GH3230高温合金绿光飞秒激光的刻蚀特性

Nickel-based superalloys exhibit high potential as raw materials for heated-end-core components because of their superior structural stability, oxidation resistance, corrosion resistance, fatigue resistance, and creep resistance. When compared to electrical discharge machining and normal pulsed laser machining, femtosecond laser machining offers higher precision and a lower heat effect. When a femtosecond laser pulse irradiates a metallic surface, electrons absorb photons and reach high temperature while the lattice remains unchanged, resulting in a low thermal effect. So, the femtosecond laser is expected to have the potential for machining GH3230 superalloys. At present, some reports have focused on femtosecond laser drilling technology and the increase of hole depth of nickel-based alloys, whereas femtosecond laser ablation technology and its characteristics on nickel-based alloys are yet to be discussed. In this study, a green femtosecond laser with a wavelength of 515 nm was used to investigate the ablation threshold, ablation rate, and ablation depth of a GH3230 nickel-based superalloy. Furthermore, an increase in the scanning width is proposed to expand the ablation depth. The effect of plasma induced by a femtosecond laser on the ablation depth is analyzed.

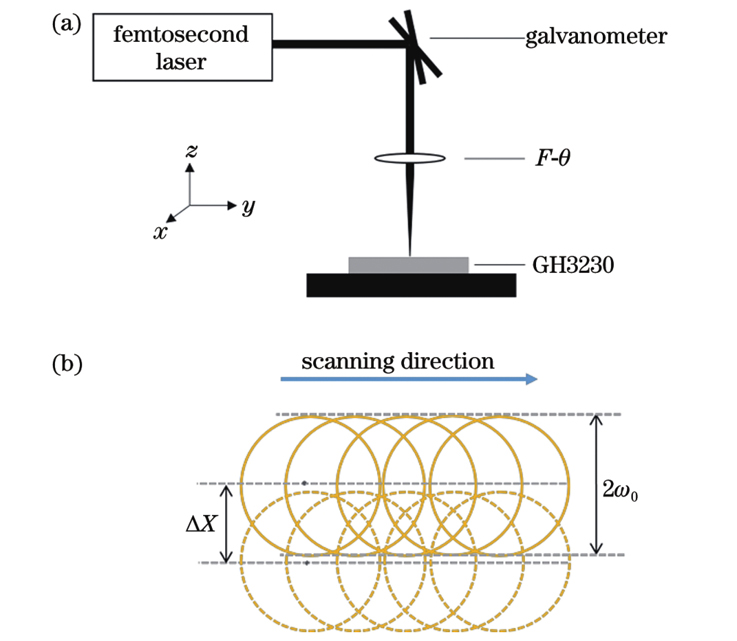

An as-forged GH3230 superalloy with a thickness of 1.2 mm was used as the base metal in laser ablation. First, a green femtosecond laser with a wavelength of 515 nm was used to ablate the GH3230 surface. The ablation width was measured using a white-light interferometer. The ablation thresholds at different scanning speeds were calculated by fitting the relationship curve between ablation width and laser fluence. The multi-pulse threshold incubation coefficient of GH3230 and ablation threshold of GH3230 under a single laser pulse were obtained by fitting the relationship curve between the ablation threshold and equivalent pulse number. The absorption spectrum of GH3230 was obtained using a spectrophotometer. After various scanning times ranging from 800 to 20000, the ablation depth and width were measured using an optical microscope (OM) with laser fluences of 1.27, 2.54 and 3.81 J/cm2. The saturation of the ablation depth and the limitation of the ablation rate were analyzed to reveal the advantages of green femtosecond laser machining. Finally, the ablation characteristics of GH3230 were adjusted using the overlapping scanning method. The ablation depth and width were measured by OM to obtain the ultimate ablation depth, ablation rate, and depth-to-width ratio. The effect of the scanning spacing is further discussed.

In this study, the ablation threshold of GH3230 using a green femtosecond laser was lower than the previously reported ablation threshold of nickel-based alloys using an infrared femtosecond laser. The main reason for this is that the absorption of the green light wave band is much higher than that of the red band. The green laser also reduces the ablation threshold owing to its higher photon energy, which possibly removes materials more efficiently. In the overlapping scanning method, both the ablation width and depth increase. The ablation efficiency of the green femtosecond laser is higher than that of the infrared femtosecond laser. As the scanning width increases, the ablation width increases, which causes the plasma to diffuse laterally and weakens the shielding effect of the plasma on the laser. The energy at the bottom of the groove increases the ablation depth and efficiency.

In this study, the single-pulse laser ablation threshold of as-forged GH3230 superalloy using a green femtosecond laser with a wavelength of 515 nm was 0.27 J/cm2. With an increase in the number of scanning, the ablation depth increases and the beam energy entering the groove bottom decreases. Finally, the ablation depth tends to saturate. In the overlapping scanning method, with an increase in ablation width, the plasma diffuses laterally and reduces the plasma density. The reduction in plasma density increases the ablation depth limit but decreases the depth-to-width ratio of the groove. Compared with an infrared femtosecond laser, the green femtosecond laser can significantly reduce the ablation threshold and improve ablation efficiency.

黄彩丽, 蒋麒, 蔺晓超, 杨诗瑞, 郭鹏, 崔梦雅, 黄婷. GH3230高温合金绿光飞秒激光的刻蚀特性[J]. 中国激光, 2023, 50(8): 0802106. Caili Huang, Qi Jiang, Xiaochao Lin, Shirui Yang, Peng Guo, Mengya Cui, Ting Huang. Ablation Characteristics of GH3230 Superalloy Using Green Femtosecond Laser[J]. Chinese Journal of Lasers, 2023, 50(8): 0802106.