1 南京航空航天大学航天学院, 江苏 南京 210001

2 中国工程物理研究院激光聚变研究中心, 四川 绵阳 621900

分离式终端光学系统(FOA)的光学元件多,输出能量高,鬼像分布复杂,给FOA的鬼像分析带来很大的挑战。利用Zemax结合自主研发软件Ghost对分离式FOA的鬼像分布进行优化设计,建立针对真空窗口和屏蔽片的角度及其与聚焦透镜的间距对FOA中鬼像分布影响的分析模型,经仿真计算得到两种适合于分离式FOA的鬼像分布方案,对比其优缺点,最终确定合理的分离式FOA鬼像分布设计方案。

光学设计 终端光学系统 分离式 鬼像分析 高功率激光装置 中国激光

2019, 46(11): 1101002

Author Affiliations

Abstract

1 National Laboratory on High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

2 Shanghai Institute of Laser Plasma, Shanghai 201800, China

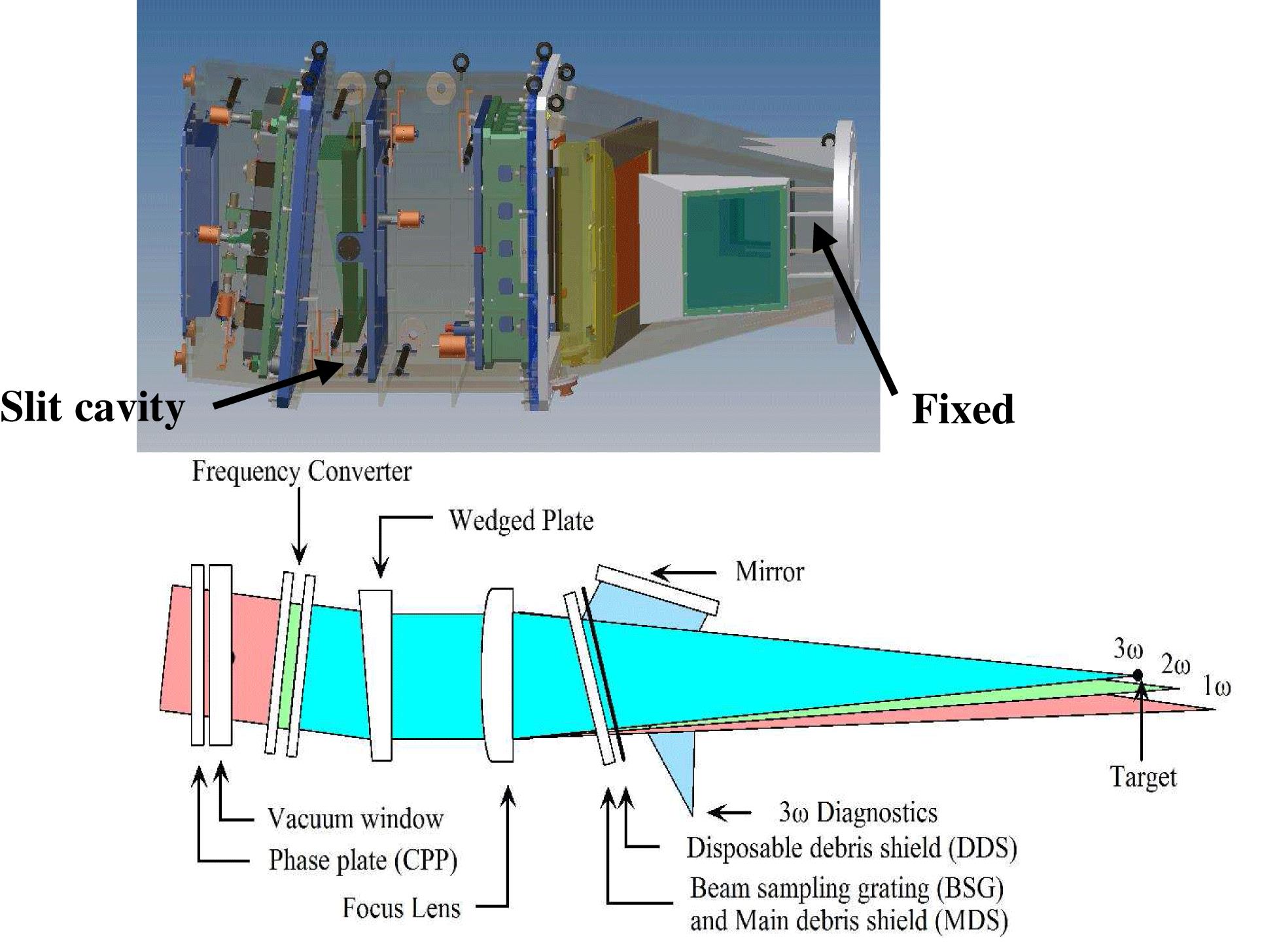

In high power laser facility for inertial confinement fusion research, final optics assembly (FOA) plays a critical role in the frequency conversion, beam focusing, color separation, beam sampling and debris shielding. The design and performance of FOA in SG-II Upgrade laser facility are mainly introduced here. Due to the limited space and short focal length, a coaxial aspheric wedged focus lens is designed and applied in the FOA configuration. Then the ghost image analysis, the focus characteristic analysis, the B integral control design and the optomechanical design are carried out in the FOA design phase. In order to ensure the FOA performance, two key technologies are developed including measurement and adjustment technique of the wedged focus lens and the stray light management technique based on ground glass. Experimental results show that the design specifications including laser fluence, frequency conversion efficiency and perforation efficiency of the focus spot have been achieved, which meet the requirements of physical experiments well.

final optics assembly high power laser facility inertial confinement fusion. High Power Laser Science and Engineering

2018, 6(2): 02000e14

Author Affiliations

Abstract

Chinese Academy of Sciences, Shanghai Institute of Optics and Fine Mechanics, National Laboratory on High Power Laser and Physics, No. 390, Qinghe Road, Jiading District, Shanghai 201800, China

The high fluence performance of high-power laser systems is set by optical damage, especially in the final optics assembly (FOA). The flaws on the frequency converter surface can cause optical intensity intensification and, therefore, damage the downstream optical elements, such as the beam sampling grating (BSG), which is an important component in the FOA. Mitigation of BSG damage caused by flaws is discussed. Physical models are established to simulate the optical field enhancement on BSG modulated by the upstream flaw, considering both the linear and nonlinear propagation effects. Numerical calculations suggest that it is important to place the BSG in a properly selected position to mitigate the laser-induced damage. Furthermore, strict controls of flaw size, modulation depth, distance between frequency converter and focusing lens, and the thickness of the focusing lens are also significant to mitigate the BSG damage. The results obtained could also give some suggestions for damage mitigation of optical components and the layout design of the final optics assembly.

damage mitigation flaw final optics assembly high-power laser hot image Collection Of theses on high power laser and plasma physics

2016, 14(1): 011021

Author Affiliations

Abstract

1 中国科学院上海光学精密机械研究所高功率激光物理联合实验室, 上海 201800

2 中国工程物理研究院上海激光等离子体研究所, 上海 201800

The wedge-shaped lens is the key and special optical component of the final optics assembly (FOA) in high power laser facility. The wedge-shaped lens wedge angle measurement plays a remarkable role in focusing performance of high power laser. If processing angle and work attitude of the wedge-shaped lens deviate from the specific work angle, big surface deviation will be introduced into the FOA. Special shape of the wedge-shaped lens is not conducive to the measurements of the transmission profile and wedge angle. A set of wedge-shaped lens measurement adjustment programmes is proposed, including measurement of the wedge-shaped lens in processing process, and off-line measurement of wedge-shaped lens during alignment and on-line measurement during the debugging process. The scheme can ensure the processing precision and working attitude of the wedge-shaped lens, guarantee the beam quality and the positioning accuracy of the FOA components of high power laser system.

光学器件 高功率激光装置 终端光学组件 楔形透镜 楔角误差 塔差 optical devices high power laser facility final optics assembly wedge-shaped lens wedge angle error tower error Collection Of theses on high power laser and plasma physics

2015, 13(1): 0408006

Author Affiliations

Abstract

1 Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, No. 390, Qinghe Road, Jiading District, Shanghai 201800, China

2 University of Chinese Academy of Sciences, No. 19A Yuquan Road, Beijing 100049, China

The Shenguang-II Upgrade (SG-II Up) facility is an under-construction high-power laser driver with eight beams, 24 kJ energy, 3 ns pulse duration and ultraviolet laser output, in the Shanghai Institute of Optics and Fine Mechanics, China. The prototype design and experimental research of the prototype final optics assembly (FOA), which is one of the most important parts of the SG-II Up facility, have been completed on the ninth beam of the SG-II facility. Thirty-three shots were fired using 1-! energy from 1000 to 4500 J and 3-! energy from 500 to 2403 J with a 3 ns square pulse. During the experiments, emphasis was given to the process of optical damage and to the effects of clean-gas control. A numerical model of the FOA generated by the Integrated Computer Engineering and Manufacturing code for Computational Fluid Dynamics (ICEMCFD) demonstrated that a flux within 1–5 l s-1 and a 180 s period is effectual to avoid contaminant sputtering to the optics. The presence of surface ‘mooning’ damage and surface spots located outside the clear aperture are induced by contaminants such as wire, silica gel and millimeter order fiber and metal.

Final Optics Assembly optical damage SG-II-Up High Power Laser Science and Engineering

2015, 3(1): 010000e7

1 中国科学院上海光学精密机械研究所高功率激光物理联合实验室, 上海 201800

2 中国工程物理研究院上海激光等离子体研究所, 上海 201800

楔形透镜是高功率激光系统终端光学组件的关键元件,也是较为特殊的光学元件,楔形透镜的楔角测量关系着高功率激光的聚焦性能。终端组件中楔形透镜的加工角度、工作姿态一旦偏离了特定的工作角度,终端组件会引入大的面形偏差,楔形透镜特殊的形状不利于楔形透镜面形、楔角的测量。提出了一整套楔形透镜测量调整方案,包括楔形透镜加工过程中的测量方案,楔形透镜安装过程中的离线测量与调整方案,以及终端组件上线调试过程中的在线调试测量方案。该套方案的实施能够保证楔形透镜的加工精度,及组件中楔形透镜能够工作在最佳工作姿态,保障了高功率激光系统终端组件的光束质量和定位精度。

光学器件 高功率激光装置 终端光学组件 楔形透镜 楔角误差 塔差

Author Affiliations

Abstract

1 Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, No.390, Qinghe Road, Jiading District, Shanghai 201800, China

2 University of Chinese Academy of Sciences, No.19A Yuquan Road, Beijing 100049, China

In order to improve laser damage resistance of the Final Optics Assembly (FOA), simulation analysis have been done for 1ω, 2ω and 3ω laser beam considering ghost images to the 4th order. The panels of ground glass scatter ghost laser around the FOA walls and the panels of architectural glass absorb the 1th order energy. The appearance of smoothing fused silica surface defect and the effect of wiping off etching contamination are researched on HF-based etching processes under ultrasonic. Now, 18 shots were executed using 310×310mm laser with 3ns pulse width. During the experiment, the third harmonic laser terminal output energy is 1500J~3500J, and the maximum laser energy flux is about 4J/cm2. This presentation addresses the optical configuration of the FOA, the simulation analysis of ghost, the way of ground glasses absorbing energy and the result of laser damage resistance of fused silica on HF-based etching processes under ultrasonic.

Laser Damage Fused Silica Final Optics Assembly High Power Laser Facility Collection Of theses on high power laser and plasma physics

2014, 12(1): 92371V

中国工程物理研究院激光聚变研究中心, 四川 绵阳 621900

终端光学组件是高功率激光驱动器的核心单元之一,承担着频率转换、光束聚焦、谐波分离和测量取样等功能。通过光学和结构设计可以实现终端光学组件的基本功能,满足高功率激光驱动器开展各项实验的基本要求,但是激光导致的终端元件损伤问题和强紫外光传输带来的若干非线性效应是制约终端光学组件总体性能的关键问题。综述了国内外高功率激光驱动器终端光学组件的研究历程,分析了终端光学组件面临的主要问题,并探讨了终端光学组件设计的主要思路。

激光器 高功率激光驱动器 终端光学组件 激光损伤 非线性效应 设计 激光与光电子学进展

2013, 50(6): 060002

1 中国科学院上海光学精密机械研究所高功率激光物理联合实验室, 上海 201800

2 中国工程物理研究院上海激光等离子体研究所, 上海 201800

提出一种可实现351 nm波长激光高通量传输的终端光学组件(FOA)的物理设计方案,研究了设计优化方法,并利用神光Ⅱ装置第九路系统开展了实验研究。实验共进行了33发激光发射:激光光束净口径310 mm,时间脉冲宽度3 ns,1053 nm波长激光能量1000~4500 J。实验获得最高三次谐波转换效率69.6%和351 nm波长激光传输通量3.76 J/cm2,同时监测到高通量激光传输引起的动态环境污染物颗粒变化数和光学元件激光诱导损伤等现象。实验结果表明,通量密度约为3 J/cm2@351 nm的光学元件损伤主要是由激光传输散射鬼光束辐照材料所激发的污染物所致。

激光器 高功率激光装置 终端光学组件 三倍频激光 激光诱导损伤

Author Affiliations

Abstract

中国科学院上海光学精密机械研究所高功率激光物理国家实验室, 上海 201800

It is important to keep away from the ghost reflection point for the arrangement design of final optics assembly (FOA) in the high power laser facility. The high power output of the “SG-Ⅱ” upgrading laser, limited target field space and complicated ghost reflection distribution lead to the difficult design of the FOA. By using the ghost image analysis software designed by ourselves, we analyzed the ghost reflection distribution of the FOA. Then, the arrangement of two types of designs for the FOA was optimized. According to the characteristics of “SG-Ⅱ” upgrading laser, we obtained the design for the FOA, which can satisfy the system requirement exactly.

光学器件 神光Ⅱ升级装置 鬼像分析 终端光学组件 排布设计 optical devices “SG-Ⅱ” upgrading laser ghost reflection analysis final optics assembly arrangement design Collection Of theses on high power laser and plasma physics

2008, 6(1): 53