激光与光电子学进展, 2023, 60 (1): 0114004, 网络出版: 2022-12-05

激光抛光DC53淬硬钢试验研究  下载: 538次

下载: 538次

Experimental Research on Laser Polishing of DC53 Hardened Steel

激光技术 激光抛光 表面形貌 功率谱密度分析 淬硬钢 显微组织 laser technique laser polishing surface morphology power spectral density analysis hardened steel microstructure

摘要

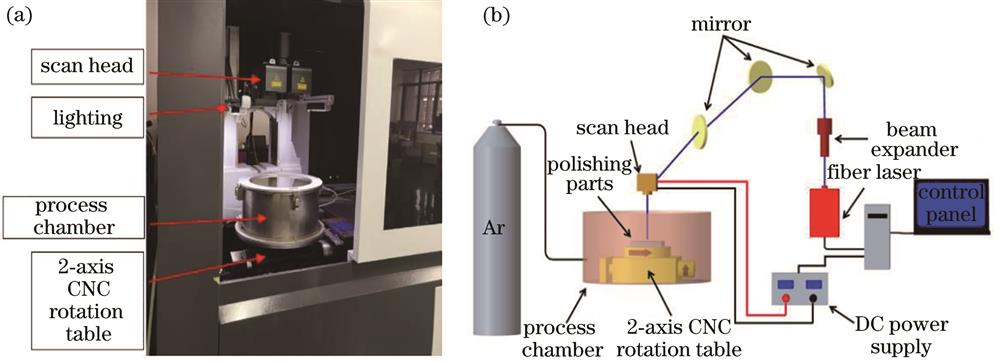

激光抛光是一种非接触式绿色自动化抛光技术,可以替代传统的抛光技术。为了研究激光抛光对DC53淬硬钢表面质量问题,采用波长为1064 nm的连续激光对DC53淬硬钢表面进行抛光处理,研究了激光抛光后材料的表面粗糙度、硬度、杨氏模量、耐腐蚀性能以及加工表面亚表层微观组织的变化。结果表明:在激光功率为180 W、扫描速度为20 mm/s、扫描间距为0.06 mm时平均粗糙度从4.829 μm降低到0.505 μm,粗糙度降低约90%,同时抛光后材料的表面硬度及耐腐蚀性能相较于初始样品均有所下降,熔融区硬度下降约40%,自腐蚀电位下降约4%。

Abstract

Laser polishing, as a noncontact green processing technology, can replace the traditional polishing technology. In this paper, the surface of DC53 hardened steel is continuously polished by a laser with a 1064 nm wavelength to investigate the effect of laser polishing on the surface quality of DC53 hardened steel. Additionally, the surface roughness, hardness, Young's modulus, corrosion resistance of the material, and the changes in the subsurface microstructure of the processed surface after laser polishing are thoroughly investigated. The experimental results show that the average roughness is reduced from 4.829 μm to 0.505 μm at a rate as high as 90% when the laser power is 180 W, the laser scan speed is 20 mm/s, and the laser scan interval is 0.06 mm. Simultaneously, the surface hardness and corrosion resistance of the material after laser polishing are reduced compared with the initial sample, the hardness of the molten zone is reduced by 40%, and the self-corrosion potential is reduced by 4%.

尹杰, 周后明, 赵振宇, 周浩, 李凯, 王超. 激光抛光DC53淬硬钢试验研究[J]. 激光与光电子学进展, 2023, 60(1): 0114004. Jie Yin, Houming Zhou, Zhenyu Zhao, Hao Zhou, Kai Li, Chao Wang. Experimental Research on Laser Polishing of DC53 Hardened Steel[J]. Laser & Optoelectronics Progress, 2023, 60(1): 0114004.