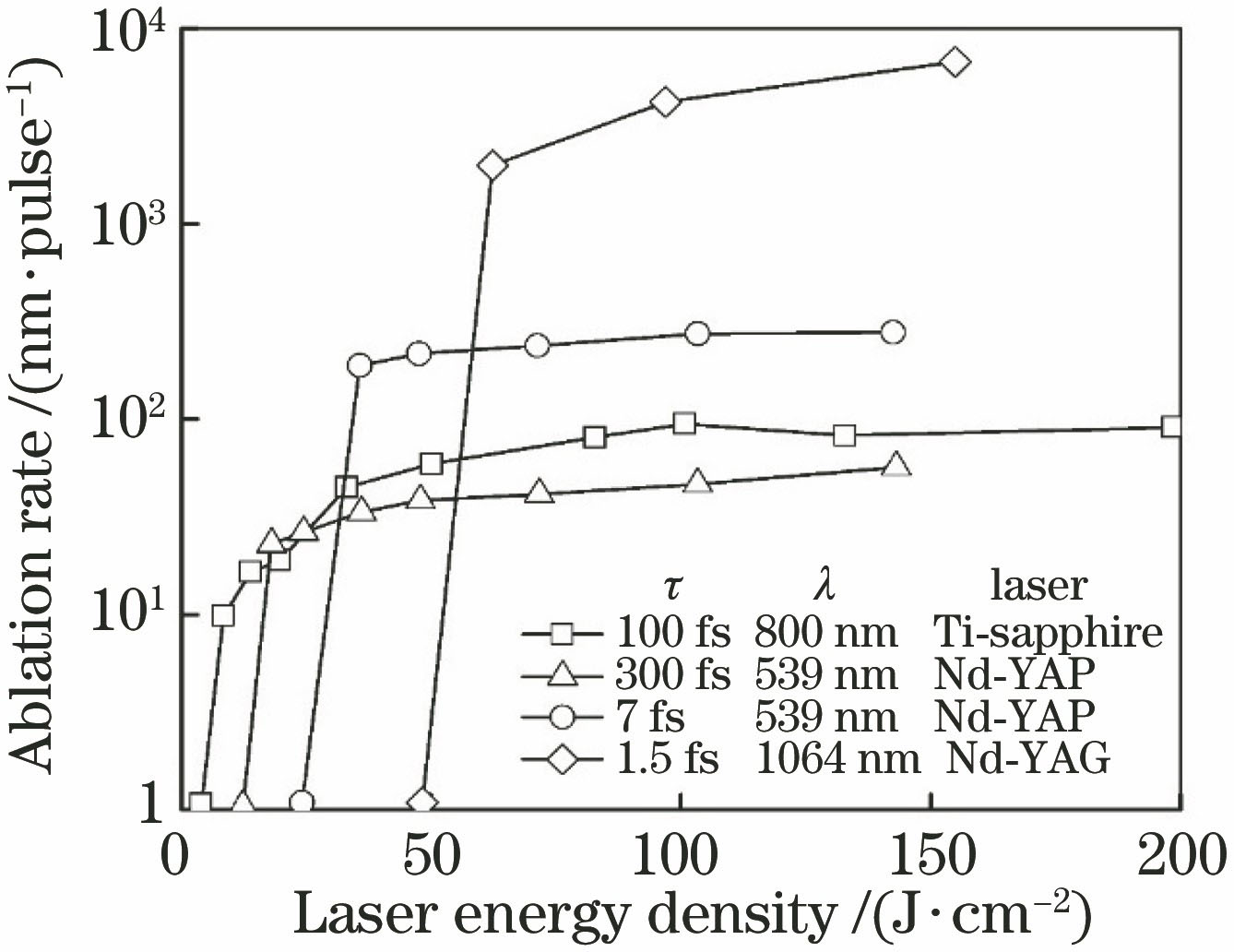

图 5. 不同脉宽下金刚石烧蚀率与激光能量密度的关系曲线

Fig. 5. Functional relationship between ablation rate of diamond and laser energy density under different pulse durations

图 6. 非线性吸收与雪崩电离机制示意图[36]

Fig. 6. Schematics of non-linear absorption and avalanche ionization mechanism[36]

图 7. 飞秒激光功率对数与单晶金刚石表面烧蚀点直径平方的拟合曲线[25]

Fig. 7. Fitting curve between logarithmic laser power and square of dimple diameter machined by femtosecond laser on SC diamond[25]

图 9. 在不同激光脉冲能量、重复扫描次数、聚焦物镜倍率下加工得到的金刚石的侧面扫描电镜图

Fig. 9. SEM photographs of polycrystalline diamond side profiles processed at different pulse energies, scanning numbers, and focusing objective magnification

图 10. 超硬材料的常见飞秒激光加工方法。(a)激光直写技术[48];(b)加速光束[59];(c)干法刻蚀辅助加工[53];(d)强度掩模投影加工[64];(e)基于SLM技术的飞秒激光双模式加工系统[61]

Fig. 10. Common femtosecond laser processing methods for ultrahard materials. (a) Laser direct writing[48]; (b) accelerated beam[59]; (c) dry etching assistant processing[53]; (d) intensity mask projection processing[64]; (e) femtosecond laser dual-mode rapid fabrication system based on SLM[61]

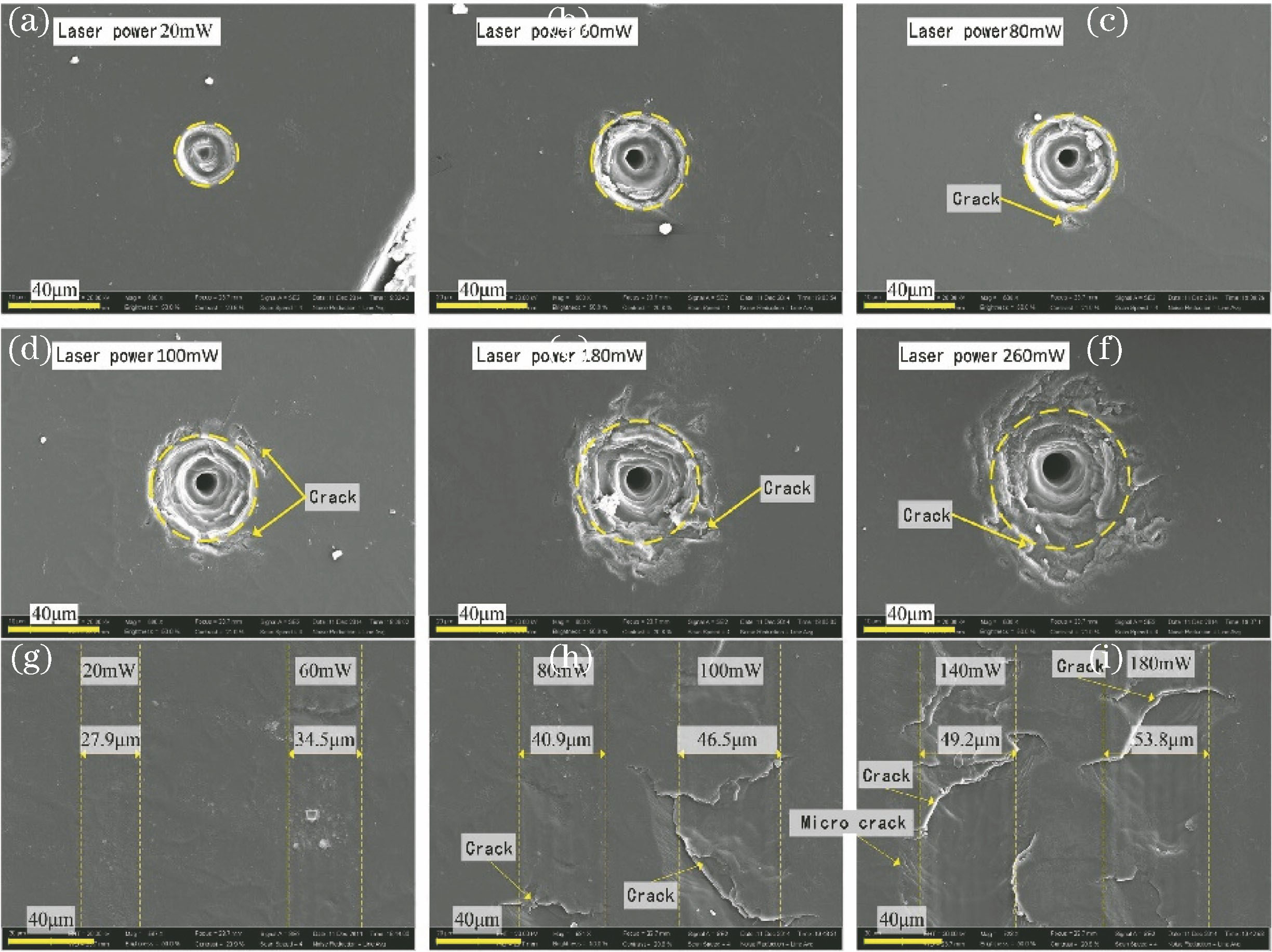

图 11. 不同功率下飞秒激光点刻蚀及线刻蚀区域的微观形貌。(a)~(f)点刻蚀;(g)~(i)线刻蚀

Fig. 11. Micro-morphologies of ablated area obtained by femtosecond laser spot etching and line etching at different laser powers. (a)-(f) Spo tetching; (g)-(i) line etching

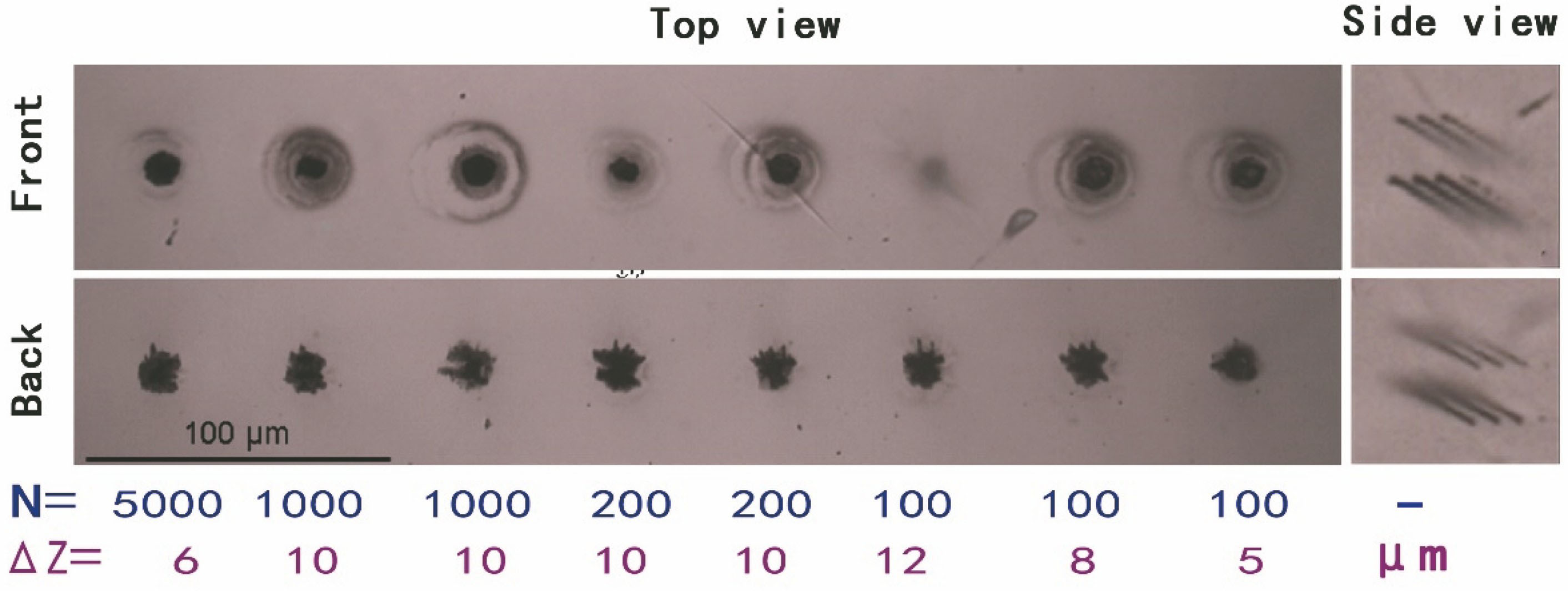

图 12. 激光能量为4 μJ的飞秒激光加工石墨通道阵列,N是脉冲数,ΔZ是步长;侧视低倍率光学显微照片显示了通过块体的石墨化通道的连续性

Fig. 12. Graphite channel arrays fabricated by femtosecond laser with energy of 4 μJ. N is number of pulses; Z is step length; side-view low-power optical micrographs illustrate continuity of graphitization channels through bulk diamond

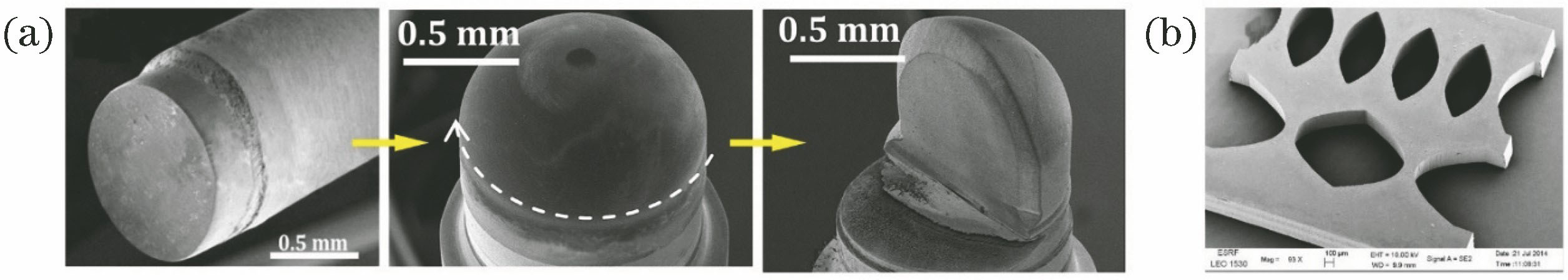

图 13. 飞秒激光直写加工的应用。(a) BLPCD微铣刀的加工过程,从左至右:BLPCD毛坯,FSPL球头成型,BLPCD微铣刀成品;(b) SC金刚石平面折射透镜的SEM照片

Fig. 13. Applications of femtosecond laser direct writing. (a) Processing process of BLPCD micromilling tool, from left to right: BLPCD blank, FSPL ball forming, finished BLPCD micromilling tool; (b) SEM photograph of SC diamond plane refractive lens

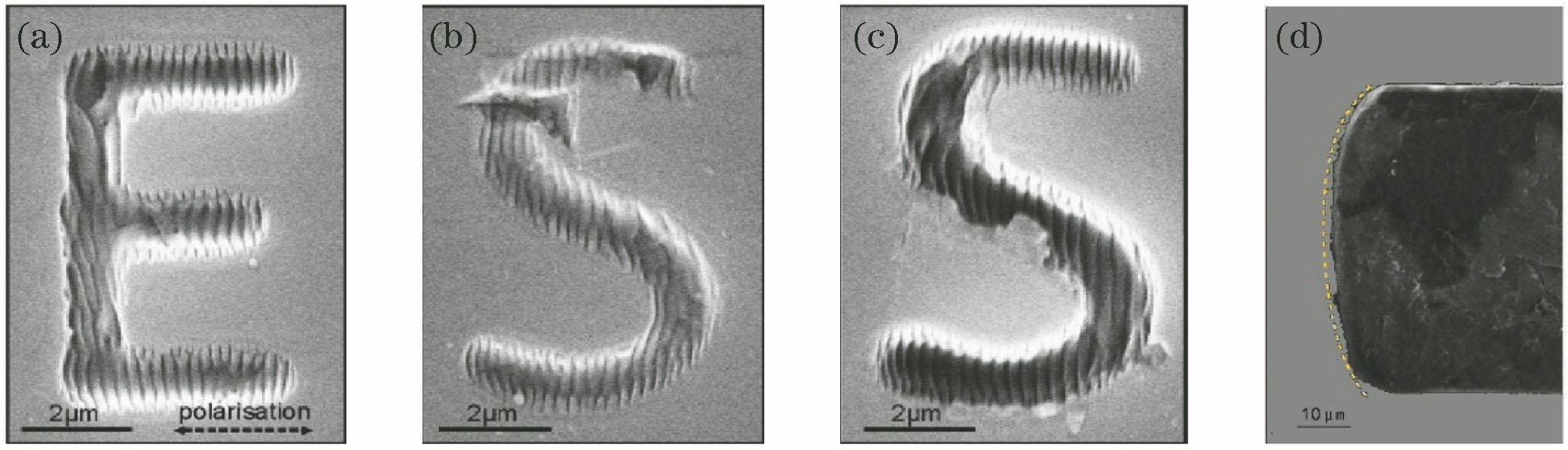

图 14. SLM技术的应用。 (a)、 (b)多晶金刚石表面10个脉冲加工字母,虚线双箭头代表激光偏振方向;(c)多晶金刚石表面50个脉冲加工的字母;(d)飞秒激光加速光束加工出的凸面SC金刚石边缘的SEM照片

Fig. 14. Applications of SLM technologies. (a)(b) Letters processed by 10 pulses on surface of polycrystalline diamond, with dotted double arrows representing direction of laser polarization; (c) letter “S” processed by 50 pulses on surface of polycrystalline diamond; (d) SEM photograph of convex SC diamond edges processed by femtosecond laser acceleration beam

图 15. 低功率下nt-CBN材料的飞秒激光点刻蚀去除机理[82]

Fig. 15. Material removal mechanism of nt-CBN by femtosecond laser spot etching at low power[82]

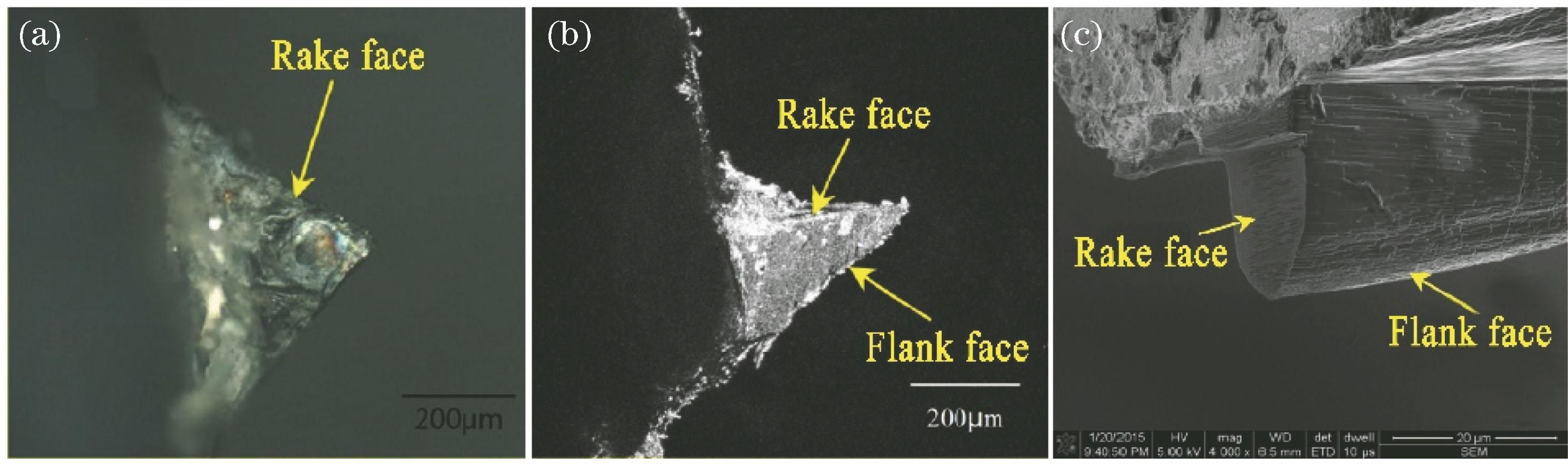

图 16. nt-CBN刀具。 (a)、(b)飞秒激光加工的nt-CBN 微刀具毛坯;(c)聚焦离子束研磨后nt-CBN微刀具成品

Fig. 16. nt-CBN tool. (a)(b) Blanks of nt-CBN micro-tool processed by femtosecond laser; (c) finished nt-CBN micro-tool after focused ion beam grinding

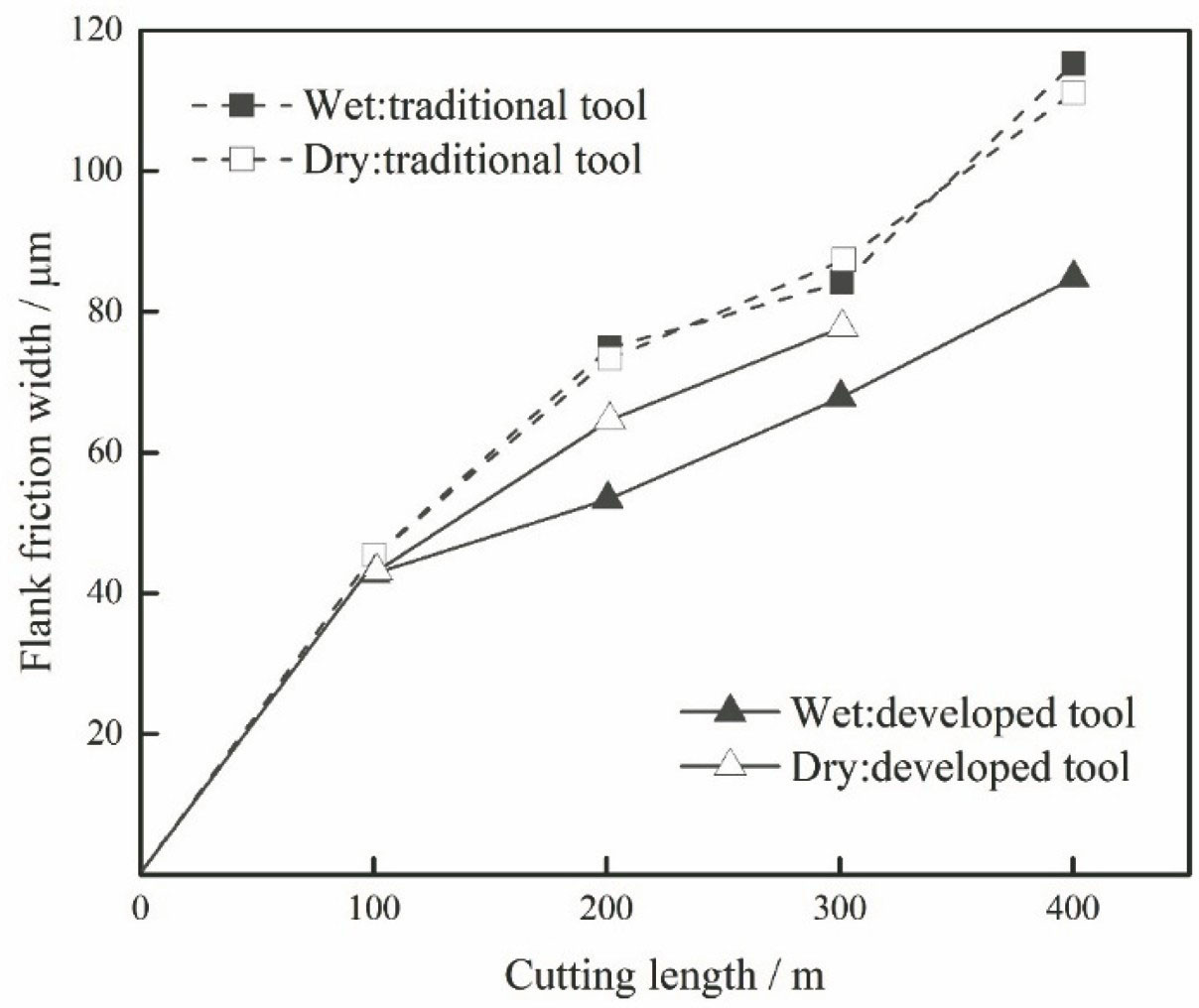

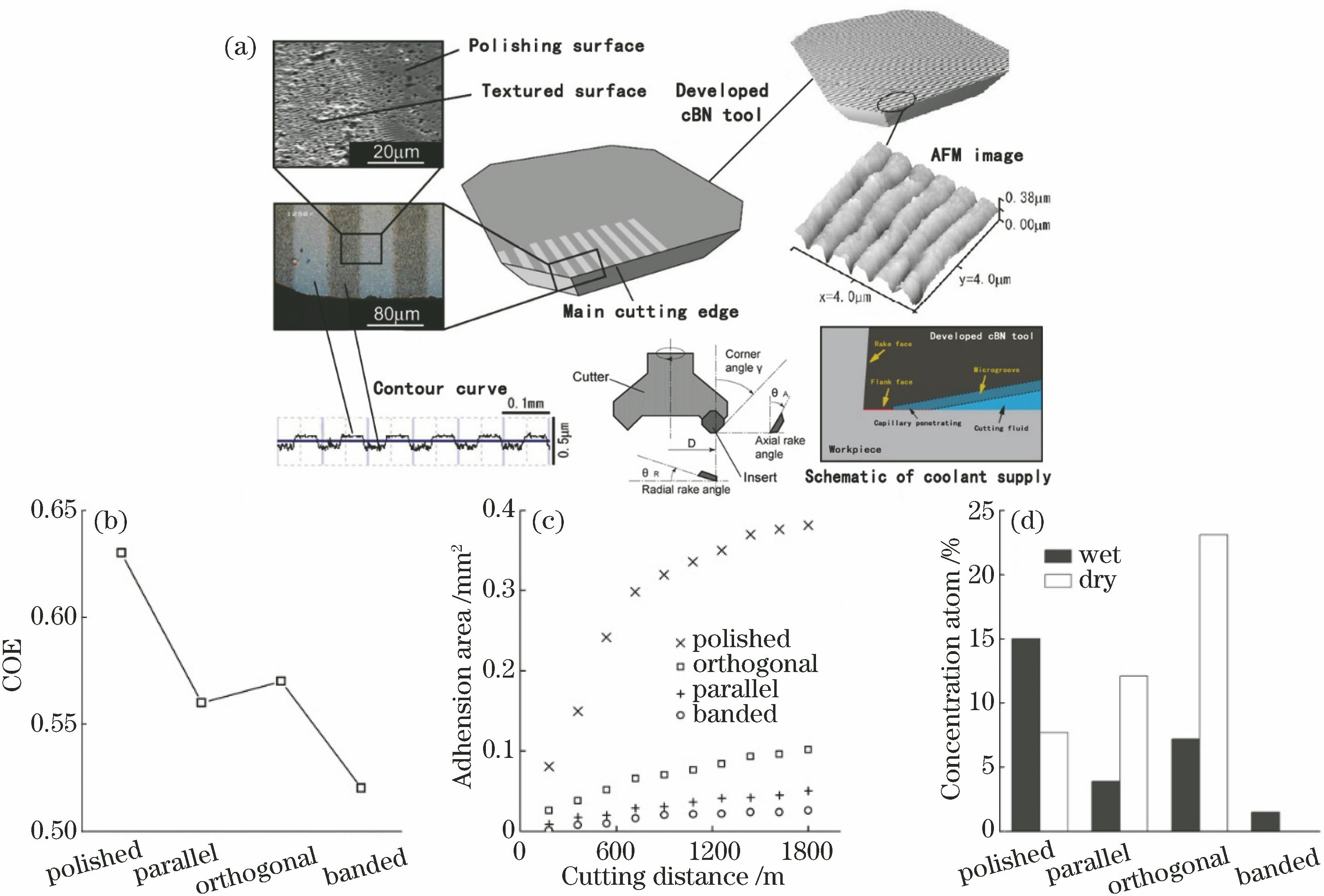

图 17. 飞秒激光诱导表面微织构CBN刀具表面微观形貌及不同刀具在不同切削条件(干加工/湿加工)下的切削实验结果分析。(a)表面微观形貌;(b)不同织构(原始抛光表面、平行微织构、交叉微织构和带状微织构)刀具的摩擦因数;(c)不同织构刀具切削长度与黏结面积的关系;(d)不同织构刀具在干/湿工况下刀具表面的黏结浓度

Fig. 17. Surface micro-morphologies of CBN tool fabricated by femtosecond laser and cutting experimental results of different tools under different cutting conditions (dry/wet processing). (a) Surface micro-morphologies; (b) comparison of friction coefficients of polished surface, parallel, orthogonal, and banded micro-textured tools; (c) relationship between cutting length and adhension area of different micro-textured tools; (d) atom concentration of targets on surface of different micro-textured tools

图 18. 微织构刀具表面黏结程度的实验结果[87]。(a)不同参数下CBN刀具切削实验后前刀面的三维轮廓,白色箭头指示区域为铝合金切削黏结; (b)干摩擦下切削长度增加至1800 m时切屑的变化,蓝色箭头及方框代表普通刀具的加工结果,红色箭头及方框代表最优方案的加工结果

Fig. 18. Experimental results of surface adhesion degree of micro-textured tools[87]. (a) Three-dimensional profile of rake face of CBN tools after cutting experiment under different parameters, where white arrow indicates cutting adhesion area of aluminum alloy; (b) changes of cutting chips when cutting length increases to 1800 m under dry friction. Processing results marked by blue arrow and box attribute to traditional tool, while red arrow and box marked results are processed by optimum tool

表 1金刚石与立方氮化硼的属性及其应用

Table1. Properties and applications of diamond and CBN

|

魏超, 马玉平, 韩源, 张遥, 陈雪辉. 飞秒激光加工超硬材料的研究进展[J]. 激光与光电子学进展, 2019, 56(19): 190003. Chao Wei, Yuping Ma, Yuan Han, Yao Zhang, Xuehui Chen. Femtosecond Laser Processing of Ultrahard Materials[J]. Laser & Optoelectronics Progress, 2019, 56(19): 190003.