服役载荷与结构参数对塔式太阳能定日镜光学精度的影响

Solar tower thermal power generation technology has the advantages of high light-electricity conversion efficiency and flexible energy storage, and it has become one of the most important ways to achieve the goal of “carbon peak and carbon neutrality”. The heliostat is the core device to realize solar energy pooling in the whole tower photovoltaic power plant. It can focus the solar energy within a certain range around the heat-absorbing tower, so as to complete the light-heat conversion in the heat-absorbing device with high quality. However, the heliostat is susceptible to structural deformation due to self-weight and wind load during service, and the distance between the heliostat and the heat-absorbing tower is relatively large. The small deformation of the reflecting mirror surface of the heliostat will lead to the reflected solar beam falling on the heat-absorbing device, which will directly lead to a decrease in the light-concentrating efficiency of the heliostat and a deterioration in the quality of the light-energy distribution of the heat-absorbing device. Therefore, it is important to investigate the service optical accuracy of the heliostat under self-weight and wind load, which can provide a basis for its lightweight and high-precision design and service performance guarantee.

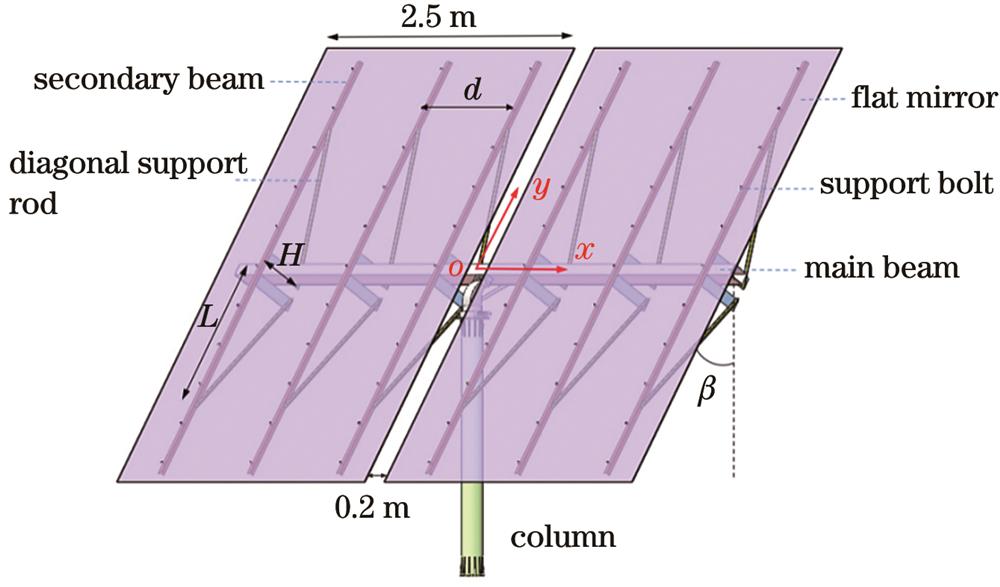

In this study, we study a typical lightweight small-scale heliostat of 20 m2. First, we establishe the three-dimensional (3D) model and the finite element simulation model. Second, we adopte a universal optical-machine integration modeling method previously proposed by the team to consider the service deformation of solar concentrators and establishe an optical-mechanical integration analytical model of the heliostat. We also investigate the influence of the key structural parameters under the effect of self-weight and wind load on the optical accuracy of the heliostat in service. The structural parameters include the spacing d and the number N of the three rows of supporting bolts at the bottom of each plane mirror, the structural parameters of the frame supporting the mirrors, and the parameters of the beam cross-section. The conclusions of the study can provide an important basis for the design of lightweight high-precision heliostat and the maintenance of heliostat's performance in service.

When the wind pressure load on the mirror surface is equal, the self-load at a height angle of 90° has the most unfavorable influence on its optical accuracy. At N=7, the maximum deformation with height angle only increases from 2.07 mm to 2.63 mm, but Dx will significantly increase from 4.21 mrad to 5.35 mrad, and Dy will only increase from 1.36 mrad to 1.73 mrad (Fig. 3). Increasing the number of supporting bolts can reduce the concave deformation of the mirror surface between adjacent bolts in a single row, thereby reducing the slope error component Dy (Fig. 4). By comparing the distribution of mirror deformation and slope error, it can be clearly observed that the maximum slope error region does not occur in the maximum deformation region, which means that there is no non-linear positive correlation between mirror total slope error and mirror deformation (Fig. 5). The decrease in stiffness of the mirror itself is the main reason for the decrease in its optical accuracy, and a support rib plate structure should be added to the back of the mirror according to actual needs, so as to enhance its load-bearing stiffness (Fig. 6). Simply increasing the size of the cantilever secondary beam angle steel may not necessarily improve the optical accuracy of the mirror but rather result in material waste. To further improve optical accuracy, efforts should be made on the structural load-bearing stiffness of the mirror itself, such as adding a support plate on the back of the mirror (Figs. 7-8). The slope of the mirror total slope error variation curve at different height angles is basically the same, with only translation differences (Fig. 9).

If the frame structure is not deformed, the deformation and slope error of the mirror surface under the same wind pressure increase with the increase in the height angle of the heliostat mirror, and the slope error component Dx along the mirror surface in the transverse direction is significantly larger than Dy along its vertical direction; the increase in the number N of mirror back bolts does not have a significant effect on Dx, but it can significantly reduce Dy,

李彬, 颜健, 周炜, 彭佑多. 服役载荷与结构参数对塔式太阳能定日镜光学精度的影响[J]. 光学学报, 2024, 44(6): 0623001. Bin Li, Jian Yan, Wei Zhou, Youduo Peng. Influence of Service Load and Structural Parameters on Optical Accuracy of Solar Tower Heliostat[J]. Acta Optica Sinica, 2024, 44(6): 0623001.