无机材料学报, 2021, 36 (6): 608, 网络出版: 2021-11-25

电催化金属辅助化学刻蚀法制备硅纳米线/多孔硅复合结构  下载: 579次

下载: 579次

电化学 金属辅助化学刻蚀法 硅纳米线 多孔硅 场发射 electrochemistry metal assisted chemical etching silicon nanowire porous silicon field emission

摘要

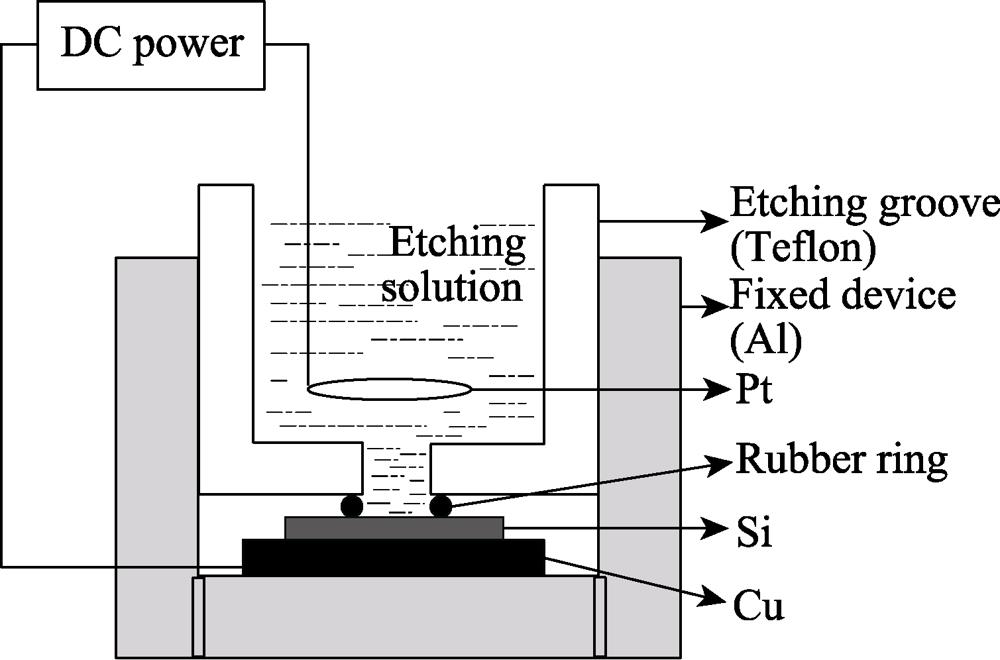

量子限制效应使硅纳米线具有良好的场致发射特性, 结合多孔硅的准弹道电子漂移模型可提高场发射器件的性能。传统的金属辅助化学刻蚀法制备硅纳米线的效率较低, 本研究在传统方法的基础上引入恒流源, 提出电催化金属辅助化学刻蚀法, 高效制备了硅纳米线/多孔硅复合结构。在外加30 mA恒定电流的条件下, 硅纳米线的平均制备速率可达308 nm/min, 较传统方法提升了173%。研究了AgNO3浓度、刻蚀时间和刻蚀电流对复合结构形貌的影响规律; 测试了采用电催化金属辅助化学刻蚀法制备样品的场发射特性。结果显示样品的阈值场强为10.83 V/μm, 当场强为14.16 V/μm时, 电流密度为64 μA/cm2。

Abstract

The quantum confinement effect brings good field emission characteristics to silicon nanowires, which is expected to improve the performance of field emission device through combination with the quasiballistic electrons drift model in porous silicon structure, but the efficiency of traditional metal assisted chemical etching is low. Constant current source was introduced on the basis of traditional metal assisted chemical etching in the present work, and a electrocatalytic metal assisted chemical etching method was proposed to achieve high-efficiency preparation of silicon nanowires and porous silicon composite structure. The preparation rate of silicon nanowires is 308 nm/min at 30 mA current, which is increased by 173% compared with that adopted the traditional method. Moreover, the effects of AgNO3 concentration, etching time and etching current on the morphology of the composite structure were investigated. The field emission characteristics of the structure prepared by electrocatalytic metal assisted chemical etching were tested. The current density is 64 μA/cm2 under the electric field of 14.16 V/μm, and threshold electric field is 10.83 V/μm.

陈力驰, 王耀功, 王文江, 麻晓琴, 杨静远, 张小宁. 电催化金属辅助化学刻蚀法制备硅纳米线/多孔硅复合结构[J]. 无机材料学报, 2021, 36(6): 608. Lichi CHEN, Yaogong WANG, Wenjiang WANG, Xiaoqin MA, Jingyuan YANG, Xiaoning ZHANG.