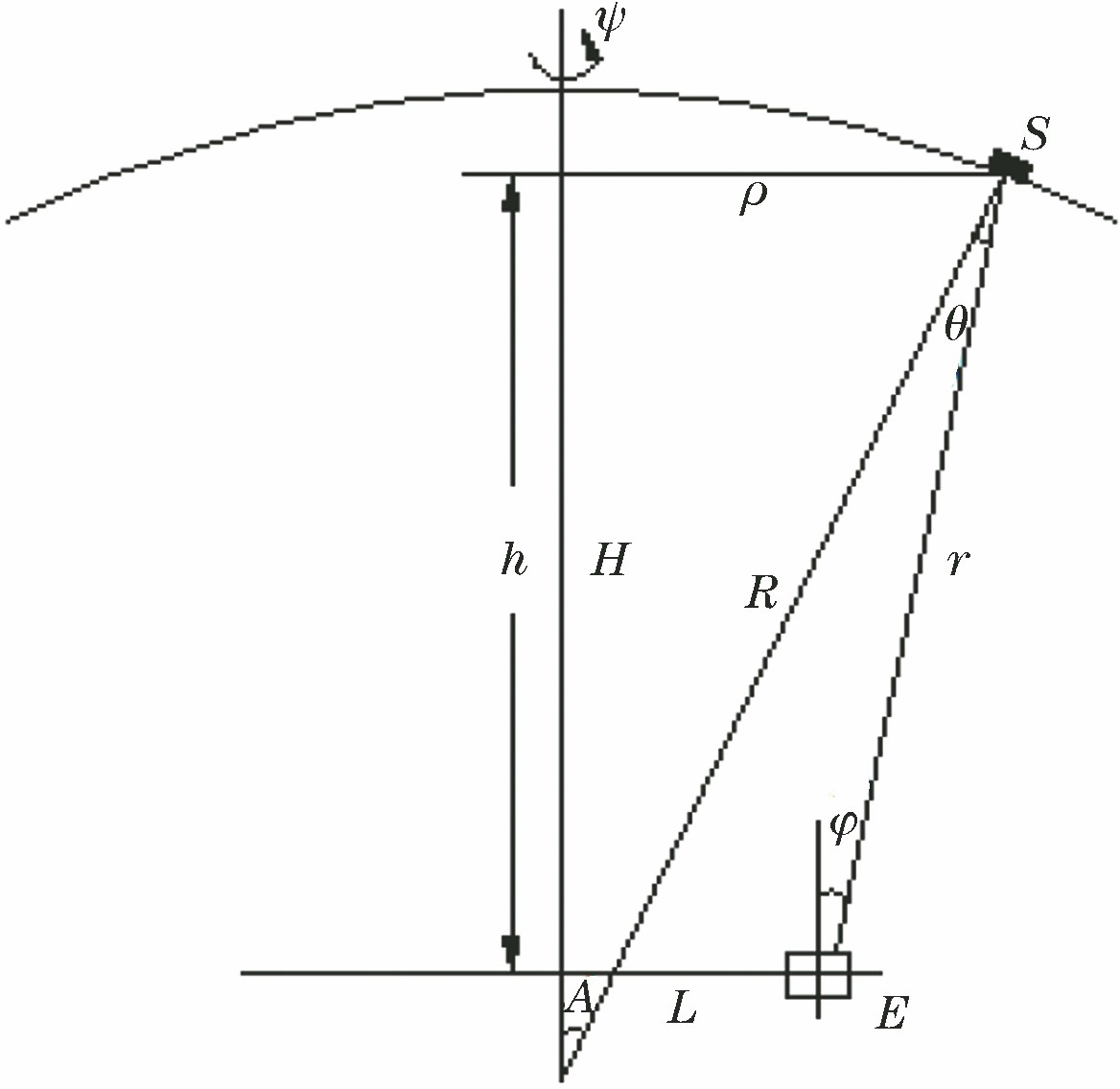

单一蒸发源膜厚分布的均匀性  下载: 1510次

下载: 1510次

付秀华, 赵迪, 卢成, 马国俊, 鲍刚华. 单一蒸发源膜厚分布的均匀性[J]. 光学学报, 2019, 39(12): 1231001.

Xiuhua Fu, Di Zhao, Cheng Lu, Guojun Ma, Ganghua Bao. Uniformity of Film Thickness Distribution for Single Evaporation Source[J]. Acta Optica Sinica, 2019, 39(12): 1231001.

[1] Jaing C C. Designs of masks in thickness uniformity[J]. Proceedings of SPIE, 2010, 7655: 76551Q.

[2] 王长军, 熊胜明. 大口径光学元件薄膜厚度均匀性修正[J]. 强激光与粒子束, 2007, 19(7): 1153-1157.

[3] 唐晋发, 顾培夫, 刘旭, 等. 现代光学薄膜技术[M]. 杭州: 浙江大学出版社, 2006: 271- 278.

Tang JF, Gu PF, LiuX, et al.Modern optical thin film technology[M]. Hangzhou: Zhejiang University Press, 2006: 271- 278.

[4] 艾万君, 熊胜明. 3.6 m大口径镀膜机膜厚均匀性分析[J]. 光电工程, 2011, 38(11): 73-78.

[5] 郭春, 孔明东, 柳存定, 等. 平面行星系统修正挡板校正膜厚均匀性[J]. 光学学报, 2013, 33(2): 0231002.

[6] 方明, 郑伟军, 吴明, 等. 平面行星夹具均匀性修正挡板设计方法研究[J]. 真空科学与技术学报, 2006, 26(4): 286-289.

[7] Kotlikov E N, Prokashev V N, Ivanov V A, et al. Thickness uniformity of films deposited on rotating substrates[J]. Journal of Optical Technology, 2009, 76(2): 100-103.

[8] 潘栋梁, 熊胜明, 张云洞, 等. 行星夹具膜厚均匀性计算[J]. 强激光与粒子束, 2000, 12(3): 277-280.

[9] 董磊, 赵元安, 易葵, 等. 不同类型蒸发源对平面夹具薄膜均匀性的影响[J]. 强激光与粒子束, 2005, 17(10): 1518-1522.

[13] 朱元强. 行星夹具膜厚均匀性分析[J]. 真空, 2010, 47(5): 57-59.

Zhu Y Q. Study on film thickness uniformity of planetary fixture[J]. Vacuum, 2010, 47(5): 57-59.

[14] 张立超, 高劲松. 基于遮挡矩阵的膜厚修正挡板的设计[J]. 光学精密工程, 2013, 21(11): 2757-2763.

付秀华, 赵迪, 卢成, 马国俊, 鲍刚华. 单一蒸发源膜厚分布的均匀性[J]. 光学学报, 2019, 39(12): 1231001. Xiuhua Fu, Di Zhao, Cheng Lu, Guojun Ma, Ganghua Bao. Uniformity of Film Thickness Distribution for Single Evaporation Source[J]. Acta Optica Sinica, 2019, 39(12): 1231001.