功率模块封装用高强度高热导率Si3N4陶瓷的研究进展

绝缘栅双极型晶体管(Insulated gate bipolar transistor, IGBT)和金属氧化物半导体场效应晶体管(Metal-oxide-semiconductor field-effect transistor, MOSFET)等电力电子器件可以有效控制和转换电能, 在汽车工业、高铁、智能电网和新能源等领域得到广泛应用[1⇓-3]。随着传统的Si基半导体被宽禁带的第三代半导体(如SiC和GaN)逐步替代, 电力电子器件向高电压、大电流、小尺寸和高输出功率方向快速发展。高功率密度对功率模块封装和封装材料提出了更高的要求, 特别是脆性的陶瓷基板材料[4⇓-6]。功率模块的结构如图1所示, 陶瓷基板位于装配有半导体芯片的电路和散热器(金属)之间, 起着绝缘、散热和支持保护的作用[7]。Al2O3、AlN和Si3N4是三种常用的陶瓷基板材料, 表1总结了三种材料的性能[8]。Al2O3陶瓷价格便宜, 工艺最成熟, 但热导率低和力学性能差使其无法满足新一代功率模块的要求[8]。AlN陶瓷的热导率高(>200 W·m-1·K-1), 但力学性能较差, 难以承受功率模块运行过程中产生的热应力,在-40~250 ℃热循环测试仅7次后陶瓷与覆铜金属的界面处就产生裂纹, 导致铜片脱落(图2), 严重影响功率模块的可靠性。与之形成鲜明对比的是, 兼具优异力学性能和高热导率的Si3N4陶瓷, 经历1000次热循环测试后, 仍与铜片结合良好[9]。因此, Si3N4陶瓷成为最具潜力的功率模块封装用陶瓷基板材料而备受关注。

![功率模块和金属化陶瓷基板示意图[7]](/richHtml/jim/2023/38/10/1117/img_1.png)

图 1. 功率模块和金属化陶瓷基板示意图[7]

Fig. 1. Schematic diagram of power module and metallized ceramic substrate[7]

表 1.

Al2O3、AlN和Si3N4三种陶瓷基板材料的性能[8]

Table 1. Properties of Al2O3, AlN and Si3N4 ceramic substrate materials[8]

|

![(a)Si3N4覆铜基板在-40~250 ℃热循环1000次后的外观; (b)AlN覆铜基板在-40~250 ℃热循环7次后的外观; (c)Cu板分层脱落的侧视图((b)中白色圆圈内)[9]](/richHtml/jim/2023/38/10/1117/img_2.png)

图 2. (a)Si3N4覆铜基板在-40~250 ℃热循环1000次后的外观; (b)AlN覆铜基板在-40~250 ℃热循环7次后的外观; (c)Cu板分层脱落的侧视图((b)中白色圆圈内)[9]

Fig. 2. Appearance of (a) Si3N4 coppered substrate after 1000 thermal cycles of -40 to 250 ℃, (b) AlN coppered substrate after 7 cycles of -40 to 250 ℃, and (c) side view of the delaminated Cu plate indicated by white circle in (b) [9]

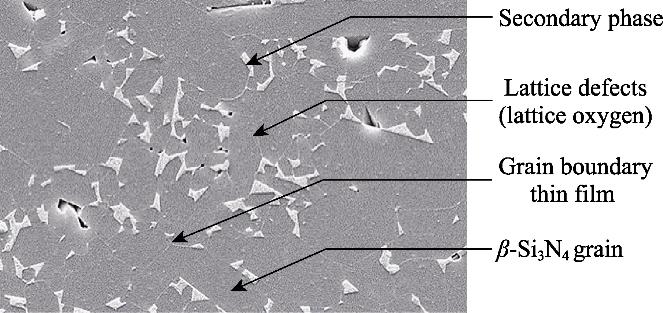

Si3N4陶瓷是结构陶瓷的典型代表, 但直到1995年Haggerty和Lightfoot预测Si3N4在室温下的本征热导率可达200~320 W·m-1·K-1, 高热导Si3N4陶瓷的研究才得到快速发展[10⇓⇓⇓⇓-15]。历经近30年的努力, Si3N4陶瓷的实测热导率达到90~182 W·m-1·K-1, 但与理论值仍有较大差距, 主要是由于在Si3N4陶瓷微结构(图3)中, Si3N4晶粒中的缺陷(杂质原子、空穴和位错等)和Si3N4晶粒之间的低热导率晶间相(约1 W·m-1·K-1), 对热导率造成了严重危害。其中, O固溶进入Si3N4晶格形成的Si空穴造成强烈的声子散射(式(1)), 是降低Si3N4陶瓷热导率的主要外部因素[16⇓-18]。当前提升Si3N4陶瓷热导率的手段主要有: (1)选用高纯Si3N4粉或更低氧含量的Si粉为原料; (2)选择有效的非氧化物烧结助剂; (3)优化烧结工艺或在高温下对样品进行退火热处理。然而, 无论采用哪种方式, 获得热导率>100 W·m-1·K-1的Si3N4陶瓷往往需要在高温下(如1900 ℃)进行长时间的烧结, 异常长大的β-Si3N4晶粒虽可以提升热导率, 但牺牲的力学性能会使Si3N4陶瓷丧失作为基板材料的优势。鉴于此, 通过优化组分配方和烧结工艺来制备兼顾热学和力学性能的Si3N4陶瓷, 成为研究者关注的重点。

图 3. 影响Si3N4陶瓷热导率的微结构因素

Fig. 3. Microstructure factors affecting the thermal conductivity of Si3N4 ceramics

Si3N4陶瓷用作基板材料, 除热学和力学性能外, 其介电击穿强度(Dielectric breakdown strength, DBS)和覆铜后的性能评价也得到广泛研究[19⇓⇓⇓⇓⇓-25]。Si3N4陶瓷基板的DBS受基板厚度、孔隙率和微结构等因素的影响; 覆铜Si3N4基板的性能评价则包括测试Si3N4基板与铜片的结合强度, 高温热循环后的界面结合情况以及基板的剩余强度等。作为功率模块封装材料的一部分, 高强高热导Si3N4陶瓷只有完成上述一系列性能评价, 才能最终实现从实验室制备到商业化应用的跨越。本文从影响Si3N4陶瓷热导率的因素入手, 系统总结了制备高热导率Si3N4陶瓷的有效烧结助剂, 以及新开发的反应烧结-重烧结(Sintering of reaction-bonded silicon nitride, SRBSN)和传统的气压烧结(Gas pressure sintering, GPS)在制备高强高热导Si3N4陶瓷领域的最新研究进展, 最后介绍了Si3N4陶瓷基板的介电击穿强度和覆铜后的性能评价, 并对未来的发展方向进行了展望。

1 Si3N4陶瓷热导率的影响因素

高热导的SiC和AlN陶瓷, 在1973年被Slack预测有高的理论热导率后, 仅仅十余年的研究热导率就达到270 W·m-1·K-1[26⇓⇓-29]。不同于这二者, 高热导Si3N4陶瓷的研究进展较为缓慢, 这一方面是因为β-Si3N4晶粒的棱柱状形貌[30-31]增加了研究微结构因素对热导率影响的难度; 另一方面是因为影响Si3N4陶瓷热导率最关键的因素——晶格氧含量, 在很长时间里都没有准确有效的测试方法, 直到20世纪末, 热气抽取技术的出现[32], 才解决了这一难题, 使影响Si3N4陶瓷热导率的多种因素得以澄清。下面将分别介绍微结构、晶格氧含量、稀土氧化物、晶格杂质和缺陷等因素对Si3N4陶瓷热导率的影响。

1.1 微结构因素的影响

Si3N4陶瓷的微结构由Si3N4晶粒和颗粒间玻璃相组成, 其中Si3N4晶粒又分为等轴状的基质晶粒和异常长大的长柱状晶粒。颗粒间玻璃相的热导率比Si3N4晶粒低很多, 对高热导率的危害也更大。基于实验结果, Hirosaki等[33-34]得出晶界膜的厚度与晶粒尺寸直接相关, 对β-Si3N4的热导率有重要影响。但由于β-Si3N4的晶粒形貌各向异性, 相关研究一直缺少理论上的支持。

Kitayama等[35]针对多种微结构因素做了更为系统深入的工作, 采用亚微米的β-Si3N4粉和另外两种α-Si3N4粉为原料, Y2O3为烧结助剂, 通过控制1800 ℃热压烧结和1850 ℃退火热处理的时间得到了不同微结构的Si3N4陶瓷, 结合修正的Wiener模型, 从理论和实验角度研究了晶粒尺寸、玻璃相体积分数和晶界薄膜厚度对Si3N4陶瓷热导率的影响。当晶界膜厚度在几十纳米范围内, β-Si3N4的热导率随晶界膜厚度的增加而快速下降, 而玻璃相的体积分数(2%~10%)则对热导率的影响较小。图4所示为在不同晶界膜厚度条件下(晶界膜厚度δ=1, 10 和50 nm),晶粒尺寸对β-Si3N4热导率的影响。随着晶粒尺寸增大, β-Si3N4的热导率起初急剧增加, 但当晶粒尺寸超过一个临界值后, 热导率也几乎恒定, 此临界值由晶界膜厚度和玻璃相的量决定(如晶界膜厚度为1 nm时, 此临界值约为1 μm)。该研究从理论和实验角度证明了Si3N4晶粒尺寸一旦超过特定的临界值, 单独依靠晶粒生长并不能提高β-Si3N4的热导率。

![晶粒尺寸对不同晶界膜厚度β-Si3N4热导率的影响规律[35]](/richHtml/jim/2023/38/10/1117/img_4.png)

图 4. 晶粒尺寸对不同晶界膜厚度β -Si3N4热导率的影响规律[35]

Fig. 4. Effect of grain size on the thermal conductivity of β -Si3N4 with various grain-boundary film thicknesses[35]

1.2 晶格氧含量的影响

Si3N4陶瓷的物相以β-Si3N4为主, 虽然不同工艺制备得到的α-Si3N4粉体的晶格氧含量很早有报道[36⇓-38], 但氧是否固溶进入β-Si3N4晶格, 固溶量是多少的问题直到20世纪末才得到有效解决。Kitayama等[17-18]通过热处理α-Si3N4和Y2O3、SiO2的混合粉(n(Y2O3) : n(SiO2)=1 : 2, 2 : 1), 得到两种β-Si3N4晶体粉, 酸处理去除第二相后, 借助热气抽取技术测得β-Si3N4的晶格氧的质量分数分别为0.258%和0.158%。之后参考AlN晶格氧含量对热导率影响的研究方法, 设计了四个组分的样品; n(α-Si3N4) : n(Y2O3) : n(SiO2)=40 : 1 : 2, 40 : 2 : 1, 40 : 2.5 : 0.5, 40 : 3 : 0, 通过热压烧结和退火热处理得到不同热导率的β-Si3N4陶瓷, 系统研究了晶格氧含量对β-Si3N4热导率的影响。

Y2O3/SiO2比率对β-Si3N4热导率和晶格氧含量的影响如图5所示, 考虑到原料α-Si3N4粉体包含的氧含量, 四个组分修正的Y2O3/SiO2分别为0.289, 0.807, 1.267和2.029。β-Si3N4的热导率随Y2O3/SiO2助剂比率的增加而增大, 当Y2O3/SiO2接近1时, 热导率显著增加。β-Si3N4晶格氧含量随Y2O3/SiO2比率增加而下降, Y2O3/SiO2>1时晶格氧含量趋于恒定。该研究结果表明, Y2O3/SiO2比率通过改变晶界相的组分进而影响β-Si3N4的晶格氧含量, 当Y2O3/SiO2≈1时, Y20N4Si12O48和Y2Si3N4O3出现在晶界相中, 晶格氧含量最低, 热导率最高; 而当Y2O3的添加量过多时, 晶界相含量增加, 并没有进一步降低晶格氧含量。因此, 为了实现β-Si3N4最优的热导率, Y2O3存在一个最佳添加量, 这与Si3N4原料粉中的氧杂质含量相关。

![通过调控Y2O3/SiO2比率改变β-Si3N4的热导率和晶格氧含量[18]](/richHtml/jim/2023/38/10/1117/img_5.png)

图 5. 通过调控Y2O3/SiO2比率改变β -Si3N4的热导率和晶格氧含量[18]

Fig. 5. Thermal conductivity and lattice oxygen content of β -Si3N4 changed by adjusting the ratio of Y2O3/SiO2[18]

1.3 稀土氧化物烧结助剂的影响

稀土氧化物(RE2O3)作为Si3N4的烧结助剂, 得到了广泛研究[39⇓⇓-42]。包括Sc、Y和镧系元素(Ln)在内的稀土元素的离子价z为+3, 且镧系元素的离子半径r随原子序数的增加而下降(镧系收缩), 其阳离子场强z/r2也随原子序数的变化而连续改变, 造成Ln-Si-O-N玻璃的热物理性质发生巨大改变, 最终影响Si3N4陶瓷本身的微结构和性能。

Kitayama等[43]使用α-Si3N4粉为原料, 六种稀土氧化物(RE=La, Nd, Gd, Y, Yb和Sc)为烧结助剂, 通过热压烧结和退火热处理制备了不同热导率的β-Si3N4陶瓷, 从微结构和晶格氧含量两方面系统研究了不同稀土氧化物对β-Si3N4热导率的影响。图6为稀土氧化物烧结助剂离子半径与β-Si3N4热导率、热扩散系数和晶格氧含量之间的关系。随着稀土元素离子半径减小, 热导率和热扩散系数增加, 晶格氧含量下降。从微结构观察发现Si3N4平均晶粒尺寸随稀土元素离子半径减小而增加, 且上述变化从La到Gd较为明显, 离子半径小于Gd时变化较小。该研究发现, 不同于AlN陶瓷, 稀土氧化物的种类对β-Si3N4陶瓷的晶粒尺寸和晶格氧含量有显著影响, 选择合适的烧结助剂对提高其热导率有重要 意义。

![稀土氧化物烧结助剂离子半径对β-Si3N4(a)热导率、(b)热扩散系数和(c)晶格氧含量的影响[43]](/richHtml/jim/2023/38/10/1117/img_6.png)

图 6. 稀土氧化物烧结助剂离子半径对β -Si3N4(a)热导率、(b)热扩散系数和(c)晶格氧含量的影响[43]

Fig. 6. Relationships between ionic radii of rare-earth oxide additives and (a) thermal conductivity, (b) thermal diffusivity and (c) lattice oxygen content of β -Si3N4[43]

1.4 其它因素的影响

除以上影响因素外, 日本电气化学工业株式会社研究团队还系统研究了大的β-Si3N4晶粒[44]、晶格杂质[45]和缺陷[46], 以及添加β-Si3N4核芯[47-48]对β-Si3N4陶瓷热导率的影响。采用高纯β-Si3N4粉为原料, Y2O3和HfO2为烧结助剂, 在1900 ℃气压烧结不同时长(4, 8, 20和48 h)制备了β-Si3N4陶瓷。结合平均场微力学模型, 实验结果和理论计算表明, Si3N4的热导率受净化了的大尺寸β-Si3N4晶粒的含量所控制。随着烧结时间的延长, 大尺寸的β-Si3N4晶粒占比增加, 且粗晶粒中的氧、铁和钙杂质的含量明显下降, 热导率从88 W·m-1·K-1 (8 h)大幅提升至120 W·m-1·K-1(48 h)。该研究显示, β-Si3N4晶粒可以通过在液相中的溶解-析出过程完成生长和净化, 从而有效降低晶格中的杂质含量并提升热导率[44]。

对于晶格缺陷的影响, 选用Yb2O3和ZrO2为烧结助剂, 在1900 ℃烧结8 h或36 h, 后者还在1700 ℃退火热处理100 h得到两种微结构差异明显的β-Si3N4陶瓷。显微分析结果表明, 延长高温烧结时间和退火热处理可以促进晶粒生长, 有效减少β-Si3N4晶粒中含Yb的小沉淀物、错配位错和生长位错等晶格缺陷(图7), 从而有效提升热导率[46]。此外, 采用相同的烧结助剂体系, 通过在高纯β-Si3N4粉体原料中添加不同体积分数的β-Si3N4晶种颗粒(0, 13%, 24%, 36%, 49%, 60%, 71%和100%), 在1950 ℃气压烧结16 h制备了不同微结构的β-Si3N4陶瓷。未添加晶种的样品具有包含异常长大的β-Si3N4晶粒和小的等轴状基质晶粒的双峰状微结构, 热导率为140 W·m-1·K-1; 而添加24%晶种的样品虽然也保持了双峰状微结构, 但晶粒尺寸相对较小, 并且热导率提升至143 W·m-1·K-1。对比结果表明, β-Si3N4的热导率受再沉积的大晶粒的量所影响, 而不被β-Si3N4的晶粒尺寸所控制[47]。该结果与Kitayama等[35]的研究结论相一致, 减小大晶粒的尺寸可以保持高的热导率, β-Si3N4晶粒尺寸并不是影响其热导率的最关键因素。因此, 对于β-Si3N4陶瓷, 通过控制微结构有望同时实现高热导率和高强度。

2 高热导率Si3N4陶瓷的有效烧结助剂

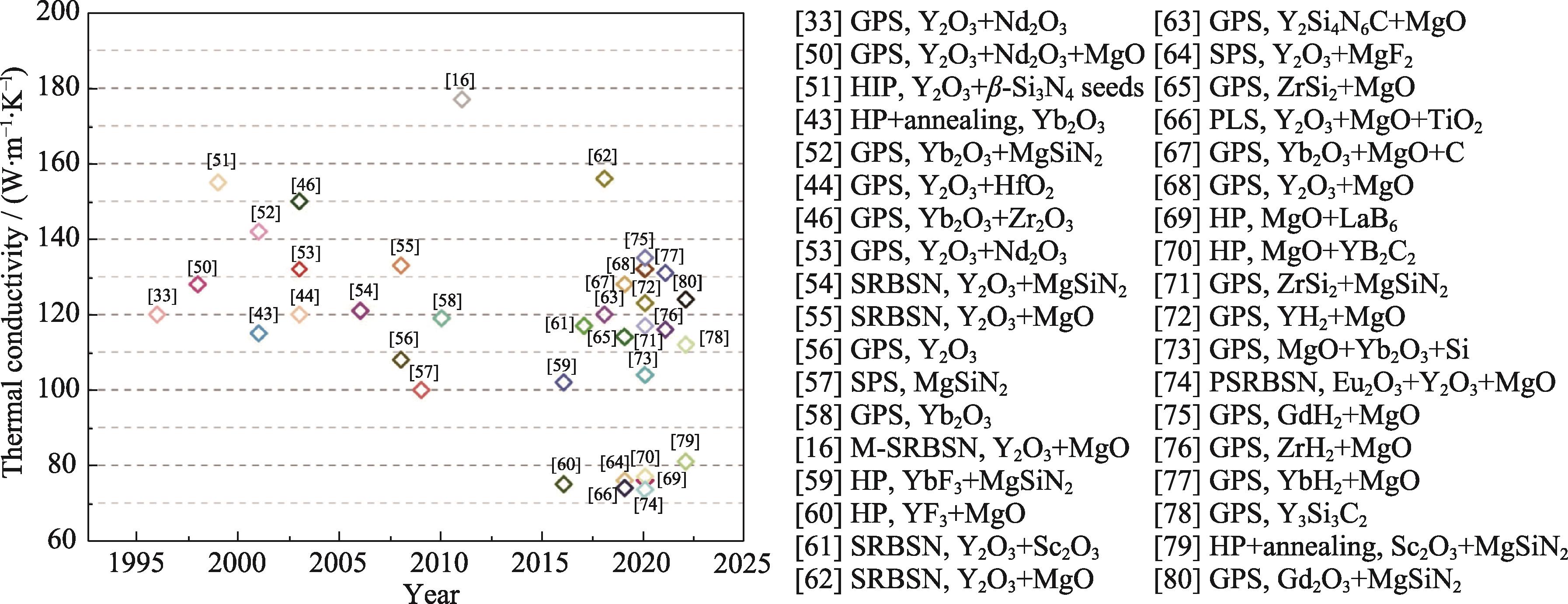

由于Si3N4中Si-N键强共价键的特性, 烧结Si3N4陶瓷需要添加一定量的烧结助剂, 在高温下与Si3N4颗粒表面的SiO2薄膜以及少量的Si3N4形成液相, 借助液相烧结实现致密化。烧结助剂固溶进入Si3N4晶格形成固溶体会严重降低热导率(例如, Al2O3与Si3N4反应形成β-Si3N4的固溶体β-SiAlON), 因此, 不固溶进入Si3N4晶格的碱土氧化物、稀土氧化物(RE2O3)和一些金属化合物是制备高热导率Si3N4陶瓷的有效助剂[49]。图8总结了1996年至今高热导Si3N4陶瓷的烧结工艺和烧结助剂体系的研究进展, 小离子半径的RE2O3(如Y2O3或Yb2O3)搭配Mg化合物, 以及非氧化物代替氧化物作为烧结助剂, 是提高Si3N4陶瓷热导率的有效方式。下面分别从氮化物烧结助剂、还原性烧结助剂和其它非氧化物烧结助剂等三个方面综述高热导率Si3N4陶瓷的有效助剂体系, 另外对三元烧结助剂体系低成本制备高强高热导Si3N4陶瓷也作简单介绍。

图 8. 不同烧结助剂体系和烧结方法制备高热导率Si3N4陶瓷的研究进展

Fig. 8. Developments of high thermal conductivity Si3N4 ceramics with different sintering additives systems and sintering methods

2.1 氮化物烧结助剂

可用作Si3N4烧结助剂的氮化物有: VN、YN、Mg3N2、AlN、Ca3N2和MgSiN2等[81-82]。其中MgSiN2不仅可以有效降低硅酸盐玻璃的熔点, 而且不会引入多余的氧杂质, 更重要的是, 目前已经可以通过燃烧合成工艺低成本、大批量地生产高纯MgSiN2粉体[83⇓⇓-86]。因此, 氮化物烧结助剂MgSiN2在制备高热导Si3N4陶瓷方面前景广阔。Peng等[57]仅以MgSiN2为烧结助剂, 1600 ℃放电等离子体烧结(SPS)12 min制备了热导率100 W·m-1·K-1的Si3N4陶瓷。Hayashi等[52]以Yb2O3-MgSiN2为烧结助剂, 在1900 ℃气压烧结48 h制备了热导率142 W·m-1·K-1的Si3N4陶瓷, 比Yb2O3-MgO的热导率提升了20.3%, 主要原因是加入MgSiN2促进了Si3N4晶粒的生长和晶格的净化。

中国科学院理化技术研究所团队[79]研究了离子半径存在明显差异的7种RE2O3(RE=Sc, Lu, Yb, Y, Gd, Nd, La)分别与MgSiN2组成复合烧结助剂时, 不同RE2O3对Si3N4微结构、力学性能和热导率的影响(图9)。热压烧结后, Si3N4陶瓷的热导率不高, 均在50 W·m-1·K-1左右; 但不同助剂体系制备的β-Si3N4陶瓷综合强韧性优异, 添加Nd2O3-MgSiN2的样品弯曲强度为1115 MPa; 退火热处理后, 不同助剂体系制备的Si3N4陶瓷晶粒尺寸增大, 热导率均得到明显提升, 且热导率随复合助剂中稀土离子半径的减小而增大。随后, 研究人员采用具有中等稀土离子半径的Gd2O3与MgSiN2组成复合烧结助剂, 通过优化组分配方, 发现当Gd2O3/MgSiN2比率为1 : 1时, Si3N4陶瓷具有最明显的双峰状微结构和最优的性能, 热导率、弯曲强度和断裂韧性分别达124 W·m-1·K-1, 648 MPa和9.12 MPa·m1/2。其中, 热导率相较于添加Gd2O3-MgO的样品提升27.8%, 主要原因是MgSiN2代替MgO后促进β-Si3N4晶粒的生长和晶间玻璃相的集中分布(图10)[80]。

![Si3N4 陶瓷的(a)平均晶粒尺寸、(b)弯曲强度、(c)断裂韧性和(d)热导率随稀土离子半径的变化[79]](/richHtml/jim/2023/38/10/1117/img_9.png)

图 9. Si3N4 陶瓷的(a)平均晶粒尺寸、(b)弯曲强度、(c)断裂韧性和(d)热导率随稀土离子半径的变化[79]

Fig. 9. Change of (a) average grain size, (b) bending strength, (c) fracture toughness, and (d) thermal conductivity of Si3N4 ceramics with radius of rare earth ion[79]

![含Gd2O3-MgSiN2烧结助剂的Si3N4 1900 ℃烧结12 h后抛光表面的元素分布图[80]](/richHtml/jim/2023/38/10/1117/img_10.png)

图 10. 含Gd2O3-MgSiN2烧结助剂的Si3N4 1900 ℃烧结12 h后抛光表面的元素分布图[80]

Fig. 10. Elemental distributions of the polished surface of Si3N4 with Gd2O3-MgSiN2 additives after sintering at 1900 ℃ for 12 h[80]

2.2 还原性烧结助剂

添加金属氢化物、少量的硅粉或碳粉等还原性助剂, 借助金属氢化物还原反应、硅热还原反应或碳热还原反应降低氧含量, 增加晶间第二相的N/O比率, 可以促进β-Si3N4晶粒的异常长大, 降低晶格氧含量, 从而有效提升Si3N4陶瓷的热导率。中国科学院上海硅酸盐研究所团队选择YH2[72,87]、GdH2[75]、YbH2[77]和ZrH2[76]分别与MgO组成复合烧结助剂, 通过两步气压烧结制备了高热导率Si3N4陶瓷。图11为ZrH2作为烧结助剂时的作用机理[76], 在ZrH2的作用下, Si3N4粉体表面的SiO2通过SiO2→ZrO2→SiO(g)的路径得以消除, 最终得益于更少的玻璃相含量和更充分的晶粒与晶粒之间的接触, 热导率最高达116.4 W·m-1·K-1。此外, 该团队还通过添加少量硅粉, 借助两步气压烧结和新的硅热还原反应制备了具有明显双峰状微结构的Si3N4陶瓷, 与不添加硅粉相比, 热导率由90.03提升至104.5 W·m-1·K-1, 断裂韧性由8.56提升至9.91 MPa·m1/2[73]。

![烧结助剂ZrH2在Si3N4陶瓷烧结中的作用机理示意图[76]](/richHtml/jim/2023/38/10/1117/img_11.png)

图 11. 烧结助剂ZrH2在Si3N4陶瓷烧结中的作用机理示意图[76]

Fig. 11. Schematic diagram of the mechanism of sintering additive ZrH2 in the sintering of Si3N4 ceramics[76]

Li等[67]采用Yb2O3-MgO为烧结助剂, 通过添加摩尔分数5%的碳, 两步气压烧结制备了高热导率Si3N4陶瓷。在第一步烧结中碳热还原反应促进了氧的消除, 在增加第二相N/O原子比的同时, 增大了β/(α+β)相的比例和棒状β-Si3N4晶粒的尺寸; 再经过第二步烧结形成了更为突出的双峰状微结构(图 12)。添加的碳使Si3N4陶瓷的热导率由102提升至128 W·m-1·K-1, 提高了~25.5%。

![添加碳对Si3N4陶瓷微结构的影响[67]](/richHtml/jim/2023/38/10/1117/img_12.png)

图 12. 添加碳对Si3N4陶瓷微结构的影响[67]

Fig. 12. Effect of carbon addition on the microstructure of Si3N4 ceramics[67]

2.3 其它非氧化物烧结助剂

制备高热导率Si3N4陶瓷的其它种类的非氧化物烧结助剂主要包括硅化物[65,71]、氟化物[60,64,88-89]、硼化物[69]和碳化物[70,78]等, 硅化物和氟化物为典型代表。中国科学院上海硅酸盐研究所团队[65]采用ZrSi2-MgO烧结助剂制备高热导率Si3N4陶瓷, ZrSi2与Si3N4表面的SiO2反应生成ZrO2和β-Si3N4晶粒, 其中新生成的ZrO2与MgO和Si3N4形成Si-Zr-Mg-O-N液相促进了Si3N4的致密化; 而原位生成的β-Si3N4晶粒作为晶种则促进了晶粒的异常长大。最终, 添加ZrSi2相较于添加ZrO2的热导率由84.58提升至113.91 W·m-1·K-1。但由于晶粒异常长大, 以及薄的晶界膜和Si3N4晶粒之间的连接较强, 添加ZrSi2的样品力学性能较差, 弯曲强度仅有519 MPa, 断裂韧性为6.27 MPa·m1/2。随后该团队采用二元非氧化物烧结助剂ZrSi2-MgSiN2, 通过形成“缺氧-富氮”的液相, 进一步制备了热导率达117.32 W·m-1·K-1的Si3N4陶瓷, 比采用ZrO2-MgO烧结助剂的样品提升了32%[71]。

山东理工大学团队[88]研究了Y2O3-MgO, Y2O3-MgF2, YF3-MgO和YF3-MgF2四种复合助剂对气压烧结Si3N4陶瓷晶粒生长动力学、力学性能和热导率的影响。研究发现YF3与SiO2反应生成SiF4气体, 可以减少SiO2含量, 增加Y2O3/SiO2的比例, 从而有助于提升热导率。另外, 借助经典的LSW理论和Arrhenius公式研究了Si3N4晶粒生长动力学, 计算得到晶粒生成指数(n)和生长活化能(Q)。如图 13 所示, 添加YF3-MgF2时, n=2.6, Q=(587.94± 15.35) kJ/mol, 明显低于添加Y2O3-MgO时的(n=3.4, Q=(702.66±11.26) kJ/mol)。因此, 添加二元氟化物的Si3N4样品表现出更优的综合性能, 热导率为69 W·m-1·K-1, 弯曲强度为751 MPa, 断裂韧性为8.75 MPa·m1/2。

![含Y2O3-MgO和YF3-MgF2烧结助剂Si3N4样品的β-Si3N4晶粒生长动力学研究[88]](/richHtml/jim/2023/38/10/1117/img_13.png)

图 13. 含Y2O3-MgO和YF3-MgF2烧结助剂Si3N4样品的β -Si3N4晶粒生长动力学研究[88]

Fig. 13. Kinetic analysis of β -Si3N4 grain growth in Si3N4 samples with Y2O3-MgO and YF3-MgF2 additives[88]

2.4 三元复合烧结助剂

使用非氧化物代替氧化物作为烧结助剂可以减少液相中的氧含量, 从而降低Si3N4的晶格氧含量, 但液相中N/O原子比增大会在一定程度上抑制致密化, 往往需要通过升高烧结温度或延长保温时间加以解决, 这无疑会增加制备成本, 同时晶粒异常长大也会危害力学性能。因此, 研究人员试图通过低温低压或低温无压烧结来低成本制备热学和力学性能兼顾的Si3N4陶瓷, 使用三元烧结助剂成为关注的重点。

Kumar等[90]对比研究了Y2O3-MgO-SiO2和Y2O3-MgO-ZrO2两种三元氧化物烧结助剂对无压烧结Si3N4陶瓷热导率的影响。1650 ℃无压烧结1 h后, Y2O3-MgO-SiO2助剂促进了α→β相转变, 但制备陶瓷的热导率较低, 仅为33.4 W·m-1·K-1; 而Y2O3-MgO-ZrO2助剂促进了晶粒的生长, 制备陶瓷的热导率提升至~50 W·m-1·K-1, 验证了三元烧结助剂低温无压烧结制备较高热导率Si3N4陶瓷的可行性。中国科学院上海硅酸盐研究所团队[66]发现TiO2-Y2O3-MgO烧结助剂与Si3N4颗粒表面的SiO2反应形成的低熔点液相可以促进Si3N4的致密化, 1810 ℃无压烧结2 h后, 陶瓷弯曲强度为756 MPa, 断裂韧性为7.69 MPa·m1/2; 当保温时长延长至4 h并退火热处理后, 最优陶瓷热导率达74 W·m-1·K-1。

广东工业大学研究团队[91]对比了Eu2O3-MgO-Y2O3和ZrO2-MgO-Y2O3两种烧结助剂体系对反应烧结-重烧结Si3N4陶瓷(SRBSN)的氮化率、致密化和热导率的影响。研究发现1400 ℃氮化2 h后, 两种助剂体系都完全氮化, 但经过高温重烧结后, Eu2O3-MgO-Y2O3助剂体系会抑制致密化, 而ZrO2-MgO-Y2O3助剂体系经过1835 ℃无压烧结4 h后促进了致密化, 相对密度达99.5%, 热导率达66.5 W·m-1·K-1, 表明同时使用氮化催化剂和烧结助剂可以低成本制备Si3N4陶瓷。进一步地, 该团队选择ZrO2+Gd2O3+MgO为烧结助剂, 研究了Si粉添加量对SRBSN力学性能和热导率的影响, 经过1400 ℃氮化2 h和1800 ℃无压烧结2 h后, 添加摩尔分数25% Si粉的样品热导率约60 W·m-1·K-1, 弯曲强度为924 MPa, 断裂韧性为10.3 MPa·m1/2, 低成本制备了具有优异综合性能的Si3N4陶瓷[92]。

3 高热导率Si3N4陶瓷的烧结工艺

制备高热导率Si3N4陶瓷的烧结工艺主要有热压烧结(Hot-pressed, HP)、放电等离子体烧结(Spark plasma sintering, SPS)、热等静压烧结(Hot isostatic pressing, HIP)、气压烧结(Gas-pressure sintering, GPS)和反应烧结-重烧结Si3N4(Sintering of reaction bonded silicon nitride, SRBSN)等。考虑到批量化烧结制备和后续加工的成本, 商业化制备功率模块封装用Si3N4陶瓷基板通常采用SRBSN和GPS工艺。

3.1 反应烧结-重烧结Si3N4工艺

氧杂质含量是影响Si3N4陶瓷热导率的最主要因素, 即使是最高纯的商业Si3N4粉也含有质量分数超过1%的氧杂质, 而得益于现代半导体产业的进步, 高纯Si粉的氧杂质和金属杂质含量明显低于Si3N4粉。受此启发, 日本产业技术综合研究所团队采用高纯Si粉为起始原料, Y2O3-MgO为烧结助剂, 通过发展改进SRBSN工艺(M-SRBSN), 制得热导率高达182 W·m-1·K-1的Si3N4陶瓷, 至今未被超越[5]。该团队首先将使用高纯Si粉为原料通过反应烧结-重烧结制备的Si3N4陶瓷(SRBSN), 与使用α-Si3N4粉为原料通过传统气压烧结制备的Si3N4陶瓷(Sintering of silicon nitride, SSN)进行比较(图14(a)), SRBSN在1900 ℃烧结3, 6, 12, 24, 48 h后热导率分别为100, 105, 117, 133和142 W·m-1·K-1, 而SSN仅分别为87, 91, 96, 103和111 W·m-1·K-1, SRBSN工艺在制备高热导率Si3N4陶瓷方面表现出更大的优势。之后通过在1400 ℃氮化4 h过程中使用更具还原性的气氛, 有效提升反应烧结Si3N4(RBSN)中的β相比例, 再经过1900 ℃烧结3, 6, 12和24 h后, M-SRBSN的热导率进一步提升至109, 125, 146和154 W·m-1·K-1。最后在1900 ℃烧结60 h+ 0.2 ℃·min-1降温退火处理, β-Si3N4晶粒尺寸进一步增大, 晶格氧含量下降, 晶间相占比降低, Si3N4陶瓷热导率提升至177 W·m-1·K-1[16,93]。

![不同烧结工艺制备Si3N4陶瓷热导率和(a)烧结时间和(b)晶格氧含量及其与(c)弯曲强度之间的关系[16,93,94]](/richHtml/jim/2023/38/10/1117/img_14.png)

图 14. 不同烧结工艺制备Si3N4陶瓷热导率和(a)烧结时间和(b)晶格氧含量及其与(c)弯曲强度之间的关系[16,93,94]

Fig. 14. Relationships between thermal conductivity of Si3N4 ceramics prepared by different sintering processes and (a) sintering time, (b) lattice oxygen content and (c) flexural strength[16,93,94]

图14(b)为不同烧结助剂和烧结工艺制备Si3N4陶瓷的热导率及其对应的晶格氧含量, M-SRBSN的晶格氧含量更低, 相应的热导率更高。图14(c)为Si3N4样品热导率与弯曲强度的对应关系, 对于相同水平的热导率, M-SRBSN表现出更高的弯曲强度, 但当热导率超过110 W·m-1·K-1后, 弯曲强度还是出现了快速下降。为解决这一问题, 研究人员将氮化温度提高到>1400 ℃, 同时将高温重烧结从1900 ℃降为1850 ℃, 成功制备了热导率>110 W·m-1·K-1, 弯曲强度约850 MPa的高强高热导Si3N4陶瓷 (图14(c))[94]。

3.2 气压烧结工艺

改进GPS工艺也是提高Si3N4陶瓷热导率的有效方式。Zhu等[95]使用Y2O3-MgSiN2烧结助剂, 通过改变样品的数目以及埋入BN粉床中的比例, 研究了4种埋粉条件对Si3N4陶瓷热导率的影响(图15)。发现埋粉条件不会影响致密化, 但对质量损失有明显影响, 且热导率随质量损失的增加而增大, 这主要是由于增加质量损失有助于晶格氧通过反应式(2)以SiO气体的形式移除。图15(c, d)所示的两种埋粉条件更有利于SiO气体挥发, 因此质量损失更大, 热导率更高, 最高达117 W·m-1·K-1。清华大学研究团队[96]在后烧结热处理Si3N4样品过程中, 使用C/Si3N4粉床来代替传统的BN/Si3N4粉床, 在不明显影响密度和弯曲强度的前提下有效消除了晶界相, 得到了热导率为123 W·m-1·K-1, 弯曲强度为986 MPa的Si3N4陶瓷。

西安交通大学研究团队[97]通过研究预烧结温度对液相烧结过程颗粒重排和α→β相转变的影响, 开发了一种制备高强高热导Si3N4陶瓷的新型两步气压烧结方法。当预烧结温度过低(1500 ℃)时, 由于液相黏度过高, 颗粒重排不够充分; 当预烧结温度过高(1550或1600 ℃)时, α→β相转变过快形成的细长β-Si3N4颗粒造成一定的空间位阻效应, 经第二步高温(1850 ℃)烧结后均不能实现完全致密化(图16(a~e))。而当预烧结温度为1525 ℃时, 得益于优化的颗粒重排和合适的α→β相转变速率, Si3N4陶瓷在1850 ℃第二步高温烧结后几乎完全致密, 形成了突出的双峰状微结构(图16(b)), 同时获得了最佳的综合性能, 热导率为79.42 W·m-1·K-1, 弯曲强度为801 MPa。

![不同预烧结温度对两步烧结后Si3N4微结构的影响((a)1500 ℃, (b)1525 ℃, (c)1550 ℃和(d)1600 ℃); (e)预烧结和两步烧结后Si3N4样品的相对密度; (f)两步烧结后Si3N4的热导率和弯曲强度[97]](/richHtml/jim/2023/38/10/1117/img_16.png)

图 16. 不同预烧结温度对两步烧结后Si3N4微结构的影响((a)1500 ℃, (b)1525 ℃, (c)1550 ℃和(d)1600 ℃); (e)预烧结和两步烧结后Si3N4样品的相对密度; (f)两步烧结后Si3N4的热导率和弯曲强度[97]

Fig. 16. Effect of different pre-sintering temperature on the microstructure of Si3N4 after two-step sintering((a) 1500 ℃, (b) 1525 ℃, (c) 1550 ℃ and (d) 1600 ℃), (e) relative density of Si3N4 samples after pre-sintering and two-step sintering, and (f) thermal conductivity and flexural strength of Si3N4 samples after two-step sintering[97]

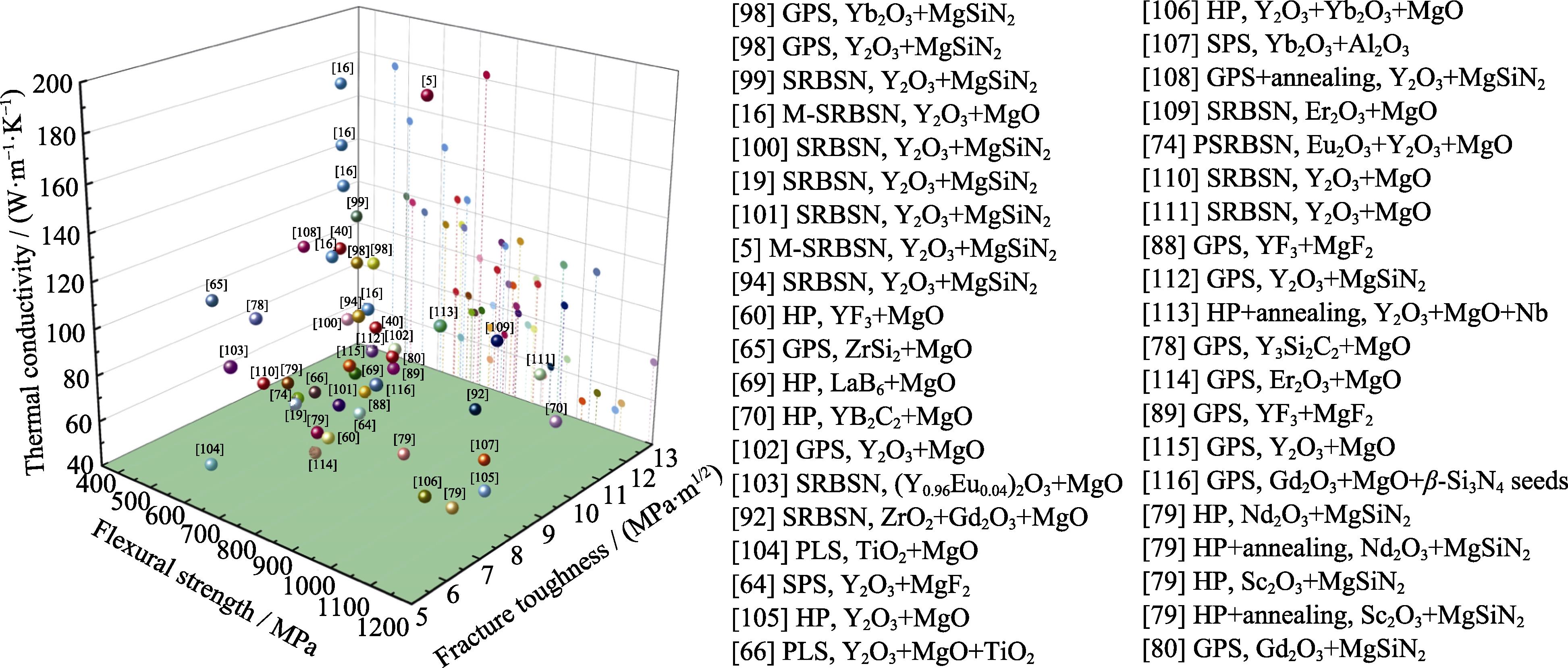

为满足第三代半导体芯片封装对陶瓷基板的性能要求, 制备兼顾力学和热学性能的高强高热导Si3N4陶瓷, 在今后很长一段时间内都将是研究关注的重点。图17总结了不同烧结方法和烧结助剂制备Si3N4陶瓷的热导率、弯曲强度和断裂韧性。已经成功实现同时达到高热导率(>150 W·m-1·K-1)和高韧性(>10 MPa·m1/2)[5], 但热导率和弯曲强度相反的变化趋势仍未解决,需要在尽可能少牺牲Si3N4陶瓷弯曲强度的基础上进一步提升其热导率。

图 17. 不同烧结方法和烧结助剂制备Si3N4陶瓷的热导率、弯曲强度和断裂韧性

Fig. 17. Thermal conductivity, bending strength and fracture toughness of Si3N4 ceramics prepared by different sintering methods and additives

4 Si3N4陶瓷基板的介电击穿强度与覆铜后的性能评价

当Si3N4陶瓷用作功率模块封装陶瓷基板材料时, 其电绝缘性和覆铜后陶瓷基板的稳定性对功率模块正常运行具有重要影响[7,24-25]。日本产业技术综合研究所团队在制得高热导率Si3N4陶瓷后, 开展了一系列针对Si3N4陶瓷基板介电击穿强度(DBS)与覆铜后性能评价的研究。

4.1 Si3N4陶瓷基板的介电击穿强度

绝缘体被介电击穿后会在内部形成导电通道, 从而失去电绝缘。介电击穿强度(DBS)定义为厚度方向上单位长度样品的击穿电压。Matsunaga等[20]研究了平均晶粒尺寸为1.28和2.84 μm的两种Si3N4陶瓷,厚度为0.25, 0.32和0.64 mm时的DBS。研究发现厚度相同时, 晶粒尺寸较小的Si3N4样品DBS更高。为了更好地发挥功率模块性能, 通常需要更薄的陶瓷基板, 因此Nakashima等[21]研究了0.285~0.015 mm厚度范围的Si3N4陶瓷样品的DBS。随着基板厚度减小, DBS从36.38增大到103.8 kV/mm; 而当Si3N4样品的厚度仅为0.015 mm时, 也获得了非常高的介电击穿电压(1.5 kV)。

有关氧化铝DBS的研究表明, 样品的孔隙率、晶粒尺寸、结晶相和晶界等微结构因素都对DBS有影响, 并且介电材料的DBS(Ebd)与样品厚度(d)之间满足式(3)的关系。Nakashima等[117]通过改变SRBSN工艺1850 ℃重烧结的时长(1, 3, 6, 12, 24和48 h), 制备了不同孔隙率和晶粒尺寸的Si3N4陶瓷, 研究了微结构因素对4种不同厚度(0.30, 0.20, 0.10和0.05 mm)Si3N4基板DBS的影响。当重烧结时长为1, 3和6 h时, Si3N4基板的DBS与厚度(d)的N次方满足式(3)的关系(式中A为常数, 取决于材料的种类和结构), 对应的N分别为0.28, 0.41和0.49 (图 18(a~c)),这主要是N的变化与基板的孔隙率相关。当烧结时长从1到6 h时, 孔隙率从5.4%降至0.5%。当烧结时长>6 h时, 实现了完全致密, β-Si3N4晶粒的平均尺寸随烧结时间延长而增加, 此时Si3N4基板厚度与DBS不满足式(3)的关系(图18(d~f)), 而是表现出DBS随最大晶粒尺寸与基板厚度比值的增加而下降的趋势。图19对此结果进行了解释, β-Si3N4晶粒与晶界相之间的界面存在高密度的悬空键, 这种界面可能是导致介电击穿的严重缺陷。基板厚度方向的晶粒数目多时(晶粒尺寸小), 介电击穿的路径更为曲折, DBS更大, 反之则反。

![基板厚度对烧结(a)1, (b)3, (c)6, (d)12, (e)24和(f)48 h的Si3N4陶瓷介电击穿强度(DBS)的影响[117]](/richHtml/jim/2023/38/10/1117/img_18.png)

图 18. 基板厚度对烧结(a)1, (b)3, (c)6, (d)12, (e)24和(f)48 h的Si3N4陶瓷介电击穿强度(DBS)的影响[117]

Fig. 18. Effect of substrate thickness on the dielectric breakdown strength (DBS) of Si3N4 ceramics sintered for (a) 1, (b) 3, (c) 6, (d) 12, (e) 24, and (f) 48 h[117]

![β-Si3N4晶粒与晶界相/晶间玻璃薄膜(IGFs)之间界面的连接路径示意图[117]](/richHtml/jim/2023/38/10/1117/img_19.png)

图 19. β -Si3N4晶粒与晶界相/晶间玻璃薄膜(IGFs)之间界面的连接路径示意图[117]

Fig. 19. Schematic images of the connecting path for the interface between β -Si3N4 grain and grain boundary phases/ intergranular glassy films (IGFs) in the substrates which have (a) smaller and (b) larger ratio of grain size to substrate thickness[117]

4.2 覆铜Si3N4陶瓷基板的性能评价

Si3N4陶瓷基板应用于功率模块封装材料时, 其两面都需要与Cu相结合形成覆铜的金属化陶瓷基板, 其中一面作为导体电路, 另一面减小与散热器之间界面热阻。在功率模块运行过程中, 覆铜陶瓷基板靠近半导体设备的热端与靠近散热器的冷端之间温差很大, 由于陶瓷与金属的热膨胀系数不匹配, 大的温差将产生大的热应力, 这对覆铜陶瓷基板的力学和热稳定性提出了更高要求, 因此需要测试覆铜后Si3N4陶瓷基板的性能, 以评价其在功率模块运行过程中的可靠性。

Miyazaki等[118]测试了-40到250 ℃热循环对4种覆铜Si3N4陶瓷基板力学和热学性能的影响(表2), 并与覆铜AlN陶瓷基板进行比较。通过声学扫描显微镜(Acoustic scanning microscope, ASM)观察, 覆铜Si3N4基板即使经历1000次热循环测试也没有出现Cu层脱落现象, 其中高热导率和高韧性的SN-1覆铜基板表现最优, 整个热循环测试过程都没有裂纹产生(图20(a~d)); 而覆铜AlN陶瓷基板仅热循环50次后就出现严重的Cu层脱落现象。图20(e)为覆铜陶瓷基板热循环测试后剩余强度与起始强度比值随热循环次数的变化, SN-1覆铜基板经历1000次热循环后强度也没有出现明显改变; 而其余覆铜陶瓷基板的强度随热循环次数增加均出现不同程度的下降。为探究SN-1覆铜基板抗热疲劳性能优异的原因, 进一步研究了热循环10次后剩余强度与起始强度比率和断裂韧性之间的关系(图20(f)), 陶瓷基板的抗热疲劳能力随断裂韧性的增加而线性增加, 表明陶瓷基板抵抗裂纹扩展能力是影响抗热疲劳性能的重要因素[119-120]。以上结果说明, 高热导率和高韧性的Si3N4更适合用作功率模块的覆铜陶瓷基板材料。

表 2.

用于热循环测试的Si3N4陶瓷基板和AlN陶瓷基板的力学和热学性能[118]

Table 2. Mechanical and thermal properties of Si3N4 ceramic substrates and AlN ceramic substrates for thermal cycle testing[118]

|

![SN-1覆铜基板不同热循环次数后的照片((a)10次, (b)100次, (c)200次和(d)1000次); (e)陶瓷覆铜基板剩余/起始强度比随热循环次数的变化; (f)10次热循环后Si3N4覆铜基板的剩余强度/初始强度比与断裂韧性的关系[118]](/richHtml/jim/2023/38/10/1117/img_20.png)

图 20. SN-1覆铜基板不同热循环次数后的照片((a)10次, (b)100次, (c)200次和(d)1000次); (e)陶瓷覆铜基板剩余/起始强度比随热循环次数的变化; (f)10次热循环后Si3N4覆铜基板的剩余强度/初始强度比与断裂韧性的关系[118]

Fig. 20. Images of the SN-1 coppered substrate after different thermal cycles ((a) 10 cycles, (b) 100 cycles, (c) 200 cycles, and (d) 1000 cycles), (e) plots of residual to initial strength ratio vs. thermal cycle number of the coppered substrates, and (f) relationship between residual to initial strength ratio and fracture toughness of the Si3N4 coppered substrates after 10 cycles[118]

5 总结与展望

高强高热导Si3N4是最具潜力的第三代半导体陶瓷基板材料。本文从影响Si3N4陶瓷热导率的因素入手, 系统综述了通过选择有效的烧结助剂、改进SRBSN工艺和GPS工艺在制备高热导率Si3N4陶瓷方面的研究进展, 最后还介绍了Si3N4基板的介电击穿强度以及覆铜后的性能评价。历经近30年的研究, 高强高热导Si3N4陶瓷取得了很大的突破, 但距离大规模商业化应用仍有一定差距。未来的研究方向包括:

1)加强对Si3N4陶瓷烧结过程的研究。当前都是通过组分配方法选择和烧结工艺优化来提高Si3N4陶瓷的热导率, 缺少对烧结过程中晶粒生长和晶格氧移除的动力学和热力学方面的研究。加强对整个烧结过程的控制, 从本质上理解微结构与热学和力学性能之间的关系, 有望更精确有效地调控Si3N4陶瓷性能。

2)降低高强高热导Si3N4陶瓷基板的制备成本。成本高仍是限制Si3N4陶瓷基板大规模商业化应用的最大障碍, 随着光伏产业的发展, 高纯Si粉的制备成本不断下降, 因此改进SRBSN方法以低成本制备高强高热导Si3N4陶瓷具有很大优势。同时, 探索稳定高效的非氧化物烧结助剂, 以制备热学与力学性能兼顾的Si3N4陶瓷仍是研究者关注的重点。

3)完善对包含Si3N4陶瓷基板在内的第三代半导体功率模块整体的性能评价。功率模块由金属化陶瓷基板、半导体器件、母材和散热金属粘合而成, 最后用树脂密封。未来除了提高Si3N4陶瓷基板的性能外, 还应加强对Si3N4陶瓷基板与其它部件结合作为整体使用时的可靠性评价。

[1] CHOI U M, BLAABJERG F, JORGENSEN S, et al. Power cycling test and failure analysis of molded intelligent power IGBT module under different temperature swing durations[J]. Microelectronics Reliability, 2016: 64: 403.

[2] CABELLO M, SOLER V, RIUS G, et al. Advanced processing for mobility improvement in 4H-SiC MOSFETs: a review[J]. Materials Science in Semiconductor Processing, 2018: 78: 22.

[28] TAKEDA Y. Development of high-thermal-conductivity SiC ceramics[J]. American Ceramic Society Bulletin, 1988: 1961.

[30] HAMPSHIRE S, PARK H K, THOMPSON D P, et al. α’-Sialon ceramics[J]. Nature, 1978: 880.

[37] PEUCKERT M, GREIL P. Oxygen distribution in silicon nitride powders[J]. Journal of Materials Science, 1987: 22: 3717.

[39] HIROSAKI N, OKADA A, MATOBA K. Sintering of Si3N4 with the addition of rare-earth-oxides[J]. Journal of the American Ceramic Society, 1988: C144.

[68] LI Y, KIM H N, WU H, et al. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: the effects of Y2O3 additive content[J]. Journal of the European Ceramic Society, 2021: 274.

[76] WANG W, YAO D, LIANG H, et al. Enhanced thermal conductivity in Si3N4 ceramics prepared by using ZrH2 as an oxygen getter[J]. Journal of Alloys and Compounds, 2021: 855: 157451.

[81] UCHIDA N, KOIZUMI M, SHIMADA M. Fabrication of Si3N4 ceramics with metal nitride additives by isostatic hot-pressing[J]. Journal of the American Ceramic Society, 1985.

[84] 杨建辉, 陈义祥, 刘光华, 等. 自蔓延高温合成制备单相氮化硅镁粉体[J]. 硅酸盐学报, 2011: 177.

[90] KUMAR K, PARK Y J, KIM M J, et al. Influence of ternary oxide additives on thermal conductivity of pressureless sintered Si3N4[J]. Materials Letters, 2022: 328: 133189.

[102] LI S, CHEN H, WANG W, et al. Effects of Y2O3/MgO ratio on mechanical properties and thermal conductivity of silicon nitride ceramics[J]. International Journal of Applied Ceramic Technology, 2022: 2873.

[106] 鲁欣欣, 刘伟, 李林, 等. MgO-Y2O3-Re2O3添加对氮化硅陶瓷微观组织及性能的影响[J]. 粉末冶金材料科学与工程, 2019: 536.

[114] JIANG C, ZHUANG Y, WANG J, et al. Preparation, microstructure, and properties of GPS silicon nitride ceramics with

[120] MIYAZAKI H, YOSHIZAWA Y I, HIRAO K, et al. Evaluation of fracture toughness of ceramic thin plates through modified single edge-precracked plate method[J]. Scripta Materialia, 2015: 103: 34.

Article Outline

付师, 杨增朝, 李江涛. 功率模块封装用高强度高热导率Si3N4陶瓷的研究进展[J]. 无机材料学报, 2023, 38(10): 1117. Shi FU, Zengchao YANG, Jiangtao LI.

![Si3N4样品的明场TEM照片[46]](/richHtml/jim/2023/38/10/1117/img_7.png)

![四种不同埋粉方式示意图[95]](/richHtml/jim/2023/38/10/1117/img_15.png)