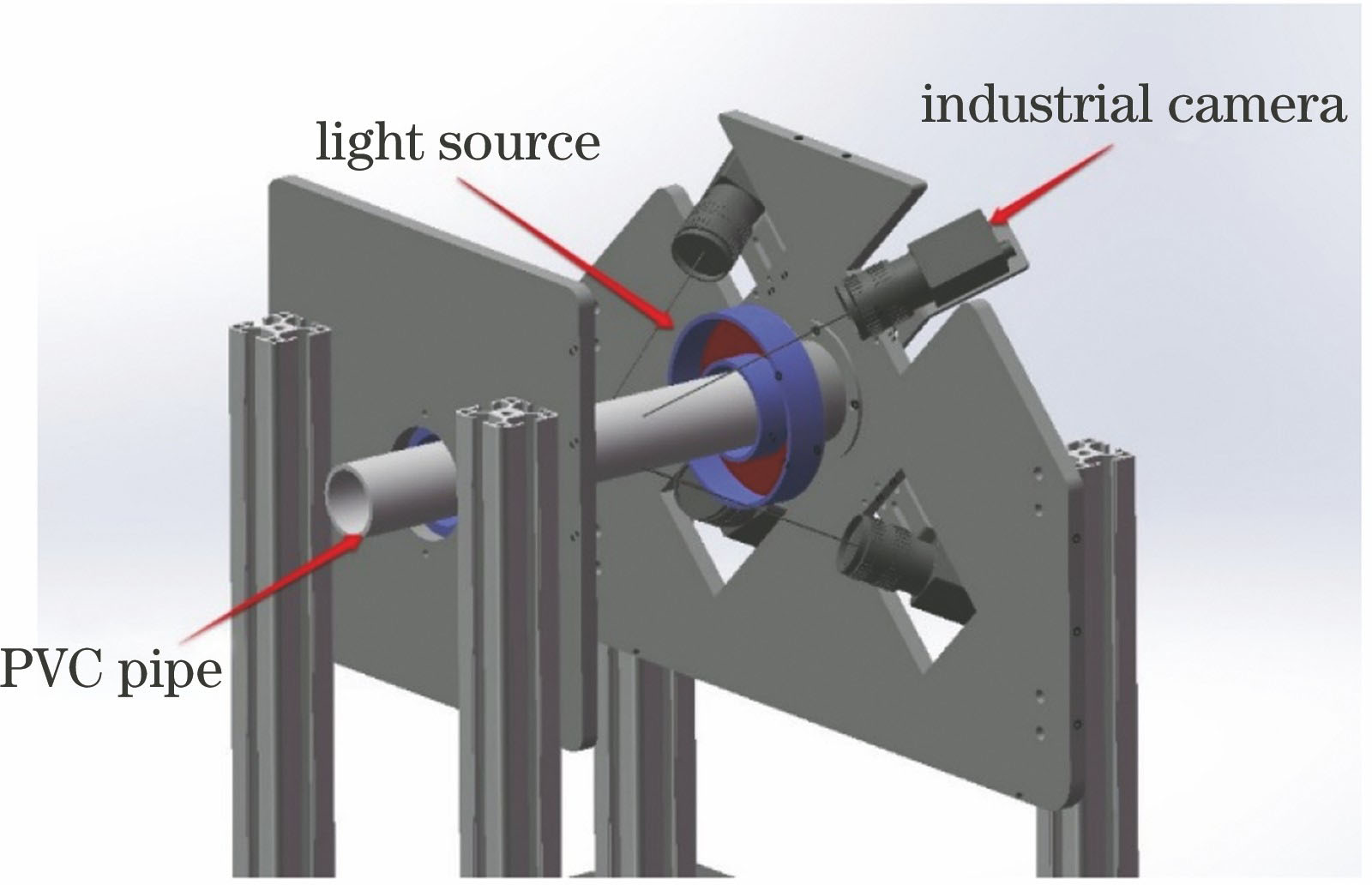

基于机器视觉的聚氯乙烯管材表面缺陷检测  下载: 1254次

下载: 1254次

李书华, 周亚同, 王丹, 何静飞, 张忠伟. 基于机器视觉的聚氯乙烯管材表面缺陷检测[J]. 激光与光电子学进展, 2019, 56(13): 131006.

Shuhua Li, Yatong Zhou, Dan Wang, Jingfei He, Zhongwei Zhang. Surface Defect Detection of Polyvinyl Chloride Pipes Based on Machine Vision[J]. Laser & Optoelectronics Progress, 2019, 56(13): 131006.

[1] 李成吾, 左继成. 国内外PVC管技术现状及发展方向[J]. 当代化工, 2015, 44(4): 711-714.

[2] 卢荣胜, 吴昂, 张腾达, 视觉, 等. 检测技术及其在缺陷检测中的应用综述[J]. 光学学报, 2018, 38(8): 0815002.

[3] 苑玮琦, 李绍丽, 李德健. 基于纹理主、旁瓣特征的雪糕棒裂缝缺陷检测[J]. 仪器仪表学报, 2017, 38(11): 2779-2787.

[4] 李克斌, 余厚云, 周申江. 基于形态学特征的机械零件表面划痕检测[J]. 光学学报, 2018, 38(8): 0815127.

[9] Hu G H, Wang Q H. Fabric defect detection via un-decimated wavelet decomposition and Gumbel distribution model[J]. Journal of Engineered Fibers and Fabrics, 2018, 13(1): 15-32.

[10] 王庆香, 李迪, 张舞杰, 等. 软性电路板金面缺陷的无监督检测[J]. 光学精密工程, 2010, 18(4): 981-987.

[11] 王泽润, 方益明, 冯海林, 等. 木材节子缺陷检测与定位方法[J]. 激光与光电子学进展, 2018, 55(5): 051501.

[13] 陈广锋, 管观洋, 魏鑫. 基于机器视觉的冲压件表面缺陷在线检测研究[J]. 激光与光电子学进展, 2018, 55(1): 011501.

[14] 马艳. 边缘检测技术在PVC型材产品检测中的应用研究[D]. 杭州: 浙江工业大学, 2004: 19- 27.

MaY. The application research of PVC product inspection by edge detection[D]. Hangzhou: Zhejiang University of Technology, 2004: 19- 27.

[15] 龙晓薇. 基于图像视觉的PVC表面缺陷检测方法及应用[D]. 长沙: 中南大学, 2007: 9- 19.

Long XW. PVC surface defect detection method based on image vision and application[D]. Changsha: Central South University, 2007: 9- 19.

[16] 龙晓薇, 阳春华, 龙永红. PVC建材表面缺陷检测系统研究与设计[J]. 计算技术与自动化, 2010, 29(2): 46-50.

[18] Prabuwono AS, SulaimanR, Hamdan AR, et al. Development of intelligent visual inspection system (IVIS) for bottling machine[C]∥TENCON 2006 - 2006 IEEE Region 10 Conference, November 14-17,2006, Hong Kong, China. New York: IEEE, 2006: 343887.

[19] 张铮, 王艳萍, 薛桂香. 数字图像处理与机器视觉: Visual C++与Matlab实现[M]. 2版. 北京: 人民邮电出版社, 2014: 70- 72.

ZhangZ, Wang YP, Xue GX. Digital image processing and machine vision: implementation of Visual C++ and Matlab[M]. 2nd ed. Beijing: Posts and Telecommunications Press, 2014: 70- 72.

[20] 蒋笑笑, 张振军, 王耀南, 等. 基于灰度投影梯度扩散的PET满瓶快速检测[J]. 电子测量与仪器学报, 2016, 30(8): 1152-1159.

[21] 高红波, 王卫星. 一种二值图像连通区域标记的新算法[J]. 计算机应用, 2007, 27(11): 2776-2777, 2785.

李书华, 周亚同, 王丹, 何静飞, 张忠伟. 基于机器视觉的聚氯乙烯管材表面缺陷检测[J]. 激光与光电子学进展, 2019, 56(13): 131006. Shuhua Li, Yatong Zhou, Dan Wang, Jingfei He, Zhongwei Zhang. Surface Defect Detection of Polyvinyl Chloride Pipes Based on Machine Vision[J]. Laser & Optoelectronics Progress, 2019, 56(13): 131006.