“人工智能赋能激光”——智能化激光制造装备及工艺研究进展  下载: 2099次

下载: 2099次

Laser manufacturing is an important component of advanced manufacturing technology, which has the advantages of high processing accuracy, wide applicability of materials, flexible non-contact processing, no loss, minimal deformation, and ease of automation integration. It has played an important role in the fields including aerospace, national defense, military, new energy vehicles, and biomedicine. It conforms to the advanced manufacturing trends of both intelligent and green manufacturing. With the popularity of the Internet and the advancement of big data technology, artificial intelligence (AI) has flourished in the past decade, providing great convenience in people's lives and promoting the transformation of the manufacturing industry from traditional to intelligent manufacturing. Applying AI to product design, production, management, and other aspects can help improve resource utilization efficiency, production efficiency, product quality, and service levels for enterprises to create greater economic value for society. Laser manufacturing and AI is becoming increasingly intertwined, driven by the rise of AI and interdisciplinary integration. AI is being utilized in various aspects of laser manufacturing, including beam shaping, beam correction, laser welding, laser cutting, laser polishing, laser additive manufacturing, and micro-nano processing. The performance of laser manufacturing equipment plays a vital role in the quality of the final product, and the application of AI to equipment design and management can improve the reliability and performance of laser equipment. Additionally, the difference of processing parameters has important influence on product quality. By establishing the relationship between processing parameters and product quality with the help of AI, the production efficiency can be improved and the production cost can be reduced significantly.

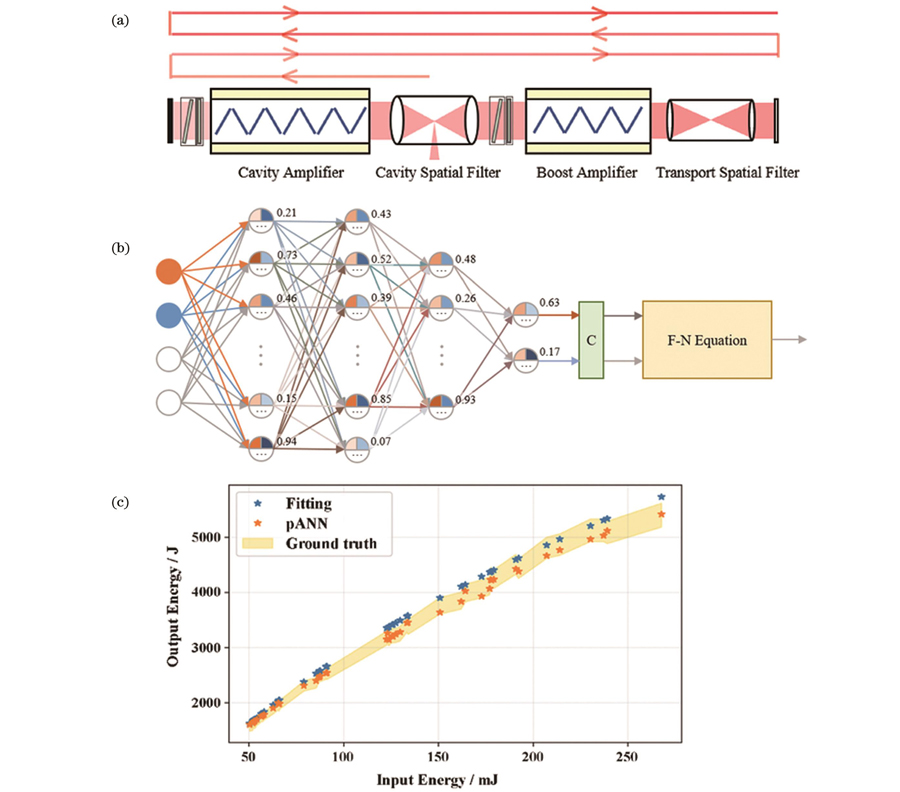

High-performance equipment is an important hardware base for high-precision and high-quality laser manufacturing. The instability of laser parameters or beam transmitting devices can lead to beam quality degradation, and in turn, poor machining quality. AI can be used to predict the translation/rotation state, output energy, phase mode, beam propagation factor, and other parameters of the beam to generate a high-quality laser beam and ensure the stability of the manufacturing process (Fig. 1). To meet the requirements of high-precision, high-efficiency manufacturing, AI is applied to beam shaping to improve the flexibility and controllability of the manufacturing process (Fig. 2). Meanwhile, AI can aid in fault detection, real-time status monitoring, and diagnosing issues in laser equipment, which not only helps to maintain normal equipment operation, but also ensures reliability and availability of laser equipment and reduces the risks of downtime and maintenance costs (Fig. 3). With the development of AI technology, its applications in laser manufacturing technologies, such as laser cutting, laser drilling, laser surface treatment, laser additive manufacturing, and laser welding, are becoming increasingly widespread, effectively improving the efficiency and quality of laser manufacturing. In the field of laser cutting, AI can not only predict the results to improve cutting efficiency, but also establish the relationship between the process parameters and cutting quality to obtain the best process parameters, reducing cutting roughness and slit width (Fig. 4). In the field of laser polishing, AI can obtain the best process parameters quickly by predicting the polishing results and ensure the stability of the polishing process through online monitoring (Fig. 5). In the field of laser cutting/drilling bones, AI can be used to process image and acoustic signals during the drilling process to achieve real-time identification of biological tissue types. Furthermore, it can be used for process optimization to achieve high-quality processing of biological bone materials (Figs. 6 and 7). In the field of laser welding, AI is currently used to predict welding quality, detect welding defects, and optimize welding process parameters (Fig. 8). In the field of laser additive manufacturing, AI assists in designing material compositions for superior mechanical properties, predicting tissue evolution and properties, constructing relationships between process parameters, optimizing additive manufacturing process, and monitoring the additive process in real time (Fig. 9).

The progress of AI has led to great changes in the manufacturing industry, promoting its development towards automation and intelligence. Laser manufacturing technology is one of the most promising advanced manufacturing technologies in the current manufacturing industry. The wide application of AI in laser manufacturing technology promotes its continuous progress. In this paper, the research status of AI in the field of laser manufacturing equipment and laser manufacturing technology is summarized. The applications of AI in beam control, equipment management, laser cutting, laser bone drilling, laser polishing, laser welding, and laser additive manufacturing are introduced. Although AI has not been widely used in practical production because of the challenges in creating algorithms, data processing, and hardware foundation, AI algorithms and data processing technology will be continuously improved, and the intelligent equipment industry will become increasingly mature. At that time, the coverage of AI in laser manufacturing will be further expanded, and the intelligence of laser manufacturing will be promoted effectively.

张宇梁, 钟占荣, 曹洁, 周运龙, 管迎春. “人工智能赋能激光”——智能化激光制造装备及工艺研究进展[J]. 中国激光, 2023, 50(11): 1101005. Yuliang Zhang, Zhanrong Zhong, Jie Cao, Yunlong Zhou, Yingchun Guan. Artificial Intelligence Empowered Laser: Research Progress of Intelligent Laser Manufacturing Equipment and Technology[J]. Chinese Journal of Lasers, 2023, 50(11): 1101005.