移动连续激光源激发Lamb波的材料弹性性质反演

Accurate mechanical properties of materials, including Young’s modulus, Poisson’s ratio, and longitudinal and shear wave speeds, are essential for material evaluation and testing. A major challenge arises when dealing with multimodal ultrasound Lamb waves, especially those that closely approach or intersect in the spectrum or dispersion curves. This complexity is often due to hardware limitations, such as the bandwidth of generation and detection. Furthermore, accurately distinguishing these modes in dispersion curves, by identifying spectral peaks through the wavenumber resolution offered by the two-dimensional Fourier transform method, often presents difficulties. Traditionally, most studies have relied on contact wedge transducer. However, laser ultrasound introduces a nondestructive testing method that significantly simplifies spatiotemporal modulation and enables non-contact generation detection. This approach is particularly advantageous for applications that require rapid material scanning, as it overcomes the challenges associated with traditional methods, enhancing accuracy and efficiency in material property analysis.

To address challenges in material parameter inversion, a novel approach was employed, utilizing a moving continuous-wave laser source to generate multimodal Lamb waves in thin plates. This method was first validated through a material-parameter inversion study. Experimental findings, illustrated in Figs. 4 and 5, confirmed the effective generation of specific Lamb waves with distinct phase velocities. Importantly, this non-contact phase-velocity matching method overcame the limitations typically encountered with transducer use in contact scanning, enhancing the accuracy of dispersion curve measurements within the targeted range. Further investigations focused on parameter sensitivities in the fitting process, specifically for aluminum plates within a phase velocity range of 2500?4000 m/s and a frequency-thickness product range of 1?20 MHz·mm. Additionally, as shown in Figs. 2 and 3, simulations and analyses were conducted to assess multimodal fitting under various noise levels. Building on these comprehensive insights, material parameters for aluminum and polystyrene plates of varying thicknesses were successfully obtained through the application of the particle swarm optimization algorithm, coupled with inertial descent.

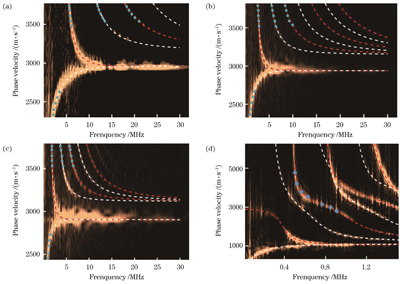

Single-modal data (specifically, the s1 modal, represented by the blue data points in Fig.5(d)) are utilized for fitting when inverting the material properties of the polystyrene plate. When comparing the final fitting results with parameters found in the literature, the error for the longitudinal wave speed is only 0.26%, while that for the shear wave speed is 3.83%. A sensitivity analysis of this study reveals that the sensitivity of the longitudinal wave in the phase velocity range of 2500?4000 m/s for the aluminum plates is relatively low. Errors in the measurement of the dispersion curve can lead to significant deviations in the inversion results of the longitudinal wave speed. However, employing multimodal fitting can reduce the inversion errors originating from these low sensitivities, as illustrated in the results presented in Table 1. In this study, multimodal-based fitting inversion results yield a longitudinal and shear wave speed errors of 1.51% and 1.28%, respectively, compared to the existing literature. These results underscore the relative accuracy of the dispersion curves generated by Lamb waves and extracted using measurement techniques.

In this study, a method involving the generation of Lamb waves using a moving laser source is employed to measure the Lamb waves with phase velocities ranging from 1000 to 4000 m/s and frequencies ranging from 1 to 20 MHz. This technique is applied to both aluminum plates (thickness: 0.5?1.6 mm) and polystyrene plates (thickness: 2.3 mm). This method effectively circumvents the limitations associated with transducer coupling during contact scanning, by utilizing non-contact generation. This approach significantly enhances the accuracy of measuring the dispersion curves within a specified range, enabling precise extraction of the phase velocity and frequency. The simulation analysis in this study investigates the impact of sensitivity and fitting modes on the inversion results. The sensitivity of the longitudinal and shear wave speeds in aluminum within phase velocity and frequency ranges of 2500?4000 m/s and 1?20 MHz, respectively, are discussed. Notably, this region exhibits higher and lower sensitivities to shear and longitudinal wave speeds, respectively. The simulation analysis reveals that noise has a more pronounced effect on longitudinal wave speed, resulting in larger deviations. In this study, a multimodal fitting method is utilized to enhance the accuracy of the final inversion results. This approach effectively addresses the challenge of multipeak distribution in the search space, which is commonly encountered in unimodal fitting methods. By leveraging accurate dispersion data obtained through simulation analysis, the particle swarm algorithm with inertial descent is applied to invert the longitudinal and shear wave speeds in aluminum and polystyrene plates. The maximum error between the final inversion results and that in the existing literatures for the aluminum plates does not exceed 1.51%. Furthermore, our experiments with polystyrene plates demonstrate that a moving laser source can successfully generate Lamb wave signals with low phase velocities, particularly in organic materials with limited surface damage thresholds. This promising technique holds significant potential for future applications in non-destructive testing and evaluation of various non-metallic materials, particularly those prone to damage, such as composites.

1 引言

准确测量材料的力学参数,如弹性模量、泊松比以及纵波和横波波速等,是对服役材料进行性能评估[1-2]和检测[3-4]的重要方面。材料力学参数的表征方法主要可以分为静态法[5-6]和动态法[7-9]。对相应材料薄板中的Lamb波频散曲线进行分析并进行参数反演是一种重要的参数表征方法。Rogers[10]利用可调角度的楔块换能器,在入射角度下激发出对应相速度的导波模式,通过测量不同相速度匹配条件下所激发的超声导波频谱得到频散曲线,分析了频散曲线拟合反演中的高敏感区域,并在此基础上进行了参数反演。结果显示,所得到的弹性模量的误差小于1%,泊松比误差小于2%。Deán等[11-12]通过干涉法测量了不同频率下模式分离后的导波波长,得到了较为准确的频率-波长域频散曲线,其最终反演的纵波波速、横波波速及厚度误差均小于1%。此外,还可以通过二维傅里叶变换将Lamb波扫查的时域数据映射到频率-波数域[13],这种方法是目前应用较广的多模式频散曲线测量方法[14-17]。对于在频谱或频散曲线上较为接近甚至相互交叉的多模态超声导波,考虑到实际实验的激发探测带宽以及换能器扫查范围等硬件限制,二维傅里叶变换方法中的波数分辨率通常难以通过识别频谱峰值的方式对频散曲线中的这些模式进行准确区分。相关研究表明:稀疏奇异值分解[18]、MUSIC[19]、ESPRIT[20]等算法可以用于处理实验中的频散数据,并可以提高波数分辨率和频散曲线的测量精度。

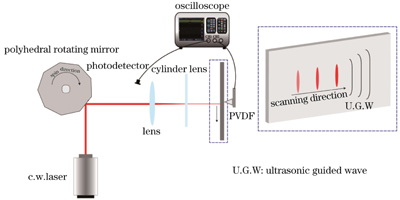

基于旋转换能器入射角度等相速度匹配的激发测量方法直接得到的频散数据通常是相速度频率域上的,已有的研究大多采用的是接触式楔块换能器,需要使用耦合剂。而激光超声是一种易于实现时空调制和非接触激发探测的超声无损检测方法,在对材料进行快速扫查等应用方面具有优势。利用振镜或转镜等器件可以方便地使激光在待测表面快速移动,因此,基于激光超声的相速度匹配激发研究得到了越来越多的关注。Yamanaka等[21]采用基于毫秒YAG脉冲激光器的扫描激光源选择性激发了特定相速度、特定模态的Lamb波。Caron等[22]则对此方法进一步开展了理论分析,并提出了一种用连续激光源替换脉冲激光源进而实现灵活选择性激发超声导波的方法[23]。基于移动连续激光源的方案随后在实验室得到应用,实现了对特定相速度Lamb波模态的高效激发,之后对转镜在不同转速下所探测的Lamb波信号进行傅里叶变换便可得到频散曲线。此外,这种方法在周期性结构的频散特性研究中得到了验证[24]。

针对材料评价与参数反演问题,笔者采用基于移动连续激光源的方法测量了薄板中多模式Lamb波的频散曲线,并在此基础上开展了材料参数反演研究。实验结果表明:通过高速转镜移动激光线源的方法可以较好地激发出相应的Lamb波模式,通过相速度匹配的非接触激发方式回避了换能器接触式扫查中耦合所导致的相关限制,提高了相应区域频散曲线的测量精度。通过仿真计算得到了铝板中相速度范围为2500~4000 m/s、频厚积为1~20 MHz·mm的Lamb波的频散曲线,然后加入随机噪声模拟实验测量误差,进而分析拟合了反演中的参数敏感度以及不同噪声水平下的多模态拟合效果。在此基础上,笔者结合惯性下降的粒子群优化算法,反演得到了不同厚度的铝板与聚苯乙烯板的材料参数。

2 频散曲线方程及反演算法

2.1 Rayleigh‑Lamb方程

根据Rayleigh-Lamb方程,任意模式下的Lamb波[25]需要满足

式中:

2.2 粒子群优化(PSO)算法

常见的参数搜索算法包括单纯形法[15,26]、差分进化算法[27]、遗传算法[28]和PSO算法[14,20,29]等。这些算法都有其各自的优点,其中PSO算法由于具有收敛速度快、算法参数少、算法简单易实现等特点,在反演问题中得到了广泛应用。PSO算法在搜索空间内根据适应性函数不断更新粒子的位置(反演参数)和速度(迭代方向),寻找全局最优解,具有较强的全局搜索能力和优秀的收敛性。此外,PSO算法还可以结合其他优化方法,如惯性下降和自适应权重等方法,进一步提高算法的反演精度和鲁棒性。

影响PSO算法收敛的参数主要包括粒子群数目、适应性函数以及速度更新规则。其中,粒子群数目是指求解空间内使用的粒子数目,该参数过小或过大都会对反演产生影响。当粒子群数目过小时,算法容易收敛到局部最优值,导致反演结果偏差较大;当粒子群数目过大时,算法反演计算的时间过长,效率较低。本文通过比较不同粒子数目(Nu=60~100)下算法的搜索质量(仿真拟合使用a0、s0、a1、s1共4个模态以及相速度范围在2500~4000 m/s之间、频率在1~20 MHz之间的Lamb波的频散数据,无随机噪声)来确定粒子群数目。粒子群数目大于80后,迭代次数为200时的均方根误差RMSE<0.01。因此,本文使用的粒子群数目为80。

适应性函数在PSO算法中用于评价迭代更新后的粒子质量。适应性函数决定了算法的最终收敛方向。在频散曲线拟合反演计算中,通常选择RMSE作为标准判断曲线的拟合程度,因此本文采用RMSE作为算法中的适应性函数。其计算公式为

式中:n为拟合中所用数据的数量;

速度更新规则采用的是惯性下降的速度迭代,即

式中:

3 拟合区域的敏感度以及拟合使用的导波模式

3.1 拟合敏感度

仿真中采用的铝参数为:纵波波速cL=6317 m/s,横波波速cT=3110 m/s,铝板厚度h=1 mm,铝板密度ρ=2700 kg/m3。

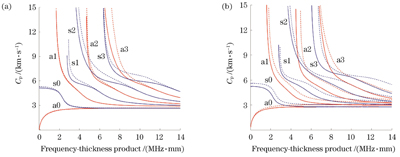

在频散曲线的拟合反演过程中,需要考虑频散曲线对纵波和横波波速的敏感度[10-11]。如

图 1. 纵波波速和横波波速引起的频散曲线变化。(a) 1.05倍(实线)和0.95倍(虚线)纵波波速引起的频散曲线变化;(b) 1.05倍(实线)和0.95倍(虚线)横波波速引起的频散曲线变化

Fig. 1. Variation of dispersion curves caused by longitudinal wave velocity (cL) and shear wave velocity (cT). (a) Variation of dispersion curves caused by 1.05cL (solid line) and 0.95cL (dashed line); (b) variation of dispersion curves caused by 1.05cT (solid line) and 0.95cT (solid line)

在频散曲线的反演过程中,需要选择敏感度大的频散区域进行反演。然而,在实际测量中,受激发与探测方法的限制,需要考虑实际实验中可以测得的信号质量。与低相速度区域相比,移动激光源法在高相速度区域的Lamb波激发效率更低。这是因为高相速度区域的Lamb波激发对应着激光源更高的移动速度,使得激光与板材的作用时间更短,激发效率更低。同时,高相速度区域对应的高阶模态Lamb波信号的频率更高且振幅更低,不易探测到。

综合上述分析,选择拟合区域的相速度上限为4000 m/s。同时,结合敏感度关系分析,选择拟合区域的相速度下限为2500 m/s(与实验测得的数据基本一致)。这是因为,在小于2500 m/s的区域,频散曲线对纵波和横波波速的敏感度较弱。观察

3.2 拟合模态选择

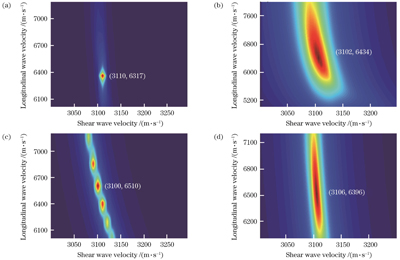

先通过仿真计算得到理论频散曲线,然后加入不同百分比的随机噪声模拟实验频散曲线的提取误差,并讨论提取误差对反演的影响。

图 2. 不同拟合条件下的RMSE分布图。(a)无噪声;(b) 0.5%噪声;(c) 0.05%噪声;(d) 1%噪声

Fig. 2. RMSE maps under different conditions. (a) No noise; (b) 0.5% noise; (c) 0.05% noise; (d) 1% noise

将

4 实验以及参数反演

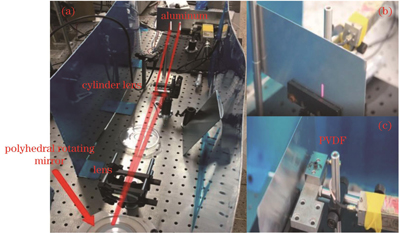

如

图 4. 实验装置图。(a)移动激光源光路;(b)铝板样品;(c)PVDF探测装置

Fig. 4. Experimental device. (a) Optical path of moving laser source; (b) aluminum plate; (c) PVDF detector

本实验中频散曲线的提取误差主要来源于频散数据的相速度不准确,而实验中激发的Lamb波的相速度与激光源移动速度是对应的。为了解决提取的频散数据相速度不准确的问题,笔者通过体波实验校准了相应的激光源移动速度[30]。根据光路的几何关系,计算得到激光源在样品表面的移动速度与转镜旋转速度之间的线性关系;然后,在材料的一侧激发,在另一侧探测直达的体波,通过材料体波方向角以及材料的厚度可以计算出该转镜转速下的激光源移动速度;最后,根据测得的激光源移动速度确定转镜的转速与激光源移动速度的系数比。准确地校准激光源的移动速度后,可以准确地得到激发的Lamb波的相速度,从而提高了频散曲线测量的准确性。

表 1. 铝板以及聚苯乙烯板纵波、横波波速的反演结果

Table 1. Inversion results of longitudinal and shear wave velocities of aluminum and polystyrene plates

|

图 5. 频散曲线(等水线图)与最终正向计算结果(虚线),其中圆点标记表示拟合数据。(a) 0.5 mm厚铝板;(b) 1.0 mm厚铝板;(c)1.6 mm厚铝板;(d) 2.3 mm厚聚苯乙烯板

Fig. 5. Dispersion curve (isometric map) and the final forward calculation result (dashed line), where dot marks represent fitting data. (a) 0.5 mm thick aluminum plate; (b) 1.0 mm thick aluminum plate; (c) 1.6 mm thick aluminum plate; (d) 2.3 mm thick polystyrene plate

频散数据的提取误差还来源于时域信号测量长度有限导致的频率分辨率不足。笔者用基于洛伦兹拟合得到的更为准确的频率进行反演。

在聚苯乙烯板的参数反演中采用的是单模态数据[s1模态,对

5 结论

采用移动激光源激发Lamb波的方法,测量了铝板(厚度为0.5~1.6 mm)与聚苯乙烯板(厚度为2.3 mm)中相速度范围为1000~4000 m/s、频率范围为1~20 MHz的Lamb波信号。该方法通过相速度匹配的非接触激发方式回避了换能器接触式扫查中耦合所导致的相关限制,提高了相应区域频散曲线的测量精度,并准确提取了频散曲线的相速度(Cp)与频率(f)。通过仿真分析了敏感度、拟合模态对反演结果的影响,讨论了铝材中相速度范围为2500~4000 m/s、频率范围为1~20 MHz的Lamb波纵波波速、横波波速在反演中的敏感度问题,该区域的横波波速的敏感度较大,而纵波波速的敏感度较小。由仿真分析可以看出,纵波波速受噪声影响偏差更大。笔者采用多模态拟合方法得到了更准确的反演结果,同时避免了单模态拟合中出现的搜索空间内的多峰分布。在仿真分析以及准确的频散数据提取的基础上,笔者利用惯性下降的粒子群算法反演出了铝板和聚苯乙烯板中的纵波波速和横波波速。铝板的最终反演结果与文献[10,32]测量值的最大误差不超过1.51%。聚苯乙烯板实验说明了移动激光源可以在表面损伤阈值小的有机材料中实现低相速度(相对于耦合材料中的纵波速度)Lamb波信号的激发。这一技术有望被应用于各种非金属材料的无损检测与评估,尤其是易损伤的复合材料,例如碳纤维、玻璃纤维等。

[1] 蒋旺, 孙凯华. 激光超声Lamb波双模共振测量薄板局部弹性模量[J]. 中国激光, 2023, 50(13): 1304004.

[2] 姬保平, 曹建树, 黄钢, 等. 钢板内应力激光超声导波检测方法研究[J]. 中国激光, 2022, 49(6): 0604001.

[3] Ying K N, Ni C Y, Dai L N, et al. Multi-mode laser-ultrasound imaging using time-domain synthetic aperture focusing technique (T-SAFT)[J]. Photoacoustics, 2022, 27: 100370.

[4] 陈楚, 应恺宁, 刘念, 等. 相移迁移法在激光超声合成孔径聚焦技术中的应用[J]. 中国激光, 2021, 48(3): 0304001.

[5] 何仁, 李英叶, 陈敬欣, 等. 三点、四点法机械性能测试建模及其在太阳电池中的应用[J]. 物理学报, 2019, 68(20): 208801.

He R, Li Y Y, Chen J X, et al. Three-point and four-point mechanical bending test modeling and application in solar cells[J]. Acta Physica Sinica, 2019, 68(20): 208801.

[6] Fathi H, Kazemirad S, Nasir V. Lamb wave propagation method for nondestructive characterization of the elastic properties of wood[J]. Applied Acoustics, 2021, 171: 107565.

[7] 顾利忠, 左铭旺, 苏菲. 声激励共振法测量微机械材料的杨氏模量[J]. 声学技术, 2000, 19(4): 187-189.

Gu L Z, Zuo M W, Su F. Acoustically-excited method for Young’s modulus measurement of micro-machined materials[J]. Technical Acoustics, 2000, 19(4): 187-189.

[8] Makeev A, Carpentier P, Shonkwiler B. Methods to measure interlaminar tensile modulus of composites[J]. Composites Part A: Applied Science and Manufacturing, 2014, 56: 256-261.

[9] 靳巧玲, 李国禄, 王海斗, 等. 纳米压痕技术在材料力学测试中的应用[J]. 表面技术, 2015, 44(12): 127-136.

Jin Q L, Li G L, Wang H D, et al. Application of the nanoindentation technique in material mechanics test[J]. Surface Technology, 2015, 44(12): 127-136.

[10] Rogers W P. Elastic property measurement using Rayleigh-Lamb waves[J]. Research in Nondestructive Evaluation, 1995, 6(1): 185-208.

[11] Deán J L, Trillo C, Doval Á F, et al. Determination of thickness and elastic constants of aluminum plates from full-field wavelength measurements of single-mode narrowband Lamb waves[J]. The Journal of the Acoustical Society of America, 2008, 124(3): 1477-1489.

[12] Fernández J L, Deán J L, Trillo C, et al. Elastic constants determination by direct measurement of the beat wavelength between A0 and S0 Lamb modes with pulsed TV holography[J]. Optics and Lasers in Engineering, 2007, 45(5): 618-630.

[13] Alleyne D, Cawley P. A two-dimensional Fourier transform method for the measurement of propagating multimode signals[J]. The Journal of the Acoustical Society of America, 1991, 89(3): 1159-1168.

[14] Lu Y, He C F, Song G R, et al. Elastic properties inversion of an isotropic plate by hybrid particle swarm-based-simulated annealing optimization technique from leaky lamb wave measurements using acoustic microscopy[J]. Journal of Nondestructive Evaluation, 2014, 33(4): 651-662.

[15] Karim M R, Mal A K, Bar-Cohen Y. Inversion of leaky Lamb wave data by simplex algorithm[J]. The Journal of the Acoustical Society of America, 1990, 88(1): 482-491.

[16] Vishnuvardhan J, Krishnamurthy C V, Balasubramaniam K. Genetic algorithm based reconstruction of the elastic moduli of orthotropic plates using an ultrasonic guided wave single-transmitter-multiple-receiver SHM array[J]. Smart Materials and Structures, 2007, 16(5): 1639-1650.

[17] Eremin A A, Glushkov E V, Glushkova N V, et al. Evaluation of effective elastic properties of layered composite fiber-reinforced plastic plates by piezoelectrically induced guided waves and laser Doppler vibrometry[J]. Composite Structures, 2015, 125: 449-458.

[18] Xu K L, Minonzio J G, Ta D A, et al. Sparse SVD method for high-resolution extraction of the dispersion curves of ultrasonic guided waves[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2016, 63(10): 1514-1524.

[19] Zabbal P, Ribay G, Chapuis B, et al. Multichannel multiple signal classification for dispersion curves extraction of ultrasonic guided waves[J]. The Journal of the Acoustical Society of America, 2018, 143(2): EL87-EL92.

[20] Chen Q, Xu K L, Ta D A. High-resolution Lamb waves dispersion curves estimation and elastic property inversion[J]. Ultrasonics, 2021, 115: 106427.

[21] Yamanaka K, Nagata Y, Koda T. Selective excitation of single-mode acoustic waves by phase velocity scanning of a laser beam[J]. Applied Physics Letters, 1991, 58(15): 1591-1593.

[22] Caron J N, DiComo G P, Nikitin S. Generation of ultrasound in materials using continuous-wave lasers[J]. Optics Letters, 2012, 37(5): 830-832.

[23] Li Z, Lomonosov A M, Ni C Y, et al. Selective generation of Lamb modes by a moving continuous-wave laser[J]. Optics Letters, 2017, 43(1): 78-81.

[24] Li J Y, Lomonosov A M, Shen Z H, et al. Spatial distribution of the phononic crystal modes excited by a moving laser source[J]. Applied Physics Letters, 2019, 115(23): 234102.

[25] 沈中华, 袁玲, 张宏超. 固体中的激光超声[M]. 北京: 人民邮电出版社, 2015.

ShenZ H, YuanL, ZhangH C. Laser ultrasound in solids[M]. Beijing: Posts & Telecom Press, 2015.

[26] Zhang R, Wan M X, Cao W W. Parameter measurement of thin elastic layers using low-frequency multi-mode ultrasonic lamb waves[J]. IEEE Transactions on Instrumentation and Measurement, 2001, 50(5): 1397-1403.

[27] Lu P, Chen S, Sheng X Z, et al. Application of the differential evolutionary algorithm to the estimation of pipe embedding parameters[J]. Sensors, 2022, 22(10): 3942.

[28] Balasubramaniam K, Rao N S. Inversion of composite material elastic constants from ultrasonic bulk wave phase velocity data using genetic algorithms[J]. Composites Part B: Engineering, 1998, 29(2): 171-180.

[29] Gao X, Tian Y, Jiao J P, et al. Non-destructive measurements of thickness and elastic constants of plate structures based on Lamb waves and particle swarm optimization[J]. Measurement, 2022, 204: 111981.

[30] 李政. 移动连续激光选择性激发超声模态的研究[D]. 南京: 南京理工大学, 2021: 31-32. 10.26789/aeb.2022.02.004

LiZ. Study on selective excitation of ultrasonic modes by moving CW laser[D]. Nanjing: Nanjing University of Science and Technology, 2021: 31-32.

[31] Higazy A A, Afifi H, Khafagy A H, et al. Ultrasonic studies on polystyrene/styrene butadiene rubber polymer blends filled with glass fiber and talc[J]. Ultrasonics, 2006, 44: e1439-e1445.

[32] Podymova N B, Kalashnikov I E, Bolotova L K, et al. Laser-ultrasonic nondestructive evaluation of porosity in particulate reinforced metal-matrix composites[J]. Ultrasonics, 2019, 99: 105959.

Article Outline

李秋雨, 李政, 陆健, 阚威威, 沈中华. 移动连续激光源激发Lamb波的材料弹性性质反演[J]. 中国激光, 2024, 51(8): 0804006. Qiuyu Li, Zheng Li, Jian Lu, Weiwei Kan, Zhonghua Shen. Elastic Property Inversion of Materials via Lamb Waves Generated by a Moving Continuous‑Wave Laser[J]. Chinese Journal of Lasers, 2024, 51(8): 0804006.