GH3230高温合金绿光飞秒激光的刻蚀特性

Nickel-based superalloys exhibit high potential as raw materials for heated-end-core components because of their superior structural stability, oxidation resistance, corrosion resistance, fatigue resistance, and creep resistance. When compared to electrical discharge machining and normal pulsed laser machining, femtosecond laser machining offers higher precision and a lower heat effect. When a femtosecond laser pulse irradiates a metallic surface, electrons absorb photons and reach high temperature while the lattice remains unchanged, resulting in a low thermal effect. So, the femtosecond laser is expected to have the potential for machining GH3230 superalloys. At present, some reports have focused on femtosecond laser drilling technology and the increase of hole depth of nickel-based alloys, whereas femtosecond laser ablation technology and its characteristics on nickel-based alloys are yet to be discussed. In this study, a green femtosecond laser with a wavelength of 515 nm was used to investigate the ablation threshold, ablation rate, and ablation depth of a GH3230 nickel-based superalloy. Furthermore, an increase in the scanning width is proposed to expand the ablation depth. The effect of plasma induced by a femtosecond laser on the ablation depth is analyzed.

An as-forged GH3230 superalloy with a thickness of 1.2 mm was used as the base metal in laser ablation. First, a green femtosecond laser with a wavelength of 515 nm was used to ablate the GH3230 surface. The ablation width was measured using a white-light interferometer. The ablation thresholds at different scanning speeds were calculated by fitting the relationship curve between ablation width and laser fluence. The multi-pulse threshold incubation coefficient of GH3230 and ablation threshold of GH3230 under a single laser pulse were obtained by fitting the relationship curve between the ablation threshold and equivalent pulse number. The absorption spectrum of GH3230 was obtained using a spectrophotometer. After various scanning times ranging from 800 to 20000, the ablation depth and width were measured using an optical microscope (OM) with laser fluences of 1.27, 2.54 and 3.81 J/cm2. The saturation of the ablation depth and the limitation of the ablation rate were analyzed to reveal the advantages of green femtosecond laser machining. Finally, the ablation characteristics of GH3230 were adjusted using the overlapping scanning method. The ablation depth and width were measured by OM to obtain the ultimate ablation depth, ablation rate, and depth-to-width ratio. The effect of the scanning spacing is further discussed.

In this study, the ablation threshold of GH3230 using a green femtosecond laser was lower than the previously reported ablation threshold of nickel-based alloys using an infrared femtosecond laser. The main reason for this is that the absorption of the green light wave band is much higher than that of the red band. The green laser also reduces the ablation threshold owing to its higher photon energy, which possibly removes materials more efficiently. In the overlapping scanning method, both the ablation width and depth increase. The ablation efficiency of the green femtosecond laser is higher than that of the infrared femtosecond laser. As the scanning width increases, the ablation width increases, which causes the plasma to diffuse laterally and weakens the shielding effect of the plasma on the laser. The energy at the bottom of the groove increases the ablation depth and efficiency.

In this study, the single-pulse laser ablation threshold of as-forged GH3230 superalloy using a green femtosecond laser with a wavelength of 515 nm was 0.27 J/cm2. With an increase in the number of scanning, the ablation depth increases and the beam energy entering the groove bottom decreases. Finally, the ablation depth tends to saturate. In the overlapping scanning method, with an increase in ablation width, the plasma diffuses laterally and reduces the plasma density. The reduction in plasma density increases the ablation depth limit but decreases the depth-to-width ratio of the groove. Compared with an infrared femtosecond laser, the green femtosecond laser can significantly reduce the ablation threshold and improve ablation efficiency.

1 引言

镍基高温合金具有良好的高温组织稳定性、耐蚀性以及抗氧化、抗疲劳、抗蠕变等性能,已被广泛应用于航空航天发动机燃烧室、叶片等热端核心部件的制造[1]。与电火花、普通脉冲激光加工相比,飞秒激光加工时的激光脉冲持续时间远短于材料内部受激电子数皮秒的弛豫时间,可以最大限度地减小热影响,实现高质量加工[2-4]。Huang等[5]采用775 nm波长飞秒激光刻蚀的镍钛合金的表面粗糙度仅为0.2 μm,与精密铣削加工的效果相当,热影响区远小于电火花加工的热影响区。Zhu等[6]利用飞秒激光在不锈钢上制孔,孔径误差小于10 μm,孔表面粗糙度在1 μm以下,加工质量优于普通脉冲或长脉冲激光的加工质量。

飞秒激光刻蚀、制孔等材料去除技术的加工规律存在相似性,材料去除深度存在极限。研究人员主要通过提高单脉冲激光能量密度来增大深度极限。Ostendorf等[7]采用780 nm波长飞秒激光刻蚀硅,结果显示:当激光能量密度为50.96 J/cm²时,沟槽的深度极限为500 μm;当提高激光能量密度至101.91 J/cm²时,沟槽的深度极限为600~700 μm。Li等[8]采用1030 nm飞秒激光多脉冲冲击K24镍基高温合金制孔,结果显示:当激光能量密度为121 J/cm²时,孔深极限为450 μm;将激光能量密度提高一倍后,孔深极限提高至600 μm。目前,针对飞秒激光镍基合金去除的研究主要集中于制孔工艺以及提高孔深极限上,而对飞秒激光刻蚀技术加工规律涉及得较少。

为了进一步探究影响镍基合金飞秒激光刻蚀的规律,本课题组采用515 nm飞秒激光刻蚀GH3230镍基高温合金,研究了GH3230高温合金的绿光飞秒激光刻蚀阈值及极限刻蚀深度,探讨了激光能量密度及扫描间距对极限刻蚀深度的影响规律。同时,本课题组在双道扫描方案中通过扩大刻蚀宽度实现了极限刻蚀深度的增大。

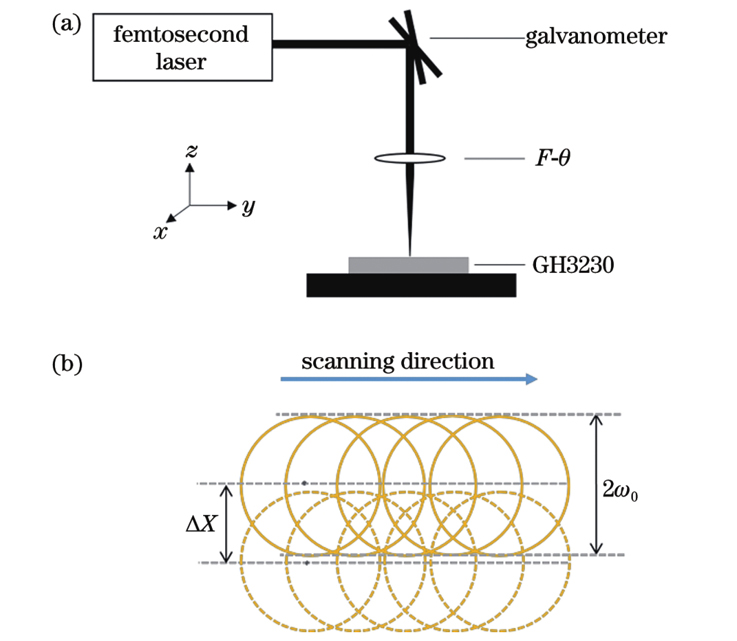

2 试验设备与方法

试验样品选用的是厚度为1.2 mm的锻造态GH3230高温合金。激光刻蚀前,依次使用400、800、1200、1500、2000目砂纸对试样表面进行打磨,以去除其表面的氧化层;再用去离子水、乙醇、丙酮溶液依次进行超声波清洗,清洗时间为10 min,清洗干净后吹干。采用TruMicro 5280 Femto Edition飞秒激光器和ISse14振镜系统进行刻蚀。激光中心波长为515 nm,脉宽为800 fs,最大脉冲频率为600 kHz,最大输出功率为75 W,F-θ镜的焦距为255 mm,聚焦光斑半径为25 μm,瑞利长度为2106 μm。

图 1. 飞秒激光刻蚀示意图。(a)试验布置;(b)激光扫描路径

Fig. 1. Schematic diagram of femtosecond laser ablation. (a) Experimental setup; (b) laser scanning path

利用Vecco NT1100白光干涉仪测量激光刻蚀深度和宽度,采用Olympus GX51光学显微镜(OM)观察样品的刻蚀形貌,采用UV-3600紫外可见近红外分光光度计测量GH3230的吸收曲线。

3 结果与讨论

3.1 刻蚀阈值

刻蚀阈值是指激光作用于材料表面使其发生破坏所需的最小激光能量密度。本研究采用面积推算法研究材料的刻蚀阈值[9]。材料表面刻蚀区域的宽度(即刻蚀线宽

其中,

式中:

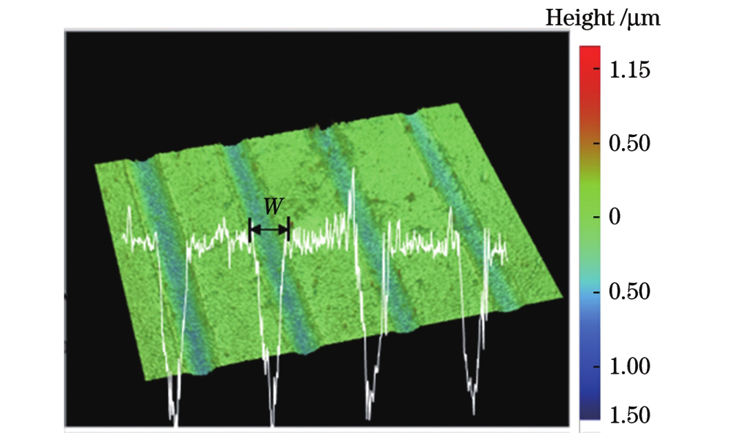

图 2. 飞秒激光刻蚀GH3230的典型表面形貌

Fig. 2. Typical surface morphology of GH3230 after femtosecond laser ablation

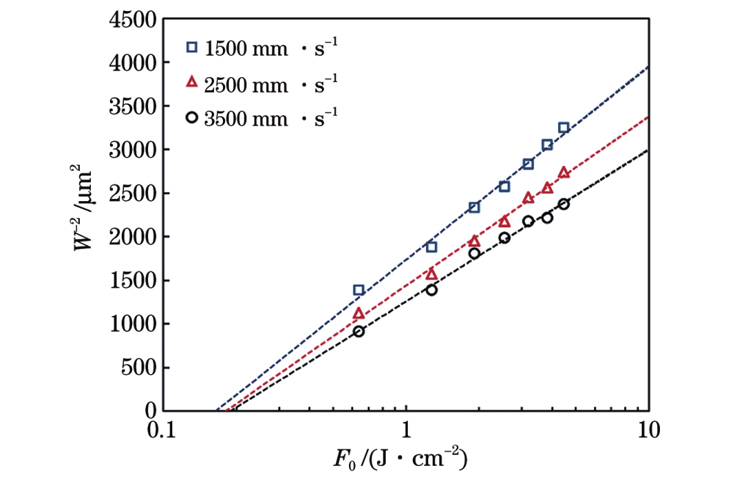

设置扫描速度为1500、2500、3500 mm/s,在三种不同扫描速度下改变激光能量密度进行刻蚀。结合式(

式中:

图 3. 不同扫描速度下刻蚀线宽与峰值能量密度F0的拟合曲线

Fig. 3. Fitted curves of ablation width and peak laser fluence at various scanning speeds

刻蚀阈值随着激光脉冲数增多而变小的现象称为阈值孵化效应[11]。孵化效应是由材料多次被激光照射诱导引起的缺陷积累造成的,这些缺陷会促进材料对激光的吸收,降低材料的刻蚀阈值[12-13]。

式中:

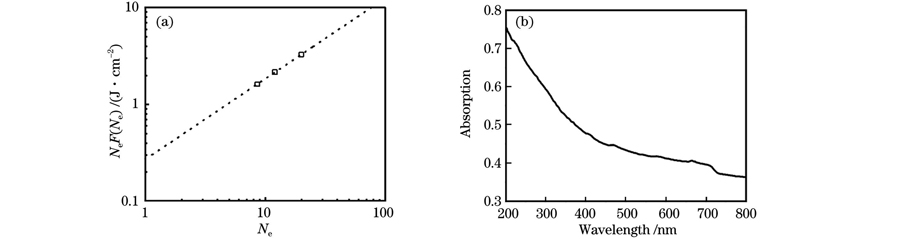

根据

图 4. GH3230阈值孵化曲线和吸收曲线。(a)

Fig. 4. Threshold incubation curve and absorption curve of GH3230. (a) Variation of

有文献报道GH4099高温合金在1064 nm飞秒激光单脉冲作用下的刻蚀阈值为0.41 J/cm2[14],CMSX-4镍基单晶高温合金在780 nm飞秒激光20个脉冲作用下的刻蚀阈值为0.18 J/cm2[15]。本研究获得的GH3230高温合金在515 nm飞秒激光单脉冲作用下的刻蚀阈值为0.27 J/cm2,在20个脉冲(扫描速度1500 mm/s)作用下的刻蚀阈值为0.16 J/cm2,明显低于文献报道的镍基合金红外飞秒激光的刻蚀阈值。材料的刻蚀阈值与材料的光吸收性质、入射激光波长等相关。

另外,根据

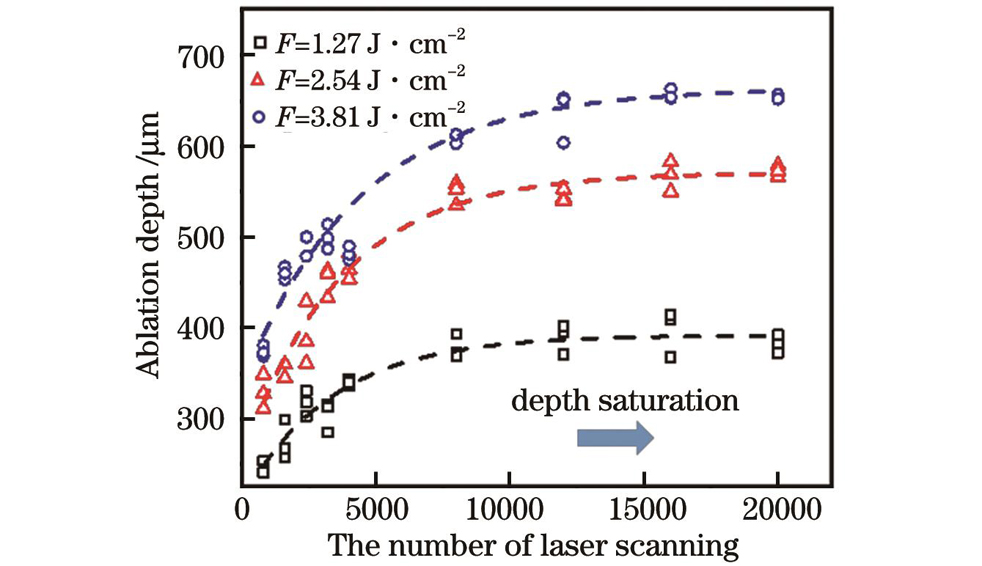

3.2 激光能量密度和扫描次数对刻蚀深度的影响

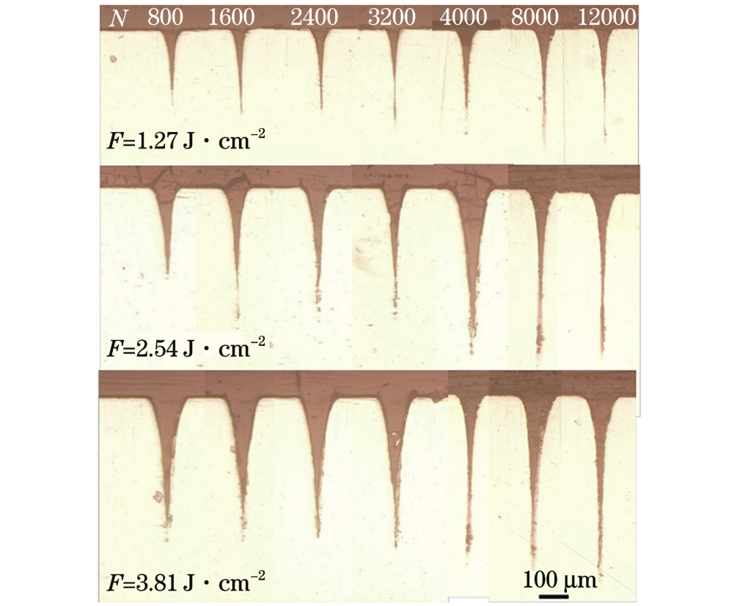

采用单道扫描的方式,保持扫描速度为2500 mm/s不变,分别选取1.27、2.54、3.81 J/cm2的能量密度进行多次扫描刻蚀。

图 5. 不同能量密度和扫描次数下刻缝的横截面形貌

Fig. 5. Cross-sectional images of ablated slits at different laser fluences and numbers of laser scannings

图 6. 刻蚀深度随能量密度和扫描次数的变化规律

Fig. 6. Variation of ablation depth with laser fluence and the number of laser scanning

为了探究扫描次数增加到一定值后刻蚀深度逐渐趋于饱和的原因,对聚焦光束在不同能量密度条件下的刻蚀阈值能量密度线进行计算。离焦量

式中:

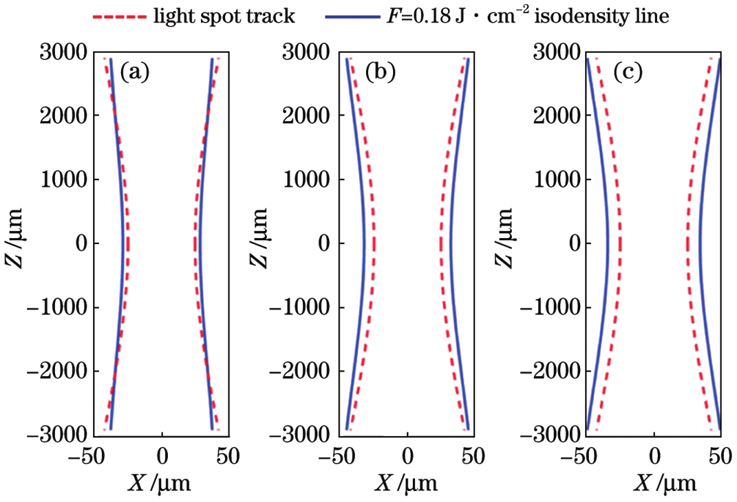

图 7. 不同能量密度下聚焦光束的形态以及刻蚀阈值能量密度线。(a)1.27 J/cm2;(b)2.54 J/cm2;(c)3.81 J/cm2

Fig. 7. Shape of focused laser beam and laser fluence distribution of ablation threshold at different laser fluences. (a) 1.27 J/cm2; (b) 2.54 J/cm2; (c) 3.81 J/cm2

然而,在三个能量密度下多次重复刻蚀的实际极限深度均远远小于3 mm。进一步分析发现,试样上表面的刻蚀缝宽均超过了刻蚀阈值对应的光斑直径,而且能量密度越大,差异越明显。三个能量密度下试样上表面的刻蚀阈值对应的光斑直径分别为57.5、64.7、68.4 μm,而深度饱和时刻缝的平均宽度分别为64.0、88.3、116.7 μm,后者分别约为前者的1.11、1.36、1.71倍。因此,多次重复刻蚀出现深度饱和的现象不是因为聚焦光束发散导致的能量密度降低,一种可能的原因是飞秒激光刻蚀时高能密度激光诱导产生等离子体和相爆炸,等离子体和相爆炸溅射产物对激光的屏蔽效应使得激光能量不能继续向深处传递[8]。刻缝宽度扩大的可能原因主要包括三方面:一是阈值孵化效应,多次刻蚀时的脉冲累积会进一步降低刻蚀阈值[12],从而扩大了激光刻蚀范围;二是高能激光诱导试样表面大气击穿形成等离子体,大气等离子体对材料的加热烧蚀扩大了刻缝入口的横向尺寸[8];三是试样表面激光诱导等离子体对激光的折射作用扩大了聚焦光斑的直径,从而导致刻缝入口尺寸增大。激光能量密度越高,激光诱导等离子体越稠密,等离子体的影响越大,刻缝宽度的扩大也就越显著。

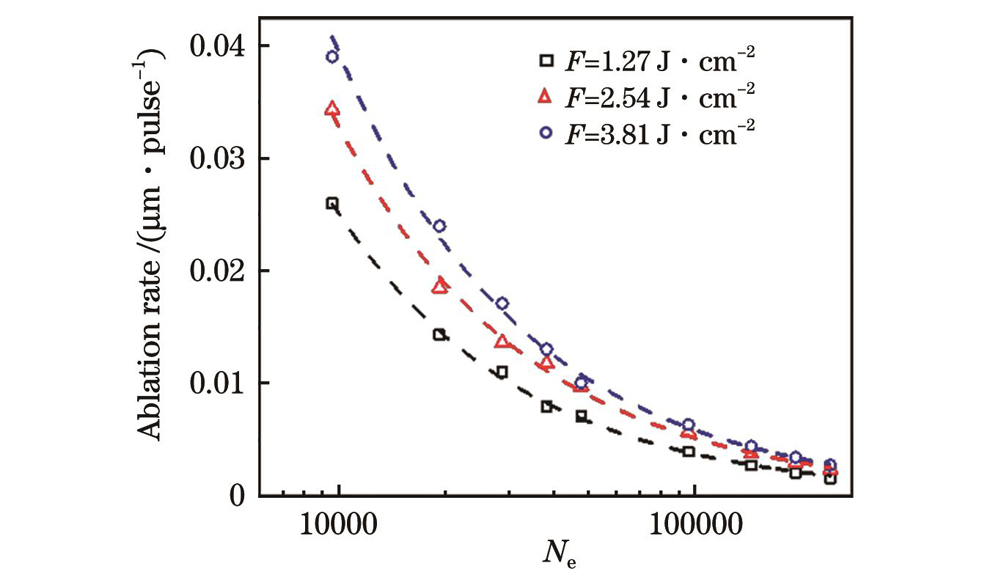

图 8. 刻蚀率随能量密度和等效脉冲数(Ne)的变化

Fig. 8. Variation of ablation rate with laser fluence and equivalent pulse number (Ne)

3.3 扫描宽度对极限刻蚀深度的影响

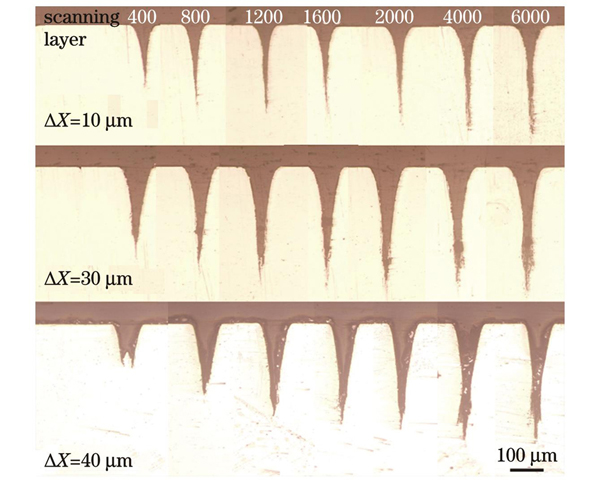

采用双道扫描方式进行刻蚀,通过调节扫描间距来改变扫描宽度,设置能量密度为1.27 J/cm2,扫描速度为2500 mm/s,扫描间距

图 9. 不同扫描间距和扫描层数下刻缝的截面形貌

Fig. 9. Cross-sectional images of ablated slits at different laser scanning spacings and scanning layer numbers

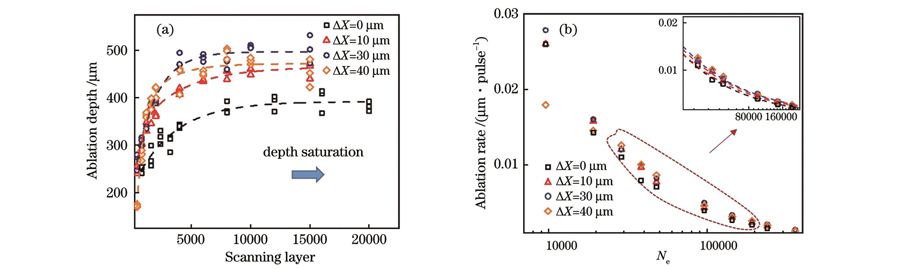

图 10. 刻蚀深度和刻蚀率随扫描间距和扫描层数的变化。(a)刻蚀深度的变化;(b)刻蚀率的变化

Fig. 10. Variation of ablation depth and ablation rate with laser scanning spacing and scanning layer number. (a) Variation of ablation depth; (b) variation of ablation rate

与单道刻蚀相比,双道刻蚀提高了极限刻蚀深度和刻蚀率。其原因可能是:双道刻蚀的刻缝变宽,等离子体横向膨胀扩散,密度变小,对激光的屏蔽效应减弱,材料的去除量增多。扫描间距为0、10、30、40 μm时,平均刻蚀宽度分别为64.0、86.0、100.2、94.1 μm,深宽比为分别为6.0、5.3、4.9、4.9。可见,通过双道刻蚀增大刻缝宽度虽然可以增大极限刻蚀深度,但刻缝的深宽比会变小。

随着扫描间距增大,双道刻蚀的极限刻蚀深度先增大后减小。其原因是随着扫描间距增加,刻缝宽度增大,等离子体横向扩散区域增大,密度变小,对激光的屏蔽效应减弱,刻蚀深度增大;进一步增大扫描间距,到达刻缝中心的激光能量密度降低,随着刻蚀深度增加,刻缝中心的激光能量密度低于材料的刻蚀阈值,刻缝内部中心区域的材料无法被去除,刻蚀深度减小,如

4 结论

本课题组采用515 nm绿光飞秒激光对锻造态GH3230高温合金进行刻蚀试验研究,得到如下结论:

1)锻造态GH3230高温合金的515 nm飞秒激光单脉冲刻蚀阈值约为0.27 J/cm2,多脉冲激光刻蚀的孵化系数为0.83;

2)随着刻蚀次数增加,刻蚀深度增大,进入缝底的光束能量变少,刻蚀深度趋于饱和,极限刻蚀深度随着激光能量密度的增大而增大;

3)在扫描间距不超过光斑直径的情况下进行双道刻蚀时,通过增大刻缝宽度可使等离子体横向膨胀扩散,密度变小,提高极限刻蚀深度,但刻缝的深宽比会减小;

4)与红外飞秒激光相比,绿光飞秒激光刻蚀镍基高温合金可使刻蚀阈值明显降低,刻蚀率显著提高。

[1] Ulutan D, Ozel T. Machining induced surface integrity in titanium and nickel alloys: a review[J]. International Journal of Machine Tools and Manufacture, 2011, 51(3): 250-280.

[2] 肖荣诗, 张寰臻, 黄婷. 飞秒激光加工最新研究进展[J]. 机械工程学报, 2016, 52(17): 176-186.

Xiao R S, Zhang H Z, Huang T. Recent progress in femtosecond pulsed laser processing research[J]. Journal of Mechanical Engineering, 2016, 52(17): 176-186.

[3] Sanner N, Utéza O, Bussiere B, et al. Measurement of femtosecond laser-induced damage and ablation thresholds in dielectrics[J]. Applied Physics A, 2009, 94(4): 889-897.

[4] Quintino L, Liu L, Miranda R M, et al. Cutting NiTi with femtosecond laser[J]. Advances in Materials Science and Engineering, 2013, 2013: 198434.

[5] Huang H, Zheng H Y, Lim G C. Femtosecond laser machining characteristics of nitinol[J]. Applied Surface Science, 2004, 228(1/2/3/4): 201-206.

[6] Zhu Q, Fan P, Li N, et al. Femtosecond-laser sharp shaping of millimeter-scale geometries with vertical sidewalls[J]. International Journal of Extreme Manufacturing, 2021, 3(4): 61-72.

[7] Ostendorf A, Kulik C, Bauer T, et al. Ablation of metals and semiconductors with ultrashort pulsed lasers: improving surface qualities of microcuts and grooves[J]. Proceedings of SPIE, 2004, 5340: 153-163.

[8] Li Q, Yang L J, Hou C J, et al. Surface ablation properties and morphology evolution of K24 nickel based superalloy with femtosecond laser percussion drilling[J]. Optics and Lasers in Engineering, 2019, 114: 22-30.

[9] 吴雪峰, 尹海亮, 李强. 飞秒激光加工碳纳米管薄膜试验研究[J]. 中国激光, 2019, 46(9): 0902002.

[10] 秦晓阳, 黄婷, 肖荣诗. 高功率绿光飞秒激光诱导产生钛表面周期性微结构[J]. 中国激光, 2019, 46(10): 1002006.

[11] See T L, Liu Z, Liu H, et al. Effect of geometry measurements on characteristics of femtosecond laser ablation of HR4 nickel alloy[J]. Optics and Lasers in Engineering, 2015, 64: 71-78.

[12] 路明雨, 张明, 张开虎, 等. 高模量碳纤维增强树脂基复合材料的皮秒激光加工阈值特性[J]. 复合材料学报, 2021, 38(11): 3601-3609.

Lu M Y, Zhang M, Zhang K H, et al. Threshold properties of high modulus carbon fiber reinforced plastic composite with picosecond laser processing[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3601-3609.

[13] 卢金龙, 黄婷, 肖荣诗. 微纳米结构TiO2的飞秒激光结合化学氧化复合制备及其光催化性能[J]. 中国激光, 2016, 43(7): 0713001.

[14] 刘海建, 陈旭, 马振武, 等. GH4099合金的飞秒激光去除阈值[J]. 机械工程材料, 2020, 44(6): 21-24.

Liu H J, Chen X, Ma Z W, et al. Femtosecond laser removal threshold of GH4099 alloy[J]. Materials for Mechanical Engineering, 2020, 44(6): 21-24.

[15] 张伟, 冯强, 程光华, 等. 飞秒激光对镍基合金的损伤机制和阈值行为[J]. 光学学报, 2014, 34(12): 1232001.

[16] 于淼, 黄婷, 肖荣诗. 长焦距绿光飞秒激光玻璃焊接[J]. 中国激光, 2020, 47(9): 0902005.

[17] Ali J M Y, Shanmugam V, Lim B, et al. Femtosecond laser ablation of dielectric layers for high-efficiency silicon wafer solar cells[J]. Solar Energy, 2018, 164: 287-291.

[18] Semaltianos N G, Perrie W, French P, et al. Femtosecond laser ablation characteristics of nickel-based superalloy C263[J]. Applied Physics A, 2009, 94(4): 999-1009.

黄彩丽, 蒋麒, 蔺晓超, 杨诗瑞, 郭鹏, 崔梦雅, 黄婷. GH3230高温合金绿光飞秒激光的刻蚀特性[J]. 中国激光, 2023, 50(8): 0802106. Caili Huang, Qi Jiang, Xiaochao Lin, Shirui Yang, Peng Guo, Mengya Cui, Ting Huang. Ablation Characteristics of GH3230 Superalloy Using Green Femtosecond Laser[J]. Chinese Journal of Lasers, 2023, 50(8): 0802106.