基于钬掺杂ZBYA玻璃光纤的中红外激光研究  下载: 1068次

下载: 1068次

与传统的ZBLAN(ZrF4-BaF2-LaF3-AlF3-NaF)玻璃相比,ZBYA(ZrF4-BaF2-YF3-AlF3)玻璃有着更加良好的热稳定性和化学稳定性。制备出ZBYA玻璃光纤,采用1150 nm拉曼光纤激光器作为泵浦源,使用Ho3+掺杂的ZBYA光纤作为增益介质实现了~2.9 μm波长的激光输出,最大输出功率达到了137 mW,斜率效率为8.9%。研究结果表明ZBYA玻璃光纤是一种潜在的用于实现中红外波段激光的增益材料。

The midinfrared (MIR) lasers at ~2.9 μm have been attracting increasing attention owing to their considerable applications in surgery, military, environmental monitoring, remote sensing, and nonlinear optics. In many ways, fiber laser has unique advantages for achieving MIR laser. In the past few decades, zirconium fluoride glass fiber, represented by ZBLAN (ZrF4-BaF2-LaF3-AlF3-NaF), has been widely used in MIR fiber lasers. However, the poor thermal and chemical stabilities of ZBLAN fibers pose a challenge to achieve higher power MIR lasers. Therefore, in this study, we fabricated ZBYA (ZrF4-BaF2-YF3-AlF3) glass fiber, which is more stable than the ZBLAN fiber, and the Ho3+ -doped ZBYA fiber was used as the gain medium to achieve a 2.9-μm MIR laser under 1150-nm pump. This result indicated that ZBYA glass fiber is a potential gain medium material for MIR fiber lasers.

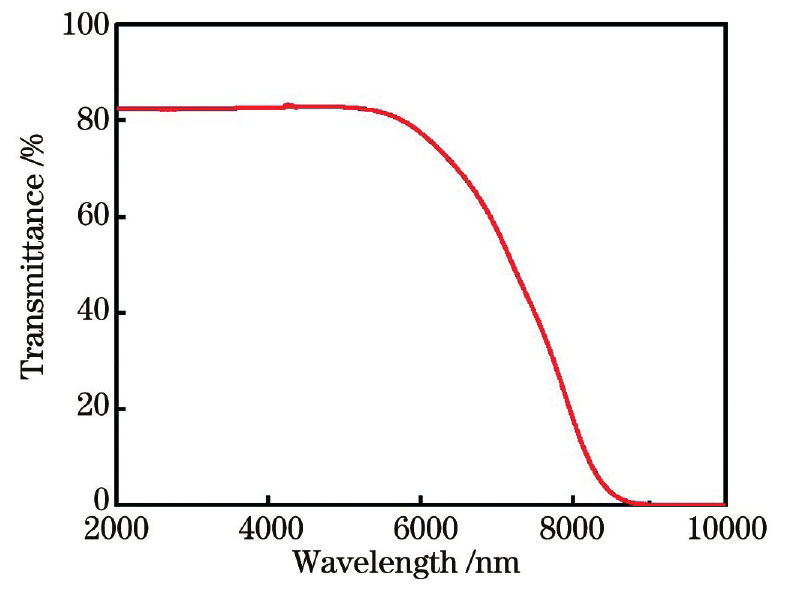

In this work, the ZBYA glass with low water content was prepared and polished. The transmittance spectrum in the range of 200010000 nm of ZBYA glass was measured using Perkin-Elmer Fourier-transform infrared (FTIR) spectrometer (Fig. 1). Differential scanning calorimetry was used to measure the thermal properties of the core and cladding glass at a heating rate of 10 K/min using a Netzsch STA449F5 analyzer (Fig. 2). By comparing the transmittance changes of the ZBYA glass and ZBLAN glass after soaking them in water for a long period (24 h), it is demonstrated that ZBYA glass has higher chemical stability (Fig. 3). Then, we created the Ho3+ -doped ZBYA glass fiber and constructed a laser system with ZBYA fiber, an 1150-nm fiber laser, a focus lens, and a dichroic mirror (Fig. 5). An output power of ~2.9 μm was measured using a power detector, and the laser spectrum was observed with an optical spectrum analyzer (YOKOGAWA AQ6377) (Figs. 6 and 7).

The transition temperature (Tg) and crystallization temperature of core and cladding glass are 333 ℃ and 334 ℃ and 406 ℃ and 405 ℃, respectively (Fig. 2). The Tg of ZBYA glass is considerably higher than that of ZBLAN glass, indicating that ZBYA glass has a higher laser damage threshold. After soaking in water for 24 h, the transmittance of ZBYA glass was considerably higher than that of ZBLAN glass, demonstrating that ZBYA glass has superior chemical stability (Fig. 3). For ~2.9-μm laser system, a ~2.9-μm laser output is observed when the pump power is 97 mW. The highest output power is 137 mW, the corresponding pump power is 1.5 W, and the slope efficiency is 8.9%. The reason for the slope efficiency being far lower than the Stokes efficiency limit in the experiment is mainly owing to the high background loss of ZBYA fiber (3 dB/m) and the large core diameter (30 μm). The center wavelength of laser output is 2855 nm, and the full width at half maxima is 1.2 nm. As shown in Fig. 8, the stability of the laser output power is monitored. In 30 min, the laser output power gradually decreases from 137 mW to 131 mW. The gradual accumulation of hydroxyl groups at the fiber’s end during laser operation results in a 2.9-μm reduction in laser power; additionally, the laser power does not fluctuate sharply.

In this study, ZBYA glass is prepared and tested and its better thermal and chemical stabilities are demonstrated. Accordingly, we fabricate the Ho3+ -doped ZBYA glass fiber and achieve a ~2.9-μm laser. The maximum output power is 137 mW, and the slope efficiency is 8.9%. Currently, the background of fiber is still high owing to the purity of raw materials; however, by optimizing the preparation process to reduce fiber loss, it is expected to achieve higher output power and slope efficiency. Furthermore, silica fiber and ZBYA fiber’s fusion splicing technology should be investigated to reduce the complexity of laser systems. The future work should focus on the preparation of double-cladding fibers to increase the maximum pump power and obtain higher power output.

徐昌骏, 张集权, 刘墨, 王顺宾, 王鹏飞. 基于钬掺杂ZBYA玻璃光纤的中红外激光研究[J]. 中国激光, 2022, 49(1): 0101016. Changjun Xu, Jiquan Zhang, Mo Liu, Shunbin Wang, Pengfei Wang. Midinfrared Laser in Ho3+ -Doped ZBYA Glass Fiber[J]. Chinese Journal of Lasers, 2022, 49(1): 0101016.