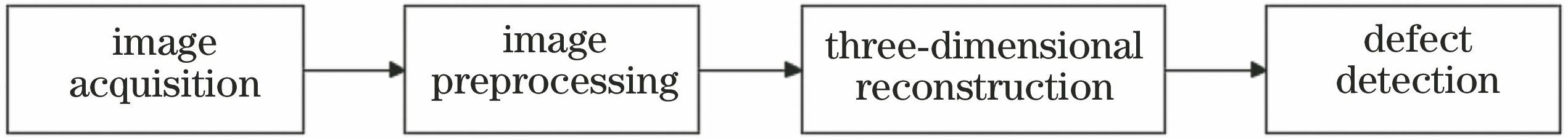

基于单幅图像的集成电路引脚共面性检测方法  下载: 1216次

下载: 1216次

吴福培, 朱树锴, 李昇平. 基于单幅图像的集成电路引脚共面性检测方法[J]. 光学学报, 2020, 40(1): 0111023.

Fupei Wu, Shukai Zhu, Shengping Li. Coplanarity Inspection Method for Integrated Circuit Pins Based on Single Image[J]. Acta Optica Sinica, 2020, 40(1): 0111023.

[1] 杨城, 邓勇. 表面贴装集成电路引脚整形研究[J]. 电子与封装, 2014, 14(9): 5-8, 32.

Yang C, Deng Y. The study of reforming pins for surface mount integrated circuit[J]. Electronics and Packaging, 2014, 14(9): 5-8, 32.

[2] 中华人民共和国国家质量监督检验检疫总局. 半导体集成电路封装术语: GB/T 14113-1993[S]. 北京: 中国标准出版社, 1993.

General administration of quality supervision, inspectionandquarantine of the people's republic of China. Terminology of packages for semiconductor integrated circuits: GB/T 14113-1993[S]. Beijing: China Standards Press, 1993.

[3] 中华人民共和国工业和信息化部. 半导体集成电路小外形封装引线框架规范: GB/T 15878-2015[S]. 北京: 中国标准出版社, 2015.

Ministry ofindustryandinformationtechnology. Semiconductor integrated circuits—specification of leadframes for small outline package: GB/T 15878-2015[S]. Beijing: China Standards Press, 2015.

[4] Wu F, Zhang X. Feature-extraction-based inspection algorithm for IC solder joints[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2011, 1(5): 689-694.

[5] Cai N, Lin J, Ye Q, et al. A new IC solder joint inspection method for an automatic optical inspection system based on an improved visual background extraction algorithm[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2016, 6(1): 161-172.

[6] Chen S H, Perng D B. Automatic optical inspection system for IC molding surface[J]. Journal of Intelligent Manufacturing, 2016, 27(5): 915-926.

[7] Wen X, Song K, Niu M, et al. A three-dimensional inspection system for high temperature steel product surface sample height using stereo vision and blue encoded patterns[J]. Optik, 2017, 130: 131-148.

[8] 宋丽梅, 周兴林, 徐可欣, 等. 基于单幅测量图像的三维缺陷检测技术[J]. 光学学报, 2005, 25(9): 1195-1200.

[9] Li Y D, Gu P H. Free-form surface inspection techniques state of the art review[J]. Computer-Aided Design, 2004, 36(13): 1395-1417.

[10] Sidki H M, Amer M. Evaluation of CMM for flatness measurements[J]. Metrology and Measurement Systems, 2008, 15(4): 585-593.

[11] 周明宝, 林大健, 郭履容, 等. 微结构表面形貌的测量[J]. 光学精密工程, 1999, 7(3): 7-13.

Zhou M B, Lin D J, Guo F R, et al. Measurement of microstructure surface topography[J]. Optics and Precision Engineering, 1999, 7(3): 7-13.

[12] YangL, GaoY, Wang XZ, et al., 2005, 295/296: 489- 494.

[15] 郭萌, 胡辽林, 李捷. 基于多幅图像的陶瓷碗表面缺陷的局部点云重建[J]. 光学学报, 2017, 37(12): 1215002.

[16] Lange R, Seitz P. Solid-state time-of-flight range camera[J]. IEEE Journal of Quantum Electronics, 2001, 37(3): 390-397.

[18] 潘伟, 赵毅, 阮雪榆. 结构光测量中获取高精度相位的新方法[J]. 光学学报, 2004, 24(5): 687-691.

[19] Bogue R. Three-dimensional measurements: a review of technologies and applications[J]. Sensor Review, 2010, 30(2): 102-106.

[20] 李进军, 赵宏. 一种基于多模式单演特征检测与匹配的三维视觉测量方法[J]. 光学学报, 2011, 31(7): 0712007.

[21] 王珊, 徐晓. 基于双目单视面的三维重建[J]. 光学学报, 2017, 37(5): 0515004.

Wang S, Xu X. 3D reconstruction based on horopter[J]. Acta Optica Sinica, 2017, 37(5): 0515004.

[22] 雷彦章, 赵慧洁, 姜宏志. 一种单双目视觉系统结合的三维测量方法[J]. 光学学报, 2008, 28(7): 1338-1342.

[23] Wei Y J, Wu C D, Wang Y, et al. Diffusion-based three-dimensional reconstruction of complex surface using monocular vision[J]. Optics Express, 2015, 23(23): 30364-30378.

[24] 曾昭鹏, 张江乐, 魏志尚, 等. 一种基于智能手机成像的三维重建方法[J]. 激光与光电子学进展, 2018, 55(11): 111502.

[25] 卢盛林, 张宪民. 无铅焊点检测光源的分析与优化设计[J]. 光学精密工程, 2008, 16(8): 1377-1383.

[26] 白雪飞, 张宗华. 基于彩色条纹投影术的三维形貌测量[J]. 仪器仪表学报, 2017, 38(8): 1912-1925.

Bai X F, Zhang Z H. 3D shape measurement based on colour fringe projection techniques[J]. Chinese Journal of Scientific Instrument, 2017, 38(8): 1912-1925.

[27] 吴福培, 郭家华, 张宪民, 等. PCB焊点表面三维质量检测方法[J]. 仪器仪表学报, 2018, 39(5): 233-240.

Wu F P, Guo J H, Zhang X M, et al. 3D quality inspection method for PCB solder joint surface[J]. Chinese Journal of Scientific Instrument, 2018, 39(5): 233-240.

吴福培, 朱树锴, 李昇平. 基于单幅图像的集成电路引脚共面性检测方法[J]. 光学学报, 2020, 40(1): 0111023. Fupei Wu, Shukai Zhu, Shengping Li. Coplanarity Inspection Method for Integrated Circuit Pins Based on Single Image[J]. Acta Optica Sinica, 2020, 40(1): 0111023.