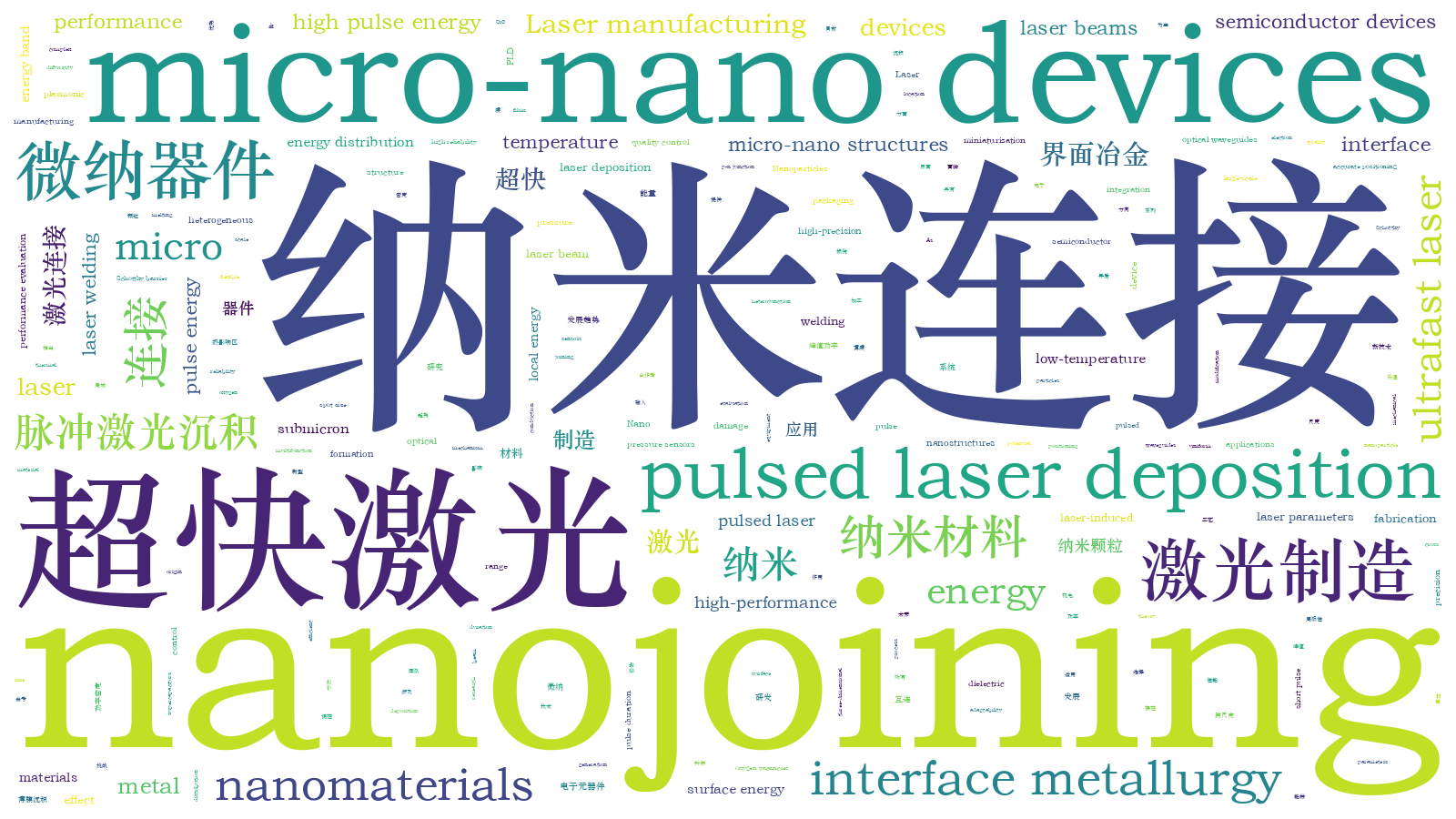

超快激光纳米连接及其在微纳器件制造中的应用  下载: 1321次

下载: 1321次

Significance With the increasing demand for the miniaturization and multifunctioning of micro/nanoelectronics and optical-electromechanical devices or systems, high-performance integration of materials at small scales is urgently needed. Nanojoining technology, which involves interconnection among low-dimension materials and even cross-dimensional nano-micro-macro materials, has shown great potential in manufacturing and developing micro-nano devices/systems.

Conventional welding/joining technologies such as ultrasonic welding, cold-pressure welding, and laser welding can be employed for the integration of diverse nanomaterials. However, to achieve high-performance and low-damage nanojoints, high-precision manipulation of input energy sources (e.g., thermal energy or laser beam) or mechanical tools (e.g., ultrasonic head or indent) is crucial in the nanojoining process, which poses great technical difficulties, thereby limiting the mass production of nanojoints and adaptability for multimaterial nanojoining. Ultrafast laser (UFL), with an extremely high pulse energy and short pulse duration, has been widely used in the precise manufacturing of a broad range of materials. Notably, a plasmonic effect, arising at the metal-dielectric interface, is a new approach to redistribute the incident optical (e.g., laser) energy with a “self-limited” effect, which is used for low-damage nanojoining. Therefore, nanojoining with UFL is promising for high-precision nanojoint formation, not only in homogeneous metal-metal structures but also in heterogeneous metal-oxide-semiconductor combinations.

Progress Local energy input within nanostructures can be redistributed because of incident laser-induced plasmonic effects (Figs.1--4). By constructing a metal-dielectric structure and simultaneously adjusting incident-laser parameters, spatial energy can be confined at local positions without the need to accurately control the spot size and spatial location of the incident laser beams. The self-limited effect of input energy contributes to the highly efficient formation of nanojoints with low damage, which permits the fabrication of complex micro-nano structures.

The interface structure of a nanojoint determines the electronic band diagram and thereby affects the electron transportation at the junction (Figs. 5 and 6). As indicated, a highly defective region with a large number of oxygen vacancies will be formed at a metal-oxide heterojunction after UFL nanojoining, which can reduce the Schottky barrier, thereby facilitating the origin and conduction of electrons at the junction. Based on this, high-performance heterojunctions with a variety of material combinations have been successfully achieved using UFL nanojoining technology. By regulating the interface structures, our team has developed several electronic nanodevices, which shows that UFL is promising for high-precise nanodevice fabrication and performance modification.

In addition, pulsed laser deposition (PLD) based on UFL developed by our group provides an alternative approach for low-temperature nanojoining (Figs.7--11). Nanoparticles fabricated via PLD possess high surface energy and fast diffusivity, which will be combined to form a connection layer composed of submicron particles. Therefore, the melting point will be close to that of bulk silver, which could be used for “low-temperature nanojoining and high-temperature service”. These UFL-deposited metal/alloy nanoparticle films have been successfully used for large-scale packaging of SiC wafers, which is expected to be widely used in the packaging of third-generation semiconductor devices that require high-temperature service and high reliability.

Accordingly, functional micro-nano devices can be fabricated based on the UFL nanojoining technology (Figs.12--19). We have developed several micro-nano devices by nanojoining nanomaterials at diverse scales, which will be used in devices such as optical waveguides, multilevel memristors, rectifier units, field-effect transistors, p-n junction units, supercapacitors, and flexible pressure sensors. This implies that the UFL nanojoining is promising for constructing basic micro-nano device units and is conducive to realizing multifunction device miniaturization.

Conclusion and Prospect UFL nanojoining is a vital way for micro-nano device fabrication. The local energy distribution within nanostructures can be well controlled, and the energy band diagram of the heterogeneous interface can be modified by interface metallurgy. In addition, low-temperature nanojoining can be realized using PLD based on UFL. The UFL nanojoining technology can be used to fabricate many micro-nano devices and has been proven to achieve excellent performance. Further research in the aspects of accurate positioning of three-dimensional structures, uniform fabrication of micro-nano patterns, common mechanism and quality control of heterogeneous interface formation, mass production, reliable performance evaluation, special equipment for nanojoining, and engineering applications will enrich and perfect nanojoining theory and technology, thereby permitting a broad range of applications in advanced micro-nano fabrications in various fields.

邹贵生, 林路禅, 肖宇, 邓钟炀, 贾强, 冯斌, 王文淦, 邢松龄, 任辉, 沈道智, 刘磊. 超快激光纳米连接及其在微纳器件制造中的应用[J]. 中国激光, 2021, 48(15): 1502001. Guisheng Zou, Luchan Lin, Yu Xiao, Zhongyang Deng, Qiang Jia, Bin Feng, Wengan Wang, Songling Xing, Hui Ren, Daozhi Shen, Lei Liu. Ultrafast Laser Nanojoining and Its Applications in the Manufacturing of Micro-Nano Devices[J]. Chinese Journal of Lasers, 2021, 48(15): 1502001.