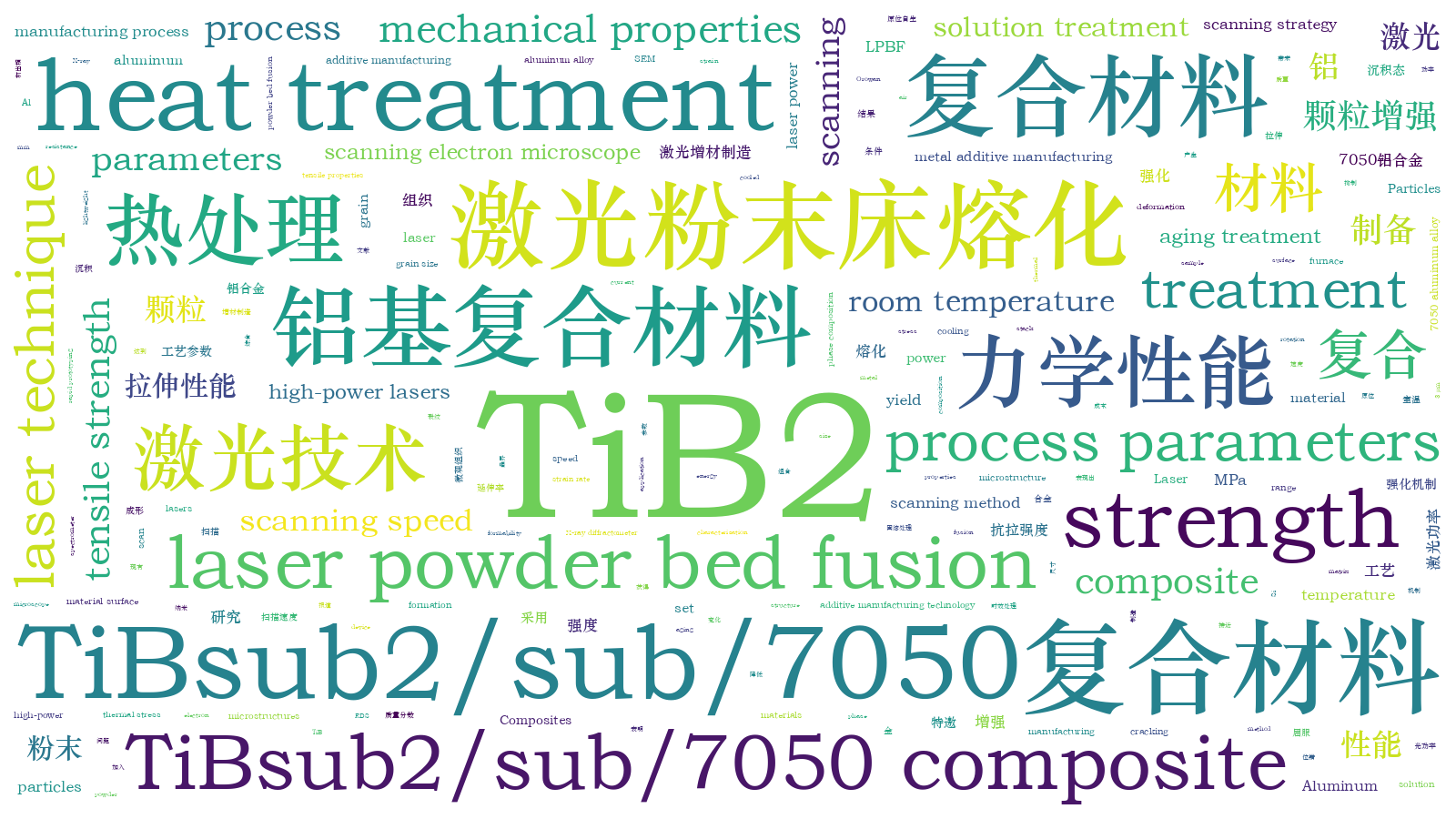

激光粉末床熔化制备TiB2颗粒增强7050铝基复合材料的组织及性能研究(特邀)特邀研究论文

Laser powder bed fusion (LPBF) is a metal additive manufacturing technology that utilizes high-power lasers to melt and stack powdered materials for rapid prototyping. However, metals used in current lightweight and high-strength LPBF processes are extremely limited. In particular, in terms of aluminum alloys, LPBF-formed aluminum alloys are mainly focused on Al-Si alloys. The inherent un-weldability of 7050 aluminum alloy and the high thermal stress induced by rapid cooling during the additive manufacturing process cause cracking or deformation during LPBF, limiting the application of LPBF technology in the preparation of this type of alloys. This study investigates the LPBF formation of TiB2/7050 composite and subsequent heat treatment (solution + aging treatment) process, exploring the effects of different process parameters and heat treatment conditions on the microstructures and room temperature tensile properties of TiB2/7050 composite.

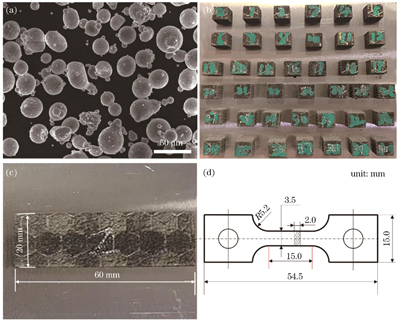

Orthogonal methods are employed to select laser process parameters, including laser power levels of 210, 225, 240, and 255 W. The scanning speed levels are set at 400, 450, 500, 550, and 600 mm/s, whereas hatch spacings are set at 75 μm and 90 μm. The scanning strategy involves a layer-by-layer rotation of 90° using the stripe scanning method. In total, there are 40 sets of process parameters. The heat treatment is conducted via solution treatment in an muffle furnace. After the samples are solubilized at 475 °C for 1 h, they are cooled in room temperature water and then aged at 120 °C for 12 h in a tubular resistance furnace before final cooling in ambient air. Tensile experiments are performed using a room temperature tensile device at a strain rate of 10-4 s-1. Tensile specimens with appropriate dimensions are prepared, and three samples in equivalent conditions are tested to obtain the average values. X-ray diffractometer is employed to analyze the phase composition of the samples. The scan angle range is set between 20° and 120° with a scan rate of 2 (°)/min. Microstructural characterization is performed using a scanning electron microscope (SEM), and the material surface elemental compositions are analyzed using an energy-dispersive spectrometer (EDS).

Under the following four sets of process parameters (laser power + scanning speed + scanning spacing), the relative densities of the printed sample are higher: 240 W+450 mm/s+75 μm (No.1), 240 W+500 mm/s+75 μm (No.2), 240 W+450 mm/s+90 μm (No.3), and 240 W+500 mm/s+90 μm (No.4). The obtained relative densities of TiB2/7050 composite samples are approximately 98.3%, 98.7%, 98.5%, and 99.1%, respectively (Fig.2). The tensile experiments under these four sets of parameters are conducted at room temperature on the as-built and heat-treated samples. In the as-built state, the TiB2/7050 composite exhibits the highest strength under the condition 240 W+450 mm/s+75 μm (No.1), with tensile strength, yield strength, and elongation being 286 MPa, 250 MPa, and 2.3%, respectively (Fig.4). After heat treatment, both the strength and plasticity of the material significantly improve for all four sets of parameters. In particular, under the as-built condition of 240 W+450 mm/s+75 μm (No.1), the material achieves tensile strength, yield strength, and elongation values of 351 MPa, 294 MPa, and 4.2%, respectively (Fig.4). Additionally, in the as-built state, the primary microstructure of the composite consists of α-Al phases and TiB2 particles. After heat treatment, a significant number of secondary phases precipitate from the matrix, and SEM results show the presence of abundant precipitates in the forms of both particles and elongated phases (Fig.6).

The addition of TiB2 particles significantly suppresses the cracking of 7050 alloys through the LPBF process and exhibits favorable formability. The optimal process parameters in the as-built state are 240 W+450 mm/s+75 μm, which result in the highest strength of the TiB2/7050 composite. The tensile strength, yield strength, and elongation are 286 MPa, 250 MPa, and 2.3%, respectively. The microstructure of the TiB2/7050 composite after heat treatment consists of fine-sized equiaxed grains. The grain size is concentrated in the range of 1?3 μm, with TiB2 particles evenly dispersed in the grain boundaries and within the equiaxed grain structure, effectively promoting the formation of heterogeneously nucleated refined grains. After heat treatment, the tensile strength, yield strength, and elongation of the specimens of TiB2/7050 composite are 351 MPa, 294 MPa, and 4.2%, respectively.

王安, 唐梓珏, 吴一, 王浩伟, 王洪泽. 激光粉末床熔化制备TiB2颗粒增强7050铝基复合材料的组织及性能研究(特邀)[J]. 中国激光, 2024, 51(4): 0402304. An Wang, Zijue Tang, Yi Wu, Haowei Wang, Hongze Wang. Microstructure and Properties of 7050 Aluminum Matrix Composites Reinforced by TiB2 Particles Fabricated Through Laser Powder Bed Fusion (Invited)[J]. Chinese Journal of Lasers, 2024, 51(4): 0402304.