高性能金属激光能量场表面热处理技术研究现状及展望(特邀)  下载: 521次特邀综述

下载: 521次特邀综述

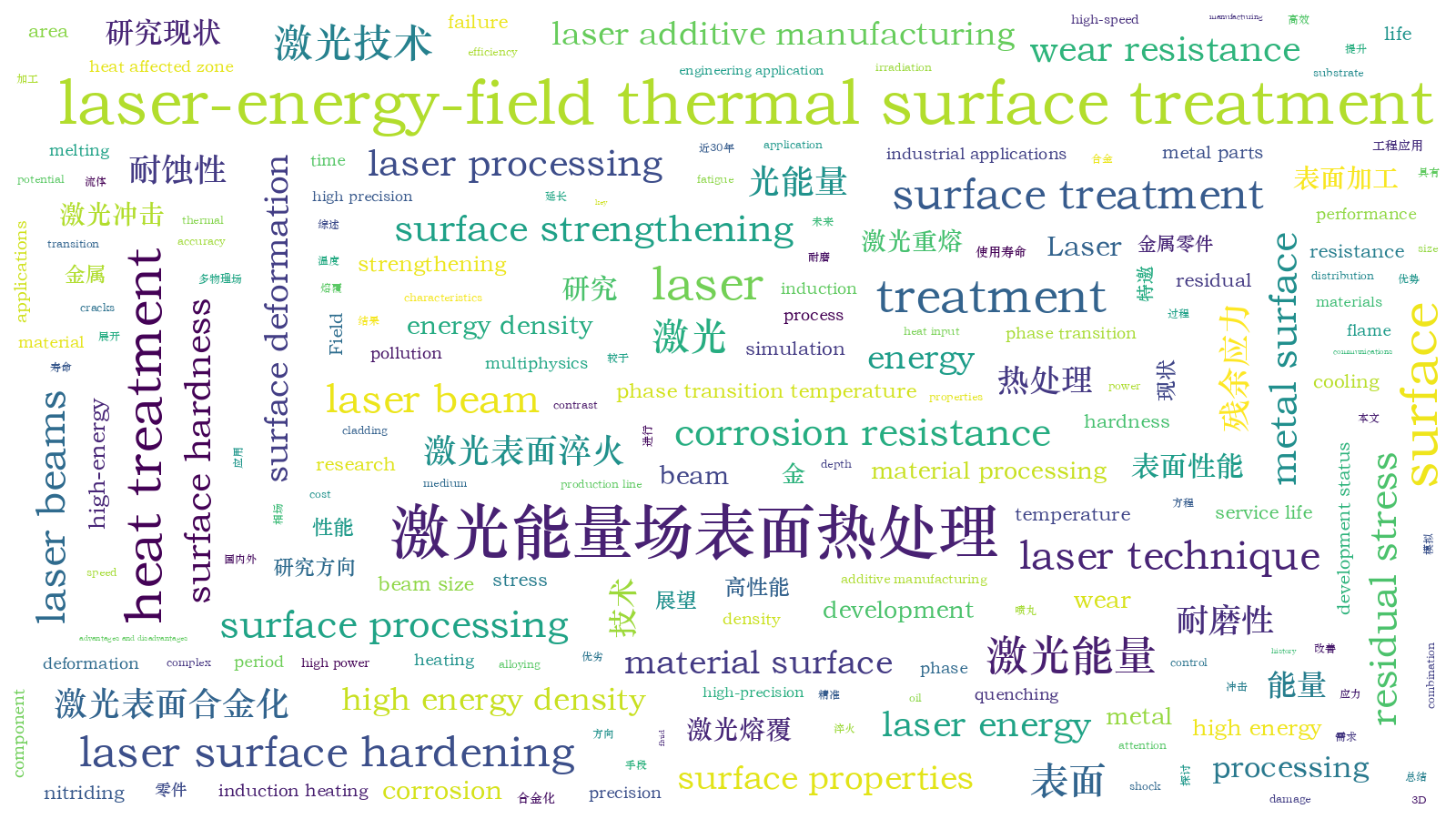

Metal part wear and corrosion are predominant forms of damage in engineering applications, prevalent in various fields of national life. Wear and corrosion initially occur on the surface of the part and further extend into the part. Fatigue, cracks, and other forms of component failure also stem from the component surface. Therefore, strengthening treatment for the surface of parts is gaining increasing attention. In material processing, most laser energy can be converted into thermal energy over a short time period. Laser processing involves a high-energy density laser beam which interacts with a metal surface, causing it to melt, gasify, change phases, and solidify. Laser surface treatment is a non-contact process in which the laser beam interacts with the material surface during processing, making it straightforward to control. Laser has the characteristics of high power and high precision, so that laser processing materials have been widely used in engineering, military, industry, communications and other almost all fields.

Surface heat treatment technology has a long development history. For example, surface heat treatment methods such as induction and flame quenching, and carburizing and nitriding processes effectively improve surface hardness, corrosion and wear resistance, and surface fatigue performance. Laser surface heat treatment achieves some advantages over traditional heat treatments. First, accuracy is the most prominent feature. In laser surface heat treatment for parts with complex 3D shapes and structures, controlling the laser beam size significantly reduces the heat affected zone, accurately controls treated and untreated areas, and minimizes heat treatment deformation and residual stress. Using traditional heat treatment methods, parts are heated to the required temperature and subsequently quenched in oil or water for high-speed cooling to achieve the required surface hardness. For heat treatment of thin-walled and high-precision parts, uncontrollable heat input such as overheating or melting leads to a large heat affected zone, surface deformation and uneven hardness distribution on the part surface. In most industrial applications, failure behaviors such as wear and corrosion only occur in specific part areas. Therefore, strengthening areas prone to failure to enhance the performance of parts and extend their service life. Hence, the advantages of using laser surface processing are prominent owing to its highly oriented nature and ability to deliver controllable energy to the desired area.

Second, laser beams have high energy density. For example, in the laser beam irradiation area, a significant amount of heat accumulates over an extremely short time period to reach the phase transition temperature in the area to be processed. Owing to the fact that laser processing only involves local areas, when the laser is inactive, heat quickly diffuses towards the substrate, causing the heating zone to cool rapidly. Therefore, compared to traditional heat treatment methods, an additional cooling medium is not required.

In terms of sustainable development, laser beam heat sources are clean, green, and pollution-free. Compared to nitriding and carburizing heat treatment processes, laser surface heat treatment does not involve chemical reactions during metal melting and pool cooling, and completely avoids chemical pollution. In the mass processing production line, the laser beam improves both laser utilization and higher heat treatment efficiency through the photosystem and the workbench, thus, reducing its cost in contrast to traditional heat treatments.

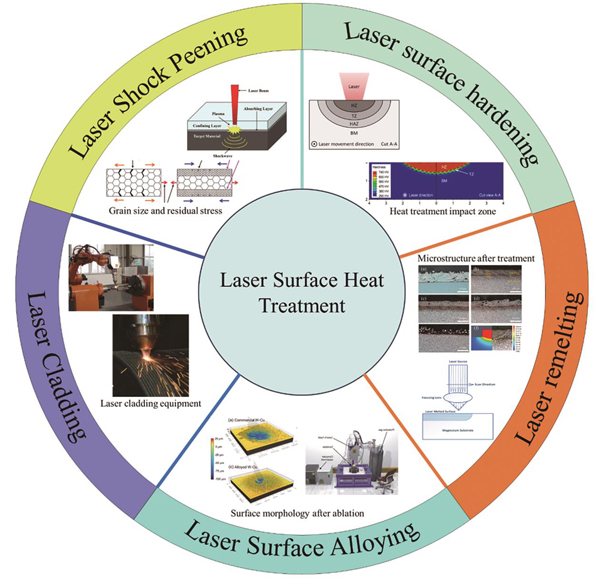

Traditional metal surface strengthening treatment methods include flame quenching, induction heating surface heat treatment, and nitriding and carburizing chemical heat treatment. Since the 1970s and 1980s, owing to laser development, laser surface heat treatment has been applied to the research of steel metal surface strengthening treatment. Therefore, this study first discusses the advantages and disadvantages of laser-energy-field surface heat treatment technologies (Table 1) and the multiphysics simulation equations of temperature, fluid and phase fields in the simulation process (Fig. 1). After which, the research and development status of five typical laser-energy-field heat treatment technologies, namely, laser surface hardening, remelting, surface alloying, cladding, and shock peening, are summarized (Figs. 2‒8). Subsequently, based on engineering application requirements, surface wear and corrosion resistance improvements, alongside the residual stress of parts are summarized (Figs. 9‒11). Finally, potential research directions for future laser-energy-field heat treatment are outlined (Fig. 12).

Laser-energy-field surface heat treatment technology is capable of improving the surface properties of metal parts. The wear and corrosion resistance alongside residual stress on the surface of a part determine its service life. In future, the combination of laser additive manufacturing, and in-depth heat treatment and multiphysics simulation assistance are expected to become key development fields for laser-energy-field surface heat treatment technologies.

1 引言

磨损和腐蚀是金属零件在工程应用中的主要破坏形式。磨损和腐蚀最初在零件表面发生,然后逐渐向零件内部蔓延。其他的零件失效形式,如疲劳和裂纹,也大多从零件表面开始。因此,对零件表面进行强化处理受到了越来越多的关注。传统的金属表面强化处理方法包括以火焰淬火和感应加热为代表的表面热处理以及以渗氮和渗碳为代表的化学热处理。自20世纪七八十年代以来,随着激光器的发展,激光表面热处理开始在钢铁等金属的表面强化处理中得到应用。

激光具有能量密度高以及相干性和方向性好等特点,在材料表面处理中得到了广泛应用[1]。可用于材料表面处理的激光器有CO2激光器、脉冲Nd∶YAG激光器、光纤激光器和准分子激光器。CO2激光器是一种以CO2作为主要工作物质的气体激光器,被广泛应用于焊接、激光加工和热处理领域。除了CO2激光器以外,Nd∶YAG固体激光器是使用最广泛的激光器。与CO2激光器相比,Nd∶YAG激光器具有波长更短、能量损失较低和激光束传输灵活等优点[2]。

在材料加工过程中,激光的大部分能量可以在短时间内转化为热能。激光加工是高能量密度的激光束与金属表面相互作用,使金属表面发生熔化、气化、相变和凝固的过程。激光表面处理是一种非接触式工艺,激光束与材料表面相互作用,易于控制。激光具有高功率和高精度的特点,因此激光加工已被广泛应用于工程、**、工业、通信等诸多领域[3-5]。然而,激光加工的高能耗会导致零件加工成本上升,限制了激光技术在零件加工中的大规模应用。

根据是否改变材料表面的元素,激光表面热处理可以分为以下两种方式:1)不改变表面合金元素的热处理方式,如激光表面淬火、激光冲击强化、激光重熔等;2)添加与母材不同的其他合金元素的方式,如激光表面合金化和激光熔覆。激光表面热处理可以基于冶金工艺原理实现表面硬化,获得高质量表面,提高母材的强度和耐磨性。但由于高性能金属价格高昂,激光表面热处理难以被大范围应用。在实际生产中,通常采用在基材表面添加其他合金元素的方法来提高基材表面的力学性能。鉴于此,笔者对5种典型的激光表面热处理技术的研究现状进行了总结,并详细阐述了提高金属材料耐磨性、耐蚀性和残余应力的激光表面热处理技术;最后,展望了激光表面热处理技术未来的发展前景。

2 激光表面热处理

2.1 激光与传统表面热处理

表面热处理技术具有悠久的发展历史。感应淬火、火焰淬火、渗碳工艺和渗氮工艺等传统表面热处理方法可以有效提高表面的硬度、耐蚀性、耐磨性和抗疲劳性[6],而激光表面热处理具有传统热处理方法无法企及的优势,如

表 1. 激光表面热处理的优劣

Table 1. Advantages and disadvantages of laser surface heat treatment

|

激光表面热处理最显著的特点是其精确性。在对三维形状结构复杂的零件进行激光表面热处理时,通过控制激光束的尺寸,可以极大地缩小热影响区,精确地控制处理区域和未处理区域,同时最大限度地减小热处理引起的变形和残余应力。相比之下,在传统热处理方法中,零件被加热到所需温度后,通过在油或水中快速冷却实现所需的表面硬度。然而,在薄壁和高精度零件的热处理过程中,由于不可控的过热或熔化等,零件表面会出现热影响区变大、表面变形和硬度分布不均匀等现象。在大多数工业应用中,磨损、腐蚀等失效现象通常只在零件的特定区域发生。因此,对易失效区域进行强化成为一种有效途径。激光加工的优势在于其高度定向的性质和向特定区域输送可控能量的能力。

激光束具有高能量密度的特点。在激光束照射区域,大量热量在极短的时间内聚集,使得待加工区域达到相变温度。由于激光处理仅涉及局部区域,当激光停止作用后,热量迅速向基体扩散,加热区迅速冷却。相较于传统热处理方式,激光表面热处理不需要额外的冷却介质[7]。

在可持续发展方面,激光热源具有清洁、绿色和无污染等特点。与渗氮、渗碳热处理过程相比,激光表面热处理过程不涉及化学反应,不会产生化学污染[8]。在大规模生产线上,通常通过导光系统和工作台来提高激光的利用效率和热处理效率,以使激光表面热处理的成本低于传统热处理。

与传统的感应或火焰淬火工艺相比,高功率的激光输入使得激光表面热处理成为高速表面处理技术。激光表面淬火硬化层的深度可能无法达到传统热处理硬化层的深度[9]。传统热处理中的氮化、渗碳、硼化等化学热处理存在加工时间长、待处理工件易变形等缺点。

激光热处理的输入能量取决于材料的吸收率。通常仅有小部分激光能量被材料吸收,大部分激光能量从表面反射出去。影响抛光金属表面对激光吸收率的一个关键因素是辐照所用的波长。对于钢等金属材料,当辐照波长较短时,吸收率增加。在较大的波长下,钢对电磁辐射的吸收非常低(吸收率<15%),因此有必要采取一定措施(如使用碳涂层)来增加金属表面对激光的吸收率。

2.2 激光表面热处理理论与模拟

激光表面热处理是局部急速加热-冷却的过程。在热处理区域,温度梯度大,同时伴随着液化、气化等物理过程,如

![激光表面热处理温度场、流动场、相转变场的多物理场耦合[10]](/richHtml/zgjg/2024/51/4/0402202/img_01.jpg)

图 1. 激光表面热处理温度场、流动场、相转变场的多物理场耦合[10]

Fig. 1. Multi-physics field coupling of temperature, flow and phase transition fields for laser surface heat treatment[10]

式中:

二极管激光器形成的具有高斯顶帽分布的矩形激光束的强度为

式中:A和B分别是激光强度分布的长度和宽度;a和b定义为激光分布边缘处的强度变化率。然后,基于相关物理参数,对

式中:

在模拟过程中,假设熔池的流动状态是层流且熔池是不可压缩的牛顿流体。人们通常用Navier-Stokes动量方程来模拟熔池的流动状态,即

式中:

3 激光表面热处理技术的研究现状

激光表面热处理,也被称为激光表面改性,是一种利用高能量密度的激光,在热和力的作用下使材料表面的微观组织结构发生改变,进而提高金属零件表面性能的技术[14]。几种典型的激光表面热处理技术如

3.1 激光表面淬火

激光表面淬火(LSH),又被称为激光表面硬化和激光相变硬化,是一种利用激光的高功率输入使基材表面奥氏体化,然后通过快速冷却使奥氏体转变成马氏体相,从而实现表面淬硬处理的表面改性技术。激光表面淬火过程中有两个重要的转变过程,即:高功率激光输入导致奥氏体相形成,奥氏体在随后的快速冷却过程中转变成马氏体相。在激光表面淬火过程中,由于激光作用时间较短,奥氏体均匀化没有完成,因此碳含量的分布会对最终形成的微观结构以及硬化区的硬度产生较大影响。激光加工参数,如激光功率、扫描速度和光斑尺寸等,会对激光表面淬火后的微观组织产生影响,并进一步影响零件的性能。

![灰口铸铁激光淬火表面的4个热影响区[15]](/richHtml/zgjg/2024/51/4/0402202/img_03.jpg)

图 3. 灰口铸铁激光淬火表面的4个热影响区[15]

Fig. 3. Four heat affected zones on the laser hardened surface of grey cast iron[15]

在优化工艺参数时,通常采用曲面响应法(RSM)。这是一种统计分析方法,用于分析和建立多个变量之间的关系,以帮助找到影响因素与响应之间的近似关系。Moradi等[16-19]以扫描速度、焦平面位置、激光功率、焦点位置和脉冲宽度为自变量,以硬化区的最大硬度和几何尺寸(深度、宽度)、母材在深度和宽度上的显微硬度偏差,以及微观结构中铁素体相的体积分数为因变量,进行了实验研究。结果表明,增加激光功率和脉冲宽度,同时降低扫描速度和焦平面的位置,可以实现更高的表面硬度、更大的穿透深度、更高的平均显微硬度和最小的铁素体体积分数。Chen等[20]在响应面法的基础上提出了中心复合设计的方法。他们的研究结果表明,硬化宽度主要由激光功率和扫描速度线性决定,而硬化区的显微硬度和硬度梯度则受激光功率、扫描速度和散焦距离的共同影响。Khorram等[21]研究了工艺参数对AISI 431不锈钢Nd∶YAG激光表面淬火的影响。结果显示:当激光频率和脉冲宽度增加时,处理区域的硬度值降低;当扫描速度和焦平面距离增加时,由于热输入减少,硬化区的几何尺寸减小,平均硬度值随着扫描速度的降低而增加。通过优化参数,他们得到了最佳的激光淬火工艺方案。此外,Mahmoudi等[22]的研究结果显示,激光脉冲能量、脉冲持续时间及扫描速度等参数会影响AISI 420马氏体不锈钢的硬化深度和腐蚀行为。激光表面淬火可以细化微观结构,从而提高马氏体不锈钢的耐点蚀能力。因此,增加激光光斑搭接率可以显著提高材料的耐点蚀能力。

当激光表面淬火无法满足材料的性能需求时,可以结合其他辅助处理方法来进一步提高零件的表面性能,例如传统后处理、气氛环境辅助、其他能量场辅助等方法。Wang等[15]对比了淬火回火、等温淬火和激光表面硬化的处理效果。Writzl等[23]结合等离子渗氮和激光淬火来提高蠕墨铸铁的抗划伤性能。在加热过程中,金属可能会与环境气体发生反应。Maharjan等[24]在不同气体氛围下对AISI 1020钢进行了激光淬火处理,发现不同气体对激光淬火后的表面具有不同的增强作用,可进一步提高被处理表面的力学性能。Lesyk等[25-26]将激光淬火与超声波冲击处理相结合,研究了其对中碳钢AISI 1045表面形貌、硬度和耐磨性的影响。细晶界渗碳体颗粒固定的超细马氏体晶粒可以提高表面硬度,从而使表面实现了优异耐磨性能并降低了材料的表面粗糙度。Maharjan等[27]将激光淬火与水冷相结合用于提高基材的表面硬度,结果显示,虽然水下激光淬火使基材表面的硬度提高了约3.5倍,但激光硬化区的尺寸(深度和宽度)明显小于传统激光硬化区。为了提高材料表面的疲劳寿命,Wang等[28-30]研究了喷丸强化对激光淬火17-4PH钢疲劳寿命的影响。结果显示:较高的残余压应力、晶粒细化和高密度位错提高了喷丸强化表面的硬度,同时残余压应力提高了零件的疲劳寿命。张群莉等[31]将激光能量与电磁感应相结合对42CrMo钢进行复合淬火处理,提高了淬硬层的深度和组织均匀性。

在各种激光表面处理方法中,激光淬火是一种有效、简单和精确的方法,因为它不需要任何配件。但是,它还具有一些需要克服的缺点,如:当激光表面淬火在重叠区域进行扫描时,单道硬化区域的硬度远高于重叠区域的硬度;将激光表面淬火与传统热处理结合时,激光的二次淬火会导致残余奥氏体增加,从而降低了表面硬度。为了提高材料对激光的吸收率,Moradi等[32]采用电泳法在样品表面沉积碳粉对样品进行硬化。结果显示,与未附着碳粉的区域相比,样品硬化区域的硬度值得到了提高。

3.2 激光重熔

激光重熔(LR)又称为激光熔凝。该技术利用激光束对材料表面进行快速加热,使其达到熔点并形成熔池。当激光束离开处理区域时,熔池迅速冷却,形成晶粒细小的表面组织。当一些零件表面存在粗大枝晶时,往往伴随着金属化合物、气孔等缺陷,这些缺陷会降低表面性能并降低零件寿命。激光重熔可以消除表面的气孔、杂质等,并可通过细化晶粒来提高表面性能。激光重熔的表面形状是激光表面热处理熔池形貌与流动的最集中体现[33]。熔池流动形成的表面结构是在体积膨胀和马兰戈尼(Marangoni)对流作用下形成的。在激光重熔过程中,熔池体积膨胀,马兰戈尼对流使熔化材料从熔池边缘流向熔池中心,熔池表面呈现“W”形[34]。

激光增材制造(LAM)是最具前景和可行性的制造技术之一,为制造业带来了变革。与传统制造技术不同,激光增材制造能够直接根据三维计算机模型制造出零件,并且可以制造内部结构复杂的零件。然而,激光增材制造所产生的固有孔隙缺陷导致其机械强度和表面精度低于传统制造的零件。激光重熔被广泛应用于激光增材制造零件的后处理中,它可以使孔隙率降低,同时可以使成分均匀,改变材料的各向异性[35],降低残余应力[36]。激光重熔在改变激光增材制造零件表面质量的同时也会改变表面的化学成分和氧化层厚度[37]。激光选区熔化(SLM)制造的Ti6Al4V合金经过激光重熔后,其表面质量、高周疲劳强度、抗压强度、耐磨性和冲击强度均有所提升[38]。Gustmann等[39]研究了激光重熔对SLM制造的Cu-Al-Ni-Mn形状记忆合金密度的影响。结果显示,激光重熔后,晶粒尺寸减小,合金密度增大,并且伴随着小于100 μm的孔隙的消失。激光重熔经济实惠,可以明显改善SLM制造的样品的表面性能[40]。然而,激光重熔作为辅助SLM制造的工艺,仍然具有一定的局限性。如,经过激光重熔后,SLM样品中小角度晶界的比例显著增加,组织显示出非常强烈的晶体学纹理,从而导致了性能的各向异性[41-42]。

激光重熔工艺参数对零件性能具有较大影响[43-44]。适宜的激光重熔工艺参数可以减少零件中的制造缺陷[45]。Chen等[46]研究了激光重熔速度对S355结构钢表面Al-Ti-Ni涂层耐蚀性的影响。结果显示,不同的扫描速度下形成了不同的金属间化合物,高扫描速度下形成的表面形貌和压应力有利于抑制裂纹扩展。此外,林丹等[47]在不同的激光功率下对铝合金微弧氧化层进行了激光重熔处理。结果显示:随着激光功率从500 W增大到900 W,孔隙率会先增大后减小;当激光功率达到1000 W时,氧化层会鼓起、开裂,粗糙度和孔隙率会增加。激光重熔还能够改善等离子喷涂层的显微硬度、结合强度和耐磨性。晶粒尺寸的减小和组织转变是提高屈服强度的重要措施。在强化机制方面,位错强化和析出强化是激光重熔的主要强化机制[48]。此外,激光重熔工艺还被用来改善喷涂Stellite 6涂层的微观结构、附着力[49],以及改善喷涂WC-Co涂层的微观结构,从而增加涂层的显微硬度以及涂层与基材的黏附性。另外,激光重熔还可以改变金属增材制造零件表面的熔池方向和晶粒形貌。卞玉超等[50]利用激光重熔提升了316L/IN718异质结构的表面粗糙度、拉伸强度,并将该异质结构的断裂方式由脆性断裂转变为韧性断裂。

额外的场辅助可以有效提高重熔层材料的性能[51]。在重熔过程中,激光重熔表面会出现起伏状缺陷。Wang等[52]采用磁场产生的洛伦兹力来阻碍熔池流动并减少重熔后的表面起伏。他们发现,通过增大磁通密度,样品的表面起伏得到了减弱。利用磁场可以减小熔池流动的特点,Nie等[53]通过施加横向静磁场,抑制了热量传递,减小了冷却速率,从而降低了残余应力。磁场辅助被认为是消除残余应力的潜在方法。

3.3 激光表面合金化

激光表面合金化(LSA)也是一种表面改性技术。该技术利用高能量密度的激光束快速加热基材,使基材与添加到其表面的合金元素一起熔化,形成合金熔池,熔池凝固后在基材表面形成新成分的合金化表面层。激光表面合金化通常采用几种不同的进给方式,包括同步进给方式、置换方式和表面气体合金化,如

![激光表面合金化实验装置示意图[54]](/richHtml/zgjg/2024/51/4/0402202/img_07.jpg)

图 5. 激光表面合金化实验装置示意图[54]

Fig. 5. Schematic diagram of the experimental setup for laser surface alloying[54]

激光表面合金化粉末主要分为三类:1)高熵合金粉末;2)TiC、SiC、WC、B和石墨粉末;3)Al、Nb等元素粉末。这三种粉末对基材表面的强化方式各不相同。高熵合金是由等原子比或接近等原子比的元素组成的多组分合金。该合金具有理想的力学性能,例如优异的抗氧化和耐蚀性、高的强度和硬度、良好的高温性能及耐磨性。采用激光表面合金化在成本较低的金属上形成高性能高熵合金涂层,可以增强材料表面的强度。Zhang等[55]通过激光表面合金化在Q235钢上制备了FeCoCrAlCu高熵合金涂层,该涂层的硬度是铁基体的3倍。Wu等[56]在商业纯铜上制备了FeCoCrAlCuNix高熵合金涂层,测试结果显示:铜基材表面形成了典型的高熵合金晶体结构,涂层的硬度是基体的6.6倍,并表现出优良的耐磨性和耐蚀性。

TiC、SiC、WC、B和石墨粉末通过与基体形成硬陶瓷相来增强表面的性能。这些粉末经过激光表面合金化后,会在基体上形成与传统渗氮和渗碳处理效果相当的强化相[57-58]。这些硬质陶瓷相具有密度小以及耐磨性和抗氧化性能优良等特点。相对于渗氮和渗碳热处理,激光表面合金化减少了能源和时间的消耗。Nath等[59]以Co和NiCr作为黏合剂,在铝基体上开发了碳化钨(WC)分散表面。在基材表面形成的陶瓷强化相和Al3Ni起到了细晶强化的作用,从而提高了铝基体表面的耐磨性。Makuch等[60]使用硼和碳来改善商业纯钛的表面性能。在塑性共晶混合物中,硬陶瓷相(TiB、TiB2、TiC)的含量影响着显微硬度值。这些陶瓷强化相不仅可以提升表面硬度,还可以防止基体氧化。

Al、Nb等元素粉末也可用于激光表面合金化,形成可以强化基体表面性能的合金相。为了改善铝合金硬度和韧性不足的问题,Almeida等[61]在纯铝基板上采用激光表面合金化形成Al-Nb合金。激光合金化形成了非常坚硬的表面层,但其中的Nb分布不均匀,合金层中存在未完全熔化的Nb颗粒。Tomida等[62]在对Al-Mg合金进行激光合金化过程中加入了Fe元素,以实现强化。结果显示:随着Fe含量增加,激光合金化层的组织从亚共晶组织转变为过共晶组织,之后又转变成针状FeAl3和细针状FeAl3,最后转变成块状Fe2Al5化合物,表面硬度和耐磨性逐渐提高。另一项研究[63]用Al粉末与纯钛基体形成了Ti3Al、TiAl、TiAl3涂层,其中,Ti3Al涂层的硬度和耐磨性相比纯钛基体有了极大提升。

3.4 激光熔覆

激光熔覆(LC)是一种利用激光热源将合金材料熔覆到基体表面,并与基体实现冶金结合的表面热处理技术。该技术可以在基体表面形成具有优异物理和化学性能的合金涂层。与激光表面合金化相比,激光熔覆涂层材料仅存在于基材/熔覆层界面或界面上方,不会与基体生成具有新相和新化学成分的表面层[64]。一般来说,激光熔覆的表面合金层比激光表面合金化的表面合金层更厚[65]。

激光熔覆过程可以通过不同的合金进给方式进行,如预置送粉、同轴送粉、离轴送粉和送丝,如

![激光熔覆送粉系统示意图[11]。(a)预置送粉系统;(b)同轴送粉系统;(c)离轴送粉系统;(d)送丝系统](/richHtml/zgjg/2024/51/4/0402202/img_08.jpg)

图 6. 激光熔覆送粉系统示意图[11]。(a)预置送粉系统;(b)同轴送粉系统;(c)离轴送粉系统;(d)送丝系统

Fig. 6. Schematic diagrams of the powder feeding systems for laser cladding[11]. (a) Preset powder feeding system; (b) coaxial powder feeding system; (c) off-axis powder feeding system; (d) wire feeding system

控制激光熔覆过程的工艺参数可以改变熔覆层的尺寸以及基体材料的熔化情况。过多的基体材料熔化会导致熔覆层被稀释,从而降低其力学性能和耐蚀性;过少的基体材料熔化则可能导致熔覆层/基体无法实现良好的冶金结合。理想情况下,基材表面应刚好达到熔化温度,最好仅有非常薄的一层基材熔化,以保证熔覆材料与基材之间的良好结合。激光熔覆层的熔深、内部缺陷和微观组织与激光功率、扫描速度、送粉方式、焦点位置等工艺参数密切相关[66-69]。中心组合设计、响应面法和多级全因子方法是常见的工艺参数研究方法[70]。送粉速度影响熔覆层的高度和宽度,扫描速度影响基体熔化的深度。较低的送粉速度和扫描速度会导致基体熔化和包层稀释;而高的扫描速度可能会增大侧角,减小熔覆焊道的宽度和高度。焦点位置的调整也会影响稀释深度,最佳激光聚焦条件是焦点在焦平面上,此时不会有稀释区(仅有熔化区)。高速激光熔覆[71]可以提高涂层的制备效率,而且涂层的耐磨性和耐蚀性也优于传统的激光熔覆层。高速激光熔覆层的微观结构更细小、致密,柱状晶间距更窄。因此,激光熔覆工艺与增材制造技术相结合可以进一步改善材料的表面性能[72-73]。

在激光熔覆过程中,施加机械振动、超声能量场、磁场、电磁复合场和静电场等其他形式的能量场,可以影响熔覆过程中熔池的宏观流动。这些辅助能量场的应用可以改善熔覆层的力学性能。熔池的孔隙率、流动特性和冷却速率影响着熔覆层的成分均匀性和晶粒尺寸。例如:电磁复合场通过在熔池表面施加向下的安培力来降低熔覆层表面的孔隙率和孔径[74];磁场的应用也可以使熔覆层的晶粒细化,从而提高涂层的硬度[68]。另外,将直流电场、交变磁场和超声场耦合来辅助激光熔覆工艺,也可以进一步细化熔覆层的微观结构,并使元素扩散得更加均匀,从而获得更高的显微硬度和更低的磨损体积[75]。

相较于其他激光表面热处理技术,激光熔覆在再制造和修复零件方面具有天然优势。通过逆向技术和高性能粉末送粉可以恢复零件尺寸和修复其表面质量。例如:将不同材料的涂层包覆在磨损部位,可以实现车轮的修复和再制造[76];使用激光熔覆工艺将H13钢粉末材料应用于45钢齿轮的再制造,可以提高齿的力学性能和几何尺寸精度[77]。

3.5 激光冲击喷丸

激光冲击喷丸(LSP),也被称为激光冲击强化,是一种利用激光冲击波来改善材料表面性能的表面处理技术。在激光冲击喷丸过程中,激光穿过透明覆面材料(通常是水)照射待处理区域的吸收层,导致该层表面汽化并形成等离子体。由于透明覆面材料的限制,等离子体压力迅速升高,将激光冲击波传递到基体材料,导致表面发生塑性变形。这种塑性变形会引起晶格畸变、位错产生和晶粒细化等微观变化,在表层形成有益的残余压应力,从而改善材料表面的抗疲劳性。相较于传统的喷丸技术,激光冲击喷丸可以产生更大深度的压应力,并且加工硬化程度较低[78]。

激光冲击喷丸已被广泛用于改善增材制造零件的表面粗糙度和残余应力。Maleki等[80]将激光冲击喷丸和超声纳米晶技术相结合,用于改善AlSi10Mg样品的力学性能和抗疲劳性。与超声波喷丸强化相比,激光冲击喷丸可以产生更大深度的压应力层,并且在提高高温疲劳寿命方面表现更好[81]。这表明激光冲击喷丸在高温下可以更有效地改善材料的耐久性能。

在改善零件表面粗糙度、残余应力分布和抗疲劳性方面,激光冲击喷丸的作用与其引起的塑性应变有关。激光冲击喷丸会在材料表面引起塑性变形、孪生、位错等缺陷,这些缺陷会使晶粒细化,从而对材料的性能产生影响。因此,研究激光冲击喷丸工艺参数对于样品中残余压应力值以及压应力层深度的控制具有深远意义。Cellard等[82]研究了激光能量密度、脉冲持续时间、冲击次数和样品厚度对冲击深度、表面粗糙度、材料硬化和残余应力的影响,结果发现残余应力受到所有参数的影响。国外研究了激光脉冲能量、激光冲击次数以及激光光斑尺寸对残余应力分布的影响,并通过优化工艺参数来提高硬度和表面粗糙度[83]、降低磨损率[84]。He等[85]在研究中发现:随着脉冲能量和冲击次数增加,冲击层的深度逐渐增大:两次冲击后的冲击层深度较一次冲击后的明显增加,但三次冲击后冲击层深度的增加并不显著。此外,冲击层下方的晶粒尺寸逐渐增大,直至与基体部分的晶粒尺寸相同。

![激光冲击喷丸处理后的微观组织[85]。(a)3 J脉冲能量,冲击一次;(b)4.6 J脉冲能量,冲击一次;(c)6 J脉冲能量,冲击一次;(d)4.6 J脉冲能量,冲击两次;(e)4.6 J脉冲能量,冲击三次;(f)微观结构变化机理示意图](/richHtml/zgjg/2024/51/4/0402202/img_10.jpg)

图 8. 激光冲击喷丸处理后的微观组织[85]。(a)3 J脉冲能量,冲击一次;(b)4.6 J脉冲能量,冲击一次;(c)6 J脉冲能量,冲击一次;(d)4.6 J脉冲能量,冲击两次;(e)4.6 J脉冲能量,冲击三次;(f)微观结构变化机理示意图

Fig. 8. Microstructures after laser impact blasting treatment[85]. (a) 3 J-once; (b) 4.6 J-once; (c) 6 J-once; (d) 4.6 J-twice; (e) 4.6 J-three times; (f) schematic diagram of microstructure change mechanism

4 激光表面热处理技术应用

4.1 耐磨性

汽轮机作为全球发电设备的主要部分,其涡轮进气阀阀门等零件在运行中承受着高冲击和摩擦载荷作用,导致其表面容易磨损和劣化。为了提高这些运动部件的耐磨性,延长其使用寿命,常常采用表面涂层来保护这些零件,防止磨损、间隙变化和氧化等失效机制的发生[86]。Inconel 625镍基高温合金涂层具有良好的高温延展性、韧性、抗疲劳性、抗蠕变性和抗氧化性以及较高的强度,常被用于制造蒸汽轮机的各种部件。对于涡轮进气阀阀门等零件,激光熔覆是制备Inconel 625合金涂层的首选方法,因为激光熔覆制备的Inconel 625合金涂层在室温和高温下都具有更高的硬度和更好的耐磨性。此外,高熵合金AlCoCrFeNi也是一种具有高强度和良好耐磨性的合金[87]。采用激光熔覆制备的AlCoCrFeNi合金涂层的硬度可达到543 HV左右,高于铸态AlCoCrFeNi高熵合金。为了进一步提高AlCoCrFeNi涂层的硬度和耐磨性,可以将TiC陶瓷颗粒直接添加到高熵合金涂层中,如此可使硬度最高提升到700 HV。

![涂层与基体的界面形貌。(a)(c)AlCoCrFeNi高熵合金与基体的界面形貌[87];(b)(d)添加TiC的AlCoCrFeNi高熵合金与基体的界面形貌[87];(e)(f)磨损测试后,电弧焊和激光熔覆Inconel 625涂层的表面形貌[85]](/richHtml/zgjg/2024/51/4/0402202/img_11.jpg)

图 9. 涂层与基体的界面形貌。(a)(c)AlCoCrFeNi高熵合金与基体的界面形貌[87];(b)(d)添加TiC的AlCoCrFeNi高熵合金与基体的界面形貌[87];(e)(f)磨损测试后,电弧焊和激光熔覆Inconel 625涂层的表面形貌[85]

Fig. 9. Interfacial morphology between the coating and the substrate. (a)(c) Interfacial morphology between AlCoCrFeNi high-entropy alloy and the substrate[87]; (b)(d) interfacial morphology between AlCoCrFeNi high-entropy alloy with TiC and the substrate[87]; (e)(f) surface morphology of arc welded and laser fused Inconel 625 coatings after wear testing[85]

在众多的激光表面热处理方法中,除了激光熔覆外,激光表面合金化和激光重熔也是常用的方法,它们常用于增强基体表面的耐磨性。激光表面合金化通过控制合金元素的添加和激光加热过程在基体表面形成新的合金相,从而提高表面的硬度和耐磨性。例如,研究人员制备了由氮化钛枝晶增强的耐磨复合涂层,并将其应用在Ti6Al4V合金上,这使得合金在双体磨损和干滑动磨损条件下均表现出了较好的耐磨性[89]。激光重熔主要被应用于共晶AlSi铸造合金上。在激光重熔过程中,合金被加热至熔点并快速冷却,从而生成了由细小的初生Si颗粒、初生α-Al基体相和细小的α相组成的微观结构[90]。随着Si颗粒尺寸减小,合金的硬度和耐磨性得到提高。这些激光表面热处理方法都可以有效地改善材料表面的耐磨性,增强材料的表面硬度,从而延长零件的使用寿命。

4.2 耐蚀性

腐蚀是工业生产中常见的材料失效形式,特别是在恶劣的环境下,如海水中的Cl-、油气中的CO2和H2等腐蚀性物质存在时,部件表面容易受到腐蚀。腐蚀行为与其他失效形式(如侵蚀、磨损、疲劳裂纹)共同作用会加速材料损失和设备故障。激光熔覆形成的合金涂层在提高表面耐蚀性方面发挥着重要作用[91]。为提高基材的耐蚀性,激光熔覆可以使用耐蚀性较好的金属,例如含Cr的合金、304不锈钢和高熵合金等,形成表面涂层。此外,金属基表面复合涂层(MMC)也被广泛应用。这种涂层具有良好的耐磨性和耐蚀性。在金属基体中加入非金属硬质碳化物颗粒,如WC、VC等,金属基体良好的延展性与硬质增强颗粒的协同作用,可使MMC具有优良的耐蚀性、耐磨性、抗冲击性、抗侵蚀性、抗疲劳性和抗断裂能力[92-94]。在激光熔覆过程中,增加熔覆速度不仅可以使枝晶细化,还可以使合金涂层的成分更加均匀。同时,高熔覆速度下制备的涂层中存在大量位错和堆垛层错,这有利于钝化膜的成核,从而在涂层上形成致密的钝化膜,进一步提高涂层的耐蚀性。

激光冲击喷丸和激光重熔也被广泛用来提高零件表面的耐蚀性。例如,FeCrAl合金常被作为核反应堆包层材料,因为其在高温蒸汽环境下具有强的耐蚀性。研究表明,在激光重熔的基础上采用水辅助可以进一步提高FeCrAl合金的抗氧化性和耐蚀性,如

![FeCrAl合金在热水环境中的腐蚀行为[95]。(a)~(c)未进行表面处理;(d)~(f)激光重熔后](/richHtml/zgjg/2024/51/4/0402202/img_12.jpg)

图 10. FeCrAl合金在热水环境中的腐蚀行为[95]。(a)~(c)未进行表面处理;(d)~(f)激光重熔后

Fig. 10. Corrosion behavior of FeCrAl alloy in a hot water environment[95]. (a)‒(c) Without surface treatment; (d)‒(f) after laser surface remelting

综上所述,激光表面热处理技术在提高材料表面耐蚀性方面具有广阔的应用前景,并可以根据具体需求选择合适的工艺参数来优化涂层性能。这些方法为工业生产中提高材料的耐久性和延长零件使用寿命提供了有效的解决方案。

4.3 残余应力

对于航空航天零部件(如喷气发动机涡轮叶片、燃气轮机)和汽车部件(如齿轮、轴)来说,疲劳失效严重影响着它们的使用寿命。疲劳裂纹主要发生在均质材料表面,其形成过程主要包括裂纹的萌生和扩展两个阶段。改善零件的表面粗糙度、增加零件表面加工硬化层的深度以及引入残余压应力可以提高其抗疲劳性。通过在零部件表面引入有益的残余压应力,可以改善零件的疲劳行为。疲劳裂纹驱动的拉应力必须克服这些压应力才能导致结构失效。通过在工作载荷引起的可能的拉伸应力上增加残余压应力可以延长疲劳寿命。深滚压、激光冲击强化、喷丸强化和低塑性抛光等方法可以对金属表面产生多种有益的影响。喷丸处理是提高表面残余压应力最常见的方法。传统喷丸处理会在材料表面产生具有高残余压应力和大加工硬化层的表面层。与机加工表面相比,传统喷丸处理后的表面粗糙度有所增大。表面压应力和高表面粗糙度所起的作用可能会相互抵消,因此难以直接比较表面处理效果。激光冲击喷丸会产生更厚的压应力层、更高的残余压应力值和更大的加工硬化深度。经过喷丸处理后,零件的疲劳寿命会显著增加[99-104]。周建忠课题组[104-105]对激光冲击喷丸抑制金属零件疲劳失效行为进行深入研究后发现,IN718合金小孔周边区域表面的残余应力呈现各向异性,激光喷丸后铝合金试样的疲劳寿命随着有效应力和极限应力比的增大而降低。如

在激光能量场表面热处理过程中,有益的残余压应力出现在激光冲击喷丸、激光表面淬火和激光重熔中,而激光熔覆中会出现加速疲劳失效的有害的残余拉应力。Kendall等[106]研究了激光熔覆层中的残余拉应力对钢轨使用和修复的影响,认为熔覆层中的残余拉应力限制了激光熔覆在提高钢轨硬度方面的应用。邓德伟等[107]分析了316L激光熔覆层中的残余应力与工艺参数之间的关系,结果表明:随着激光功率、送粉速率增大以及扫描速度减小,残余应力表现出逐渐增大的趋势。在激光表面淬火后,硬化区域出现了残余压应力。在淬火马氏体和回火马氏体/贝氏体区之间的过渡区,应力状态由压应力转变为拉应力。残余应力与显微硬度、微观结构密切相关[108]。在激光重熔过程中,回火索氏体向细小的马氏体转变,表面的快速熔化-凝固会细化晶粒[109]。晶粒细化将导致晶界百分比增加。当疲劳裂纹从一个晶粒穿过晶界到达另一个晶粒时,疲劳裂纹会被晶界阻挡。即使晶界未能阻挡疲劳裂纹,由于相邻晶粒的晶体学取向不同,疲劳裂纹的扩展方向也会不可避免地发生改变,因此疲劳裂纹在细小晶粒中传播会消耗更多能量。

5 结束语

本文探讨了激光能量场表面热处理技术的优缺点以及处理过程中的多物理场耦合,同时综述了5种典型的激光能量场表面热处理技术的发展及其在改善材料表面性能方面的应用。随着过去30年激光能量场表面热处理技术的累积,现阶段通常结合新的增材制造技术和表面热处理方法来改善工件的表面性能。为充分利用激光能量场表面热处理的优势,未来可从以下几方面(如

1)与激光增材制造深度融合。增材制造在制造复杂结构零件方面具有巨大优势,但其表面精度较低,制约了该技术的进一步发展与应用。在激光增材制造的全过程中可以实时进行表面热处理,即在零件制造的同时改善其表面性能,从而可使零件具有更高的性能和可靠性。将激光增材制造与激光表面处理技术深度融合,可以发挥两者各自的技术优势。

2)多物理场耦合。在激光能量场表面热处理过程中,温度场、流场和相场之间存在复杂的耦合关系。通过引入电场、磁场、声场等辅助手段,可以改变上述物理场在热处理过程中的演变,从而精确控制熔池的微观结构和凝固速率,获得理想的微观组织和晶粒形貌,最终达到提高材料表面性能的目的。

3)深入开展激光能量场的理论模拟。激光能量场表面热处理过程涉及多物理场和多尺度。以强耦合的方式将固有的物理场演变和辅助制造的物理场融合,结合并行计算和GPU等加速手段来加速计算模拟过程,建立能够同时求解多物理场耦合方程的计算模型,可以更真实地模拟激光能量场表面热处理的全过程,深入揭示激光表面处理的本质。

4)结合深度学习神经网络实现激光表面热处理工艺参数的智能优化。工艺参数作为激光表面热处理过程中最关键的控制参数,直接影响着熔池的形貌、微观组织和表面性能。对于不同的零件,需要进行大量复杂的实验设计来确定最优的工艺参数,从而严重制约了激光表面热处理技术的发展。基于深度学习神经网络的智能优化方法,可以大幅提高激光表面热处理技术的效率和精确度。通过精确预测材料热处理后的性能,可以最大限度地优化工艺参数,提高材料的性能和质量。同时,这种方法还可以减少对实验的依赖,降低实验成本和时间投入。

[1] 张继业, 彭航宇, 曹军胜, 等. 15 kW光纤耦合半导体激光淬火光源[J]. 中国激光, 2023, 50(5): 0501004.

[2] Muthukumaran G, Dinesh Babu P. Laser transformation hardening of various steel grades using different laser types[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2021, 43(2): 103.

[3] Zhan J B, Wu J Z, Ma R J, et al. Effect of microstructure on the superelasticity of high-relative-density Ni-rich NiTi alloys fabricated by laser powder bed fusion[J]. Journal of Materials Processing Technology, 2023, 317: 117988.

[4] Ji C, Li K, Zhan J B, et al. The effects and utility of homogenization and thermodynamic modeling on microstructure and mechanical properties of SS316/IN718 functionally graded materials fabricated by laser-based directed energy deposition[J]. Journal of Materials Processing Technology, 2023, 319: 118084.

[5] Zhan J B, Wu J Z, Ma R J, et al. Tuning the functional properties by laser powder bed fusion with partitioned repetitive laser scanning: toward editable 4D printing of NiTi alloys[J]. Journal of Manufacturing Processes, 2023, 101: 1468-1481.

[6] Di J, Yao J N, Li M, et al. Progress in laser surface modification technology of titanium alloy[J]. Journal of Physics: Conference Series, 2022, 2346(1): 012011.

[7] Babu P D, Marimuthu P. Status of laser transformation hardening of steel and its alloys: a review[J]. Emerging Materials Research, 2019, 8(2): 188-205.

[8] Chi Y M, Gu G C, Yu H J, et al. Laser surface alloying on aluminum and its alloys: a review[J]. Optics and Lasers in Engineering, 2018, 100: 23-37.

[9] Martínez S, Lamikiz A, Ukar E, et al. Analysis of the regimes in the scanner-based laser hardening process[J]. Optics and Lasers in Engineering, 2017, 90: 72-80.

[10] Li C, Yu Z B, Gao J X, et al. Numerical simulation and experimental study of cladding Fe60 on an ASTM 1045 substrate by laser cladding[J]. Surface and Coatings Technology, 2019, 357: 965-977.

[11] Tamanna N, Crouch R, Naher S. Progress in numerical simulation of the laser cladding process[J]. Optics and Lasers in Engineering, 2019, 122: 151-163.

[12] 熊安辉, 刘延辉, 李客, 等. 灰铸铁表面激光重熔的数值模拟与工艺试验[J]. 激光与光电子学进展, 2022, 59(3): 0316007.

[13] Liverani E, Lutey A H A, Ascari A, et al. A complete residual stress model for laser surface hardening of complex medium carbon steel components[J]. Surface and Coatings Technology, 2016, 302: 100-106.

[14] Moradi M, Arabi H, Jamshidi Nasab S, et al. A comparative study of laser surface hardening of AISI 410 and 420 martensitic stainless steels by using diode laser[J]. Optics & Laser Technology, 2019, 111: 347-357.

[15] Wang B X, Pan Y M, Liu Y, et al. Wear behavior of composite strengthened gray cast iron by austempering and laser hardening treatment[J]. Journal of Materials Research and Technology, 2020, 9(2): 2037-2043.

[16] Moradi M, Ghorbani D, Moghadam M K, et al. Nd∶YAG laser hardening of AISI 410 stainless steel: microstructural evaluation, mechanical properties, and corrosion behavior[J]. Journal of Alloys and Compounds, 2019, 795: 213-222.

[17] Casalino G, Moradi M, Moghadam M K, et al. Experimental and numerical study of AISI 4130 steel surface hardening by pulsed Nd∶YAG laser[J]. Materials, 2019, 12(19): 3136.

[18] Moradi M, Arabi H, Shamsborhan M. Multi-objective optimization of high power diode laser surface hardening process of AISI 410 by means of RSM and desirability approach[J]. Optik, 2020, 202: 163619.

[19] Moradi M, KaramiMoghadam M. High power diode laser surface hardening of AISI 4130; statistical modelling and optimization[J]. Optics & Laser Technology, 2019, 111: 554-570.

[20] Chen C R, Zeng X B, Wang Q T, et al. Statistical modelling and optimization of microhardness transition through depth of laser surface hardened AISI 1045 carbon steel[J]. Optics & Laser Technology, 2020, 124: 105976.

[21] Khorram A, Davoodi Jamaloei A, Jafari A, et al. Nd∶YAG laser surface hardening of AISI 431 stainless steel; mechanical and metallurgical investigation[J]. Optics & Laser Technology, 2019, 119: 105617.

[22] Mahmoudi B, Torkamany M J, Aghdam A R S R, et al. Laser surface hardening of AISI 420 stainless steel treated by pulsed Nd∶YAG laser[J]. Materials & Design (1980‒2015), 2010, 31(5): 2553-2560.

[23] Writzl V, Rovani A C, Pintaude G, et al. Scratch resistances of compacted graphite iron with plasma nitriding, laser hardening, and duplex surface treatments[J]. Tribology International, 2020, 143: 106081.

[24] Maharjan N, Zhou W, Wu N E. Direct laser hardening of AISI 1020 steel under controlled gas atmosphere[J]. Surface and Coatings Technology, 2020, 385: 125399.

[25] Lesyk D A, Martinez S, Mordyuk B N, et al. Combining laser transformation hardening and ultrasonic impact strain hardening for enhanced wear resistance of AISI 1045 steel[J]. Wear, 2020, 462/463: 203494.

[26] Lesyk D A, Martinez S, Mordyuk B N, et al. Effects of laser heat treatment combined with ultrasonic impact treatment on the surface topography and hardness of carbon steel AISI 1045[J]. Optics & Laser Technology, 2019, 111: 424-438.

[27] Maharjan N, Zhou W, Zhou Y, et al. Underwater laser hardening of bearing steels[J]. Journal of Manufacturing Processes, 2019, 47: 52-61.

[28] Wang Z, Jiang C H, Gan X Y, et al. Influence of shot peening on the fatigue life of laser hardened 17-4PH steel[J]. International Journal of Fatigue, 2011, 33(4): 549-556.

[29] Wang Z, Luan W Z, Huang J J, et al. XRD investigation of microstructure strengthening mechanism of shot peening on laser hardened 17-4PH[J]. Materials Science and Engineering: A, 2011, 528(21): 6417-6425.

[30] Wang Z, Jiang C H, Gan X Y, et al. Effect of shot peening on the microstructure of laser hardened 17-4PH[J]. Applied Surface Science, 2010, 257(4): 1154-1160.

[31] 张群莉, 林坚, 陈智君, 等. 基于MSC.Marc软件的电磁感应复合激光淬火相变研究[J]. 中国激光, 2021, 48(11): 1103002.

[32] Moradi M, Karami Moghadam M, Kazazi M. Improved laser surface hardening of AISI 4130 low alloy steel with electrophoretically deposited carbon coating[J]. Optik, 2019, 178: 614-622.

[33] 熊庭超, 殷延益, 陆丹华, 等. 激光重熔/电化学沉积交互处理铜涂层的微观组织及机理研究[J]. 中国激光, 2023, 50(4): 0402007.

[34] Xu J L, Zou P, Liu L, et al. Investigation on the mechanism of a new laser surface structuring by laser remelting[J]. Surface and Coatings Technology, 2022, 443: 128615.

[35] Xue P S, Zhu L D, Ning J S, et al. The crystallographic texture and dependent mechanical properties of the CrCoNi medium-entropy alloy by laser remelting strategy[J]. Journal of Materials Science & Technology, 2022, 111: 245-255.

[36] Yu Z Y, Zheng Y, Chen J M, et al. Effect of laser remelting processing on microstructure and mechanical properties of 17-4 PH stainless steel during laser direct metal deposition[J]. Journal of Materials Processing Technology, 2020, 284: 116738.

[37] Vaithilingam J, Goodridge R D, Hague R J M, et al. The effect of laser remelting on the surface chemistry of Ti6Al4V components fabricated by selective laser melting[J]. Journal of Materials Processing Technology, 2016, 232: 1-8.

[38] Karimi J, Antonov M, Kollo L, et al. Role of laser remelting and heat treatment in mechanical and tribological properties of selective laser melted Ti6Al4V alloy[J]. Journal of Alloys and Compounds, 2022, 897: 163207.

[39] Gustmann T, Schwab H, Kühn U, et al. Selective laser remelting of an additively manufactured Cu-Al-Ni-Mn shape-memory alloy[J]. Materials & Design, 2018, 153: 129-138.

[40] 陈帅, 陶凤和, 贾长治, 等. 激光重熔对选区激光熔化成形4Cr5MoSiV1钢组织和性能的影响[J]. 表面技术, 2020, 49(12): 209-219.

Chen S, Tao F H, Jia C Z, et al. Effect of laser remelting on microstructure and properties of 4Cr5MoSiV1 steel fabricated by selective laser melting[J]. Surface Technology, 2020, 49(12): 209-219.

[41] Wei K W, Lv M, Zeng X Y, et al. Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy[J]. Materials Characterization, 2019, 150: 67-77.

[42] Zhou J T, Han X, Li H, et al. Investigation of layer-by-layer laser remelting to improve surface quality, microstructure, and mechanical properties of laser powder bed fused AlSi10Mg alloy[J]. Materials & Design, 2021, 210: 110092.

[43] 王建刚, 高士友, 陈旭升, 等. 激光重熔A356铝合金表面的力学性能[J]. 中国激光, 2020, 47(4): 0402002.

[44] 邓德伟, 江浩, 李振华, 等. 基于BP神经网络的激光熔覆参数多目标优化[J]. 激光与光电子学进展, 2023, 60(17): 1714001.

[45] Zhan J B, Lu Y J, Lin J X. On the martensitic transformation temperatures and mechanical properties of NiTi alloy manufactured by selective laser melting: effect of remelting[J]. Acta Metallurgica Sinica (English Letters), 2021, 34: 1223-1233.

[46] Chen H X, Kong D J. Effects of laser remelting speeds on microstructure, immersion corrosion, and electrochemical corrosion of arc-sprayed amorphous Al-Ti-Ni coatings[J]. Journal of Alloys and Compounds, 2019, 771: 584-594.

[47] 林丹, 谷高扬, 商剑. 激光重熔处理对铝合金微弧氧化层组织及性能的影响[J]. 金属热处理, 2023, 48(4): 264-272.

Lin D, Gu G Y, Shang J. Effect of laser remelting on microstructure and properties of micro-arc oxidation layer on aluminum alloy[J]. Heat Treatment of Metals, 2023, 48(4): 264-272.

[48] Han T Y, Liu Y, Liao M Q, et al. Refined microstructure and enhanced mechanical properties of AlCrFe2Ni2 medium entropy alloy produced via laser remelting[J]. Journal of Materials Science & Technology, 2022, 99: 18-27.

[49] Ciubotariu C R, Frunzăverde D, Mărginean G, et al. Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings[J]. Optics & Laser Technology, 2016, 77: 98-103.

[50] 卞玉超, 彭英博, 宋凌峰, 等. 基于激光重熔优化工艺的激光选区熔化316L/IN718异质异构研究[J]. 中国激光, 2021, 48(18): 1802009.

[51] Li K, Ma R J, Zhang M, et al. Hybrid post-processing effects of magnetic abrasive finishing and heat treatment on surface integrity and mechanical properties of additively manufactured Inconel 718 superalloys[J]. Journal of Materials Science & Technology, 2022, 128: 10-21.

[52] Wang L, Yao J H, Hu Y, et al. Suppression effect of a steady magnetic field on molten pool during laser remelting[J]. Applied Surface Science, 2015, 351: 794-802.

[53] Nie J W, Chen C Y, Shuai S S, et al. Effect of static magnetic field on the evolution of residual stress and microstructure of laser remelted inconel 718 superalloy[J]. Journal of Thermal Spray Technology, 2020, 29(6): 1410-1423.

[54] Qiao Q, Cristino V A M, Tam L M, et al. Laser surface alloying of titanium alloy with silver: microstructure, hardness and corrosion property[J]. Surface and Coatings Technology, 2023, 458: 129357.

[55] Zhang S, Wu C L, Yi J Z, et al. Synthesis and characterization of FeCoCrAlCu high-entropy alloy coating by laser surface alloying[J]. Surface and Coatings Technology, 2015, 262: 64-69.

[56] Wu C L, Zhang S, Zhang C H, et al. Phase evolution and properties in laser surface alloying of FeCoCrAlCuNix high-entropy alloy on copper substrate[J]. Surface and Coatings Technology, 2017, 315: 368-376.

[57] Sun G F, Zhou R, Li P, et al. Laser surface alloying of C-B-W-Cr powders on nodular cast iron rolls[J]. Surface and Coatings Technology, 2011, 205(8/9): 2747-2754.

[58] 蒲飞, 刘元富, 徐向阳, 等. 激光表面合金化制备TiC/Fe3Al复合涂层组织及TiC演变规律[J]. 中国激光, 2014, 41(7): 0703002.

[59] Nath S, Pityana S, Dutta Majumdar J. Laser surface alloying of aluminium with WC+Co+NiCr for improved wear resistance[J]. Surface and Coatings Technology, 2012, 206(15): 3333-3341.

[60] Makuch N, Kulka M, Dziarski P, et al. Laser surface alloying of commercially pure titanium with boron and carbon[J]. Optics and Lasers in Engineering, 2014, 57: 64-81.

[61] Almeida A, Petrov P, Nogueira I, et al. Structure and properties of Al-Nb alloys produced by laser surface alloying[J]. Materials Science and Engineering: A, 2001, 303(1/2): 273-280.

[62] Tomida S, Nakata K. Fe-Al composite layers on aluminum alloy formed by laser surface alloying with iron powder[J]. Surface and Coatings Technology, 2003, 174/175: 559-563.

[63] Guo B G, Zhou J S, Zhang S T, et al. Tribological properties of titanium aluminides coatings produced on pure Ti by laser surface alloying[J]. Surface and Coatings Technology, 2008, 202(17): 4121-4129.

[64] 杜彦斌, 何国华, 周志杰, 等. 20Cr13表面激光熔覆15-5PH涂层组织和性能研究[J]. 激光与光电子学进展, 2023, 60(9): 0914002.

[65] Zhu L D, Xue P S, Lan Q, et al. Recent research and development status of laser cladding: a review[J]. Optics & Laser Technology, 2021, 138: 106915.

[66] Riquelme A, Rodrigo P, Escalera-Rodríguez M D, et al. Analysis and optimization of process parameters in Al-SiCp laser cladding[J]. Optics and Lasers in Engineering, 2016, 78: 165-173.

[67] Goodarzi D M, Pekkarinen J, Salminen A. Analysis of laser cladding process parameter influence on the clad bead geometry[J]. Welding in the World, 2017, 61(5): 883-891.

[68] Wang Q, Zhai L L, Zhang L, et al. Effect of steady magnetic field on microstructure and properties of laser cladding Ni-based alloy coating[J]. Journal of Materials Research and Technology, 2022, 17: 2145-2157.

[69] Sun Y W, Hao M Z. Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd∶YAG laser[J]. Optics and Lasers in Engineering, 2012, 50(7): 985-995.

[70] 任思学, 李景彬, 史亚盟, 等. 工艺参数对20CrMnTi基激光熔覆Ni60A-TiC涂层组织及耐磨性能的影响[J]. 中国激光, 2023, 50(8): 0802207.

[71] Yuan W Y, Li R F, Chen Z H, et al. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings[J]. Surface and Coatings Technology, 2021, 405: 126582.

[72] 金宸宇, 葛鸿浩, 张亚周, 等. 激光熔覆316L粉末多层堆积过程中熔覆层Cr元素分布机制研究[J]. 中国激光, 2023, 50(12): 1202205.

[73] 李佳宜, 刘玉德, 周裕圣, 等. 激光重熔对TC4选区激光熔化成形质量及力学性能的影响[J]. 激光与光电子学进展, 2022, 59(5): 0514006.

[74] Zhang N, Liu W W, Deng D W, et al. Effect of electric-magnetic compound field on the pore distribution in laser cladding process[J]. Optics & Laser Technology, 2018, 108: 247-254.

[75] Hu G F, Yang Y, Sun R, et al. Microstructure and properties of laser cladding NiCrBSi coating assisted by electromagnetic-ultrasonic compound field[J]. Surface and Coatings Technology, 2020, 404: 126469.

[76] Zhu Y, Yang Y, Mu X, et al. Study on wear and RCF performance of repaired damage railway wheels: assessing laser cladding to repair local defects on wheels[J]. Wear, 2019, 430/431: 126-136.

[77] Zhu L D, Wang S H, Pan H C, et al. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology[J]. Journal of Manufacturing Processes, 2020, 49: 344-354.

[78] King A, Steuwer A, Woodward C, et al. Effects of fatigue and fretting on residual stresses introduced by laser shock peening[J]. Materials Science and Engineering: A, 2006, 435/436: 12-18.

[79] Lim H, Kim P, Jeong H, et al. Enhancement of abrasion and corrosion resistance of duplex stainless steel by laser shock peening[J]. Journal of Materials Processing Technology, 2012, 212(6): 1347-1354.

[80] Maleki E, Bagherifard S, Unal O, et al. Superior effects of hybrid laser shock peening and ultrasonic nanocrystalline surface modification on fatigue behavior of additive manufactured AlSi10Mg[J]. Surface and Coatings Technology, 2023, 463: 129512.

[81] Liu S J, Kim Y, Jung J, et al. Effect of ultrasonic shot peening and laser shock peening on the microstructure and microhardness of IN738LC alloys[J]. Materials, 2023, 16(5): 1802.

[82] Cellard C, Retraint D, François M, et al. Laser shock peening of Ti-17 titanium alloy: influence of process parameters[J]. Materials Science and Engineering: A, 2012, 532: 362-372.

[83] Chupakhin S, Klusemann B, Huber N, et al. Application of design of experiments for laser shock peening process optimization[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(5/6/7/8): 1567-1581.

[84] Premnath M, Muruganandhan R, Abeens M. A study on the effect of various process parameters on low pulsed energy of laser shock peening without ablative layer on the mechanical behavior of AA 7075 T651[J]. Surface Topography: Metrology and Properties, 2022, 10(1): 015044.

[85] He Z, Shen Y, Tao J, et al. Laser shock peening regulating aluminum alloy surface residual stresses for enhancing the mechanical properties: roles of shock number and energy[J]. Surface and Coatings Technology, 2021, 421: 127481.

[86] Feng K, Chen Y, Deng P S, et al. Improved high-temperature hardness and wear resistance of Inconel 625 coatings fabricated by laser cladding[J]. Journal of Materials Processing Technology, 2017, 243: 82-91.

[87] Li Y T, Wang K M, Fu H G, et al. Microstructure and wear resistance of in situ TiC reinforced AlCoCrFeNi-based coatings by laser cladding[J]. Applied Surface Science, 2022, 585: 152703.

[88] Cai Z B, Cui X F, Liu Z, et al. Microstructure and wear resistance of laser cladded Ni-Cr-Co-Ti-V high-entropy alloy coating after laser remelting processing[J]. Optics & Laser Technology, 2018, 99: 276-281.

[89] Jiang P, He X L, Li X X, et al. Wear resistance of a laser surface alloyed Ti-6Al-4V alloy[J]. Surface and Coatings Technology, 2000, 130(1): 24-28.

[90] Tomida S, Nakata K, Shibata S, et al. Improvement in wear resistance of hyper-eutectic Al-Si cast alloy by laser surface remelting[J]. Surface and Coatings Technology, 2003, 169/170: 468-471.

[91] 孙磊, 郭雨嘉, 张盼盼, 等. 激光合金化改性8YSZ热障涂层的抗热腐蚀性能研究[J]. 中国激光, 2023, 50(4): 0402002.

[92] Zhang Z, Yu T, Kovacevic R. Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC[J]. Applied Surface Science, 2017, 410: 225-240.

[93] Liu H X, Wang C Q, Zhang X W, et al. Improving the corrosion resistance and mechanical property of 45 steel surface by laser cladding with Ni60CuMoW alloy powder[J]. Surface and Coatings Technology, 2013, 228: S296-S300.

[94] Bartkowski D, Młynarczak A, Piasecki A, et al. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding[J]. Optics & Laser Technology, 2015, 68: 191-201.

[95] Hu Y H, Ling Y H, Zhong H D, et al. Effect of cryogenic laser surface modification on the microstructure evolution and corrosion resistance of accident-tolerant FeCrAl alloys[J]. Surface and Coatings Technology, 2023, 466: 129637.

[96] Wang H, Ning C Y, Huang Y H, et al. Improvement of abrasion resistance in artificial seawater and corrosion resistance in NaCl solution of 7075 aluminum alloy processed by laser shock peening[J]. Optics and Lasers in Engineering, 2017, 90: 179-185.

[97] Trdan U, Grum J. Evaluation of corrosion resistance of AA6082-T651 aluminium alloy after laser shock peening by means of cyclic polarisation and EIS methods[J]. Corrosion Science, 2012, 59: 324-333.

[98] Pantelis D I, Bouyiouri E, Kouloumbi N, et al. Wear and corrosion resistance of laser surface hardened structural steel[J]. Surface and Coatings Technology, 2002, 161(2/3): 125-134.

[99] Nikitin I, Altenberger I. Comparison of the fatigue behavior and residual stress stability of laser-shock peened and deep rolled austenitic stainless steel AISI 304 in the temperature range 25‒600 ℃[J]. Materials Science and Engineering: A, 2007, 465(1/2): 176-182.

[100] Keller S, Chupakhin S, Staron P, et al. Experimental and numerical investigation of residual stresses in laser shock peened AA2198[J]. Journal of Materials Processing Technology, 2018, 255: 294-307.

[101] Maawad E, Sano Y, Wagner L, et al. Investigation of laser shock peening effects on residual stress state and fatigue performance of titanium alloys[J]. Materials Science and Engineering: A, 2012, 536: 82-91.

[102] Salimianrizi A, Foroozmehr E, Badrossamay M, et al. Effect of laser shock peening on surface properties and residual stress of Al6061-T6[J]. Optics and Lasers in Engineering, 2016, 77: 112-117.

[103] Brockman R A, Braisted W R, Olson S E, et al. Prediction and characterization of residual stresses from laser shock peening[J]. International Journal of Fatigue, 2012, 36(1): 96-108.

[104] 黄舒, 王作伟, 盛杰, 等. 激光喷丸强化IN718合金孔周表面残余主应力分布特性[J]. 中国激光, 2017, 44(2): 0202004.

[105] 周建忠, 徐增闯, 黄舒, 等. 基于不同应力比下激光喷丸强化6061-T6铝合金的疲劳裂纹扩展性能研究[J]. 中国激光, 2011, 38(9): 0903006.

[106] Kendall O, Abrahams R, Paradowska A, et al. Influence of multi-layer laser cladding depositions and rail curvature on residual stress in light rail components[J]. Engineering Failure Analysis, 2023, 150: 107330.

[107] 邓德伟, 常占东, 马云波, 等. 工艺参数对316L激光熔覆层组织性能及残余应力的影响[J]. 应用激光, 2021, 41(1): 83-88.

[108] Soriano C, Leunda J, Lambarri J, et al. Effect of laser surface hardening on the microstructure, hardness and residual stresses of austempered ductile iron grades[J]. Applied Surface Science, 2011, 257(16): 7101-7106.

[109] Zhao X H, Zhang H C, Liu Y. Effect of laser surface remelting on the fatigue crack propagation rate of 40Cr steel[J]. Results in Physics, 2019, 12: 424-431.

[110] Liu X Q, Yu J B, Shuai S S, et al. Cell-to-dendrite transition induced by a static transverse magnetic field during lasering remelting of the nickel-based superalloy[J]. Metallurgical and Materials Transactions B, 2018, 49(6): 3211-3219.

[111] Razavipour M, Legoux J G, Poirier D, et al. Artificial neural networks approach for hardness prediction of copper cold spray laser heat treated coatings[J]. Journal of Thermal Spray Technology, 2022, 31(3): 525-544.

[112] LiuZ, YanR H. Simulation analysis of temperature field of Ni60 nickel-based alloy femtosecond laser cladding high-speed steel substrate[M]∥XuM, YangL, ZhangL, et al. China academic conference on printing and packaging. Lecture notes in electrical engineering. Singapore: Springer, 2023, 991: 643-647.

[113] Simoni F, Huxol A, Villmer F J. Improving surface quality in selective laser melting based tool making[J]. Journal of Intelligent Manufacturing, 2021, 32(7): 1927-1938.

Article Outline

李坤, 房嘉辉, 廖若冰, 姜艳红, 徐俊, 李景阳, 曹华军, 雒泰民, 张金. 高性能金属激光能量场表面热处理技术研究现状及展望(特邀)[J]. 中国激光, 2024, 51(4): 0402202. Kun Li, Jiahui Fang, Ruobing Liao, Yanhong Jiang, Jun Xu, Jingyang Li, Huajun Cao, Taimin Luo, Jin Zhang. Current Research Status and Future Prospects for High-Performance Metal Laser-Energy-Field Surface Heat Treatment Technologies (Invited)[J]. Chinese Journal of Lasers, 2024, 51(4): 0402202.

![激光重熔形成“W”形的表面结构[34]](/richHtml/zgjg/2024/51/4/0402202/img_06.jpg)

![激光冲击喷丸装置示意图[79]](/richHtml/zgjg/2024/51/4/0402202/img_09.jpg)

![残余压应力抑制裂纹扩展[105]](/richHtml/zgjg/2024/51/4/0402202/img_13.jpg)

![激光表面热处理展望[110-113]](/richHtml/zgjg/2024/51/4/0402202/img_14.jpg)