新型高掺Tm3+石英光纤制备及2.0 μm激光性能研究  下载: 647次

下载: 647次

The 2.0 μm-band single-frequency laser has the advantages of narrow linewidth, low noise, and good monochromaticity, which is widely used in many fields, such as precision measurement, spaceborne lidar, and high-resolution spectroscopy. Compared with multi-component glass fibers, the rare-earth-doped silica fiber is the core gain medium of fiber lasers, which boasts stable physical and chemical properties, high mechanical strength, and easy system integration. However, it is difficult to achieve the high-concentration doping of rare earth ions by traditional fabrication processes. There is still a gap in the doping concentration between the reported multi-component glass and the silica glass prepared by mature modified chemical vapor deposition (MCVD) combined with the liquid-phase doping process. Used in the short gain fiber for single-frequency lasers based on a distributed Bragg reflection (DBR) structure, the highly Tm3+-doped technique ensures that the fiber has higher effective absorption to the pump source and a lower laser output threshold, which is more conducive to improving the laser performance of the system. For the high gain medium of 2.0 μm-band single-frequency lasers, how to further improve the concentration of Tm3+ in silica glass becomes the focus of this paper.

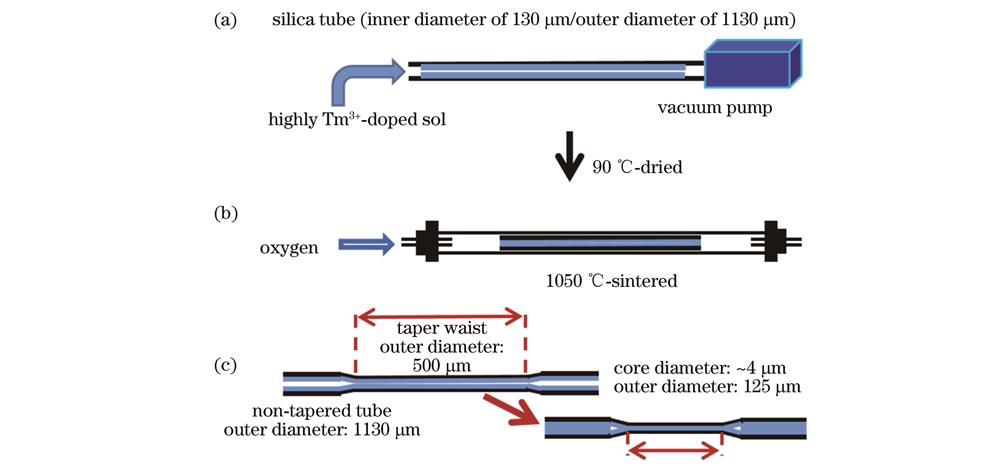

We use Tetracthoxysilane (TEOS) as the silicon source, Al2O3 as the network-forming body, and La2O3 as the dispersant of silica glass to prepare highly Tm3+-doped silica sol. Firstly, the high silica glass with the Tm3+ doping concentration of 8.29×1020 cm-3 is prepared by the sol-gel method and high-temperature sintering technology, which has good optical quality, and its spectral properties are characterized. Secondly, the sol-gel coating and melting taper drawing methods are combined innovatively to coat the inner wall of the silica capillary tube. After the film is heat-treated and tapered step by step, the silica fiber with a core diameter of about 4 μm and a cladding diameter of 125 μm is prepared, and the doping concentration of Tm3+ can reach as high as 8.29×1020 cm-3 in the silica fiber. This highly Tm3+-doped silica fiber could be easily fusion-spliced with commercial passive silica fibers. Finally, an all-optical fiber laser system with a DBR structure is built to test the laser performance.

In this paper, we fabricate highly Tm3+-doped high silica glass with a concentration of 8.29×1020 cm-3 by the sol-gel method and high-temperature sintering process. The highly Tm3+-doped silica fiber with a core diameter of about 4 μm and a cladding diameter of 125 μm is also prepared by the sol-gel coating and double melting taper drawing methods. For better laser performance of the highly Tm3+-doped high silica fiber prepared by this innovative process, the follow-up work will be carried out from the following two aspects: the composition control of the core glass and the optimization of the coating process. In terms of composition, the glass with the best fluorescence can be selected through different components. In terms of coating technology, the film thickness can be designed and adjusted, and the core size is adjusted to achieve better NA and mode-field matching when the silica fiber is fused with passive optical fibers. Meanwhile, a 789 nm source can be selected to further study the performance of fiber lasers. To sum up, this fiber preparation method has the potential to realize highly Tm3+-doped silica fibers, which is expected to be applied in 2.0 μm single-frequency fiber lasers and passively mode-locked fiber lasers with a high fundamental repetition rate.

1 引言

2.0 μm波段激光因处于大气传输窗口(1.7~2.1 μm)和人眼安全波段(1.4~2.1 μm),在大气通信、激光遥感以及生物医学等领域有广泛的应用前景[1-4]。而2.0 μm波段单频激光更是凭借线宽窄、噪声小、单色性好、相干长度长等优势,在精密测量、星载激光雷达、高分辨光谱等领域[5-9]获得了广泛关注。Tm3+掺杂玻璃及光纤是获得2.0 μm激光的重要增益材料。目前,基于Tm3+掺杂的石英光纤、多组分玻璃光纤均获得了2.0 μm波段单频激光。其中,多组分玻璃由于成分调节范围大,稀土掺杂浓度高,是当前实际中采用的主要高增益介质。华南理工大学和天津大学等单位分别在锗酸盐[10]和硅酸盐[11]等软玻璃中相继实现了Tm3+掺杂浓度为8.0×1020 cm-3和8.52×1020 cm-3的高掺杂,光纤在1.95 μm处分别获得了3.6 dB/cm和1.7 dB/cm的增益系数。然而,由于玻璃软化点、热膨胀系数相差较大,多组分软玻璃光纤和石英光纤间的熔接困难导致其应用受限。

稀土掺杂石英玻璃光纤与石英光纤无源器件系统兼容性好,但传统制备工艺难以实现稀土离子的高浓度掺杂。2019年,Lu等[12]采用改进的化学气相沉积(MCVD)结合液相掺杂工艺,在Tm/Al共掺石英玻璃中实现了铥离子5.66×1020 cm-3的掺杂浓度,其Tm3+掺杂浓度与已报道的多组分玻璃相比仍有差距。基于分布式布拉格反射(DBR)结构的单频激光器所使用的增益光纤较短,高的Tm3+掺杂浓度保证了光纤对泵源更有效的吸收以及更低的激光输出阈值,更有利于提升系统的激光性能。为实现2.0 μm波段单频激光高增益,进一步提高稀土离子在石英玻璃里的掺杂浓度成为了近年来的研究热点。溶胶凝胶(SG)法因实验条件简单,液相条件下原料可均匀混合,通过水解缩合反应生成分子级产物,可在石英玻璃中实现稀土离子分子级高浓度均匀掺杂,从而受到大量研究人员的关注。2019年,Xia等[13]采用SG法和旋涂工艺,成功制备出Yb3+最高掺杂浓度(物质的量分数)为30%的透明铝硅玻璃薄膜;2020年,Xia等[14]结合镀膜和熔融拉锥工艺,成功制备出Yb3+掺杂浓度(质量分数)高达5.7%的石英光纤,并实现了光信噪比为70 dB的1.03 μm激光输出。

本文针对目前在2.0 μm波段单频激光中石英玻璃相较于软玻璃Tm3+ 掺杂浓度低的问题,以正硅酸乙酯(TEOS)作为硅源、Al2O3作为石英玻璃网络形成体、La2O3作为分散剂,创新性地将溶胶镀膜法和熔融拉锥工艺相结合,成功研制出Tm3+的掺杂浓度高达8.29×1020 cm-3的石英光纤,该离子掺杂浓度与多组分玻璃中的含量相当[10-11];同时对光纤进行了增益性能分析,相关研究方法和结论将有助于推动高增益石英光纤的进一步发展。

2 实验内容

2.1 玻璃及光纤的制备

溶胶组分设计为2.3Tm2O3-3.4La2O3-8.6Al2O3-85.7SiO2(各组分前面的数字加百分号代表物质的量分数),命名为2.3T。以纯度为99.99%的TEOS为硅源,以硝酸盐水合物形式引入相应氧化物,其纯度为分析纯,通过水解缩合反应生成透明溶胶。为表征纤芯玻璃的光谱性能,采用同种原料和组分,利用溶胶凝胶法和高温烧结工艺制备相应成分块体玻璃,具体制备工艺流程可参考文献[15]。最后将玻璃样品两面研磨抛光成厚度为2 mm的玻璃片,用于光谱测试。

石英光纤的制备工艺流程如

图 1. 石英毛细管内壁镀膜及熔融拉锥制得Tm3+高掺石英光纤示意图。(a)镀膜;(b)热处理;(c)熔融二次拉锥

Fig. 1. Schematic diagrams of highly Tm3+-doped silica fiber prepared by coating on inner wall of silica capillary and tapering.(a) Coating; (b) heat treatment; (c) secondary fused tapering

2.2 玻璃样品的性能测试与表征

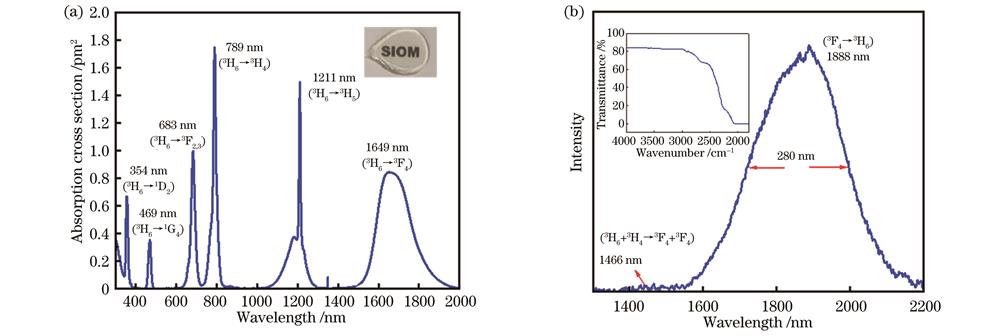

图 2. Tm3+高掺杂高硅氧玻璃光谱性能。(a)吸收截面;(b)发射光谱(插图为红外透过谱)

Fig. 2. Spectral performance of highly Tm3+-doped high-silica glass. (a) Absorption cross section; (b) emission spectrum (inset is infrared transmission spectrum)

表 1. Tm3+高掺高硅氧玻璃的物理性能

Table 1. Physical properties of highly Tm3+-doped high silica glass

|

式中:

式中:

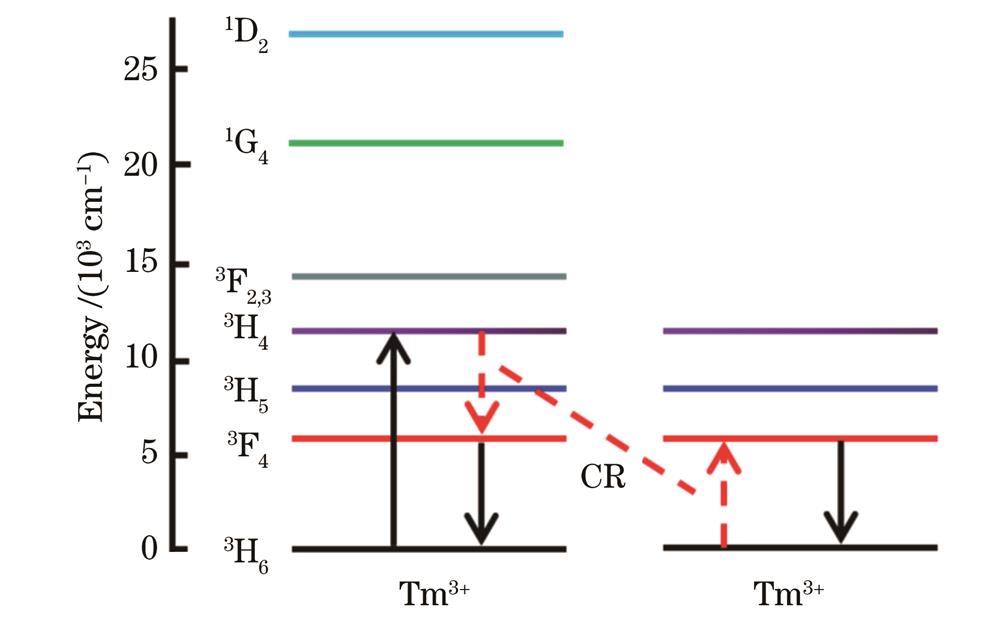

图 3. Tm3+能级简图以及粒子间交叉弛豫

Fig. 3. Simplified energy level diagram of Tm3+ and cross relaxation between Tm3+ ions

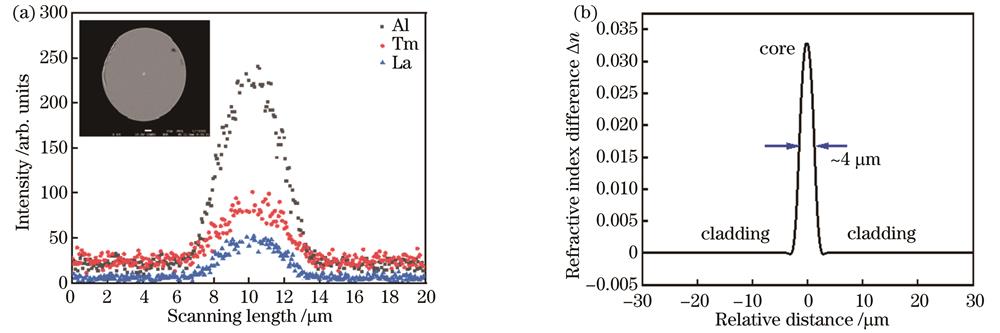

采用型号为JXA-8230的电子探针显微分析仪(EPMA)设备对石英光纤的端面进行电子探针扫描,所得元素分布如

式中:

图 4. 高掺Tm3+石英光纤的物理性能。(a)光纤端面元素分布(插图:光纤端面);(b)光纤折射率分布

Fig. 4. Physical properties of highly Tm3+-doped silica optical fiber. (a) Element distribution at end face of optical fiber (inset is end face of optical fiber) ; (b) refractive index distribution of optical fiber

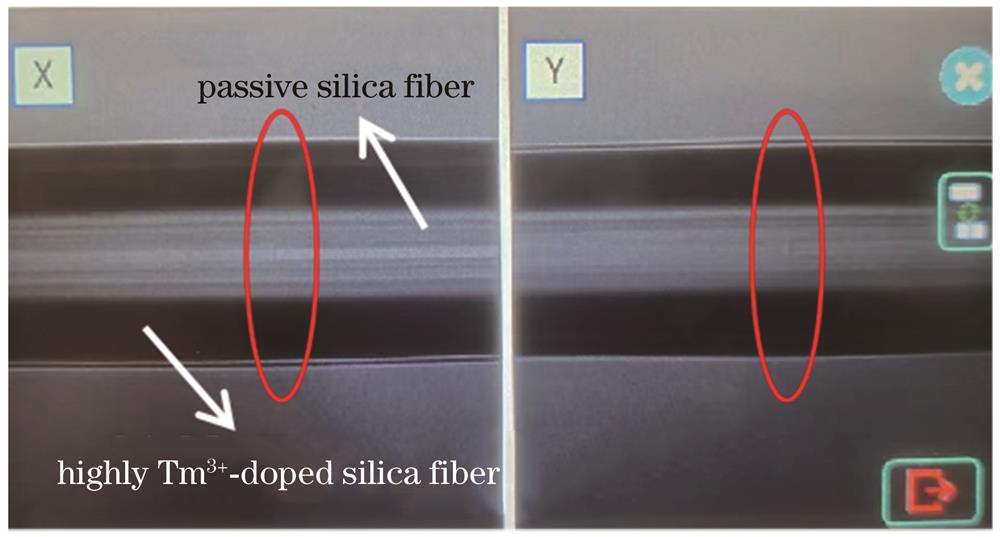

图 5. 高掺Tm3+石英光纤与无源石英光纤熔接效果图

Fig. 5. Images of fusion splicing between highly Tm3+ -doped silica optical fiber and passive silica optical fiber

3 分析与讨论

3.1 高掺Tm3+石英光纤的激光性能研究

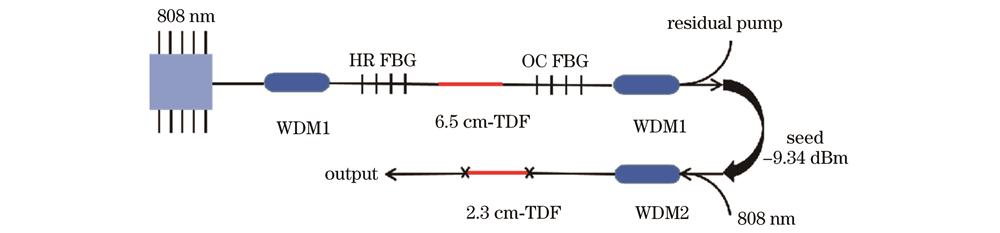

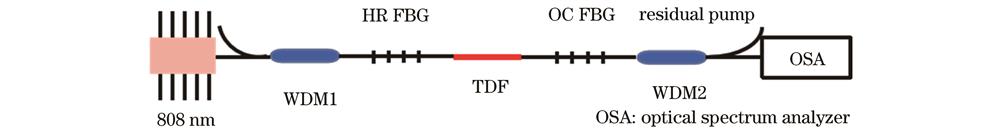

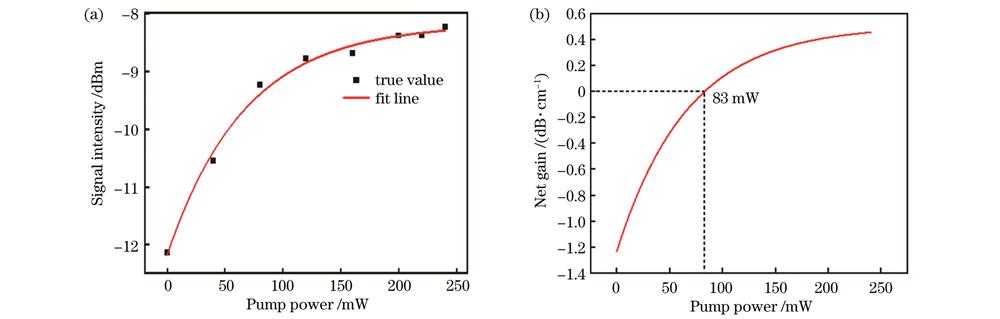

为探究高掺Tm3+石英光纤的激光性能,搭建了如

图 6. 基于全光纤化线性腔结构的1947 nm型光纤激光器

Fig. 6. 1947 nm fiber laser based on all-fiber linear cavity structure

泵浦光经793 nm/1950 nm波分复用器(WDM1)的泵浦端输出至谐振腔,利用WDM2分离1947 nm信号激光与残余泵浦光。对长度分别为2.3 cm、4.6 cm、6.5 cm的增益光纤进行激光效率测试,将吸收泵浦功率、输出激光功率进行线性拟合,斜率效率如

图 7. 高掺Tm3+石英光纤激光性能。(a)不同光纤长度下的斜率效率;(b)4.6 cm高掺Tm3+石英光纤激光光谱(插图为1944~1951 nm范围的激光光谱)

Fig. 7. Laser performance of highly Tm3+-doped silica optical fiber. (a) Slope efficiency for different fiber length; (b) laser spectrum of 4.6-cm highly Tm3+-doped silica optical fiber (inset is laser spectrum in range of 1944-1951 nm)

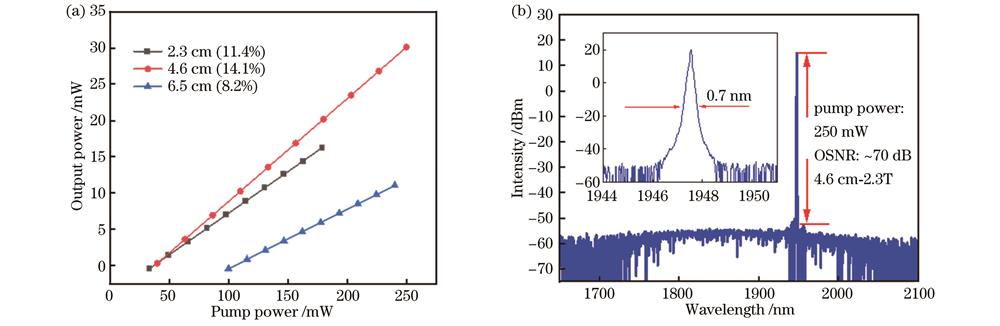

3.2 高掺Tm3+石英光纤的增益性能研究

为了进一步研究高掺Tm3+石英光纤的增益性能,自主搭建了1947 nm信号源以及掺铥光纤放大器,如

图 9. 2.3 cm高掺Tm3+石英光纤增益特性。(a)不同泵浦功率下输出信号的强度;(b)增益系数曲线

Fig. 9. Gain characteristics of 2.3-cm highly Tm3+-doped silica optical fiber. (a) Output signal intensity for different pump power; (b) gain coefficient curve

为了实现高增益高功率2.0 μm波段单频激光,目前实验中大多采用793 nm[20]、1565 nm[21]等波段激光器泵浦掺Tm3+有源光纤,让高掺Tm3+短纤有更好的吸收和放大性能。本实验中Tm3+高掺高硅氧玻璃的最强吸收波长位于789 nm,因此,可采用789 nm的泵浦光进行泵浦,或者采用长波长(1565 nm)泵浦光提升量子效率。后续工作拟采用789 nm波段泵浦源对此光纤进行深入研究,使用该波长泵浦石英光纤可提高对激发光的利用率,有望进一步提高石英光纤的激光性能。

4 结论

采用溶胶凝胶法和高温烧结技术制备了Tm3+掺杂浓度为8.29×1020 cm-3、光学质量较好的高硅氧玻璃。创新性地采用溶胶镀膜和熔融拉锥工艺相结合的技术,研制出了芯径约为4 μm、外径为125 μm的高掺Tm3+石英光纤,并对光纤的激光性能进行了测试。采用808 nm激光泵浦2.3 cm、4.6 cm和6.5 cm三种不同长度的高掺Tm3+石英光纤,得到的最高斜率效率达14.1%,1947 nm处可实现的光信噪比约为70 dB;选用2.3 cm的短光纤测试了光纤的增益性能,得到的净增益系数为0.48 dB/cm。为进一步提高此创新工艺所制备的高掺Tm3+石英光纤激光性能,后续工作将从纤芯玻璃组分调控、镀膜工艺优化两方面开展。组分方面,可通过不同组分玻璃筛选出荧光效果最佳的玻璃配方;工艺方面,设计并调控膜层厚度,通过对纤芯尺寸的调控使得与无源光纤熔接时有更好的NA、模场匹配。同时,后续可选用789 nm波段泵浦源对光纤激光性能进行进一步研究。综上所述,此光纤制备方法在实现石英光纤的高Tm3+掺杂浓度方面具有潜力,有望推动2.0 μm石英光纤单频及高重频锁模光纤激光器的应用。

[1] Chen H L, Gao L F, Qin Z P, et al. Recent advances of low-dimensional materials in mid- and far-infrared photonics[J]. Applied Materials Today, 2020, 21: 100800.

[2] Wagener T J, Demma N, Kmetec J D, et al. 2 μm LIDAR for laser-based remote sensing: flight demonstration and application survey[J]. IEEE Aerospace and Electronic Systems Magazine, 1995, 10(2): 23-28.

[3] XieX M, XuQ, HuW Y, et al. A brief review of 2 μm laser scalpel[C]//2020 IEEE 5th Optoelectronics Global Conference, September 7-11, 2020, Shenzhen, China. New York: IEEE Press, 2020: 63-67.

[4] 张安军, 段嘉霖, 邢颍滨, 等. 掺铥激光在生物医疗领域的应用[J]. 激光与光电子学进展, 2022, 59(1): 0100004.

[5] ScholleK, LamriniS, KoopmannP, et al. 2 µm laser sources and their possible applications[M]//Pal B. Frontiers in guided wave optics and optoelectronics. London: InTech, 2010.

[6] Gibert F, Pellegrino J, Edouart D, et al. 2-μm double-pulse single-frequency Tm∶fiber laser pumped Ho∶YLF laser for a space-borne CO2 lidar[J]. Applied Optics, 2018, 57(36): 10370-10379.

[7] Ma J, Qin Z P, Xie G Q, et al. Review of mid-infrared mode-locked laser sources in the 2.0 μm-3.5 μm spectral region[J]. Applied Physics Reviews, 2019, 6(2): 021317.

[8] 杨昌盛, 岑旭, 徐善辉, 等. 单频光纤激光器研究进展[J]. 光学学报, 2021, 41(1): 0114002.

[9] 周朴, 粟荣涛, 马阎星, 等. 激光相干合成的研究进展: 2011—2020[J]. 中国激光, 2021, 48(4): 0401003.

[10] Tang G W, Wen X, Huang K M, et al. Tm3+-doped barium gallo-germanate glass single-mode fiber with high gain per unit length for ultracompact 1.95 µm laser[J]. Applied Physics Express, 2018, 11(3): 032701.

[11] 张钧翔, 史伟, 史朝督, 等. 新型高掺铥硅酸盐玻璃光纤及其光纤激光的研究[J]. 红外与激光工程, 2021, 50(9): 20200424.

[12] Lu Y, Feng G F, Wang M, et al. Tm3+-doped silica-glass fiber for ∼2-μm fiber laser[J]. Applied Optics, 2019, 58(7): 1747-1751.

[13] Xia L S, Yu C L, Sun S Y, et al. Preparation and characterization of sol-gel derived highly transparent aluminosilicate glass thin films with ultrahigh doping level of Yb3+ ions[J]. Optical Materials, 2019, 98: 109352.

[14] Xia L S, Wang M, Kuan P W, et al. Paving way for fabrication of silica-based single-frequency seed laser: ultrahighly Yb-doped optical fibers via sol-gel method combined with silica tube inner wall coating and fusion-tapering technique[J]. Optics & Laser Technology, 2020, 131: 106425.

[15] 李志兰, 王世凯, 王欣, 等. 溶胶凝胶法制备的掺铥石英玻璃光谱性质及光纤激光性能[J]. 中国激光, 2013, 40(8): 0806003.

[16] Li M, Bai G X, Guo Y Y, et al. Investigation on Tm3+-doped silicate glass for 1.8 μm emission[J]. Journal of Luminescence, 2012, 132(7): 1830-1835.

[17] 焦孟珺, 王欣, 胡丽丽. Tm2O3掺杂浓度对锗酸盐玻璃热稳定性及光谱性质的影响[J]. 中国激光, 2018, 45(6): 0603001.

[18] 王雪. 改性石英玻璃的结构和2 μm光谱及其光纤性能研究[D]. 上海: 中国科学院上海光学精密机械研究所, 2017.

WangX. Study on the structure and 2 μm spectrum of modified Shi Ying glass and its fiber properties[D]. Shanghai: Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, 2017.

[19] Ruan L, Wang W T, Zhang Z J, et al. Fabrication of thulium-doped silica optical fiber[J]. Proceedings of SPIE, 1998, 3557: 67-70.

[20] Fu S J, Shi W, Lin J C, et al. Single-frequency fiber laser at 1950 nm based on thulium-doped silica fiber[J]. Optics Letters, 2015, 40(22): 5283-5286.

[21] Zhang Z, Boyland A J, Sahu J K, et al. High-power single-frequency thulium-doped fiber DBR laser at 1943 nm[J]. IEEE Photonics Technology Letters, 2011, 23(7): 417-419.

Article Outline

沈骁, 杨广利, 王亚飞, 陈应刚, 于春雷, 韦玮, 胡丽丽. 新型高掺Tm3+石英光纤制备及2.0 μm激光性能研究[J]. 光学学报, 2023, 43(4): 0414001. Xiao Shen, Guangli Yang, Yafei Wang, Yinggang Chen, Chunlei Yu, Wei Wei, Lili Hu. Preparation of Highly Tm3+-Doped Silica Fibers and Study of 2.0 μm Laser Performance[J]. Acta Optica Sinica, 2023, 43(4): 0414001.