光电工程, 2022, 49 (12): 220120, 网络出版: 2023-01-17

镍基合金薄板激光焊接研究进展

Research progress in laser welding of Nickel-based alloy sheet

镍基合金 激光焊接 微观组织 力学性能和耐腐蚀性能 焊接变形 nickel-based alloy laser welding microstructure mechanical properties and corrosion resistance welding deformation

摘要

随着航空航天、能源动力和石油化工等领域的快速发展,镍基合金薄板焊接技术成为决定核心零部件使用性能的关键因素之一。镍基合金薄板焊接对热输入敏感,易出现元素偏析、脆性相析出导致焊缝性能降低及产生焊接变形等问题。本文介绍了镍基合金薄板激光焊接技术的研究进展,分别总结了镍基合金薄板的激光自熔焊接和激光填丝焊接两种焊接技术下的焊缝微观组织演变、力学性能和耐腐蚀性能变化以及焊接变形规律,提出了未来研究应重点考虑对焊缝微观组织的预测,并结合先进的算法,提出微观组织、力学性能和耐腐蚀性能的自适应调控策略,进而开发出新型智能化焊接工艺。

Abstract

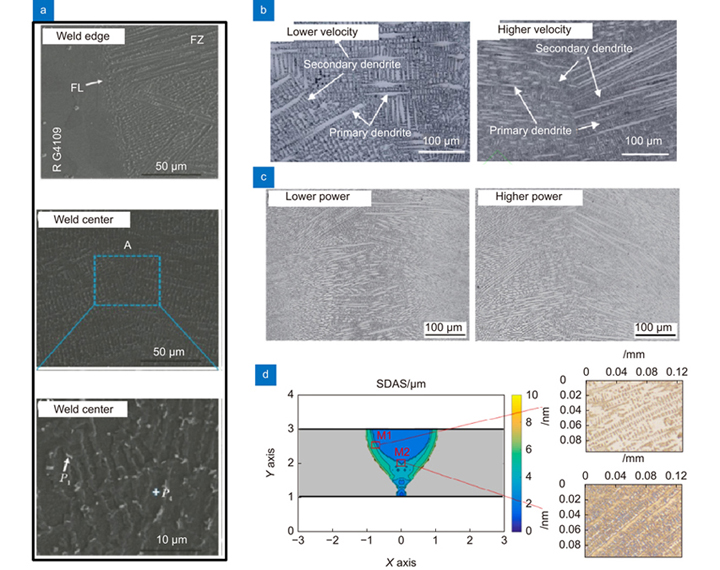

Overview: With the rapid development of aerospace, energy power, petrochemical, and other fields, nickel-based alloy sheet welding technology has become one of the key factors determining the performance of core components. The welding of nickel base alloy sheet is sensitive to the heat input, and it is easy to cause element segregation and brittle phase precipitation, which will reduce the weld performance and produce welding deformation. This paper introduces the research progress of laser welding technology of nickel base alloy sheet, and summarizes the evolution of weld microstructure, changes of mechanical properties and corrosion resistance, and the rules of welding deformation under two kinds of welding technologies including laser autogenous welding and laser welding with filler wire of nickel base alloy sheet. The research of the autogenous laser welding process focuses on Ni-Cr and Ni-Cr-Mo alloys. The grain morphology and element segregation are analyzed, including refining microstructure and inhibiting the formation of precipitates, by means of adjusting the process parameters, using ultrasonic vibration, and using a low-temperature cooling process. The microhardness of the two kinds of alloy welds is better than that of base metal, because of the finer grains in the welds. Tensile strength at room temperature can reach about 90% of the base metal, but high-temperature tensile performance is comparable to the base metal. Ni-Cr alloy welded joints show good high-temperature plasticity. The relatively lower tensile strength of the welded joints is relative to the worse morphology of the weld surfaces. The fatigue properties and corrosion resistance of the Ni-Cr-Mo alloy welds are comparable to those of the base metal. The research of laser welding of nickel-based alloy sheets with filler wire focuses on the Ni-Cr-Mo alloy, and the grain morphology, element segregation, and its regulation are still the focuses of the research. The microhardness and room temperature tensile strength of the welded joints with filler wire are better than those of the base metal. The better room temperature tensile strength of the welded joints benefits from both the finer weld grains and the occurrence of the reinforcement. Corrosion tests show that the welded joints have comparable corrosion resistance to the base metal. Welding deformation of nickel-based alloy sheets includes shrinkage deformation, deflection, and angular deformation. Compare with the traditional arc welding process, laser welding shows lower heat input, and thus, it leads to smaller deformation. At present, the research of welding deformation of nickel-based alloy sheet mainly concentrates on the prediction of deformation through the finite element method and reducing deformation through process parameters adjustment, restraint intensity control, and utilizing auxiliary processes. Future research should focus on the prediction of weld microstructure and the propose of various adaptive control strategies for microstructure, mechanical properties and corrosion resistance by combining with advanced algorithms. Besides, developing new types of intelligent welding processes is also an important part.With the rapid development of aerospace, energy power, petrochemical, and other fields, nickel-based alloy sheet welding technology has become one of the key factors determining the performance of core components. The welding of nickel base alloy sheet is sensitive to the heat input, and it is easy to cause element segregation and brittle phase precipitation, which will reduce the weld performance and produce welding deformation. This paper introduces the research progress of laser welding technology of nickel base alloy sheet, and summarizes the evolution of weld microstructure, changes of mechanical properties and corrosion resistance, and the rules of welding deformation under two kinds of welding technologies including laser autogenous welding and laser welding with filler wire of nickel base alloy sheet. It is proposed that the prediction of weld microstructure should be considered in the future research, which should combine with advanced algorithms to propose the adaptive control strategy of microstructure, mechanical properties and corrosion resistance, developing a new intelligent welding process.

岳考捷, 贾晨, 王云嵩, 牛方勇, 马广义, 吴东江. 镍基合金薄板激光焊接研究进展[J]. 光电工程, 2022, 49(12): 220120. Kaojie Yue, Chen Jia, Yunsong Wang, Fangyong Niu, Guangyi Ma, Dongjiang Wu. Research progress in laser welding of Nickel-based alloy sheet[J]. Opto-Electronic Engineering, 2022, 49(12): 220120.