飞秒激光加工超硬材料的研究进展  下载: 2827次

下载: 2827次

魏超, 马玉平, 韩源, 张遥, 陈雪辉. 飞秒激光加工超硬材料的研究进展[J]. 激光与光电子学进展, 2019, 56(19): 190003.

Chao Wei, Yuping Ma, Yuan Han, Yao Zhang, Xuehui Chen. Femtosecond Laser Processing of Ultrahard Materials[J]. Laser & Optoelectronics Progress, 2019, 56(19): 190003.

[1] Li S L, Huang Z P, Ye Y K, et al. Femtosecond laser inscribed cladding waveguide lasers in Nd∶LiYF4 crystals[J]. Optics & Laser Technology, 2018, 102: 247-253.

[2] 陈燕青, 高炳攀, 林炎章, 等. 飞秒激光微加工制备金属线栅太赫兹偏振片[J]. 中国激光, 2018, 45(8): 0802005.

[3] Xu H L, Sun H B. Femtosecond laser 3D fabrication of whispering-gallery-mode microcavities[J]. Science China Physics, Mechanics & Astronomy, 2015, 58(11): 114202.

[4] Balbus G H, Echlin M P, Grigorian C M, et al. Femtosecond laser rejuvenation of nanocrystalline metals[J]. Acta Materialia, 2018, 156: 183-195.

[5] Zhang R, Huang C Z, Wang J, et al. Micromachining of 4H-SiC using femtosecond laser[J]. Ceramics International, 2018, 44(15): 17775-17783.

[6] Kawashima T, Sano T, Hirose A, et al. Femtosecond laser peening of friction stir welded 7075-T73 aluminum alloys[J]. Journal of Materials Processing Technology, 2018, 262: 111-122.

[7] 张学谦, 邢松龄, 刘磊, 等. 带热障涂层的高温合金飞秒激光旋切打孔[J]. 中国激光, 2017, 44(1): 0102013.

[8] 丁腾, 王雪辉, 王关德, 等. 高重频飞秒激光焊接石英玻璃[J]. 中国激光, 2018, 45(7): 0701007.

[9] Wang M L, Yang L J, Zhang S, et al. Experimental investigation on the spiral trepanning of K24 superalloy with femtosecond laser[J]. Optics & Laser Technology, 2018, 101: 284-290.

[10] OstendorfA,[\s]{1}KorteF,[\s]{1}KamlageG,[\s]{1}et[\s]{1}al.[\s]{1}3D[\s]{1}laser[\s]{1}microfabrication:[\s]{1}principles[\s]{1}and[\s]{1}applications[M].[\s]{1}Weinheim:[\s]{1}Wiley-VCH[\s]{1}Verlag[\s]{1}GmbH[\s]{1}&[\s]{1}Co.[\s]{1}KGaA,[\s]{1}2006.[\s]{1}

[11] 胡文锦, 许兵, 史杨, 等. 飞秒激光制备高敏感度流量传感器[J]. 中国激光, 2018, 45(9): 0902001.

[12] 龙婧, 熊伟, 刘莹, 等. 基于飞秒激光直写的三维高定向碳纳米管组装[J]. 中国激光, 2017, 44(1): 0102003.

[13] Sato Y, Tsukamoto M, Shinonaga T, et al. Femtosecond laser-induced periodic nanostructure creation on PET surface for controlling of cell spreading[J]. Applied Physics A, 2016, 122(3): 184-186.

[14] Baumgart J, Humbert L, Boulais É, et al. Off-resonance plasmonic enhanced femtosecond laser optoporation and transfection of cancer cells[J]. Biomaterials, 2012, 33(7): 2345-2350.

[15] Xu H L, Cheng Y, Chin S L, et al. Femtosecond laser ionization and fragmentation of molecules for environmental sensing[J]. Laser & Photonics Reviews, 2015, 9(3): 275-293.

[16] Gamaly E G, Rode A V, Luther-Davies B, et al. Ablation of solids by femtosecond lasers: ablation mechanism and ablation thresholds for metals and dielectrics[J]. Physics of Plasmas, 2002, 9(3): 949-957.

[17] Bonse J, Krüger J. Probing the heat affected zone by chemical modifications in femtosecond pulse laser ablation of titanium nitride films in air[J]. Journal of Applied Physics, 2010, 107(5): 054902.

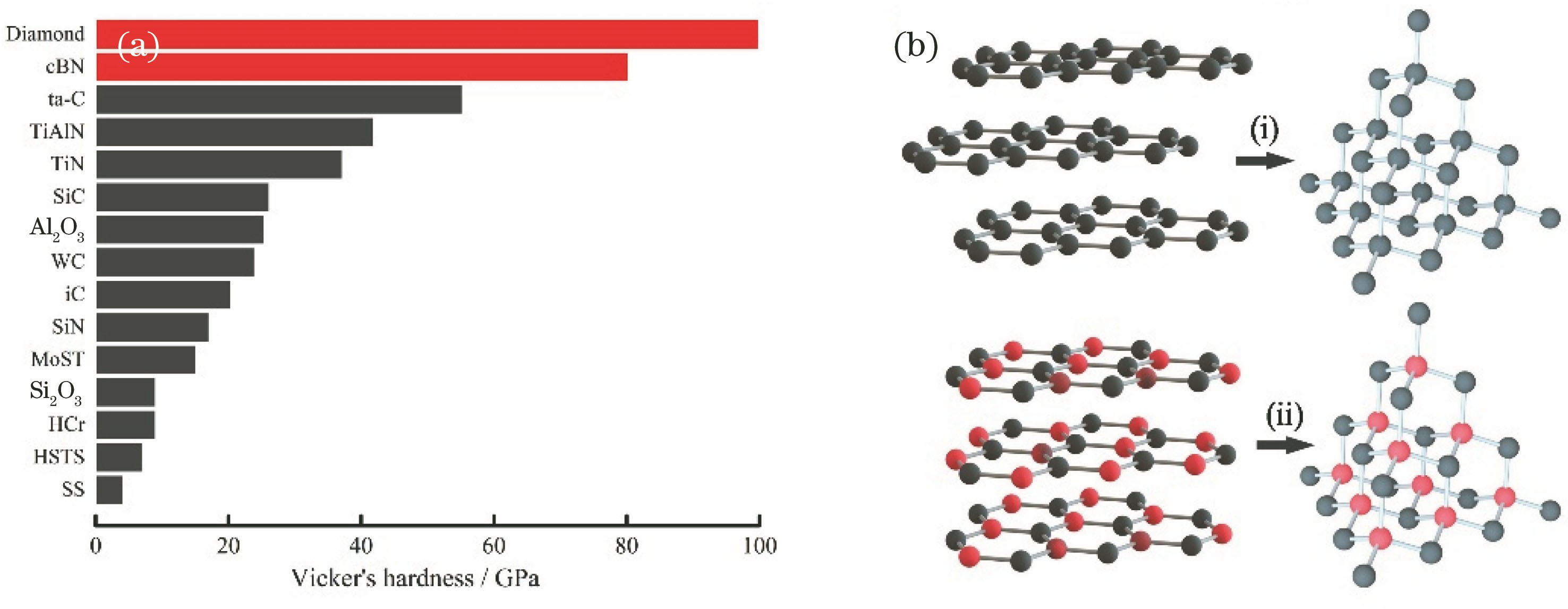

[18] RiedelR,[\s]{1}WiehlL,[\s]{1}ZerrA,[\s]{1}et[\s]{1}al.[\s]{1}Superhard[\s]{1}materials[M][\s]{1}∥[\s]{1}Dronskowski[\s]{1}R,[\s]{1}Kikkawa[\s]{1}S,[\s]{1}Stein[\s]{1}A.[\s]{1}Handbook[\s]{1}of[\s]{1}solid[\s]{1}state[\s]{1}chemistry.[\s]{1}Weinhein:[\s]{1}Wiley-VCH[\s]{1}Verlag[\s]{1}GmbH[\s]{1}&[\s]{1}Co.[\s]{1}KGaA,[\s]{1}2017:[\s]{1}175-[\s]{1}200.[\s]{1}

[19] Phaal C. Surface studies of diamond[J]. Industrial Diamond Review, 1965: 486-489.

[20] Sawaoka A. Boron nitride: structural changes by shock compression and preparation of superhard compacts by very high pressure sintering[J]. American Ceramic Society Bulletin, 1983, 62(12): 1379-1383.

[21] Tan D Z, Sharafudeen K N, Yue Y Z, et al. Femtosecond laser induced phenomena in transparent solid materials: fundamentals and applications[J]. Progress in Materials Science, 2016, 76: 154-228.

[22] SugiokaK,[\s]{1}MeunierM,[\s]{1}PiquéA.[\s]{1}Laser[\s]{1}precision[\s]{1}microfabrication[M].[\s]{1}Berlin:[\s]{1}Springer,[\s]{1}2010.[\s]{1}

[23] Mikhail[\s]{1}R.[\s]{1}Selecting[\s]{1}industrial[\s]{1}laser[\s]{1}optics[J/OL].[\s]{1}Vision[\s]{1}Spectra,[\s]{1}2014-07[2019-02-15].[\s]{1}https:∥www.photonics.com/Articles/Selecting_Industrial_Laser_Optics/a55750.

[24] Konov V I. Laser in micro and nanoprocessing of diamond materials[J]. Laser & Photonics Reviews, 2012, 6(6): 739-766.

[25] Wu M T, Guo B, Zhao Q L, et al. The influence of the ionization regime on femtosecond laser beam machining mono-crystalline diamond[J]. Optics & Laser Technology, 2018, 106: 34-39.

[26] Liu N. Processing of back surface of Si wafers with a pulsed Nd∶YAG laser[J]. Journal of Laser Micro/ Nanoengineering, 2016, 11(2): 232-238.

[27] 李智华, 范敬钦, 李普年, 等. 能量累积效应对飞秒激光诱导表面周期结构的影响[J]. 中国激光, 2010, 37(1): 68-73.

[28] Liang J C, Liu W D, Li Y, et al. A model to predict the ablation width and calculate the ablation threshold of femtosecond laser[J]. Applied Surface Science, 2018, 456: 482-486.

[29] Nathala C S R, Ajami A, Husinsky W, et al. . Ultrashort laser pulse ablation of copper, silicon and gelatin: effect of the pulse duration on the ablation thresholds and the incubation coefficients[J]. Applied Physics A, 2016, 122: 107.

[30] Forster M, Huber C, Armbruster O, et al. 50-nanometer femtosecond pulse laser induced periodic surface structures on nitrogen-doped diamond[J]. Diamond and Related Materials, 2017, 74: 114-118.

[31] Kononenko V V, Kononenko T V, Pimenov S M, et al. Effect of the pulse duration on graphitisation of diamond during laser ablation[J]. Quantum Electronics, 2005, 35(3): 252-256.

[32] 董志伟, 张伟斌, 郑立威, 等. 利用飞秒激光和纳秒激光脉冲加工金刚石[J]. 红外与激光工程, 2015, 44(3): 893-896.

[33] Wu B Y, Deng L M, Liu P, et al. Effects of picosecond laser repetition rate on ablation of Cr12MoV cold work mold steel[J]. Applied Surface Science, 2017, 409: 403-412.

[34] Park C, Farson D F. Precise machining of disk shapes from thick metal substrates by femtosecond laser ablation[J]. The International Journal of Advanced Manufacturing Technology, 2016, 83: 2049-2056.

[35] 叶地发, 刘杰. 飞秒强激光场中的原子、分子: 非微扰现象研究[J]. 物理, 2009, 38(12): 908-913.

Ye D F, Liu J. Nonperturbative phenomena of atoms and molecules irradiated by ultra-strong femtosecond laser pulses[J]. Physics, 2009, 38(12): 908-913.

[36] KönigK,[\s]{1}OstendorfA.[\s]{1}Optically[\s]{1}induced[\s]{1}nanostructures:[\s]{1}biomedical[\s]{1}and[\s]{1}technical[\s]{1}applications[M].[\s]{1}Berlin,[\s]{1}München,[\s]{1}Boston:[\s]{1}Walter[\s]{1}de[\s]{1}Gruyter[\s]{1}GmbH,[\s]{1}2015:[\s]{1}50-[\s]{1}51.[\s]{1}

[37] Wang J, Wang C H, Liu Y S, et al. Microstructure and chemical bond evolution of diamond-like carbon films machined by femtosecond laser[J]. Applied Surface Science, 2015, 340: 49-55.

[38] Liu X, Du D, Mourou G. Laser ablation and micromachining with ultrashort laser pulses[J]. IEEE Journal of Quantum Electronics, 1997, 33(10): 1706-1716.

[39] HiranoM,[\s]{1}Kawamura[\s]{1}KI,[\s]{1}Hosono[\s]{1}H.[\s]{1}Encoding[\s]{1}of[\s]{1}holographic[\s]{1}grating[\s]{1}and[\s]{1}periodic[\s]{1}nano-structure[\s]{1}by[\s]{1}femtosecond[\s]{1}laser[\s]{1}pulse[J].[\s]{1}Applied[\s]{1}Surface[\s]{1}Science,[\s]{1}2002,[\s]{1}197/198:[\s]{1}688-[\s]{1}698.[\s]{1}

[40] Wulz T, Canfield B K, Davis L M, et al. Pulsed femtosecond-laser machining and deep reactive ion etching of diamond[J]. Diamond and Related Materials, 2017, 74: 108-113.

[41] 梁德志, 王敏, 杜晨林, 等. 飞秒激光背部湿刻石英玻璃微通道的研究[J]. 激光技术, 2017, 41(2): 174-177.

[42] Qin[\s]{1}SJ,[\s]{1}Li[\s]{1}W[\s]{1}J.[\s]{1}Process[\s]{1}characterization[\s]{1}of[\s]{1}fabricating[\s]{1}3D[\s]{1}micro[\s]{1}channel[\s]{1}systems[\s]{1}by[\s]{1}laser-micromachining[J].[\s]{1}Sensors[\s]{1}and[\s]{1}Actuators[\s]{1}A:Physical,[\s]{1}2002,[\s]{1}97/98:[\s]{1}749-[\s]{1}757.[\s]{1}

[43] Chen L, Zhang P, Chen J X, et al. Influence of processing parameters on the structure size of microchannel processed by femtosecond laser[J]. Optics & Laser Technology, 2018, 106: 47-51.

[44] Zhao Q L, Jiang T, Dong Z W, et al. Ablation threshold and material removal mechanisms of SiC processed by femtosecond laser[J]. Journal of Mechanical Engineering, 2010, 46(21): 172-177.

[45] Zhang P, Chen L, Chen J X, et al. Material removal effect of microchannel processing by femtosecond laser[J]. Optics and Lasers in Engineering, 2017, 98: 69-75.

[46] Ogawa Y, Ota M, Nakamoto K, et al. A study on machining of binder-less polycrystalline diamond by femtosecond pulsed laser for fabrication of micro milling tools[J]. CIRP Annals, 2016, 65(1): 245-248.

[47] Chen J Y, Jin T Y, Tian Y J. Development of an ultrahard nanotwinned CBN micro tool for cutting hardened steel[J]. Science China Technological Sciences, 2016, 59(6): 876-881.

[48] Yin J, Chen G Y, Xiong B, et al. Femtosecond pulsed laser fabrication of a novel SCD grinding tool with positive rake angle[J]. Applied Physics A, 2018, 124: 859.

[49] 熊彪, 陈根余, 殷赳, 等. 飞秒激光加工单晶金刚石锥形阵列的试验研究[J]. 应用激光, 2018, 38(2): 270-277.

[50] 黄建衡, 梁国文, 李冀, 等. 飞秒激光制备多晶金刚石微结构阵列[J]. 中国激光, 2017, 44(3): 0302007.

[51] Li G, Feng G Y, Wang S T, et al. Femtosecond laser assisted fabrication of networked semi-occlusive microfluidic channel on fused silica glass surface[J]. Optik, 2017, 140: 953-958.

[52] Wang F, Shan C, Yan J P, et al. Application of femtosecond laser technique in single crystal diamond film separation[J]. Diamond and Related Materials, 2016, 63: 69-74.

[53] Liu X Q, Chen Q D, Guan K M, et al. Dry-etching-assisted femtosecond laser machining[J]. Laser & Photonics Reviews, 2017, 11(3): 1600115.

[54] 姜俊, 刘晋桥, 徐颖, 等. 曲面基底衍射光学元件的激光直写技术[J]. 中国激光, 2017, 44(6): 0602002.

[55] Hoppius[\s]{1}JS,[\s]{1}MaragkakiS,[\s]{1}KanitzA,[\s]{1}et[\s]{1}al.[\s]{1}Optimization[\s]{1}of[\s]{1}femtosecond[\s]{1}laser[\s]{1}processing[\s]{1}in[\s]{1}liquids[J].[\s]{1}Applied[\s]{1}Surface[\s]{1}Science,[\s]{1}2019,[\s]{1}467/468:[\s]{1}255-[\s]{1}260.[\s]{1}

[56] Jia X, Dong L L. Fabrication of complex micro/nanopatterns on semiconductors by the multi-beam interference of femtosecond laser[J]. Physics Procedia, 2014, 56: 1059-1065.

[57] Simmonds R D, Salter P S, Jesacher A, et al. Three dimensional laser microfabrication in diamond using a dual adaptive optics system[J]. Optics Express, 2011, 19(24): 24122-24128.

[58] Murphy S A, Booth M, Li L, et al. Laser processing in 3D diamond detectors[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2017, 845: 136-138.

[59] Mathis A, Courvoisier F, Froehly L, et al. Micromachining along a curve: femtosecond laser micromachining of curved profiles in diamond and silicon using accelerating beams[J]. Applied Physics Letters, 2012, 101(7): 071110.

[60] 饶生龙, 吴培超, 张晨初, 等. 基于空间光调制器的能量可控飞秒激光加工[J]. 中国激光, 2017, 44(1): 0102008.

[61] 吴培超, 张晨初, 杨亮, 等. 基于空间光调制器的飞秒激光双模式快速加工[J]. 中国激光, 2018, 45(10): 1001005.

[62] O'Keeffe K. Robinson T, Hooker S M. Generation and control of chirped, ultrafast pulse trains[J]. Journal of Optics, 2010, 12(1): 015201.

[63] Mills B, Feinaeugle M, Sones L, et al. Sub-micron-scale femtosecond laser ablation using a digital micromirror device[J]. Journal of Micromechanics and Microengineering, 2013, 23(3): 035005.

[64] Mills B, Heath D J, Feinaeugle M, et al. Laser ablation via programmable image projection for submicron dimension machining in diamond[J]. Journal of Laser Applications, 2014, 26(4): 041501.

[65] Aharonovich I, Greentree A D, Prawer S. Diamond photonics[J]. Nature Photonics, 2011, 5(7): 397-405.

[66] Kononenko T V, Komlenok M S, Pashinin V P, et al. Femtosecond laser microstructuring in the bulk of diamond[J]. Diamond and Related Materials, 2009, 18(2/3): 196-199.

[67] Takayama N, Yan J W. Mechanisms of micro-groove formation on single-crystal diamond by a nanosecond pulsed laser[J]. Journal of Materials Processing Technology, 2017, 243: 299-311.

[68] 乔玲玲, 储蔚, 王哲, 等. 基于整形飞秒激光脉冲的三维微纳制备[J]. 光学学报, 2019, 39(1): 0126012.

[69] Polikarpov M, Snigireva I, Morse J, et al. Large-acceptance diamond planar refractive lenses manufactured by laser cutting[J]. Journal of Synchrotron Radiation, 2015, 22(1): 23-28.

[70] Kononenko T V, Ralchenko V G, Ashkinazi E E, et al. Fabrication of polycrystalline diamond refractive X-ray lens by femtosecond laser processing[J]. Applied Physics A, 2016, 122: 152.

[71] 徐世珍, 宋文亮, 祖小涛. 金刚石表面飞秒激光直写微米石墨线[J]. 实验室研究与探索, 2016, 35(4): 52-54.

Xu S Z, Song W L, Zu X T. Study of graphite line micromachining on diamond surface by femtosecond laser direct writing[J]. Research and Exploration in Laboratory, 2016, 35(4): 52-54.

[72] Robertson J. Amorphous carbon[J]. Advances in Physics, 1986, 35(4): 317-374.

[73] Robertson J. Diamond-like amorphous carbon[J]. Materials Science and Engineering: R: Reports, 2002, 37(4/5/6): 129-281.

[74] Milne W I. Electronic devices from diamond-like carbon[J]. Semiconductor Science and Technology, 2003, 18(3): S81-S85.

[75] Yasumaru N, Miyazaki K, Kiuchi J. Femtosecond-laser-induced nanostructure formed on hard thin films of TiN and DLC[J]. Applied Physics A: Materials Science & Processing, 2003, 76(6): 983-985.

[76] Yasumaru N, Miyazaki K, Kiuchi J. Control of tribological properties of diamond-like carbon films with femtosecond-laser-induced nanostructuring[J]. Applied Surface Science, 2008, 254(8): 2364-2368.

[77] Pimenov S M, Jaeggi B, Neuenschwander B, et al. Femtosecond laser surface texturing of diamond-like nanocomposite films to improve tribological properties in lubricated sliding[J]. Diamond and Related Materials, 2019, 93: 42-49.

[78] Zavedeev E V, Zilova O S, Barinov A D, et al. Femtosecond laser microstructuring of diamond-like nanocomposite films[J]. Diamond and Related Materials, 2017, 74: 45-52.

[79] Nikaido S, Natori T, Saito R, et al. Nanostructure formation on diamond-like carbon films induced with few-cycle laser pulses at low fluence from a Ti∶sapphire laser oscillator[J]. Nanomaterials, 2018, 8(7): 535.

[81] Revel P, Jouini N, Thoquenne G, et al. High precision hard turning of AISI 52100 bearing steel[J]. Precision Engineering, 2016, 43: 24-33.

[82] 靳田野, 陈俊云, 王金虎, 等. 纳米孪晶立方氮化硼的飞秒激光材料去除机理[J]. 机械工程学报, 2019, 55(9): 198-205.

Jin T Y, Chen J Y, Wang J H, et al. Material removal mechanism of nanotwinned cubic boron nitride by femtosecond laser ablation[J]. Journal of Mechanical Engineering, 2019, 55(9): 198-205.

[83] Voevodin A A, Zabinski J S. Supertough wear-resistant coatings with ‘chameleon’ surface adaptation[J]. Thin Solid Films, 2000, 370(1/2): 223-231.

[84] Voevodin A A, Fitz T A, Hu J J, et al. Nanocomposite tribological coatings with “chameleon” surface adaptation[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2002, 20(4): 1434-1444.

[85] Voevodin[\s]{1}AA,[\s]{1}Shtansky[\s]{1}DV,[\s]{1}Levashov[\s]{1}EA,[\s]{1}et[\s]{1}al.[\s]{1}Nanostructured[\s]{1}thin[\s]{1}films[\s]{1}and[\s]{1}nanodispersion[\s]{1}strengthened[\s]{1}coatings[M].[\s]{1}Dordrecht:[\s]{1}Springer,[\s]{1}2004:[\s]{1}1-[\s]{1}8.[\s]{1}

[86] Sugihara T, Enomoto T. Development of a cutting tool with a nano/micro-textured surface: improvement of anti-adhesive effect by considering the texture patterns[J]. Precision Engineering, 2009, 33(4): 425-429.

[87] Sugihara T, Enomoto T. Improving anti-adhesion in aluminum alloy cutting by micro stripe texture[J]. Precision Engineering, 2012, 36(2): 229-237.

[88] Sugihara T, Enomoto T. Crater and flank wear resistance of cutting tools having micro textured surfaces[J]. Precision Engineering, 2013, 37(4): 888-896.

[89] Sugihara T, Tanaka H, Enomoto T. Development of novel CBN cutting tool for high speed machining of inconel 718 focusing on coolant behaviors[J]. Procedia Manufacturing, 2017, 10: 436-442.

[90] Voevodin A A, Zabinski J S. Laser surface texturing for adaptive solid lubrication[J]. Wear, 2006, 261(11/12): 1285-1292.

[91] Basnyat P, Luster B, Muratore C, et al. Surface texturing for adaptive solid lubrication[J]. Surface and Coatings Technology, 2008, 203(1/2): 73-79.

[92] 杨奇彪, 肖晨光, 陈中培, 等. 激光诱导氧化铝陶瓷刀具的表面浸润性[J]. 激光与光电子学进展, 2017, 54(10): 101401.

[93] 杨奇彪, 陈中培, 杨涛, 等. 飞秒激光加工YG6不同微织构表面浸润性研究[J]. 激光与光电子学进展, 2018, 55(9): 091404.

[94] Shaw[\s]{1}MC,[\s]{1}Cookson[\s]{1}JO.[\s]{1}Metal[\s]{1}cutting[\s]{1}principles[M].[\s]{1}2nd[\s]{1}ed.[\s]{1}New[\s]{1}York:[\s]{1}Oxford[\s]{1}University[\s]{1}Press,[\s]{1}2005.[\s]{1}

魏超, 马玉平, 韩源, 张遥, 陈雪辉. 飞秒激光加工超硬材料的研究进展[J]. 激光与光电子学进展, 2019, 56(19): 190003. Chao Wei, Yuping Ma, Yuan Han, Yao Zhang, Xuehui Chen. Femtosecond Laser Processing of Ultrahard Materials[J]. Laser & Optoelectronics Progress, 2019, 56(19): 190003.