基于改进灰度重心法的轨道扣件重构与故障诊断【增强内容出版】

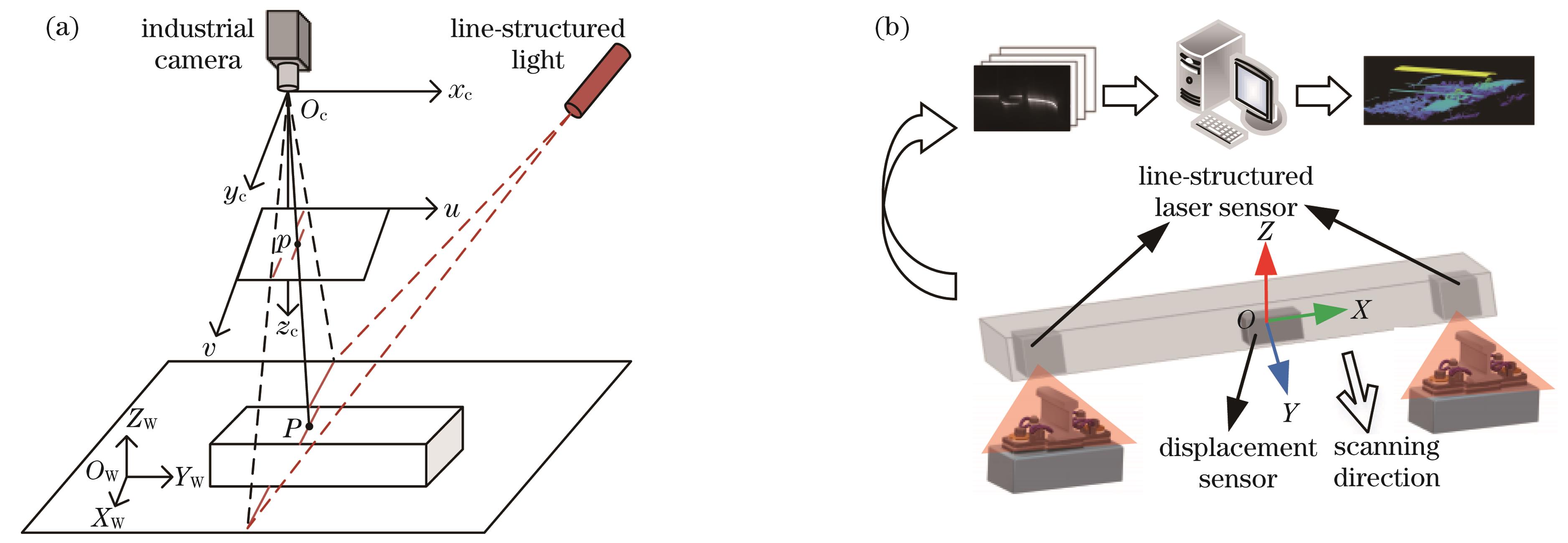

The status detection of track fasteners is an important task in railway facility inspection and maintenance. Fastener failures mainly manifest in defects such as missing, damage, incorrect installation of fastener components, and looseness of fasteners. Faulty fasteners can cause changes in track parameters, posing significant safety hazards. Therefore, strengthening the status detection of track fasteners has important practical significance for ensuring the safe operation of trains. At present, many researchers have conducted fault diagnosis research on fastener status based on 2D and 3D images. The fault detection of fasteners based on 2D images is greatly affected by factors such as lighting conditions, environmental background, and the ability to identify small defects in fasteners; moreover, depth information is not available, making it difficult to detect the tightness of fasteners. The detection accuracy based on 3D image data is low and there is a single detection parameter. Research in this area is relatively limited and immature. Based on line-structured light for detection, the distribution of the light strip modulated by the surface of the track fastener is scattered and affected by different environmental light intensities and surface stains of the fastener. Existing methods for extracting the centerline of line-structured light cannot simultaneously consider universality, accuracy, and robustness, making it difficult to accurately extract the centerline of the light strip. The reconstructed point cloud model of the fastener has many noisy points and poor accuracy, which makes it difficult to diagnose fastener faults. Therefore, this article reports on a light strip centerline extraction method and fastener fault diagnosis method suitable for precise reconstruction of track fasteners. The objective is to realize high-precision and high-robustness fault diagnosis of track fasteners, timely eliminating safety hazards and ensuring reliable service of fasteners and safe operation of trains.

In response to the difficulty in accurately extracting the centerline of the line-structured light strip modulated by track fasteners, this study proposes a centerline extraction method based on the improved grayscale center of the gravity method. This method mainly consists of four steps. First, a filter is used to maintain the overall grayscale stability of the image, making the light stripe image brighter. Gaussian filtering is used to filter out noise in the image, while making the distribution of light stripes uniform and closer to a Gaussian distribution. Second, an adaptive segmentation threshold for light stripe segmentation is calculated to reduce the impacts of different lighting intensities and surface stains on the centerline extraction, effectively completing the coarse extraction of light stripes. Third, linear interpolation is performed between the adjacent pixel points of the light strip in coarse extraction to refine the grayscale distribution of the light strip. The center point of the light strip is calculated using the grayscale center of the gravity method to accurately extract the centerline. Finally, the extracted center point is checked; if the point is not located on the light strip, the median pixel that meets the conditions is used as the center point of the light strip for correction. The feasibility and robustness of the proposed method are verified by comparing the experimental results of centerline extraction under different influencing conditions. This study is based on the reconstructed fastener point cloud model. By constructing a detection combination classifier of fastener defects, different defective fasteners can be diagnosed and classified. By measuring the looseness value of the nut, the distance between the fastener and the seam is indirectly measured to achieve fastener looseness detection.

An accuracy detection experiment is conducted on the fault diagnosis system of the elastic strip I-type split fastener by building an indoor structured light sensor. The experimental results show that the overall measurement error of the system is less than 0.2 mm (Table 1). Subsequently, 100 normal fasteners and 100 faulty fasteners are diagnosed under normal lighting conditions using a structured light sensor device on the inspection vehicle line. The experimental results show that the system has a fastener fault detection rate of 96%, a misdiagnosis rate of 3% [Fig.12(a)], and a maximum error of 0.18 mm in fastener tightness detection [Fig.12(b)]. Finally, by conducting fault diagnosis on track fasteners with surface stains under different environmental light intensity conditions, the experimental results show that the overall system is less affected by different environmental light intensities and surface stains on the fasteners (Table 2), and the system has strong robustness and fault diagnosis ability, meeting the detection requirements of track fasteners.

Currently, the fault diagnosis parameters for fasteners based on 3D images are not comprehensive and the detection accuracy is low. There is scarce and immature research in this area. Therefore, this study independently designs and builds a track fastener fault diagnosis system based on line-structured light to scan, reconstruct, and diagnose the elastic strip I-type split fastener. First, in response to the difficulty in extracting the centerline of the light strip modulated by fasteners, a centerline extraction method based on the improved grayscale center of the gravity method is studied, and the fastener point cloud model is accurately reconstructed. Second, a combined classifier model for fastener defect detection is established to achieve fastener defect detection. Finally, by measuring the looseness of the fastening nut, the problem of difficult direct measurement of the fastening gap is solved. The experimental results show that under normal lighting conditions, the fault detection rate of the diagnostic system is 96%, and the detection error of fastener looseness is less than 0.2 mm. The fastener fault diagnosis model has good detection performance and robustness, which is of great practical significance for timely detection and maintenance of faulty fasteners, thereby ensuring safe operation of trains.

肖圳, 孙世政, 郑天成, 庞珂, 魏子杰. 基于改进灰度重心法的轨道扣件重构与故障诊断[J]. 中国激光, 2024, 51(8): 0804003. Zhen Xiao, Shizheng Sun, Tiancheng Zheng, Ke Pang, Zijie Wei. Reconstruction of Rail Fasteners and Fault Diagnosis Based on Improved Grayscale Gravity Center Method[J]. Chinese Journal of Lasers, 2024, 51(8): 0804003.