激光熔化沉积TC11钛合金双重退火后的组织和力学性能研究  下载: 826次封面文章

下载: 826次封面文章

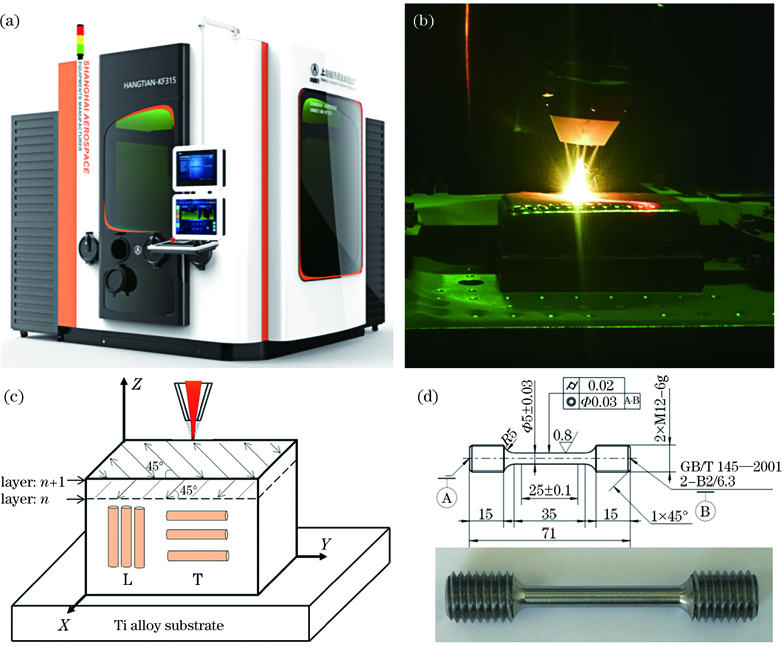

Objective TC11 titanium alloy is lightweight and has high strength, and it has a great potential to replace high-strength steel as the main bearing components of aerospace, allowing for lightweight application. Traditional manufacturing of large titanium alloy structural parts generally requires large forging equipment and moulds, resulting in considerable manufacturing challenges, such as low material utilisation, long manufacturing cycles and high equipment and production costs. Laser melting deposition uses metal powder or wire as raw materials to form layer by layer via laser rapid melting, and it can directly realize the near-net shape of complex metal parts from the CAD model. Because this technology does not involve thermal-mechanical processing, the amount of removal is small, and it can avoid the dependence on moulds and large forging equipment, it can significantly reduce the manufacturing cost and cycle of large metal components in the aerospace field. The microstructure of titanium alloy deposited using laser melting is complex and the mechanical properties are anisotropic. To meet the application requirements of aerospace main load-bearing components, the heat treatment of TC11 titanium alloy components formed using laser melting deposition must be studied to homogenise the structure and anisotropy and improve the overall performance of laser melting deposited parts.

Methods The as-deposited TC11 titanium alloy was subjected to double annealing heat treatment in this study to investigate the effects of different annealing temperatures on the microstructure and mechanical properties of the TC11 titanium alloy. In this study, a Z-shaped scanning strategy was used to perform laser melting deposition of TC11 titanium alloy bulk. The scanning trajectory between the layers was deflected by 90°, and argon gas was introduced during the forming process to reduce the amount of water and oxygen volume fraction in the glove box less than 5×10 -5. The deposited sample and the heat-treated test bar were processed into standard tensile samples, and their tensile properties at room temperature were tested on a universal tensile testing machine. Kroll’s reagent was used to corrode a TC11 titanium alloy sample (the volume ratio of HF, HNO3, and H2O is 1∶2∶7). The structure, element distribution, phase composition, and fracture morphology of the deposited and heat-treated titanium alloy were detected and analysed using an optical microscope (OM), scanning electron microscope (SEM), and energy dispersive X-ray spectrometer (EDS), and the relationship between heat treatment-structure-performance was established, providing guidance for improving the comprehensive properties of TC11 titanium alloy components deposited by laser melting.

Results and Discussions Along the deposition direction, the structure of TC11 titanium alloy exhibited alternate growth of columnar grain zone and equiaxed grain zone (Fig.2). The deposited state’s micro-structure was composed of the Widmanstatten and mesh basket structures, and a portion of the clustered phase in the equiaxed zone grew through the entire grain. The phase of the intragranular basket structure gradually coarsened as the annealing temperature increased and the aspect ratio gradually decreased. When the annealing temperature rose to 1025 ℃, the intragranular structure abruptly changed into a fine needle-like basket structure and the aspect ratio increased. With the increase of the temperature, the grain boundary α phase gradually appeared discontinuous, spheroidised and disappeared. When the annealing temperature was 1025 ℃, the continuous grain boundary α phase was reformed in the equiaxed grain boundary (Fig.4). With the increase of annealing temperature, the overall tensile strength (Rm) showed a slight decrease; when the annealing temperature was 1025 ℃, Rm increased, and the range of variation in tensile strength was ≤3.76%. With the increase of the high-temperature annealing temperature, the yield strength (Rp0.2) did not change much, and the range of variation in yield strength was ≤1.16%. The percentages of elongation after fracture (A) of transverse sample showed a slight change as the high-temperature annealing temperature increased, and the longitudinal sample increased first and then decreased. In general, the reduction of area (Z) showed an overall trend that increased first and then decreased. The yield ratio increased as the high-temperature annealing temperature increased, reaching its maximum at 1010 ℃. The laser melting deposition of TC11 titanium alloy had a strength that was nearly isotropic, and heat treatment had little effect on the anisotropy of tensile and yield strength.

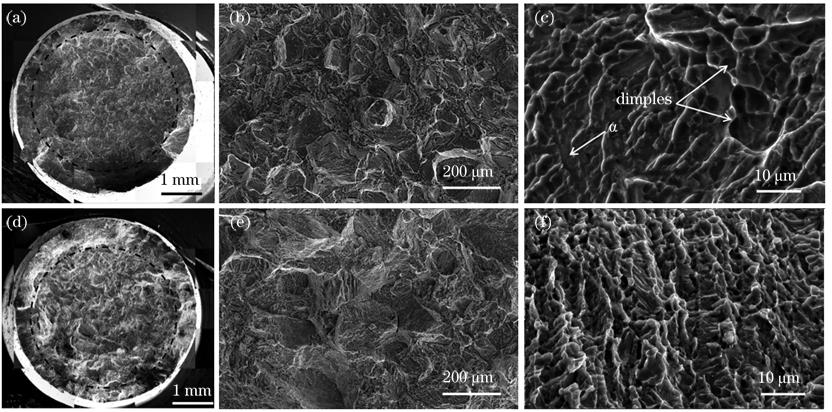

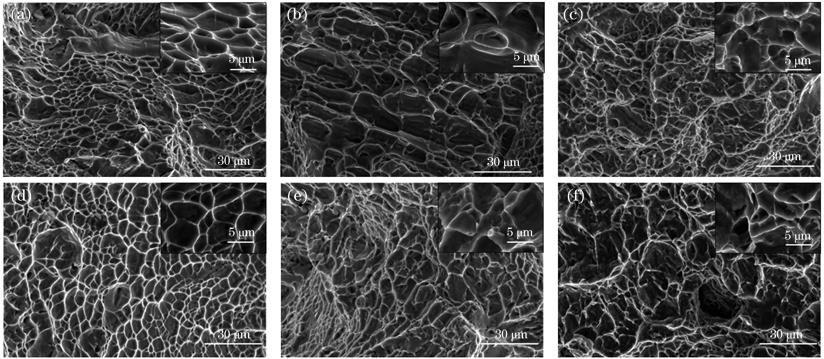

Conclusions The deposited structure of TC11 titanium alloy exhibits columnar/equiaxial alternate growth along the deposition direction owing to competition between heterogeneous nucleation and epitaxial growth nucleation. The deposited microstructure is mainly composed of the Widmanstatten structure composed of grain boundary cluster α phase and the intracrystalline fine needle-like basket structure. As the annealing temperature increases, the aspect ratio of the intragranular α phase decreases, and the grain boundary α phase appears discontinuous, spheroidised, and partial disappeared. When the annealing temperature is 1025 ℃, the grain boundary reforms a continuous grain boundary α phase, and the intragranular structure abruptly changes to a refined mesh basket structure. Both the mechanical properties of deposited and heat-treated TC11 titanium alloy can meet forging standards, and double annealing can significantly improve the deposited mechanical properties. Owing to the intragranular and grain boundary structure, as the annealing temperature rises, the strength of the TC11 titanium alloy first decreases and then increases, whereas the plasticity increases first and then decreases. With the increase of annealing temperature, the yield ratio first increases and then decreases, reaching the maximum at 1010 ℃. The strength anisotropy of TC11 titanium alloy in the as-deposited and dual-phase zones is less than 3%, which is close to isotropy; the plasticity anisotropy first increases, then decreases, and is smallest at 995 ℃. The transverse and longitudinal tensile fractures of the deposited state exhibit intergranular fracture characteristics as a result of the intragranular structure and continuous grain boundaries; after double annealing, the grain boundaries appear discontinuous, spheroidised, and disappeared, and the cracks continue to grow by the mechanism of micropore aggregation, and the fracture surface shows the characteristics of ductile fracture, and the dimple fractures are the most uniform at 995 ℃.

1 引言

钛合金具有密度小、强度高以及耐腐蚀和弱磁等特点,已被广泛应用于航空、航天、化工、海洋工程等现代工业及**重大装备中的大型整体关键承力构件上,其用量的多少已成为衡量航空航天等装备技术是否先进的重要标志之一[1]。TC11(Ti-6.5Al-3.5Mo-1.5Zr-0.25Si)钛合金是我国开发的可在500 ℃以下长期服役的α+β型高温钛合金,其室温强度高,热强性好,是制造航空发动机、高压压气机盘及叶片的主要材料[2]以及航天器主承力构件的潜在材料,与IMI685合金的性能相当。但钛合金的加工性能差,传统的加工工艺难以满足高性能、大尺寸钛合金结构件的加工需求。大型钛合金结构件的传统制造一般需要大型锻压设备及大型模具,制造难度大,材料利用率低,制造周期长,设备成本和生产成本高,因此,大型关键钛合金构件的制造技术被公认为是航空、航天等高端重大装备的核心关键制造技术之一[3]。激光熔化沉积(LMD)也被称为激光近净成形(LENS),属于激光增材制造技术的一种[4]。该技术以金属粉末或丝材为原料,通过激光快速熔凝逐层堆积,可直接通过CAD模型实现复杂金属零件的近净成形,因不涉及热机械加工以及较少的去除量,可避免对模具和大型锻压设备的依赖,从而可以显著降低航空、航天领域大型金属构件的制造成本和周期[5-6]。

组织和力学性能是激光熔化沉积钛合金研究的热点。在激光熔化沉积过程中,钛合金粉末流在激光束作用下形成熔池,随着熔池移动形成熔覆层。移动的熔池对已沉积层的重熔和反复的热作用决定了成形件的组织和力学性能。双相钛合金成形件的微观组织通常表现为外延生长的粗大β柱状晶和晶内呈细片层状的α+β网篮组织或马氏体组织,力学性能通常表现出高强低塑且各向异性的特点[7-10]。后续热处理工艺可以优化和改善钛合金成形件的组织和力学性能。激光熔化沉积由于与锻件的传统加工工艺、热历程存在差异,其成形钛合金的微观组织与传统锻件组织差异较大,传统锻件的热处理工艺并不适用,因此需要建立针对激光熔化沉积钛合金的热处理工艺。激光熔化沉积TC4钛合金经固溶时效热处理后,初生α相的长径比减小,组织中的短棒状α相增多,形成网篮组织[11];随着固溶温度升高,α相粗化现象明显。Zhang等[12]对TC4钛合金成形件进行双重退火处理后发现,随着退火温度升高,初生α相的长径比和体积分数减小,导致退火件的强度降低、塑性升高。关于激光熔化沉积TC11钛合金的热处理工艺研究较少。黄瑜等[13]对激光立体成形TC11钛合金进行热处理后发现:在950~970 ℃进行热处理后,组织是以等轴α相、条状α相和β转变组织为主的近三态组织,晶界α相逐渐破碎、球化和消失;当退火温度超过再结晶温度后,组织是由粗大α板条组成的魏氏组织及细小的β相,晶界α相基本没有破碎。Huang等[14]采用两种热处理制度对沉积态TC11钛合金进行了热处理,结果表明:经热等静压(HIP)+固溶时效热处理之后,TC11钛合金内部缺陷减少,组织得以优化,其组织和力学性能与近无缺陷的TC11钛合金达到同一水平。

综上,激光熔化沉积钛合金的组织比较复杂,力学性能存在各向异性现象。为满足航天主承力构件的应用需求,需要对激光熔化沉积TC11钛合金构件的热处理工艺进行研究,以消除组织的各向异性,提升激光熔化沉积成形构件的综合性能。本研究团队采用激光熔化沉积技术制备TC11钛合金块体,然后对其进行双重退火热处理,以提升TC11钛合金的综合力学性能。通过分析不同退火温度下TC11钛合金的组织和性能演变规律,获得了优化的热处理工艺,为激光熔化沉积TC11钛合金取代高强钢作为航天主承力构件,实现轻量化应用提供工艺指导。

2 试验材料与方法

本研究采用的设备是自主研发的多轴联动同轴送粉激光熔化沉积增材制造系统(LMD system),如

图 1. 激光熔化沉积系统。(a)系统实物图;(b)成形过程;(c)成形轨迹;(d)拉伸试样

Fig. 1. Laser melting deposition system. (a) Photo of the system; (b) forming process; (c) forming path; (d) tensile sample

表 1. TC11钛合金粉末的化学成分

Table 1. Chemical composition of TC11 titanium alloy powder

|

表 2. 双重退火热处理工艺

Table 2. Double annealing heat treatment

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

采用Kroll’s试剂(HF、HNO3、H2O的体积比为1∶2∶7)对TC11钛合金试样经打磨、抛光后的表面进行腐蚀,然后采用光学显微镜(OM)、扫描电镜(SEM)、X射线能谱仪(EDS)等对沉积态和热处理态钛合金的组织、元素分布、相组成、断口形貌等进行检测和分析,摸索热处理、组织、性能之间的对应关系,为提升激光熔化沉积TC11钛合金构件的综合性能提供指导。

3 结果与分析

3.1 微观组织

图 2. 沉积态TC11钛合金的组织。(a)单道组织; (b)A区组织; (c)B区组织; (d)成形件的组织.

Fig. 2. Microstructures of as-deposited TC11 titanium alloy. (a) Single cladding microstructure; (b) microstructure of A zone; (c) microstructure of B zone; (d) microstructure of formed parts

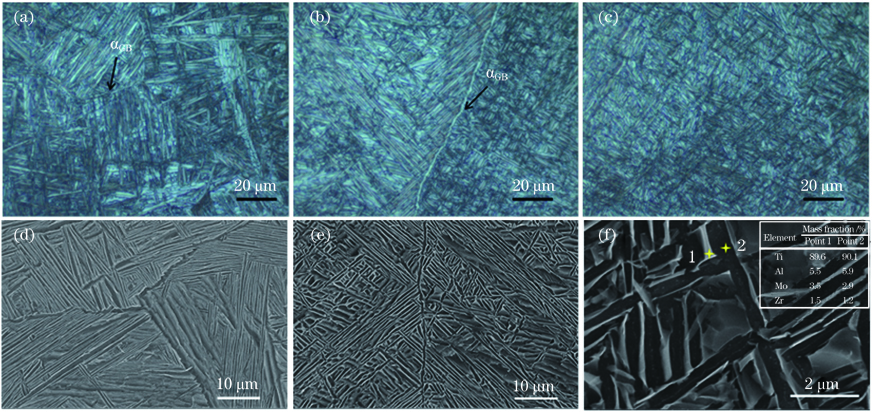

分别对成形件等轴晶区和柱状晶区的微观组织进行局部放大,放大形貌如

图 3. 沉积态TC11钛合金的显微组织。(a)等轴晶区的OM形貌;(b)柱状晶区的OM形貌;(c)晶内组织的OM形貌;(d)等轴晶区的SEM形貌;(f)柱状晶区的SEM形貌;(e) 晶内组织的SEM形貌及EDS点分析

Fig. 3. Microstructures of as-deposited TC11 titanium alloy. (a) OM morphology of equiaxed zone; (b) OM morphology of columnar zone; (c) intragranular OM mophology; (d) SEM morphology of equiaxed zone; (e) SEM morphology of columnar zone; (f) intragranular SEM morphology and EDS point analysis

对沉积态TC11钛合金进行双重退火,退火温度对TC11钛合金晶内微观组织的影响如

随着退火温度升高,晶界α相的变化情况如

图 4. 不同退火温度下TC11钛合金的微观组织。(a1) 950 ℃,晶内组织;(a2) 950 ℃,晶界;(a3) 950 ℃,α相的SEM形貌;(b1) 965 ℃,晶内组织;(b2) 965 ℃,晶界;(b3) 965 ℃,α相的SEM形貌;(c1) 980 ℃,晶内组织;(c2) 980 ℃,晶界;(c3) 980 ℃,α相的SEM形貌;(d1) 995 ℃,晶内组织;(d2) 995 ℃,晶界;(d3) 995 ℃,α相的SEM形貌;(e1) 1010 ℃,晶内组织;(e2) 1010 ℃,晶界;(e3) 1010 ℃,α相的SEM形貌;(f1) 1025 ℃,晶内组织;(f2) 1025 ℃,晶界;(f3)1025 ℃,α相的SEM形貌

Fig. 4. Microstructures of TC11 titanium alloy at different annealing temperatures. (a1) Intragranular microstructure at annealing temperature of 950 ℃; (a2) grain boundary at annealing temperature of 950 ℃; (a3) SEM morphology of α phase at annealing temperature of 950 ℃; (b1) intragranular microstructure at annealing temperature of 965 ℃; (b2) grain boundary at annealing temperature of 965 ℃; (b3) SEM morphology of α phase at annealing temperature of 965 ℃; (c1) intragranular microstructure at annealing temperature of 980 ℃; (c2) grain boundary at annealing temperature of 980 ℃; (c3) SEM morphology of α phase at annealing temperature of 980 ℃; (d1) intragranular microstructure at annealing temperature of 995 ℃; (d2) grain boundary at annealing temperature of 995 ℃; (d3) SEM morphology of α phase at annealing temperature of 995 ℃; (e1) intragranular microstructure at annealing temperature of 1010 ℃; (e2) grain boundary at annealing temperature of 1010 ℃; (e3) SEM morphology of α phase at annealing temperature of 1010 ℃; (f1) intragranular microstructure of α phase at annealing temperature of 1025 ℃; (f2) grain boundary at annealing temperature of 1025 ℃; (f3) SEM morphology of α phase at annealing temperature of 1025 ℃

3.2 力学性能

采用万能拉伸试验机对沉积态和热处理态钛合金拉伸试样进行测试,试验结果表明,激光熔化沉积态和双重退火态TC11钛合金的强度和塑性均满足GJB 2744A锻件标准。沉积态和热处理态TC11钛合金的横向和纵向室温拉伸力学性能数据如

屈服强度常作为零件失效的计算强度,因此提升材料的屈强比(Rp0.2/Rm)能够提升材料的强度储备和服役性能。

图 5. 拉伸性能。(a)横向拉伸性能;(b)纵向拉伸性能;(c)屈强比;(d)各向异性

Fig. 5. Tensile properties. (a) Transverse tensile properties; (b) longitudinal tensile properties; (c) yield strength ratio; (d) anisotropy

为表征成形材料横、纵方向的各向异性,本文用强度和塑性在横、纵方向上的性能偏差E表示成形件的各向异性。各向异性的计算公式为

式中:L表示纵向性能;T表示横向性能。

图 6. 沉积态TC11钛合金的拉伸断口形貌。(a)纵向断口的宏观形貌;(b)纵向断口的低倍形貌;(c)纵向断口的微观形貌;(d)横向断口的宏观形貌;(e)横向断口的低倍形貌;(f)横向断口的显微形貌

Fig. 6. Tensile fractures of as-deposited TC11 titanium alloy. (a) Macroscopic morphology of longitudinal fracture; (b) longitudinal fracture at low magnification; (c) longitudinal fracture at high magnification; (d) macroscopic morphology of transverse fracture; (e) transverse fracture at low magnification; (f) transverse fracture at high magnification

如

图 7. 不同温度下热处理后TC11钛合金的拉伸断口形貌。(a) 950 ℃;(b) 965 ℃;(c) 980 ℃;(d) 995 ℃;(e) 1010 ℃;(f) 1025 ℃

Fig. 7. Tensile fractures of TC11 titanium alloy heat-treated at different temperatures. (a) 950 ℃; (b) 965 ℃; (c) 980 ℃; (d) 995 ℃; (e) 1010 ℃; (f) 1025 ℃

4 结论

采用激光熔化沉积技术制备了TC11钛合金,并对沉积态TC11钛合金进行双重退火热处理,研究了沉积态和双重退火态TC11钛合金的组织和力学性能,为TC11钛合金航天主承力构件的轻量化应用提供经验。得到的具体结论如下:

1) 在异质形核和外延生长形核两种机制的竞争下,TC11钛合金的沉积态组织沿沉积方向呈柱状晶和等轴晶交替生长的现象。沉积态微观组织主要由晶界集束α相组成的魏氏组织及晶内细针状网篮组织构成。沉积态TC11钛合金经双重退火后组织明显粗化,且随着退火温度升高,晶内α相的长径比减小,晶界α相出现断续、球化和消失现象;当退火温度为1025 ℃时,晶界重新形成连续晶界α相,晶内组织突变为细化的网篮组织。

2) TC11钛合金沉积态和热处理态的力学性能均满足锻件标准要求,双重退火可显著提升沉积态的力学性能。受晶内和晶界组织的影响,随着退火温度升高,TC11钛合金的强度总体先降低后升高,塑性整体上呈先增后降的趋势。随着退火温度升高,屈强比先升高后降低,并于1010 ℃时达到最大。沉积态和双相区内退火TC11钛合金强度的各向异性<3%,表现为趋近各向同性的特征,塑性各向异性呈先增后减的趋势,在995 ℃退火后塑性的各向异性最小。

3) 受晶内组织及连续晶界的影响,沉积态TC11横、纵向拉伸断口均表现为沿晶断裂特征;双重退火后,晶界出现断续、球化和消失现象,裂纹以微孔聚集机制不断长大,断口表现为韧性断裂特征,在995 ℃退火后,断口上的韧窝最均匀。

[1] 王华明, 张述泉, 王韬, 等. 激光增材制造高性能大型钛合金构件凝固晶粒形态及显微组织控制研究进展[J]. 西华大学学报(自然科学版), 2018, 37(4): 9-14.

Wang H M, Zhang S Q, Wang T, et al. Progress on solidification grain morphology and microstructure control of laser additively manufactured large titanium components[J]. Journal of Xihua University (Natural Science Edition), 2018, 37(4): 9-14.

[2] 姚梦, 刘勇, 朱景川. TC11钛合金双重热处理工艺设计[J]. 热处理技术与装备, 2016, 37(5): 65-70.

Yao M, Liu Y, Zhu J C. Process design on double heat treatment of TC11 titanium alloy[J]. Heat Treatment Technology and Equipment, 2016, 37(5): 65-70.

[3] 赵永庆, 葛鹏. 我国自主研发钛合金现状与进展[J]. 航空材料学报, 2014, 34(4): 51-61.

Zhao Y Q, Ge P. Current situation and development of new titanium alloys invented in China[J]. Journal of Aeronautical Materials, 2014, 34(4): 51-61.

[4] Saboori A, Gallo D, Biamino S, et al. An overview of additive manufacturing of titanium components by directed energy deposition: microstructure and mechanical properties[J]. Applied Sciences, 2017, 7(9): 883.

[5] Qiu C L, Ravi G A, Dance C, et al. Fabrication of large Ti-6Al-4V structures by direct laser deposition[J]. Journal of Alloys and Compounds, 2015, 629: 351-361.

[6] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690-2698.

Wang H M. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2690-2698.

[7] Kobryn P A, Semiatin S L. The laser additive manufacture of Ti-6Al-4V[J]. Journal of Metals, 2001, 53(9): 40-42.

[8] 孙坤, 向文丽, 舒鑫柱. 不同取向对激光快速成形Ti-6Al-4V合金力学性能的影响[J]. 中国有色金属学报, 2020, 30(3): 566-570.

Sun K, Xiang W L, Shu X Z. Effects of different orientations on mechanical proprieties of laser rapid forming Ti-6Al-4V alloy[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(3): 566-570.

[9] Han Y F, Lu W J, Jarvis T, et al. Investigation on the microstructure of direct laser additive manufactured Ti6Al4V alloy[J]. Materials Research, 2015, 18(s1): 24-28.

[10] Wu X H, Liang J, Mei J F, et al. Microstructures of laser-deposited Ti-6Al-4V[J]. Materials & Design, 2004, 25(2): 137-144.

[11] 王文博, 马瑞鑫, 井志成, 等. 固溶时效处理对激光3D打印TC4合金组织与性能的影响[J]. 中国激光, 2019, 46(10): 1002003.

[13] 黄瑜, 陈静, 张凤英, 等. 热处理对激光立体成形TC11钛合金组织的影响[J]. 稀有金属材料与工程, 2009, 38(12): 2146-2150.

Huang Y, Chen J, Zhang F Y, et al. Influence of heat treatment on microstructure of laser solid forming Ti-6.5Al-3.5Mo-1.5Zr-0.25Si alloys[J]. Rare Metal Materials and Engineering, 2009, 38(12): 2146-2150.

[14] Huang B Y, Li H X, Zhang Y B, et al. Formability of TC11 titanium alloy fabricated by direct laser deposition[J]. Rare Metal Materials and Engineering, 2013, 42(S2): 178-182.

[15] Wang T, Zhu Y Y, Zhang S Q, et al. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing[J]. Journal of Alloys and Compounds, 2015, 632: 505-513.

[16] 黄柏颖. 激光直接沉积TC11钛合金组织及性能研究[D]. 济南: 山东建筑大学, 2013.

Huang BY. The microstructure and properties of TC11 titanium alloy by directed laser deposition[D]. Jinan: Shandong Jianzhu University, 2013.

郝云波, 赵凯, 黄叶玲, 齐超琪, 杜洋. 激光熔化沉积TC11钛合金双重退火后的组织和力学性能研究[J]. 中国激光, 2021, 48(22): 2202001. Yunbo Hao, Kai Zhao, Yeling Huang, Chaoqi Qi, Yang Du. Microstructures and Mechanical Properties of Doubled Annealed Laser Melting Deposited TC11 Titanium Alloy[J]. Chinese Journal of Lasers, 2021, 48(22): 2202001.