高功率大芯径环形光斑可调信号合束器的研究

Adjustable-ring-mode fiber lasers hold significant application value in the field of lithium battery welding, with the fiber combiner serving as a pivotal component, playing a crucial role in improving the performance of these fiber lasers. Presently, there is a growing body of research dedicated to power improvement and beam quality optimization for signal combiners. This research predominantly revolves around modifying the number of input ports and varying the core diameter of the output fiber. Comparatively, there is a dearth of studies focusing on circular beam adjustable signal combiners. Compared with traditional high-power fiber lasers, the adjustable-ring-mode fiber laser can prevent spattering and improve welding stability. The performance of this combiner is such that the center and external ports can operate independently. Based on this working principle, a signal combiner featuring a large-core-diameter output fiber is fabricated. This combiner attains exceptional transmission efficiency, superior beam quality, and remarkable resistance to high and low temperatures, rendering it suitable for the new field of lithium battery welding.

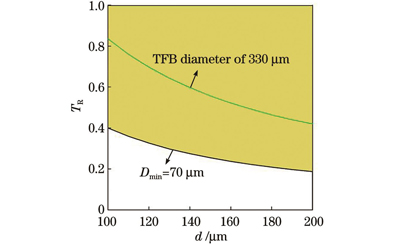

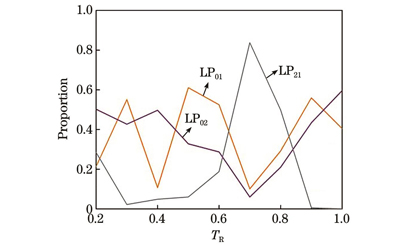

Utilizing beam incoherent synthesis technology, a simulation of the beam combiner is conducted using RSoft software. This simulation scrutinizes alterations in its mode field. The designed beam combiner satisfies the principles of adiabatic taper and brightness conservation. The relationship between the taper ratio and input fiber diameter is analyzed, delineating the range of taper ratio that ensures the autonomous operation of inner and outer ring fibers, even with different input fiber diameters. Considering the impact of cone size on cutting and welding processes, the cone size is determined, and the variations in the three mode fields under varying taper ratios are simulated and analyzed. Subsequently, the influence of the hydrofluoric acid solution concentration on the corrosion time and corrosion efficiency is studied, with pretreatment of the input fibers based on the research findings. Finally, the taper fiber bundle is fabricated using the sleeve method, and the fusion cone fiber bundle and output fiber are fused together using a welding machine, culminating in the successful construction of the combiner.

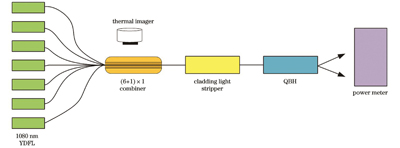

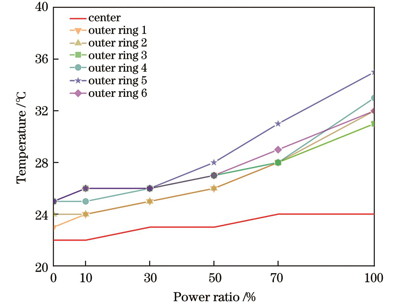

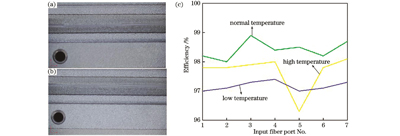

The designed fiber combiner exhibits good transmission characteristics, with each port achieving a transmission efficiency of ≥98% (Table 1). As the power levels increase, the temperature at each port increases by 25?35 ℃ (Fig. 7). Each port of the fiber combiner can independently handle power levels exceeding 3 kW, and when operating in tandem, the inner and outer rings collectively handle power levels surpassing 6 kW. This underscores its capacity to perform reliably at higher power levels, ensuring exceptional stability. Furthermore, the beam quality factor (M2) of the central port is 1.76, with the central curve showcasing a good Gaussian distribution. Any defects observed may be attributed to quartz block head (QBH) compatibility. The external port M2 demonstrates remarkable consistency, as elucidated in Table 2, and the maximum M2 value recorded stands at a mere 88.2, underscoring the outstanding beam quality of both the central and outer rings. Compared with previous results, we consider that this combiner represents the best beam-quality performance. Further enhancements can be achieved through adjustments in the taper ratio or a change in the input fiber type. High- and low-temperature resistance tests show that the transmission efficiency of the combiner decreases slightly under both high- and low-temperature conditions; however, it remains above 97% (Fig. 10). This change is more pronounced at low temperatures than at high temperatures, likely attributable to thermal expansion and contraction-induced bending within the adhesive. Notably, an excessive cutting angle leads to greater welding loss.

In this study, we investigate the key components of a ring spot adjustable fiber laser beam combiner. Through theoretical research and simulation experiments, we find that the input fiber cladding diameter measures 100 μm and the TFB diameter is 330 μm. Subsequently, we fabricate a large-core-diameter toroidal beam spot tunable signal bundler with high beam quality, and we accomplish this with a taper ratio of 0.835. In the context of a large-core-diameter circular dual-core fiber, we manufacture a high-beam-quality large-core-diameter circular spot adjustable signal combiner. The overall transmission efficiency of the combiner exceeds 98%, and it exhibits good transmission characteristics. In the beam quality test, the center M2 is 1.76, while the outer ring M2 ranges between 82 and 89. By adjusting the input port, we can direct either circular Gaussian beams or circular flat top beams independently onto the surface of the working material, or simultaneously apply both to the material surface. Finally, we conduct an environmental reliability test on the combiner, subjecting it to three distinct temperature conditions. The results show that the efficiency of each port experiences a slight decline at both high and low temperatures in comparison to that at room temperature. Notably, the transmission efficiency is the lowest at lower temperatures, attributable to cone bending; however, the transmission efficiency still remains above 97%. The all-fiber ring-spot adjustable signal combiner exhibits the advantages of exceptional transmission characteristics, minimal thermal effects, and superior beam quality. Consequently, it holds substantial promise in the growing laser composite welding market. With the further development of laser composite welding, beam-mode adjustable signal combiners featuring varying output core diameters will undergo more extensive research. Additionally, potential modifications to the TFB structure may enable the center of the annular dual-core fiber to withstand higher power output, expanding its applications further.

1 引言

近些年来,激光器在激光切割[1-2]、焊接[3-4]等多领域中得到了广泛应用。光纤激光器属于激光器的一个重要分支,高功率光纤激光器具有光束质量高、传输效率好、结构紧凑等优点[5-7]。特别是随着新能源时代的到来,光纤激光器在锂电池焊接领域中具有很好的应用前景。其中环形光束模式可调光纤激光器主要用于激光复合焊接,其内外环两束激光在环形双芯光纤中传输,通过调节输入端各端口的通光功率,可控制内外环的输出功率[8-10]。环形可调模式激光器焊接相对于其他焊接方法具有防飞溅、提高焊接稳定性以及更加便捷安全的特性[11-13]。Mohammadpour等[14]从钢焊接角度分析了可调环形模式光纤激光器和标准单光束光纤激光器的焊接性能,可调环形模式激光器增加了获得高质量焊缝的可能性。形成环形双光束输出的途径有很多,相比于光束透镜[15]以及其衍射光学元件[16],基于非相干合成技术制作的全光纤结构信号合束器,结构紧凑,合成效率高。

为了提升光纤激光器的性能,现有的研究大多以改变输入光纤和输出光纤的类型和参数为主要手段,对光纤合束器的性能进行了大量的实验研究[17-23]。2018年,国防科技大学制作了输出光纤直径为50 μm的7×1光学功率合束器[17],输出功率为14 kW时光纤输出头温升为35 ℃,温升系数小于2.5 ℃/kW,输出光束质量因子(M2)为5.37。2020年,该课题组制作了输出光纤芯径为50 μm/70 μm/360 μm的3×1功率合束器[18],总效率约为99%,M2为6。2021年,该课题组制作了输出光纤芯径为50 μm/400 μm的3×1光纤功率合束器[19],在总传输功率为8.95 kW的情况下,合束器的输出功率为8.62 kW,整体传输效率大于96%,M2=4.035。同年,该课题组用氢氟酸腐蚀光纤和低折射率毛细管制作了输出光纤纤芯为50 μm的3×1信号合束器[20],总传输效率达到了98%,M2约为3.6。直到2023年,才开始有报道使用环形双芯光纤(50 μm/70 μm/150 μm/170 μm/360 μm)作为输出光纤制作可调环模信号合束器。华中科技大学的Zhou等 [21]提出一种中心光束均匀分布的可调环模全光纤级联信号合束器,该结构由3×1合束器和(6+1)×1合束器串联而成。由于中心光束和环形光束独立传输,该级联合束器的传输效率达96.2%,M2为5.24。国防科技大学的Fu等[22]采用光纤腐蚀技术保证(6+1)×1光纤合束器的光束质量,将3×1光纤信号合束器与(6+1)×1中心端口级联,M2=4.45,总传输效率大于95%。该级联合束器由于含有3×1光纤信号合束器,未能完全展现(6+1)×1光纤合束器的光束质量。以环形双芯光纤作为输出光纤的(6+1)×1光纤合束器的光束质量有待改善,传输效率可以进一步提高。

拉锥比是影响光束质量的一个重要因素,大多数情况下为了达到更好的耦合效果,需要熔锥光纤束(TFB)的拉锥量较大,光束质量易受到影响。我们使用尽可能接近于1的拉锥比实现耦合,并使用大芯径环形双芯光纤(50 μm/70 μm/600 μm/620 μm/660 μm)作为输出光纤,通过调控拉锥比实现了合束器单独输出中心和外环光束或中心、外环光束的同时输出。通过理论研究与实验,我们制作的合束器在保证高功率输出的同时,M2仅为1.76。另外,由于合束器的应用环境难以预料,开展了耐环境测试,在高低温环境下对合束器进行了传输效率测试,以确保合束器在高温环境和低温环境下都展现出良好的传输特性。

2 理论分析与仿真

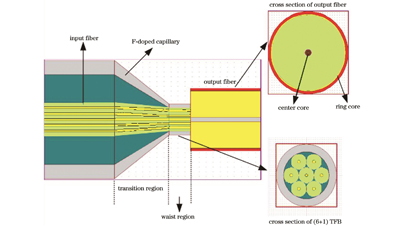

(6+1)×1信号合束器一般由7根25 μm/250 μm 输入光纤和1根50 μm/70 μm/600 μm/620 μm/660 μm输出光纤组成。

图 1. (6+1)×1信号合束器的结构及TFB和输出光纤的截面

Fig. 1. Structure of (6+1)×1 signal combiner and cross sections of TFB and output fiber

TFB要遵守绝热拉锥和亮度守恒两个原则。绝热拉锥需要控制过渡区长度,当过渡区长度大于10 mm时,传输效率最高[23],但过渡区长度过长也会导致封装难度大,因此我们选择15 mm作为过渡区域的长度,后面的锥腰区域我们设置为6 mm。亮度守恒要求满足

式中:

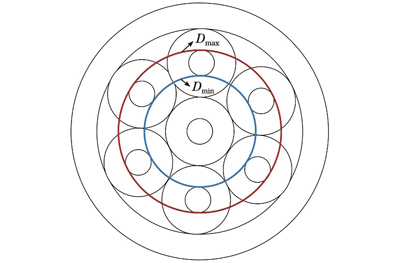

为了实现光斑可调,使中心和外环可以独立工作,拉锥比(

式中:

图 2. TFB横截面上外环输入光束的通光范围

Fig. 2. Transmission range of outer ring input beam on TFB cross section

基于差分光束传播法(BPM)进行了仿真,我们选取LP01、LP02、LP21模式进行了模拟,设置变量为

3 实验

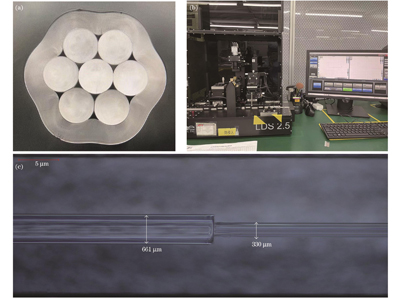

在大芯径(6+1)×1信号合束器的制作过程中,我们选用7根25 μm/250 μm(数值孔径为0.065)多模光纤作为输入光纤,50 μm/70 μm/600 μm/620 μm/660 μm(数值孔径为0.22)环形双芯光纤作为输出光纤。低折射率掺氟毛细管的内外径为950 μm/1250 μm,其数值孔径为0.22,在进行锥形光纤束制作之前需要对光纤进行预处理。氢氟酸溶液浓度越高,腐蚀速度越快,选用氢氟酸溶液对光纤包层进行处理,可以有效减小光纤的包层直径,并且纤芯直径不会受到影响,对于改变光纤拉锥比具有重要作用。而后使用电荷耦合元件(CCD)对腐蚀后的光纤进行挑选。

第一步是使用石墨丝拉锥机对掺氟管进行锥形化处理。第二步是基于套管法使用处理后的掺氟管进行穿管处理,将7根腐蚀后的光纤穿入掺氟管,使光纤尽可能均匀整齐,保证管内洁净度。第三步是采用氢氧焰拉锥机进行拉锥,调节好参数,将TFB直径拉至330 μm,在拉锥过程中进行抽气处理,使其耦合得更紧密。第四步是使用切割刀切割锥体,在显微镜下观察端面具体细节。

图 5. TFB的熔接图像。(a) TFB截面图;(b)熔接机装置图;(c)熔接点侧视图

Fig. 5. Weld images of TFB. (a) Cross section of TFB; (b) installation diagram of welding machine; (c) side view of weld point

4 结果与讨论

4.1 传输效率测试

设计了光路对合束器进行性能测试,首先进行传输效率测试。

光源由自制高功率输出头输出的功率为3.092 kW,光源经过合束器后,各端口的最高功率仍能达到3.058 kW。

表 1. 合束器各端口的信号传输效率

Table 1. Signal transmission efficiency of combiner at each port

|

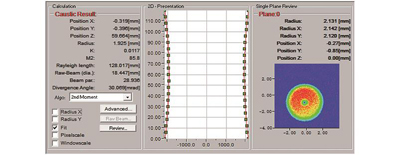

4.2 光束质量测试

对合束器进行光束质量测试,使用激光焦点分析仪测量该合束器的光束质量,光源各端口在二阶矩模式下的M2在1.1左右,经过合束器后测试数据如

表 2. 信号合束器各端口的光束质量

Table 2. Beam quality of signal combiner at each port

|

4.3 耐环境测试

为了验证合束器的耐高低温能力,对该实验样品进行环境可靠性测试。使用高低温循环箱对合束器进行温度测试,温度变化范围为-30~70 ℃,在循环低温以及高温处对产品进行效率测试,

图 10. 耐环境测试实验图。(a)低温-30 ℃下的实验样品;(b)高温70 ℃下的实验样品;(c)三种情况下各端口的效率

Fig. 10. Experimental diagrams of environmental resistance test. (a) Experimental sample at low temperature of -30 ℃; (b) experimental sample at high temperature of 70 ℃; (c) efficiencies of each port in three cases

5 结论

对环形光斑可调光纤激光器的关键元器件光纤合束器进行了研究,通过理论研究、仿真实验,发现选择输入光纤包层直径为100 μm,TFB直径为330 μm,

[1] 严淼宁, 周磊, 梁佳楠, 等. 纳秒光纤激光精密切割超弹镍钛合金薄板工艺技术的研究[J]. 机电工程技术, 2023, 52(1): 85-88.

Yan M N, Zhou L, Liang J L, et al. Research on nanosecond fiber laser precision cutting process technology of superelastic nitinol sheets[J]. Mechanical & Electrical Engineering Technology, 2023, 52(1): 85-88.

[2] 陈胜, 黄辉宇, 董雄炜, 等. 激光切割技术的研究现状[J]. 有色金属加工, 2022, 51(5): 1-6, 26.

Chen S, Huang H Y, Dong X W, et al. Research status of laser cutting technology[J]. Nonferrous Metals Processing, 2022, 51(5): 1-6, 26.

[3] Ceglarek D, Colledani M, Váncza J, et al. Rapid deployment of remote laser welding processes in automotive assembly systems[J]. CIRP Annals, 2015, 64(1): 389-394.

[4] Haeusler A, Hollatz S, Olowinsky A, et al. Quality improvement of the surface of laser micro welds by using a dual beam setup[J]. Journal of Laser Applications, 2018, 30(3): 032423.

[5] 杨青, 俞本立, 甄胜来, 等. 光纤激光器的发展现状[J]. 光电子技术与信息, 2002(5): 13-18.

Yang Q, Yu B L, Zhen S L, et al. The survey of optic fiber lasers[J]. Optoelectronic Technology & Information, 2002(5): 13-18.

[6] 马思烨, 张闻宇, 邱佳欣, 等. 高功率连续光纤激光器技术发展概述[J]. 光纤与电缆及其应用技术, 2019(5): 1-6, 34.

Ma S Y, Zhang W Y, Qiu J X, et al. Review on technology development of high power CW fiber laser[J]. Optical Fiber & Electric Cable and Their Applications, 2019(5): 1-6, 34.

[7] 焦磊, 宋跃江, 张旭苹. 四波混频增强多波长布里渊掺铒光纤激光器的实验研究[J]. 光学学报, 2011, 31(2): 0214007.

[8] 朱加琦. 复合环形光束产生方法及其点焊特点研究[D]. 武汉: 华中科技大学, 2021.

ZhuJ Q. Study on the method of generating composite annular beam and its spot welding characteristics[D]. Wuhan: Huazhong University of Science and Technology, 2021.

[9] Zhao Y Q, Li X, Liu Z Q, et al. Stability enhancement of molten pool and keyhole for 2195 Al-Li alloy using fiber-diode laser hybrid welding[J]. Journal of Manufacturing Processes, 2023, 85: 724-741.

[10] Wang L, Gao X D, Kong F R. Keyhole dynamic status and spatter behavior during welding of stainless steel with adjustable-ring mode laser beam[J]. Journal of Manufacturing Processes, 2022, 74: 201-219.

[11] Maina M R, Okamoto Y, Okada A, et al. High surface quality welding of aluminum using adjustable ring-mode fiber laser[J]. Journal of Materials Processing Technology, 2018, 258: 180-188.

[12] Wang L, Mohammadpour M, Yang B X, et al. Monitoring of keyhole entrance and molten pool with quality analysis during adjustable ring mode laser welding[J]. Applied Optics, 2020, 59(6): 1576-1584.

[13] Yang H, Tang X H, Hu C, et al. Study on laser welding of copper material by hybrid light source of blue diode laser and fiber laser[J]. Journal of Laser Applications, 2021, 33(3): 032018.

[14] Mohammadpour M, Wang L, Kong F R, et al. Adjustable ring mode and single beam fiber lasers: a performance comparison[J]. Manufacturing Letters, 2020, 25: 50-55.

[15] Volpp J, Vollertsen F. Impact of multi-focus beam shaping on the process stability[J]. Optics & Laser Technology, 2019, 112: 278-283.

[16] Rasch M, Roider C, Kohl S, et al. Shaped laser beam profiles for heat conduction welding of aluminium-copper alloys[J]. Optics and Lasers in Engineering, 2019, 115: 179-189.

[17] 陈子伦, 雷成敏, 王泽锋, 等. 基于输出光纤为50 μm的7×1光纤功率合束器实现大于14 kW的高光束质量光纤激光合成[J]. 中国激光, 2018, 45(4): 0415001.

[18] Wu W J, Chen Z L, Wang Z F, et al. Beam combining of fiber lasers by a 3×1 signal combiner at a power >13 kW[J]. Optical Fiber Technology, 2020, 54: 102109.

[19] 付敏, 李智贤, 王泽锋, 等. 高光束质量3×1光纤功率合束器的研制[J]. 红外与激光工程, 2022, 51(5): 20210354.

[20] Wu W J, Chen Z L, Wang Z F, et al. Novel 3×1 signal combiner with high-power fiber laser output of high beam quality[J]. Optik, 2021, 225: 165353.

[21] Zhou Y Y, Qiu Q, Yang A B, et al. All-fiber cascaded combiners for high-power adjustable-ring mode laser beam with a flattop central beam[J]. Optics & Laser Technology, 2023, 163: 109324.

[22] Fu M, Wang J W, Li Z X, et al. Research on adjustable ring-mode fiber signal combiner[J]. Photonics, 2023, 10(2): 195.

[23] Zhou H, Chen Z L, Zhou X F, et al. All-fiber 7×1 signal combiner for high power fiber lasers[J]. Applied Optics, 2015, 54(11): 3090-3094.

[24] Zou S Z, Yu H J, Zuo J X, et al. Kilowatt-level 4×1 fiber combiner of low brightness loss with a square core output fiber[J]. Journal of Lightwave Technology, 2021, 39(7): 2130-2135.

[25] Stachowiak D. High-power passive fiber components for all-fiber lasers and amplifiers application—design and fabrication[J]. Photonics, 2018, 5(4): 38.

Article Outline

万志强, 杨瑷碧, 杨光华, 于珊, 胡紫晔, 唐吉龙, 魏志鹏. 高功率大芯径环形光斑可调信号合束器的研究[J]. 中国激光, 2024, 51(8): 0801004. Zhiqiang Wan, Aibi Yang, Guanghua Yang, Shan Yu, Ziye Hu, Jilong Tang, Zhipeng Wei. Ring Light Spot Adjustable Signal Combiner with High Power and Large Core Diameter[J]. Chinese Journal of Lasers, 2024, 51(8): 0801004.