激光与光电子学进展, 2023, 60 (15): 1514010, 网络出版: 2023-08-18

激光重熔对浇铸及CMT堆焊巴氏合金组织的影响

Laser Remelting Effect on Casting and CMT Surfacing Babbitt Metal Microstructure

激光技术 巴氏合金 激光重熔 表面与界面 硬度 laser technique Babbitt metal laser remelting surface and interface hardness

摘要

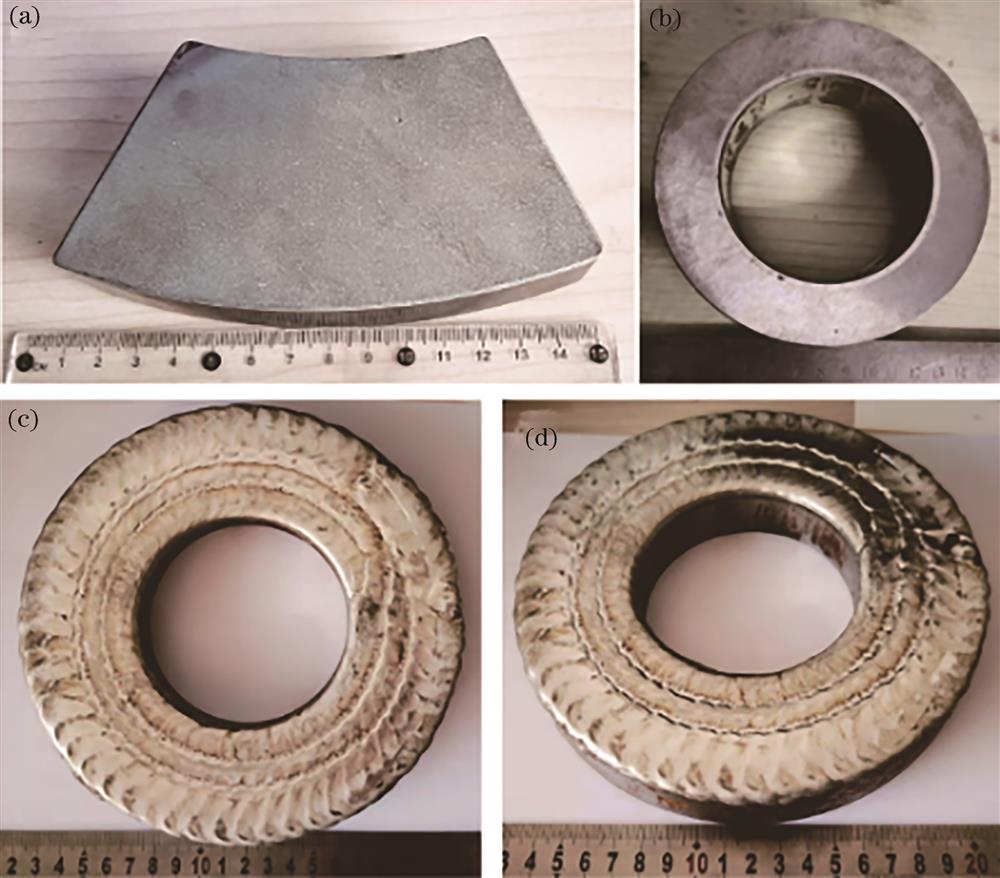

在工业领域中,通过铸造所制备的巴氏合金往往存在缺陷。为了探究如何减少巴氏合金在组织和性能上的缺陷,对比了通过传统浇铸和冷金属过渡焊接(CMT)两种方法在20钢基体上所制备巴氏合金层的组织和性能,并在其表面进行了激光重熔试验。利用金相显微镜、扫描电镜、能谱仪以及维氏硬度计等仪器检测了浇铸、堆焊巴氏合金和重熔巴氏合金层的组织和硬度,通过对比分析可知,CMT堆焊层组织较浇铸层更细,与钢基体的冶金结合更强。激光重熔在细化晶粒、消除粗大组织的同时,未产生偏析、气孔等缺陷。不同激光功率对于巴氏合金层的组织和性能影响各不相同,激光功率分别为300 W和500 W时,堆焊、浇铸试样的重熔层硬度达到最大值35.16 HV0.025和36.92 HV0.025。激光重熔对巴氏合金组织和性能的强化效果显著,对于滑动轴承的研究有着巨大的工程应用价值和发展前景。

Abstract

In the industrial field, babbitt alloys prepared by casting often have defects. In order to reduce the defects in microstructure and properties of babbitt alloy, the microstructure and properties of Babbitt layer prepared on 20 steel substrate by traditional casting and cold metal transfer (CMT) surfacing are compared. In addition, laser remelting (LR) experiments were conducted on the Babbitt layer surface. The microstructure of casting, surfacing, and remelting Babbitt layers were, respectively, measured by metallographic microscope, scanning electron microscope, and energy dispersive spectrometer, while hardness was tested for all three using the Vickers hardness (HV). The results show that the CMT surfacing layer microstructure is finer than that of casting layers and metallurgical bonding with steel substrate is stronger. Meanwhile, LR can refine grain to eliminate coarse microstructure without segregation and porosity. Different laser powers have different effects on the microstructure and properties of Babbitt metal. At laser powers of 300 W and 500 W the hardness of remelting Babbitt layer surfacing and casting samples reach the maximum of 35.16 HV0.025 and 36.92 HV0.025,respectively. This means that the LR effect on Babbitt metal microstructure and properties has great engineering application value and development prospect for plain bearing research.

邓德伟, 汪峻宇, 孟凡民, 万泓明, 孙奇, 张勇. 激光重熔对浇铸及CMT堆焊巴氏合金组织的影响[J]. 激光与光电子学进展, 2023, 60(15): 1514010. Dewei Deng, Junyu Wang, Fanmin Meng, Hongming Wan, Qi Sun, Yong Zhang. Laser Remelting Effect on Casting and CMT Surfacing Babbitt Metal Microstructure[J]. Laser & Optoelectronics Progress, 2023, 60(15): 1514010.