新型高掺Tm3+石英光纤制备及2.0 μm激光性能研究  下载: 647次

下载: 647次

The 2.0 μm-band single-frequency laser has the advantages of narrow linewidth, low noise, and good monochromaticity, which is widely used in many fields, such as precision measurement, spaceborne lidar, and high-resolution spectroscopy. Compared with multi-component glass fibers, the rare-earth-doped silica fiber is the core gain medium of fiber lasers, which boasts stable physical and chemical properties, high mechanical strength, and easy system integration. However, it is difficult to achieve the high-concentration doping of rare earth ions by traditional fabrication processes. There is still a gap in the doping concentration between the reported multi-component glass and the silica glass prepared by mature modified chemical vapor deposition (MCVD) combined with the liquid-phase doping process. Used in the short gain fiber for single-frequency lasers based on a distributed Bragg reflection (DBR) structure, the highly Tm3+-doped technique ensures that the fiber has higher effective absorption to the pump source and a lower laser output threshold, which is more conducive to improving the laser performance of the system. For the high gain medium of 2.0 μm-band single-frequency lasers, how to further improve the concentration of Tm3+ in silica glass becomes the focus of this paper.

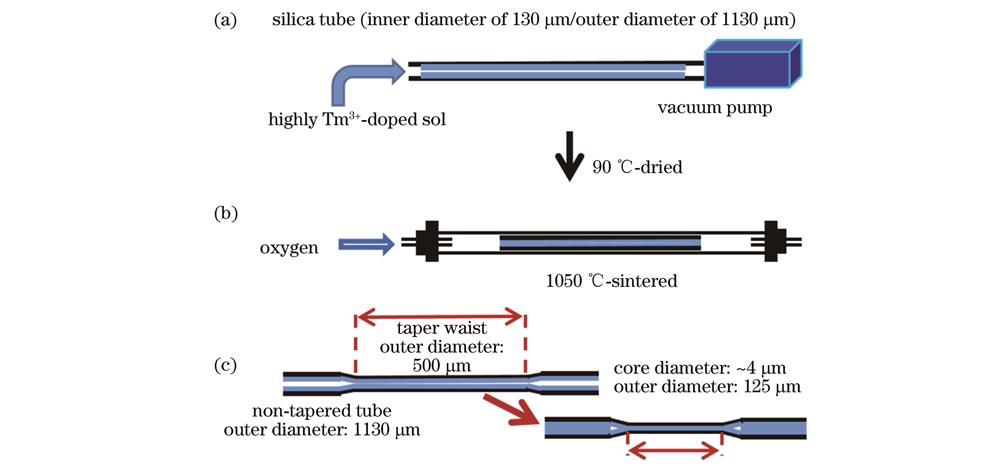

We use Tetracthoxysilane (TEOS) as the silicon source, Al2O3 as the network-forming body, and La2O3 as the dispersant of silica glass to prepare highly Tm3+-doped silica sol. Firstly, the high silica glass with the Tm3+ doping concentration of 8.29×1020 cm-3 is prepared by the sol-gel method and high-temperature sintering technology, which has good optical quality, and its spectral properties are characterized. Secondly, the sol-gel coating and melting taper drawing methods are combined innovatively to coat the inner wall of the silica capillary tube. After the film is heat-treated and tapered step by step, the silica fiber with a core diameter of about 4 μm and a cladding diameter of 125 μm is prepared, and the doping concentration of Tm3+ can reach as high as 8.29×1020 cm-3 in the silica fiber. This highly Tm3+-doped silica fiber could be easily fusion-spliced with commercial passive silica fibers. Finally, an all-optical fiber laser system with a DBR structure is built to test the laser performance.

In this paper, we fabricate highly Tm3+-doped high silica glass with a concentration of 8.29×1020 cm-3 by the sol-gel method and high-temperature sintering process. The highly Tm3+-doped silica fiber with a core diameter of about 4 μm and a cladding diameter of 125 μm is also prepared by the sol-gel coating and double melting taper drawing methods. For better laser performance of the highly Tm3+-doped high silica fiber prepared by this innovative process, the follow-up work will be carried out from the following two aspects: the composition control of the core glass and the optimization of the coating process. In terms of composition, the glass with the best fluorescence can be selected through different components. In terms of coating technology, the film thickness can be designed and adjusted, and the core size is adjusted to achieve better NA and mode-field matching when the silica fiber is fused with passive optical fibers. Meanwhile, a 789 nm source can be selected to further study the performance of fiber lasers. To sum up, this fiber preparation method has the potential to realize highly Tm3+-doped silica fibers, which is expected to be applied in 2.0 μm single-frequency fiber lasers and passively mode-locked fiber lasers with a high fundamental repetition rate.

沈骁, 杨广利, 王亚飞, 陈应刚, 于春雷, 韦玮, 胡丽丽. 新型高掺Tm3+石英光纤制备及2.0 μm激光性能研究[J]. 光学学报, 2023, 43(4): 0414001. Xiao Shen, Guangli Yang, Yafei Wang, Yinggang Chen, Chunlei Yu, Wei Wei, Lili Hu. Preparation of Highly Tm3+-Doped Silica Fibers and Study of 2.0 μm Laser Performance[J]. Acta Optica Sinica, 2023, 43(4): 0414001.