Ti中间层厚度对光束摆动焊接7075铝合金显微组织和力学性能的影响

The 7-series aluminum alloy is a heat-treatable aluminum alloy widely used in aerospace, rail transit, and other fields because of its excellent specific strength. Laser beam swing welding is a new method developed from conventional laser-welding technology. It can reduce the temperature gradient, stabilize the welding process, and inhibit the formation of pores and other defects in the weld. The addition of alloying elements is currently the focus of research for improving the weld performance. Many researchers worldwide have shown that adding rare-earth elements or Zr, Ti, and other elements to the weld can improve the mechanical properties. However, research on the effect of Ti addition on the microstructure and properties of 7075 aluminum alloy weld is not yet comprehensive. In this study, a systematic investigation of the effect of the thickness of a Ti metal interlayer on the microstructure and mechanical properties of 7075 aluminum alloy weld joints is reported.

In this study, 2 mm thick 7075 aluminum alloy and Ti foils of different thicknesses were used. First, welds with different thicknesses of Ti metal intermediate layers were prepared using laser beam swing welding. Then, methods, such as scanning electron microscopy (SEM), X-ray diffraction (XRD), energy-dispersive X-ray spectroscopy (EDS), and electron backscatter diffraction (EBSD), were used to analyze the effects of different Ti interlayer thicknesses on the microstructures and phases of the weld metal. Finally, by analyzing the fracture location and considering the changes in the tensile strength of the joint, the influence of adding different thicknesses of Ti metal intermediate layers on the mechanical properties of the joint was determined.

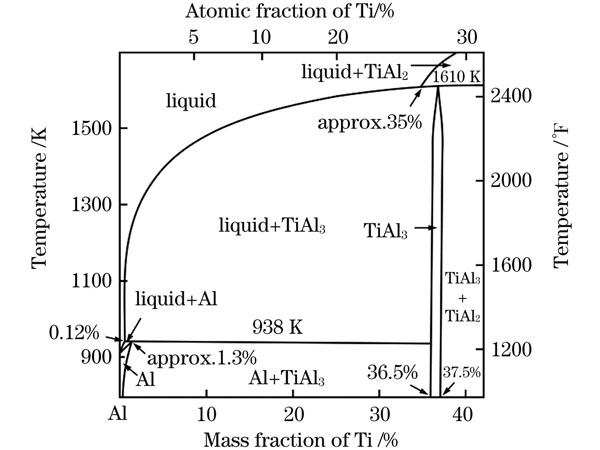

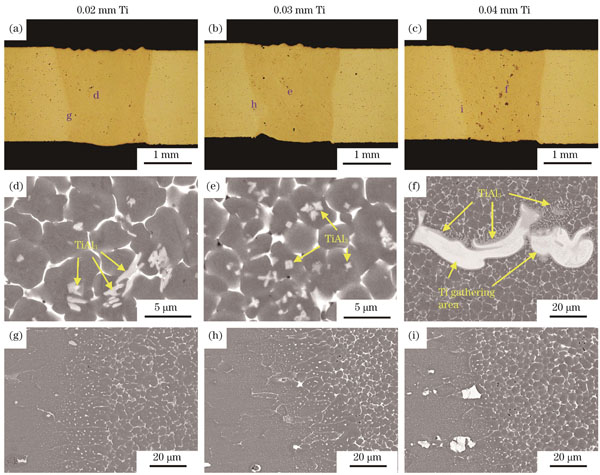

When the thickness of Ti intermediate layer is 0.02 mm, the Ti content in the liquid metal is relatively low. During the cooling solidification process, Al grains precipitate simultaneously with TiAl3, and the TiAl3 phase forms a short rod-shaped distribution near the interface of the aluminum grains during the solidification process. When the thickness of Ti intermediate layer is 0.03 mm, the liquid metal first precipitates a high-melting-point TiAl3 phase during the solidification process. The precipitated phase is small and cross shaped. As the temperature continues to decrease, the TiAl3 phase dispersed in the molten pool becomes the substrate for heterogeneous nucleation. When the thickness of Ti intermediate layer is 0.04 mm, excess Ti cannot be dissolved in liquid Al, and a large area of unmelted Ti is retained. At the interface between this phase and the Al grains, a short rod-shaped TiAl3 phase forms to envelop the unmelted Ti. When the thickness of the Ti intermediate layer is 0.02 mm, the influence of Ti on the fusion line is relatively small. The fusion line on both sides of the weld becomes the weak position of the welded joint owing to the reduction in alloy element segregation and the strengthening phase. When the thickness of the Ti interlayer increases to 0.03 mm, the interface between a small amount of Ti gathering area and the Al grains in the weld becomes the crack source. When the thickness of the Ti interlayer continues to increase to 0.04 mm, a large number of cracks are generated in a large area of the Ti gathering area, and these cracks continue to extend and connect with each other, resulting in joint failure.

By studying the effects of Ti intermediate layer thickness on the weld formation, microstructure, and mechanical properties of the weld after adding different thicknesses of Ti metal intermediate layers in 7075 aluminum alloy during laser beam swing welding, the following conclusions can be drawn.

(1) With the increase in Ti intermediate layer layer thickness from 0.02 to 0.04 mm, a short rod-like TiAl3 phase, cross-shaped TiAl3 phase, and large area of Ti gathering area appear in the weld. The EBSD results indicate that the microstructure of the weld area with the addition of the Ti intermediate layer consists of fine equiaxed grains. When a 0.03 mm thick Ti intermediate layer is added, the average equivalent circular diameter of the equiaxed grain area in the weld is 3.34 μm. The weighted average value of the grain area is 1.7% of the grain size of the base material.

(2) The fine TiAl3 phase is mainly distributed within the Al grains owing to the formation of the high-melting-point TiAl3 phase as the heterogeneous core of the Al grains during the solidification process and the segregation of Zn, Mg, and Cu at the grain boundaries, resulting in the formation of hard and brittle phases, such as Al2CuMg, which weakens the grain boundaries.

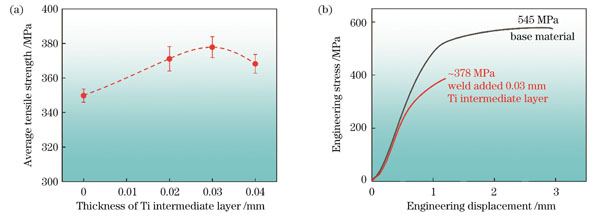

(3) As the thickness of the intermediate Ti metal layer increases from 0.02 to 0.04 mm, the average tensile strength of the joint shows a pattern of first increasing and then decreasing. When the thickness of the Ti intermediate layer is 0.03 mm, the average tensile strength is the highest, reaching about 377.8 MPa, which is 69% of the base material strength.

(4) When the thickness of the Ti intermediate layer is 0.02 mm, the weak position of the joint are located at the grain boundaries of the fusion zone and the heat-affected zone. When the thickness of the Ti intermediate layer is 0.03 mm, the weak position of the joint is in the fine equiaxed crystal zone on both sides of the weld. When the thickness of Ti interlayer is 0.04 mm, the weak position of the joint is in the Ti gathering area in the middle of the weld.

1 引言

7系铝合金以Zn、Mg为主要强化元素,是一种可热处理强化铝合金,其以优异的比强度被广泛应用于航空航天、轨道交通等领域[1-4]。7系铝合金的主要强化相为η相(MgZn2)和T相(Al2Mg3Zn3)[5-6]。7075铝合金具有较高的比强度,但焊接性能较差,因此被称为超高强难焊铝合金[7]。目前,7075铝合金结构件的连接技术主要有铆接技术、搅拌摩擦焊接技术、电弧焊接技术、激光焊接技术等[8-11]。其中,激光焊接技术具有高柔性、高焊接效率、能量精准可控等特点,受到了国内外学者的广泛关注。

激光焊接7075铝合金的主要难点可总结为如下三点:1)在成形方面,7075铝合金由于含有较高的Zn元素,在激光焊接过程中面临缺陷频发的问题,而且焊缝区域的热裂纹敏感性高;2)在显微组织层面,熔化焊接破坏了母材原有的显微组织,改变了第二相的形态和分布,同时,合金元素在快速非平衡凝固条件下易于晶界处发生偏析;3)在力学性能方面,激光焊接破坏了母材原有的热处理组织,减弱了母材的加工硬度和第二相强化,而且合金元素在晶界偏析会导致接头的整体力学性能显著下降[12-14]。Hu等[15-16]研究了7050激光-熔化极惰性气体保护焊(MIG)复合焊接接头的软化和失效行为,着重研究了热影响区与焊缝金属之间的细等轴晶区的微观组织和力学性能。结果表明:在细等轴晶区的大角度晶界处存在由ω相(Al7Cu2Fe)和S相(Al2CuMg)组成的网状结构,由于这些硬相与软晶粒的塑性不相容,在低整体塑性变形下,晶间相通过微孔洞成核并相互连接导致了细等轴晶区的晶界断裂。为解决这一问题,他们通过在焊接时引入激光光束摆动和脉冲磁场的方法获得了波浪状和间断的细等轴晶区以及更高的沉淀相密度,从而大大提高了接头的抗拉强度。尽管可以通过焊后热处理等手段来补强接头的力学性能[17-18],但制备焊后即可满足力学性能要求的7系铝合金焊接接头是未来的发展趋势。

光束摆动焊接技术是在常规激光焊接技术之上发展起来的,是一种激光光斑在小范围内快速高频摆动的激光焊接工艺[19-20]。激光摆动焊接技术在增大熔池宽度的同时降低了温度梯度,使焊接过程中的熔池行为趋于稳定,从而可以改善焊缝成形,并有效抑制焊缝中气孔等缺陷的形成[21-24]。焊缝合金化是目前提升焊缝性能的研究热点。Sokoluk等[25]研究了7075铝合金焊缝中添加纳米TiC颗粒对热裂纹缺陷和接头抗拉强度的影响,结果表明:纳米TiC颗粒不仅可以改变焊缝金属中α-Al晶粒和二次相的形态,还可以改变液态金属的凝固方式(消除凝固裂纹缺陷),提高焊接接头抗拉强度至392 MPa。国内外的大量研究已表明在焊缝中添加稀土元素或Zr、Ti等元素可以实现接头力学性能的提升[26-27],但目前关于Ti元素对7075铝合金焊缝组织及性能影响的研究尚不全面。为此,笔者采用单因素实验的方法,从工艺、组织、性能的角度进行分析,系统研究了Ti金属中间层厚度对7075铝合金焊缝组织和焊接接头力学性能的影响。

2 试验材料及方法

基材为轧制态7075-T6铝合金,其化学成分见

表 1. 基材的化学成分表

Table 1. Chemical composition list of base metal

|

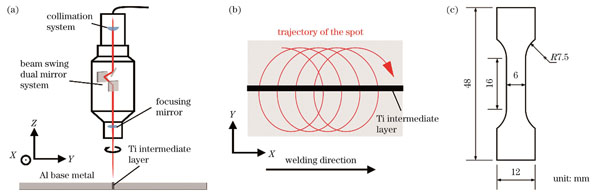

采用IPG公司的YLS-30000光纤激光器进行焊接,激光器的最大输出功率为30 kW。激光头采用IPG FLW D50摆动焊接头,焦点处的光斑直径为0.5 mm。通过KUKA机器人控制激光焊接头的运动。为避免焊缝金属氧化,焊接过程中用高纯氩气作为保护气体,气体流量为30 L/min,焊接过程示意图如

图 1. 激光焊接以及拉伸试样示意图。(a)激光摆动焊接示意图;(b)激光光斑的移动轨迹;(c)拉伸试样的几何尺寸

Fig. 1. Schematic diagrams of laser welding and tensile specimens. (a) Diagram of laser swing welding; (b) trajectory of the laser spot; (c) dimension of tensile specimens

采用电火花线切割机切割金相试样及拉伸试样。使用自动研磨抛光机(EcoMet 250,BUEHLER)制备金相样品,使用Keller试剂腐蚀样品表面20 s。使用电解抛光仪(LectroPol-5,Struers)对机械磨抛的金相试样表面作进一步抛光处理。使用日本岛津公司的XRD-7000型X射线衍射仪(XRD)检测焊缝区域的物相。使用Carl Zeiss的Gemini SEM300扫描电子显微镜(SEM)获取金相试样及拉伸断口的SEM图像[29-30]。在观察显微组织时,为了获取具有更高衬度的图像,采用背散射电子(BSE)模式[31]。扫描电子显微镜还配备有牛津仪器的Aztec Nordlys Max3电子背散射衍射(EBSD)探头,以获取EBSD数据[32]。沿着焊缝方向加工出3个垂直于焊缝的拉伸试样,试样的几何尺寸如

3 试验结果及分析

3.1 Ti金属中间层对焊缝成形及组织的影响

根据

表 2. 焊缝熔宽参数表

Table 2. Melting width parameter list of the weld

|

由

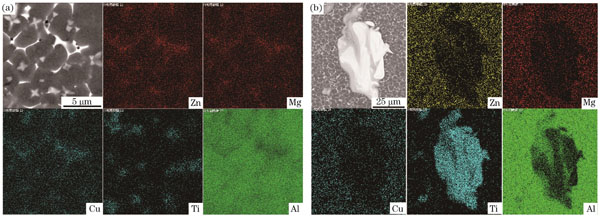

图 4. 添加不同厚度中间层的焊缝的面扫图。(a)添加0.03 mm厚Ti中间层的焊缝中部的面扫图;(b)添加0.04 mm厚Ti中间层焊缝中Ti元素聚集区的面扫图

Fig. 4. Mapping results of the middle region of the welds added Ti intermediate layer with different thicknesses. (a) Mapping results of the middle region of the weld added 0.03 mm thick Ti intermediate layer; (b) mapping results of the Ti gathering area in the weld added 0.04 mm thick Ti intermediate layer

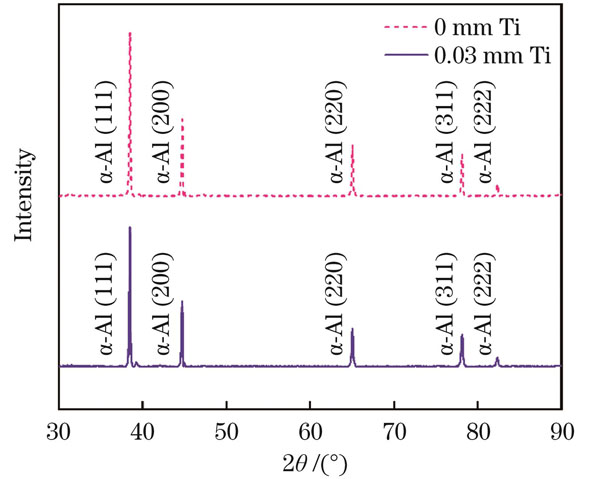

对比不加Ti中间层和加0.03 mm厚Ti中间层焊缝的XRD图像可知,二者焊缝金属中的相均主要为α-Al,第二相未呈现出明显的峰,但加入Ti中间层后α-Al峰的强度有所下降,如

图 5. 添加0.03 mm厚Ti中间层前后焊缝的XRD结果

Fig. 5. XRD results of the welds before and after adding 0.03 mm thick Ti intermediate layer

表 3. 添加0.03 mm厚Ti中间层焊缝中十字形相的化学成分

Table 3. Chemical composition of the cross-shaped phase in the weld added 0.03 mm thick Ti intermediate layer

|

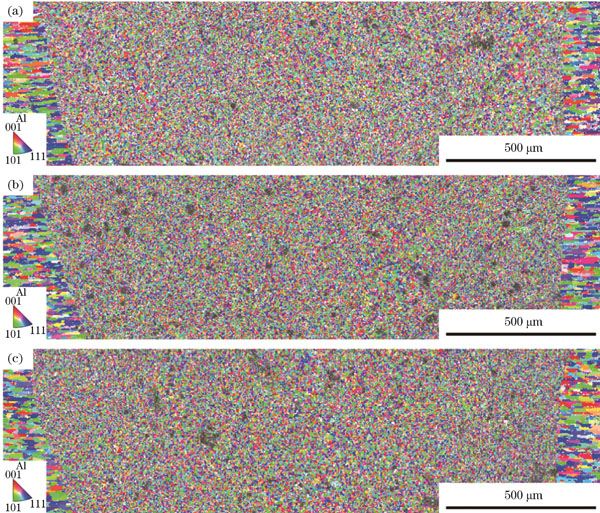

由

图 6. 各焊缝的IPF图。(a)添加0.02 mm厚Ti中间层的焊缝;(b)添加0.03 mm厚Ti中间层的焊缝;(c)添加0.04 mm厚Ti中间层的焊缝

Fig. 6. IPF images of each weld. (a) Weld added 0.02 mm thick Ti intermediate layer; (b) weld added 0.03 mm thick Ti intermediate layer; (c) weld added 0.04 mm thick Ti intermediate layer

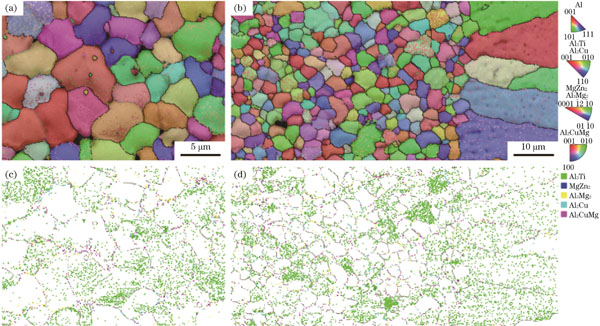

图 7. 添加0.03 mm厚Ti中间层焊缝各区域的组织及相分布。(a)(c)中部细等轴晶区;(b)(d)右侧熔合线附近区域

Fig. 7. Microstructure and phases distribution in the weld added 0.03 mm thick Ti intermediate layer. (a)(c) Fine equiaxed region in the middle region; (b)(d) the area near the fusion line on the right

综上可知:1)当Ti中间层厚度为0.02 mm时,液态金属中的Ti元素含量较低,在冷却凝固过程中,Al晶粒与TiAl3相同时析出,其中TiAl3相在凝固过程中形成了短棒状并分布于Al晶粒的界面附近。2)当Ti中间层的厚度为0.03 mm时,液态金属在凝固过程中首先析出高熔点的TiAl3相,析出相尺寸细小;随着温度不断降低,弥散在熔池中的TiAl3相成为异质形核的基底。3)当Ti中间层为0.04 mm时,过量的Ti元素无法溶解在液态Al中,形成了大面积未熔Ti元素;在未熔Ti元素与Al晶粒的界面处,Ti与Al反应生成了一层短棒状TiAl3相,并且该相将未熔Ti包裹住。

3.2 Ti金属中间层对焊接接头力学性能的影响

接下来研究Ti金属中间层厚度与接头抗拉强度的关系。由

图 8. 添加不同厚度Ti中间层的焊接接头的拉伸性能。(a)接头平均抗拉强度随Ti中间层厚度的变化;(b)工程应力-位移曲线

Fig. 8. Tensile properties of the joint added Ti intermediate layer with different thicknesses. (a) Average tensile strength of the joint varying with the thickness of Ti intermediate layer; (b) engineering stress-displacement curve

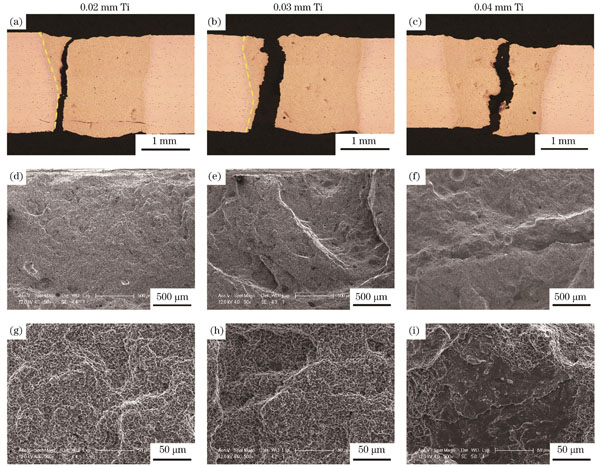

各接头拉伸断裂后的形貌如

图 9. 各焊接接头拉伸断裂后的形貌。(a)(b)(c)拉伸断裂位置;(d)(e)(f)拉伸断口的宏观形貌;(g)(h)(i)拉伸断口的微观特征

Fig. 9. Morphology of each joint after tensile failure. (a)(b)(c) Tensile break location; (d)(e)(f) macro morphology of tensile fracture; (g)(h)(i) micro morphology of tensile fracture

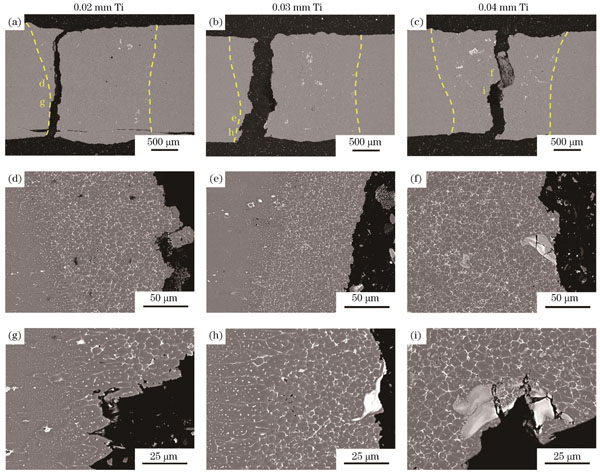

图 10. 背散射模式下的断口形貌。(a)~(c)拉伸断裂位置;(d)~(i)拉伸断口的微观形貌

Fig. 10. Fracture morphology captured at back scattering mode. (a)‒(c) Tensile break location; (d)‒(i) micro morphology of tensile fracture

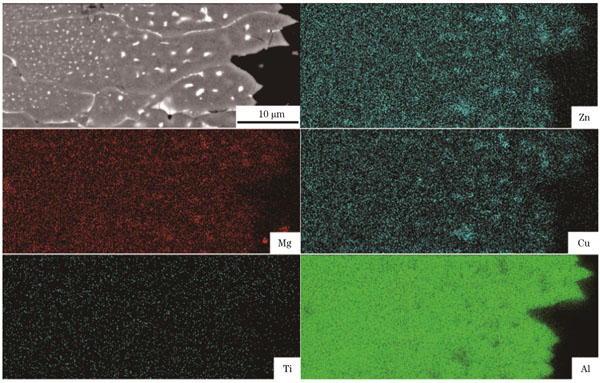

笔者进一步研究了添加0.02 mm厚Ti中间层时焊接接头断裂起源于熔合线处晶界的原因。如

图 11. 添加0.02 mm厚Ti中间层时,接头断口熔合区的面扫结果

Fig. 11. Mapping results of the fusion zone in the tensile fracture of the joint added 0.02 mm thick Ti intermediate layer

综上可知:当Ti中间层厚度为0.02 mm时,Ti元素对熔合线处组织的影响较小,焊缝两侧熔合线处在合金元素偏析和强化相减少的影响下成为焊接接头的薄弱位置;当Ti中间层厚度增大到0.03 mm时,焊缝中少量的Ti元素聚集区与Al晶粒之间的界面成为裂纹源;当Ti中间层继续增大到0.04 mm时,大量大面积的Ti元素聚集区内部产生了大量裂纹,这些裂纹不断延伸并相互连接,最终导致接头失效。

4 结论

针对添加有不同厚度Ti金属中间层的7075铝合金进行激光光束摆动焊接试验,研究了中间层对焊缝成形、微观组织和力学性能的影响,得到以下结论:

1)随着Ti金属中间层厚度从0.02 mm增加至0.04 mm,焊缝中依次出现了短棒状TiAl3相、十字形TiAl3相、大面积的Ti元素聚集区。添加Ti中间层后的焊缝组织为细小的等轴晶;添加0.03 mm厚Ti中间层时,焊缝等轴晶区晶粒的平均等效圆直径为3.34 μm,晶粒面积加权平均值为母材晶粒的1.7%。

2)细小的TiAl3相主要分布在Al晶粒内,这是由于凝固过程中高熔点的TiAl3相成为了Al晶粒的异质核心,而Zn、Mg、Cu元素在晶界处发生偏析生成了Al2CuMg等硬脆相,导致晶界弱化。

3)随着Ti金属中间层厚度从0.02 mm增加至0.04 mm,接头平均抗拉强度呈现出先增大后减小的规律;当Ti中间层厚度为0.03 mm时,平均抗拉强度最大,为(377.8±6.1)MPa,达到了母材强度的69%。

4)当Ti中间层厚度为0.02 mm时,接头力学性能薄弱位置在熔合区和热影响区晶粒的晶界处;当Ti中间层厚度为0.03 mm时,接头的薄弱位置在焊缝两侧的细等轴晶区;当Ti中间层厚度为0.04 mm时,接头的薄弱位置在焊缝中部的Ti元素聚集区。

[1] Azarniya A, Taheri A K, Taheri K K. Recent advances in ageing of 7xxx series aluminum alloys: a physical metallurgy perspective[J]. Journal of Alloys and Compounds, 2019, 781: 945-983.

[2] 顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020, 47(5): 0500002.

[3] Oropeza D, Hofmann D C, Williams K, et al. Welding and additive manufacturing with nanoparticle-enhanced aluminum 7075 wire[J]. Journal of Alloys and Compounds, 2020, 834: 154987.

[4] 霍望图, 孙涛涛, 雷诚心, 等. 高强7000(Al-Zn-Mg-Cu)系铝合金成形性研究进展[J]. 中国材料进展, 2020, 39(12): 924-933.

Huo W T, Sun T T, Lei C X, et al. Research progress on formability of high-strength 7000(Al-Zn-Mg-Cu) series aluminum alloy[J]. Materials China, 2020, 39(12): 924-933.

[5] Zhao H, Gault B, Ponge D, et al. Parameter free quantitative analysis of atom probe data by correlation functions: application to the precipitation in Al-Zn-Mg-Cu[J]. Scripta Materialia, 2018, 154: 106-110.

[6] 王杰. 高温预析出及Cu含量对7系铝合金组织及性能的影响[D]. 合肥: 合肥工业大学, 2022. 10.3808/jei.202200472

WangJ. Effect of high temperature pre-precipitation and Cu content on microstructure and properties of 7 series aluminum alloy[D]. Hefei: Hefei University of Technology, 2022.

[7] 陈轩, 李萌蘖, 卜恒勇, 等. 7系铝合金焊接技术的研究现状及展望[J]. 材料导报, 2023, 37(13): 200-208.

Chen X, Li M N, Bu H Y, et al. Research status and progress on the welding technologies of 7XXX series aluminum alloy[J]. Materials Reports, 2023, 37(13): 200-208.

[8] Zhang L, Li X Y, Nie Z R, et al. Comparison of microstructure and mechanical properties of TIG and laser welding joints of a new Al-Zn-Mg-Cu alloy[J]. Materials & Design, 2016, 92: 880-887.

[9] Hayat F. Electron beam welding of 7075 aluminum alloy: microstructure and fracture properties[J]. Engineering Science and Technology, 2022, 34: 101093.

[10] Christy J V, Mourad A H I, Sherif M M, et al. Review of recent trends in friction stir welding process of aluminum alloys and aluminum metal matrix composites[J]. Transactions of Nonferrous Metals Society of China, 2021, 31(11): 3281-3309.

[11] Luo G Y, Cheng M P, Liu C H, et al. Improving mechanical properties of quasi-continuous-wave laser beam welded 7075 aluminum alloy through microstructural refinement and homogenization of the fusion zone[J]. Optics & Laser Technology, 2022, 153: 108221.

[12] Mi G Y, Jiang Y M, Wang C M, et al. New insight into microstructure and mechanical properties of heterostructures 7075 Al joint prepared via single mode laser welding[J]. Journal of Materials Research and Technology, 2023, 24: 463-474.

[13] Zhao H, Chakraborty P, Ponge D, et al. Hydrogen trapping and embrittlement in high-strength Al alloys[J]. Nature, 2022, 602(7897): 437-441.

[14] 吕新蕊, 刘婷婷, 廖文和, 等. 高强铝合金7075激光粉末床熔融凝固裂纹的消除与质量控制[J]. 中国激光, 2022, 49(14): 1402209.

[15] Hu Y N, Wu S C, Shen Z, et al. Fine equiaxed zone induced softening and failure behavior of 7050 aluminum alloy hybrid laser welds[J]. Materials Science and Engineering: A, 2021, 821: 141597.

[16] Hu Y N, Wu S C, Guo Y, et al. Inhibiting weld cracking in high-strength aluminium alloys[J]. Nature Communications, 2022, 13: 5816.

[17] Sun W, Zhu Y, Marceau R, et al. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity[J]. Science, 2019, 363(6430): 972-975.

[18] 张嘉恒, 胡志力. 铝合金搅拌摩擦焊接头组织热稳定性[J]. 机械工程学报, 2022, 58(6): 73-80.

Zhang J H, Hu Z L. Microstructural thermal stability of aluminum alloy friction stir welding joint[J]. Journal of Mechanical Engineering, 2022, 58(6): 73-80.

[19] 李尚仁. 中厚板铝合金激光摆动焊接工艺研究[D]. 武汉: 华中科技大学, 2020.

LiS R. Study on laser swing welding technology of medium and heavy plate aluminum alloy[D]. Wuhan: Huazhong University of Science and Technology, 2020.

[20] Wang L, Gao M, Zhang C, et al. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy[J]. Materials & Design, 2016, 108: 707-717.

[21] Liu T T, Mu Z Y, Hu R Z, et al. Sinusoidal oscillating laser welding of 7075 aluminum alloy: hydrodynamics, porosity formation and optimization[J]. International Journal of Heat and Mass Transfer, 2019, 140: 346-358.

[22] 雷正龙, 毕思源, 张新瑞, 等. 2195铝锂合金T型接头双侧激光摆动焊接组织与性能分析[J]. 中国激光, 2022, 49(8): 0802003.

[23] 陈琳. 铝合金薄板激光摆动搭接焊缝成形机理及其熔池行为研究[D]. 武汉: 华中科技大学, 2022. 10.1016/j.jmrt.2021.09.141

ChenL. Study on forming mechanism and molten pool behavior of laser swing lap weld of aluminum alloy sheet[D]. Wuhan: Huazhong University of Science and Technology, 2022.

[24] Chen L, Wang C M, Mi G Y, et al. Effects of laser oscillating frequency on energy distribution, molten pool morphology and grain structure of AA6061/AA5182 aluminum alloys lap welding[J]. Journal of Materials Research and Technology, 2021, 15: 3133-3148.

[25] Sokoluk M, Cao C Z, Pan S H, et al. Nanoparticle-enabled phase control for arc welding of unweldable aluminum alloy 7075[J]. Nature Communications, 2019, 10: 98.

[26] Wang Z P, Wang M L, Li Y G, et al. Effect of pretreatment on microstructural stability and mechanical property in a spray formed Al-Zn-Mg-Cu alloy[J]. Materials & Design, 2021, 203: 109618.

[27] 陈夏明, 王晓南, 颜倩, 等. 镍箔对DP980/A6061异种激光焊接接头组织性能的影响[J]. 中国激光, 2018, 45(11): 1102002.

[28] 郭和平, 陈超, 杨雅静, 等. 酸洗对TA1钛箔腐蚀的试验研究[J]. 失效分析与预防, 2020, 15(5): 297-300.

Guo H P, Chen C, Yang Y J, et al. Experimental study on corrosion of TA1 titanium foil by pickling[J]. Failure Analysis and Prevention, 2020, 15(5): 297-300.

[29] 李汉林, 何涛, 霍元明, 等. AA6063铝合金韧性断裂断口分析[J]. 上海工程技术大学学报, 2021, 35(3): 197-200.

Li H L, He T, Huo Y M, et al. Fracture analysis of ductile fracture of AA6063 aluminum alloy[J]. Journal of Shanghai University of Engineering Science, 2021, 35(3): 197-200.

[30] 王荣. 机械装备的失效分析(续前): 第3讲 断口分析技术(下)[J]. 理化检验(物理分册), 2016, 52(12): 833-840.

Wang R. Failure analysis of mechanical equipment (continued): lecture 3 fracture analysis technology (part 1)[J]. Physical Testing and Chemical Analysis (Part A: Physical Testing), 2016, 52(12): 833-840.

[31] 薛青松, 陈丽, 倪宾, 等. 背散射电子成像与能谱技术结合用于金属负载型催化剂的分散性研究[J]. 分析科学学报, 2022, 38(2): 237-242.

Xue Q S, Chen L, Ni B, et al. Dispersion of metal supported catalysts by combination of backscattered electron imaging and energy dispersive spectroscopy[J]. Journal of Analytical Science, 2022, 38(2): 237-242.

[32] 朱政武. 纵向磁场作用下中厚板激光-电弧复合焊接工艺及机理研究[D]. 武汉: 华中科技大学, 2021.

ZhuZ W. Study on laser-arc hybrid welding technology and mechanism of medium and heavy plate under longitudinal magnetic field[D]. Wuhan: Huazhong University of Science and Technology, 2021.

米高阳, 蒋熠鸣, 王春明, 张铭洋, 欧阳求保. Ti中间层厚度对光束摆动焊接7075铝合金显微组织和力学性能的影响[J]. 中国激光, 2023, 50(24): 2402102. Gaoyang Mi, Yiming Jiang, Chunming Wang, Mingyang Zhang, Qiubao Ouyang. Effect of Ti Intermediate Layer Thickness on Microstructure and Mechanical Properties of 7075 Aluminum Alloy by Laser Beam Swing Welding[J]. Chinese Journal of Lasers, 2023, 50(24): 2402102.