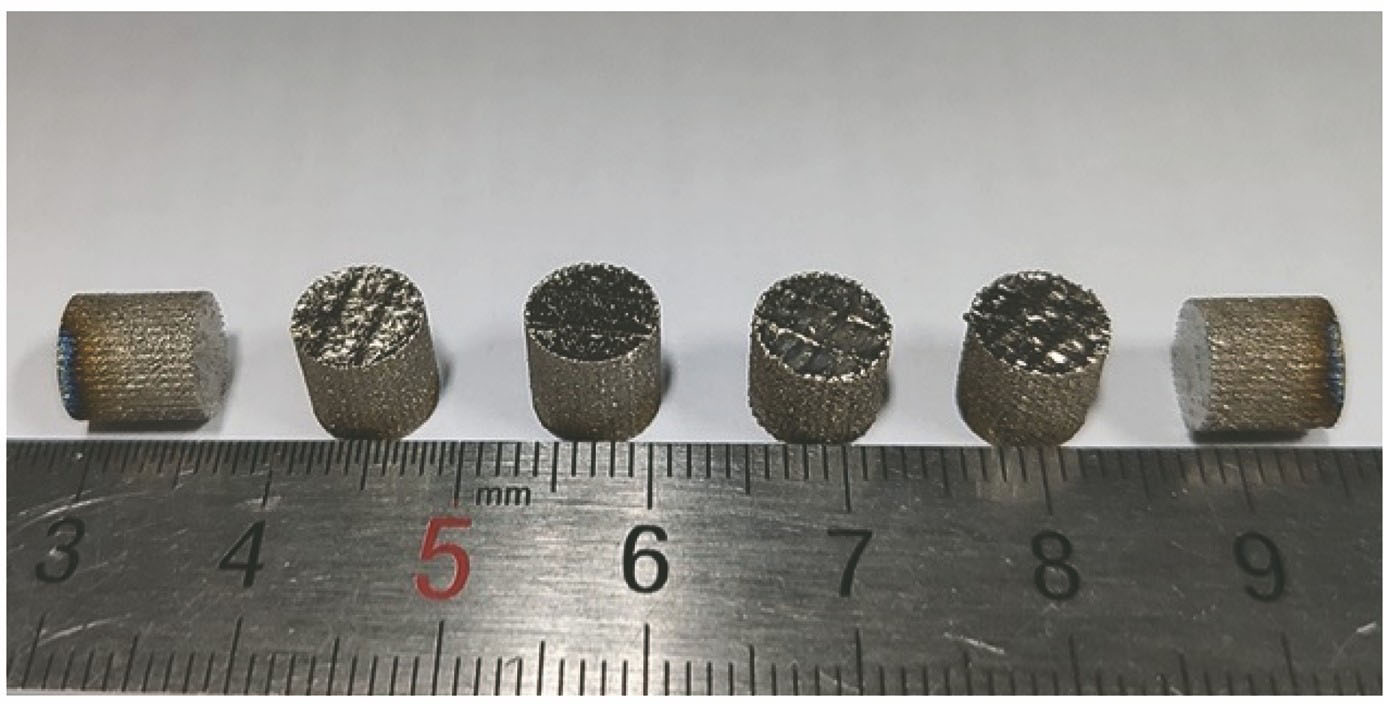

激光选区熔化成形Ti-5%TiN复合材料在Hank溶液中的电化学腐蚀性能  下载: 1129次

下载: 1129次

赵宇, 宋振明, 金剑波, 谢敏, 赵淑珍, 周圣丰. 激光选区熔化成形Ti-5%TiN复合材料在Hank溶液中的电化学腐蚀性能[J]. 中国激光, 2019, 46(9): 0902005.

Zhao Yu, Song Zhenming, Jin Jianbo, Xie Min, Zhao Shuzhen, Zhou Shengfeng. Electrochemical Corrosion Properties of Ti-5%TiN Composites Formed by Selective Laser Melting in Hank''''s Solution[J]. Chinese Journal of Lasers, 2019, 46(9): 0902005.

[1] Obadele B A, Olubambi P A, Andrews A, et al. Electrochemical behaviour of laser-clad Ti6Al4V with CP Ti in 0.1 M oxalic acid solution[J]. Journal of Alloys and Compounds, 2015, 646: 753-759.

[2] 孙荣禄, 刘勇, 杨德庄. 钛合金表面激光熔覆NiCrBSi-TiC复合涂层的组织和摩擦磨损性能[J]. 中国激光, 2003, 30(7): 659-662.

[4] 杨光, 何帅, 钦兰云, 等. WC颗粒增强钛基复合涂层的组织和高温磨损性能研究[J]. 应用激光, 2013, 33(4): 365-369.

[6] Maja M E, Falodun O E, Obadele B A, et al. Nanoindentation studies on TiN nanoceramic reinforced Ti-6Al-4V matrix composite[J]. Ceramics International, 2018, 44(4): 4419-4425.

[7] RomeroF, AmigóV, Salvador MD, et al. Mechanical and microstructural properties of titanium matrix composites reinforced by TiN particles[J]. Materials Science Forum, 2007, 534/535/536: 825- 828.

[12] Attar H, Ehtemam-Haghighi S, Kent D, et al. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes[J]. Materials Science and Engineering: A, 2017, 705: 385-393.

[13] Bose S, Pathak L C, Singh R. Response of boride coating on the Ti-6Al-4V alloy to corrosion and fretting corrosion behavior in Ringer's solution for bio-implant application[J]. Applied Surface Science, 2018, 433: 1158-1174.

[14] 李俊峰, 魏正英, 卢秉恒. 钛及钛合金激光选区熔化技术的研究进展[J]. 激光与光电子学进展, 2018, 55(1): 011403.

[15] 赵淑珍, 金剑波, 谢敏, 等. 扫描速率对激光熔覆Cu80Fe20偏晶涂层组织与耐磨性能的影响[J]. 中国激光, 2019, 46(3): 0302005.

[21] Wu B T, Pan Z X, Li S Y, et al. The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution[J]. Corrosion Science, 2018, 137: 176-183.

[22] Jovic V D, Barsoum M W. Corrosion behavior and passive film characteristics formed on Ti, Ti3SiC2, and Ti4AlN3 in H2SO4 and HCl[J]. Journal of the Electrochemical Society, 2004, 151(2): B71-B76.

赵宇, 宋振明, 金剑波, 谢敏, 赵淑珍, 周圣丰. 激光选区熔化成形Ti-5%TiN复合材料在Hank溶液中的电化学腐蚀性能[J]. 中国激光, 2019, 46(9): 0902005. Zhao Yu, Song Zhenming, Jin Jianbo, Xie Min, Zhao Shuzhen, Zhou Shengfeng. Electrochemical Corrosion Properties of Ti-5%TiN Composites Formed by Selective Laser Melting in Hank''''s Solution[J]. Chinese Journal of Lasers, 2019, 46(9): 0902005.