光学仪器, 2022, 44 (3): 88, 网络出版: 2022-07-08

皮秒脉冲隐形切割碳化硅晶圆实验研究  下载: 751次

下载: 751次

Research on stealth dicing silicon carbide wafer by picosecond laser pulses

摘要

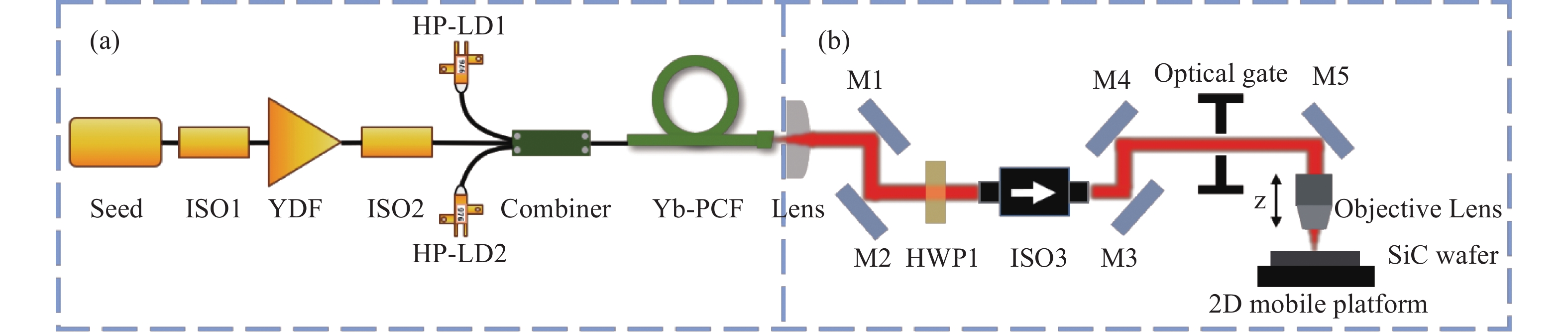

为了实现高速度切割碳化硅(SiC)晶圆,采用自行研制的高能量皮秒脉冲光纤激光器进行了隐形切割实验。依据切片的截面形貌、表面热损伤区和边缘直线度,分析了皮秒激光器的切割结果,并探究了单脉冲能量和扫描速度对切片质量的影响。结果表明,当使用中心波长为1030 nm、重复频率为100 kHz、单脉冲能量为20 μJ、脉冲宽度约为100 ps的皮秒脉冲隐形切割360 μm厚度的SiC晶圆时,切片的质量能够满足实际应用要求,且激光的扫描速度可达400 mm/s,相应的切割速度为44.44 mm/s,高于其他相关报道。

Abstract

In order to realize high-speed cutting of silicon carbide (SiC) wafers, stealth dicing experiments were carried out by using self-developed high-energy picosecond pulsed fiber lasers. According to the cross-section topography, surface thermal damage area and edge straightness of the slices, cutting results of the picosecond lasers were analyzed, and the effects of single pulse energy and scanning speed on the slice quality were explored. The results showed that when a picosecond laser with center wavelength of 1030 nm, repetition rate of 100 kHz, pulse energy of 20 μJ, and pulse width of about 100 ps was used for stealth dicing of a SiC wafer with thickness of 360 μm. The quality of the slices can meet the requirements of practical applications. The scanning speed can reach 400 mm/s and the corresponding cutting speed was 44.44 mm/s, which was higher than other related reports.

宋燕国, 郭旭, 王嫣鸾, 郝强. 皮秒脉冲隐形切割碳化硅晶圆实验研究[J]. 光学仪器, 2022, 44(3): 88. Yanguo SONG, Xu GUO, Yanluan WANG, Qiang HAO. Research on stealth dicing silicon carbide wafer by picosecond laser pulses[J]. Optical Instruments, 2022, 44(3): 88.